1. S7-1200 PLC 1211C model CM1241 communication module;

2. Panasonic temperature controller KT4-1;

3. Qixi inverter HD700 series;

4. MCGS TPC 7062K touch screen.

The S7-1200 PLC sets data for the temperature controller and inverter via the touch screen, including temperature setpoint (SV);

Inverter frequency setting and operation control;

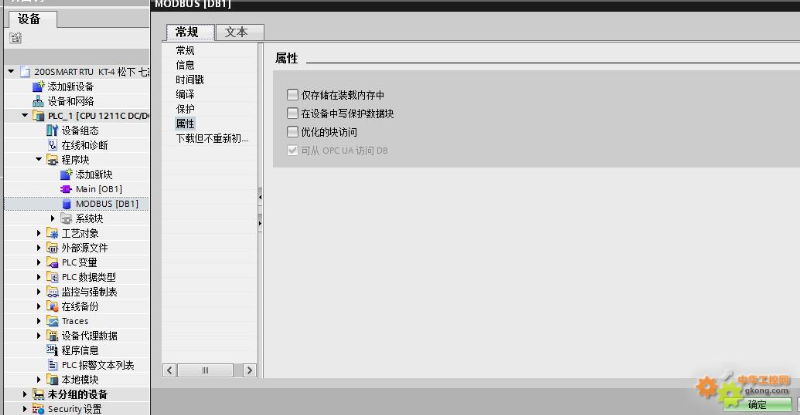

The touch screen communicates with the S7-1200 PLC via Ethernet, facilitating the S7-1200 DB block to make settings related to the two slaves on the touch screen, familiarizing with the S7-1200’s serial communication capabilities.

1. Kunlun Tongtai configuration software communication parameters:

Client/Server settings: Client network type: TCP IP address: 192.168.3.111 port number: 30002. Panasonic temperature controller parameter settings:

Communication baud rate: 9600 station number: 1 parity: no parity communication method: MODBUS RTU mode. This temperature controller has its own protocol and also supports ASCII communication mode, which can be set via parameters.3. Qixi inverter parameter settings:

Communication baud rate: 9600 station number: 2 parity: no parity communication method: MODBUS RTU

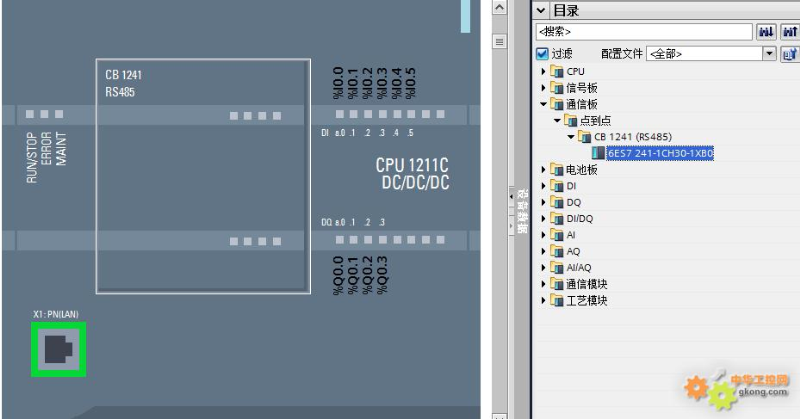

1. Select device model

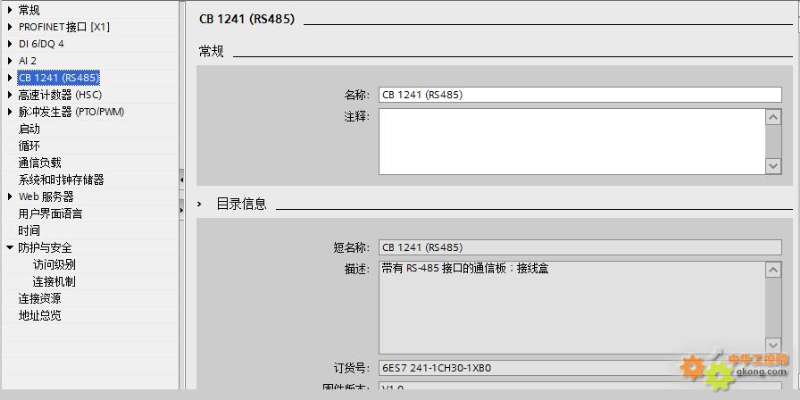

2. Select signal board and set communication parameters related to the signal board

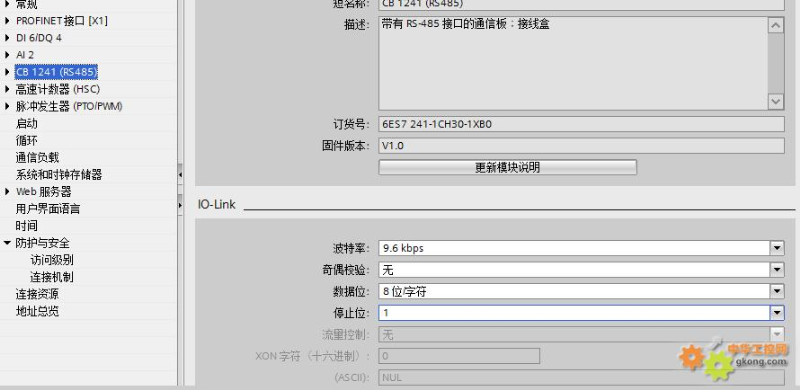

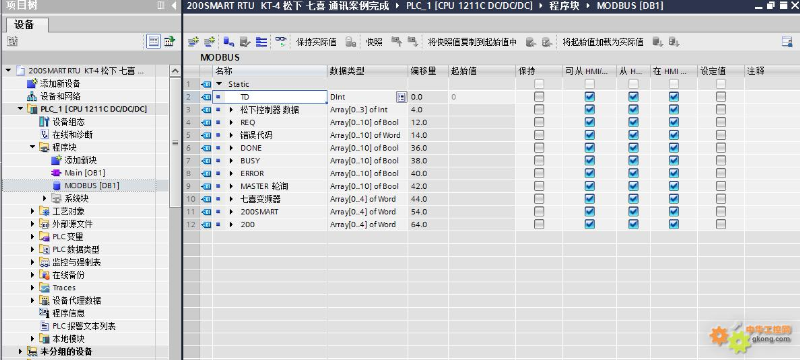

3. Create DB block and access non-optimized blocks

4. Configure the array to complete the master and slave command completion bits, error bits, and other related settings

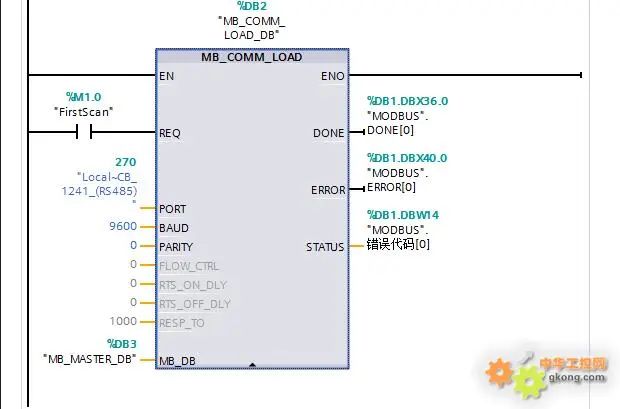

5. “MB_COMM_LOAD_DB” master station initialization program parameters, polling the next instruction

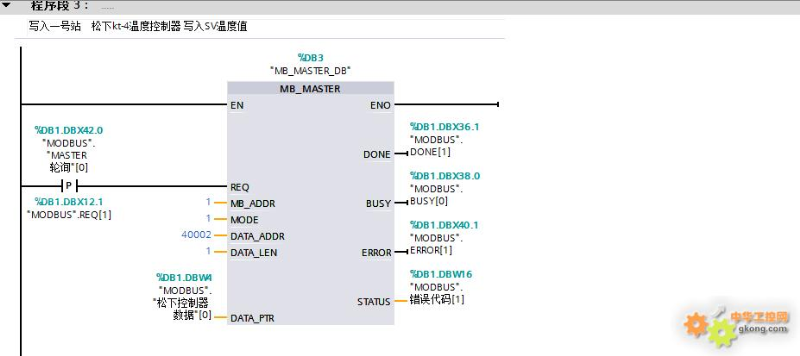

6. Panasonic controller’s SV value

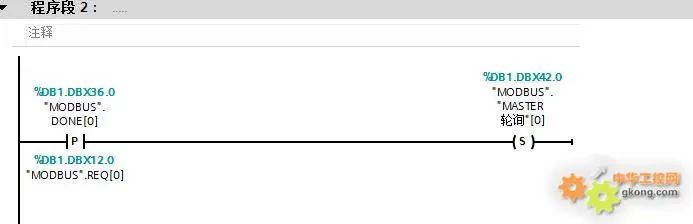

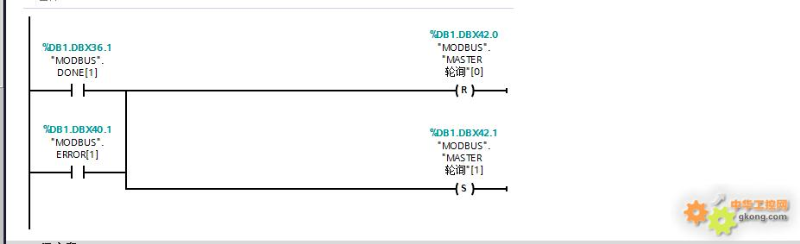

7. Poll the next instruction and reset this instruction

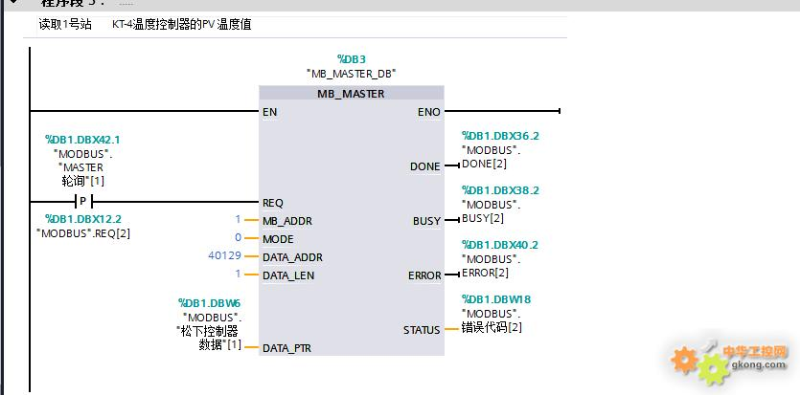

8. Monitor the Panasonic temperature controller’s PV value

9. Poll the next instruction and reset this instruction

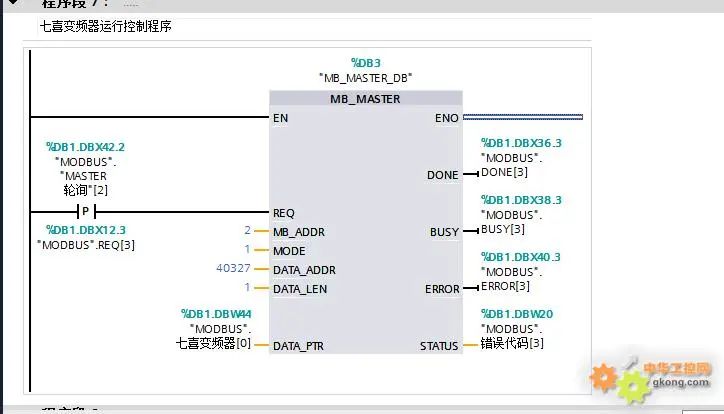

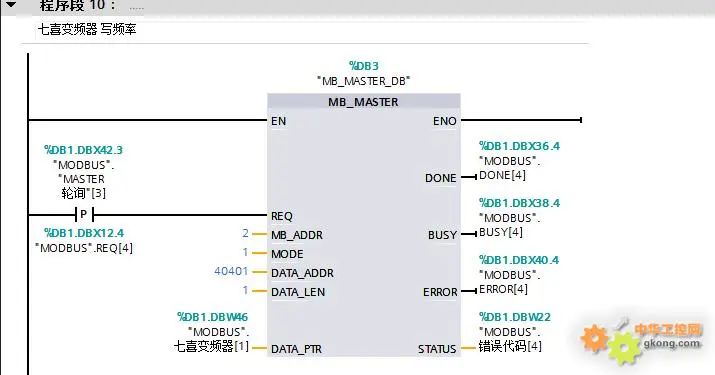

10. Reading and writing operation control commands for the Qixi inverter

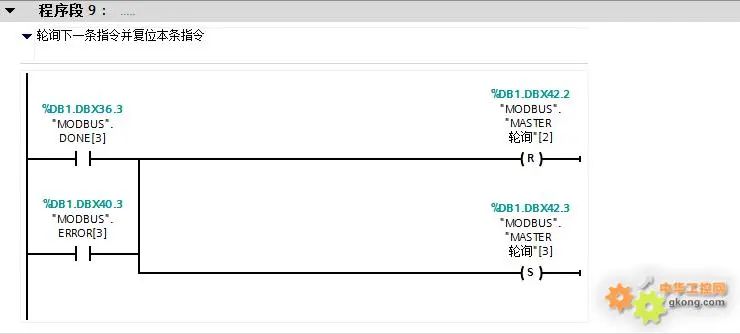

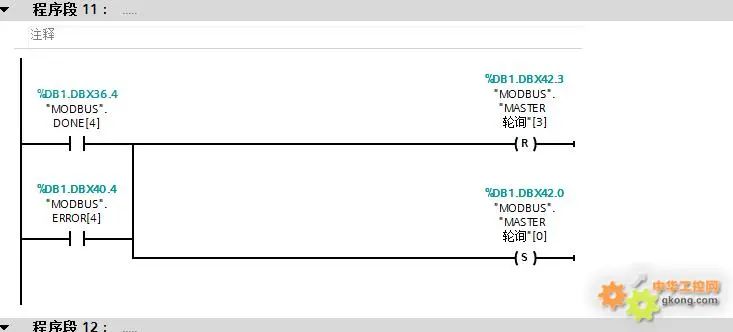

11. Poll the next instruction and reset this instruction

12. Writing frequency command to the Qixi inverter

13. Poll the previous command that writes the SV value of Panasonic and reset this instruction

Due to two read and write commands for both the Panasonic temperature controller and the Qixi inverter, SV, PV temperature values, frequency values, and write operation control, if multiple writes and reads are needed, a lot of master station “MB_MASTER_DB” polling commands will be required, which will increase the polling conditions of the program.

It is also possible to set the number of writes in the DATE_LEN length, allowing for batch reading and writing. This article is just a starting point, hoping everyone can gain a deeper understanding of S7-1200 serial communication.

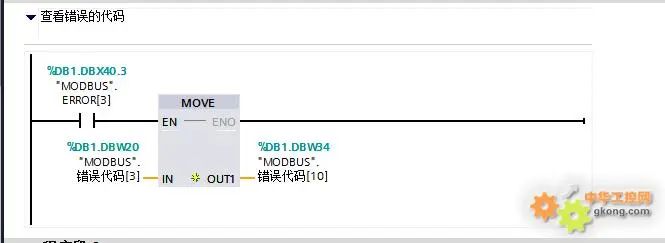

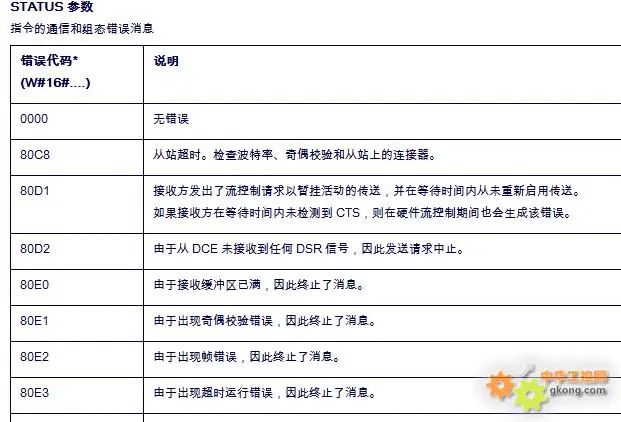

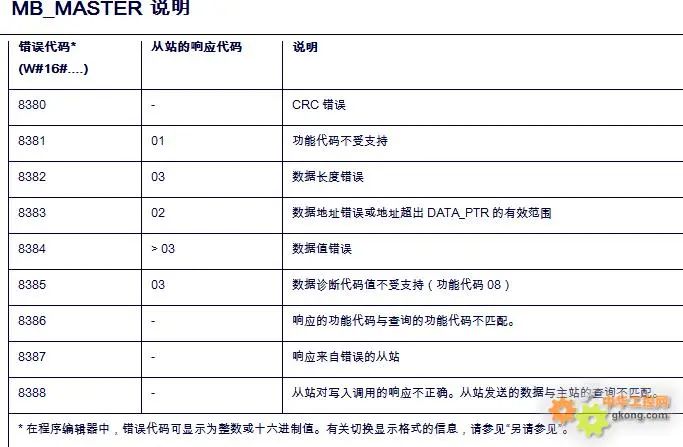

14. The program uses four “MB_MASTER_DB” master station commands to write the temperature to the temperature controller’s SV, monitor the PV temperature, and write frequency and operation control commands to the Qixi inverter, as well as check the error codes and relevant information of “MB_MASTER_DB”.

Only three images are captured, and relevant information can also be found in the help manual of the software by pressing F1.

The following video is a demonstration after I completed the communication:

Followed Follow Replay Share Like Watch MoreTechnical Training

0/0

00:00/01:58Progress bar, 0 percentPlay00:00/01:5801:58Full screen Playing at high speed 0.5x 0.75x 1.0x 1.5x 2.0x Ultra clear Smooth

Continue watching

[Including Program] Step-by-Step Guide to Siemens S7-1200 MODBUS RTU Communication with Temperature Controller and Inverter

Reprint, [Including Program] Step-by-Step Guide to Siemens S7-1200 MODBUS RTU Communication with Temperature Controller and InverterTechnical TrainingAdded to Top StoriesEnter comment Video Details

2021 Junior Electrician Exam Question Bank Full Version (Includes Answers)

Inverter Fault Query and Repair Difficult? Just One Click!

One Click to Brush through All Electrical Exam Questions, Do You Not Have This Artifact Yet?

Which of the Five Major Electrical Drawing Software (CAD, Eplan, CADe_simu…) Do You Pick?

Latest Electrical Version CAD Drawing Software, Attached Super Detailed Installation Tutorial!

Latest Electrical Drawing Software EPLAN, Attached Super Detailed Installation Tutorial!

Common Problems for Beginners Using S7-200 SMART Programming Software (With Download Links)

Super Comprehensive Electrical Calculation EXCEL Spreadsheet, Automatically Generated! No Need to Ask for Electrical Calculations!

Bluetooth Headphones, Electrician/PLC Entry Books Given Away? Come and Get Your Electrical Gifts!

PLC Programming Basics: Ladder Diagram and Control Circuits (With 1164 Practical Cases of Mitsubishi PLC)

Still Can’t Understand Electrical Diagrams? Take Away the Basics of Electrician Diagram Recognition and Simulation Software, Quickly Get Started with Theory and Practice!

12 Free Electrician Videos, 10GB Software/Electronic Book Materials, 30 Days of Free Electrician Live Classes Given Away!