Many students learning about Weintek touch screen communication skills generally know how to communicate with PLCs, such as M area addresses, V area addresses, and Q area addresses, which are quite simple. Especially for DB block addresses like S7-1200, we often don’t know where to start. So how do we associate them? Let’s take a simple approach to achieve this.

Step 1: (Create DB Block and Write Address)

Step 2: (Create Variable Table Address)

Step 3: (Write Forward and Reverse Interlock Program in OB1 Main Program)

Step 4: (Double-click CPU Properties – Protection – Connection Mechanism – Check Allow Communication Access from Partners (PLC, HM, OPC, etc.) using PUT/GET)

Step 5: (Download Program to PLC and Monitor)

1. Weintek Touch Screen Configuration

Step 1: (System Parameter Settings)

Device Type – Siemens S7-1200/S7-1500 (Absolute Addressing) (Ethernet)

Interface Type: Ethernet

IP Address: Enter 1200 PLC IP Address (192.168.0.144)

Step 2: (Click to Get Tag Information – Select All and Click Confirm)

1. Design Weintek Touch Screen Interface

Step 1: (Associate Button DB Addresses)

Forward Start Address S7-1200 PLC: %DB1.DBX0.0 corresponds to Weintek Touch Screen: DB1Bit0 Reverse Start Address S7-1200 PLC: %DB1.DBX0.1 corresponds to Weintek Touch Screen: DB1Bit1

Stop Address S7-1200 PLC: %DB1.DBX0.2 corresponds to Weintek Touch Screen: DB1Bit2

Forward Start Button Parameters are as follows:

Reverse Start Button Parameters are as follows:

Stop Button Parameters are as follows:

Step 2: (Associate Indicator Light Addresses)

Forward Running Indicator Light Parameters are as follows:

Reverse Running Indicator Light Parameters are as follows:

-

Design Weintek Interface

1. Operation Demonstration

Step 1: (Forward Start Operation)

Step 2: (Reverse Start Operation)

Step 3: (Stop Operation)

Demonstration and communication successful. At this point, everything has been completed. Some students may encounter problems in the above steps, so I will list common issues for reference:

Common Problems and Solutions:

Problem 1: If the online automatic tag retrieval fails or cannot retrieve, how to solve it?

Answer: You can choose to manually import tags, the method is as follows:

Step 1: (Click the export button in the upper left corner of the variable table to export variables)

Step 2: (Select the location and name for variable export)

Step 3: (Variable export successful)

Step 4: (System Parameter Configuration)

Device Type – Siemens S7-1200/S7-1500 (Absolute Addressing) (Ethernet)

Interface Type: Ethernet

IP Address: Enter 1200 PLC IP Address (192.168.0.246)

Step 5: (Click Import Tags)

Step 6: (Import Tag Selection – Import Files (d;*db) Linear)

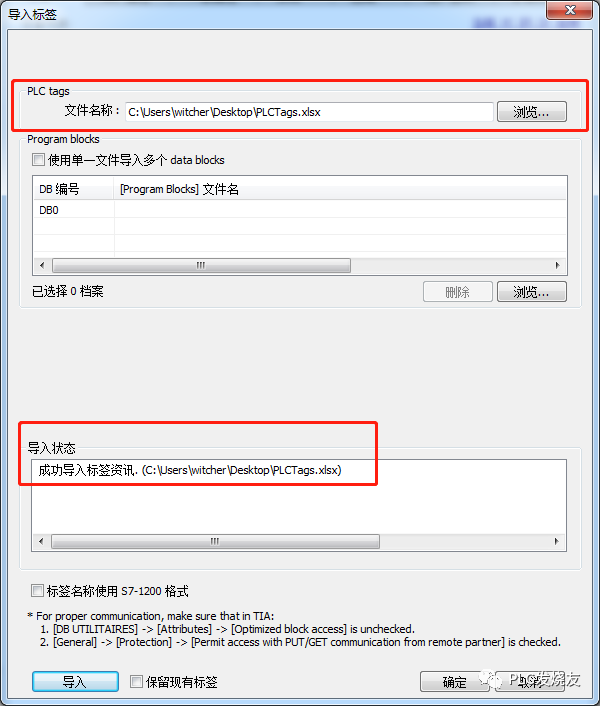

Step 7: (PLC Tags – Location of PLC Export Variable Table)

Step 8: (Select All – Click Confirm)

Step 9: (Tag Import Successful)

Problem 2: If there is no address or no DB offset address when creating DB block in PLC, how to solve it?

Answer: Cancel block optimization access and recompile, the method is as follows:

Step 1: (Select DB Data Block – Right-click Properties)

Step 2: (DB Block – Right-click Properties – Cancel Optimized Block Access)

Source: Technical Training Network, Author: Xu Chenshuang, Reproduction without permission is prohibited~

Complete Question Bank for Junior Electrician Examination 2023 (Including Answers)

Three Must-Have Tools for Electricians, Open with WeChat!

[Collection] The “Path” of a Ten-Year Veteran Electrician, Secrets to Earning Over Ten Thousand a Month!

Which of the Five Major Electrical Drawing Software (CAD, Eplan, CADe_simu…) do you pick?

Latest Electrical CAD Drawing Software, with Detailed Installation Tutorial!

Latest Electrical Drawing Software EPLAN, with Detailed Installation Tutorial!

Common Issues with S7-200 SMART Programming Software for Beginners (Includes Download Link)

Comprehensive Electrical Calculation EXCEL Sheets, Automatically Generated! No Need for Help with Electrical Calculations!

Bluetooth Headphones, Books for Electricians/PLC Beginners Given Away? Come Get Your Electrical Gifts!

Basic Skills in PLC Programming: Ladder Diagrams and Control Circuits (Includes 1164 Practical Cases for Mitsubishi PLC)

Still Can’t Understand Electrical Diagrams? Take the Basics of Electrical Diagram Recognition and Simulation Software for a Quick Start!

12 Free Electrician Video Courses, 10GB Software/E-Book Materials, and 30 Days of Free Electrician Live Courses!