Modbus TCP is a very traditional and widely used communication protocol, and many smart devices support this protocol. Siemens S7-200SMART and the 1200 and 1500 series support it for free (300 and 400 series incur high fees), and it has been made into a standard library, making it very convenient to use. Below is a brief introduction to the configuration steps for the client; the server configuration is even simpler and can be explored on your own:

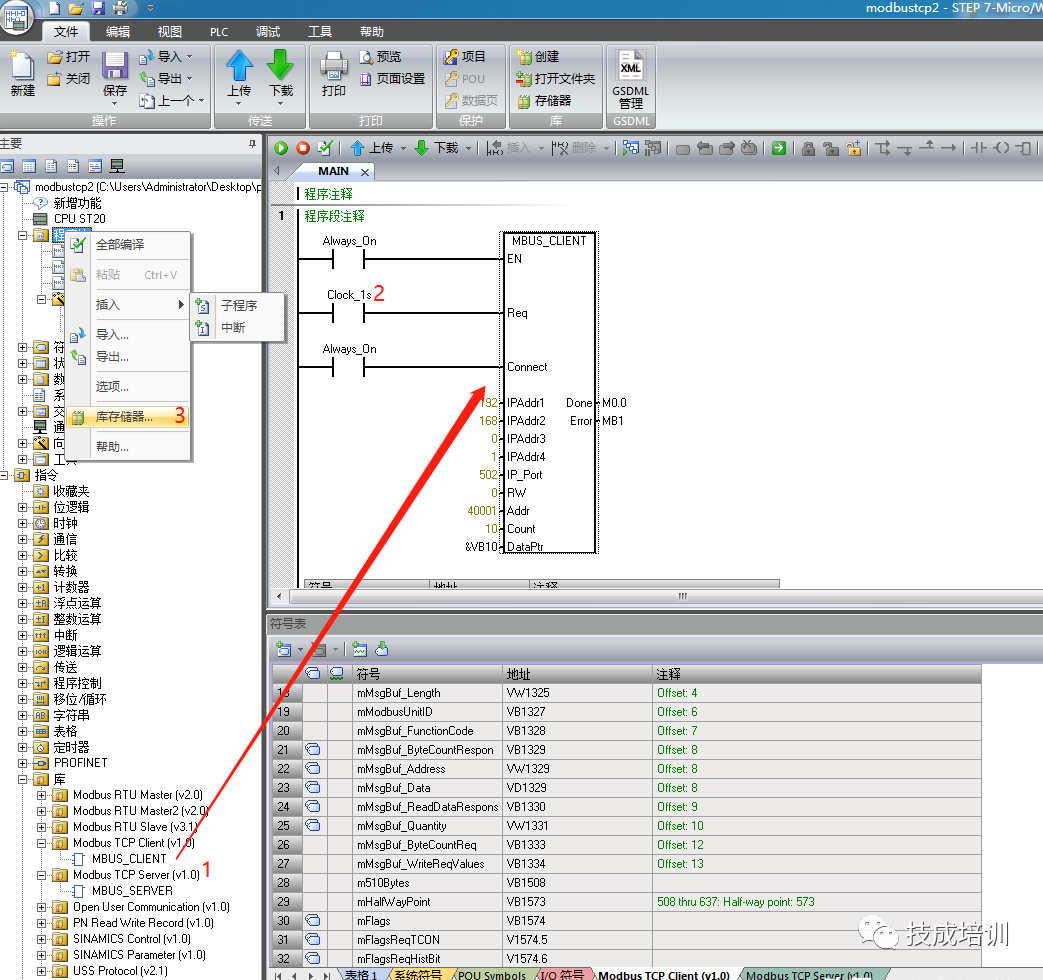

Directly drag the MBUS_CLIENT into the MAIN program, set the startup conditions and query frequency (Req side, rising edge trigger). Then set the communication parameters. If you do not understand, you can press F1 for detailed instructions.

Just a reminder: Compared to MODBUS RTU, there are no issues with speed, parity, etc., but you still need to set the IP address and port (usually 502) of the other party, the address area of the information, and the storage location of the returned data (this starts from VB10 for 20 bytes, as the unit of 40001 is two-byte words).

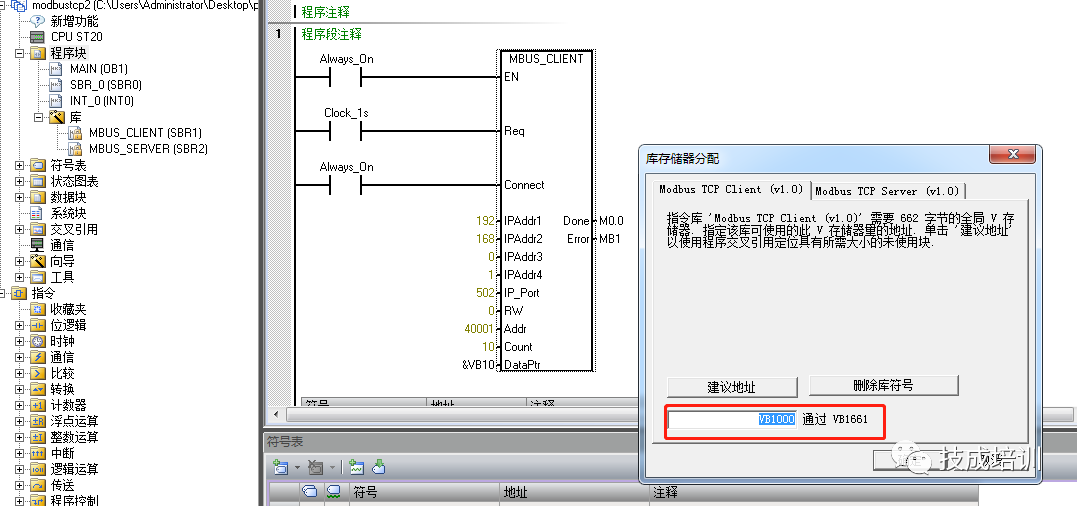

Refer to the entry marked as 3 in the image above to bring up the configuration interface. If you are unsure about the storage area usage, you can click “Suggest Address.”

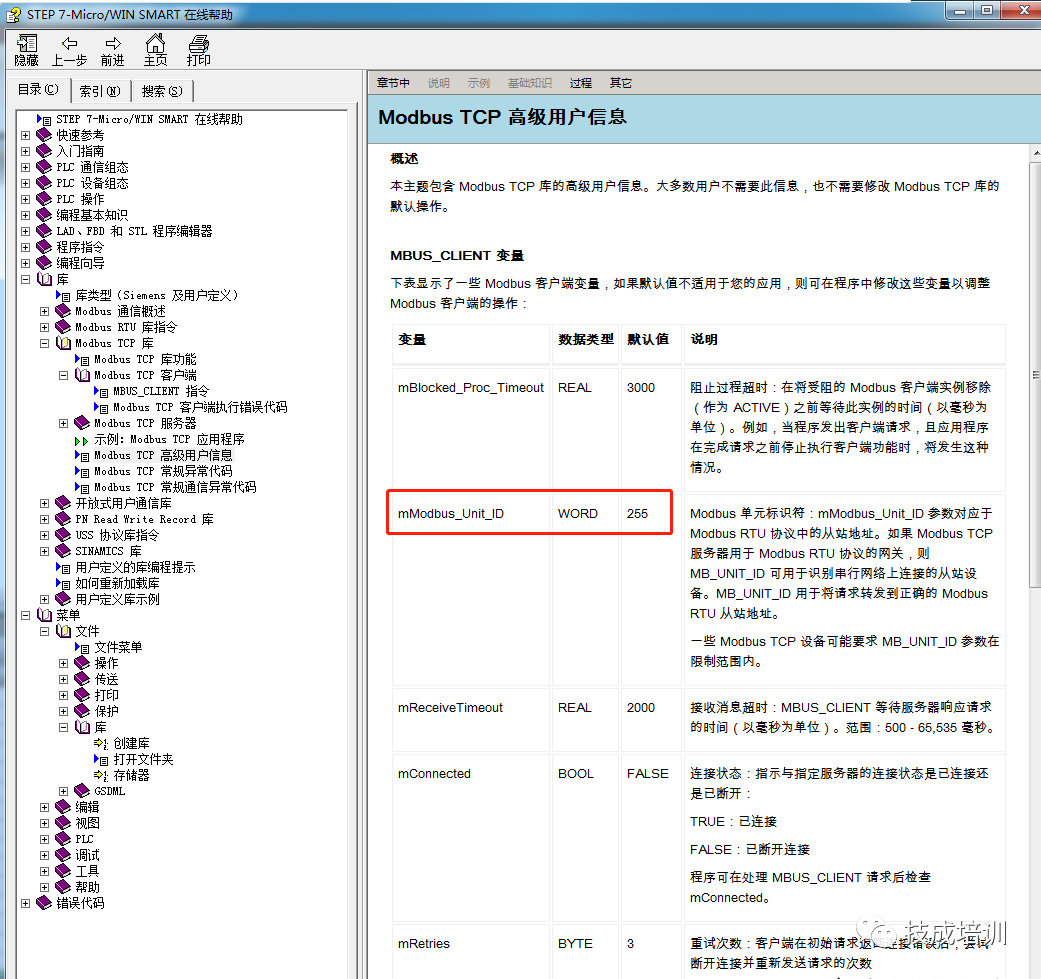

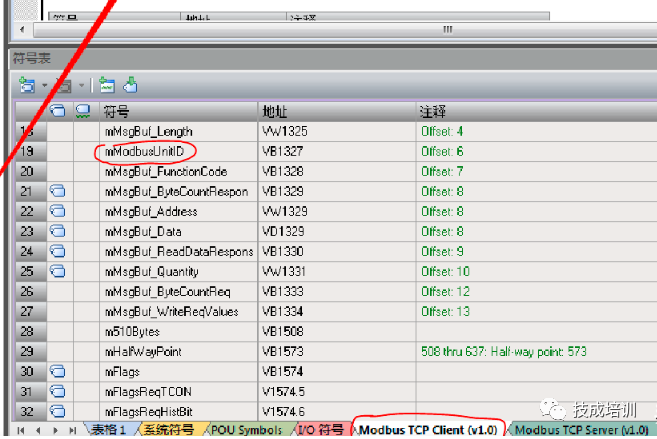

The device being read has an ID number, which is implicit and must be consistent with the device. Please check the address in the Modbus TCP Client’s symbol table and assign an initial value through the program.

1) The above only configures a reading module. If there are multiple address areas, you can configure multiple reading modules for reading and writing.

2) The returned continuous data area must be split into variables by yourself. If the protocol is not uniform, you may also need to reverse the byte order yourself. Communication is not an easy task, so do not be impatient.

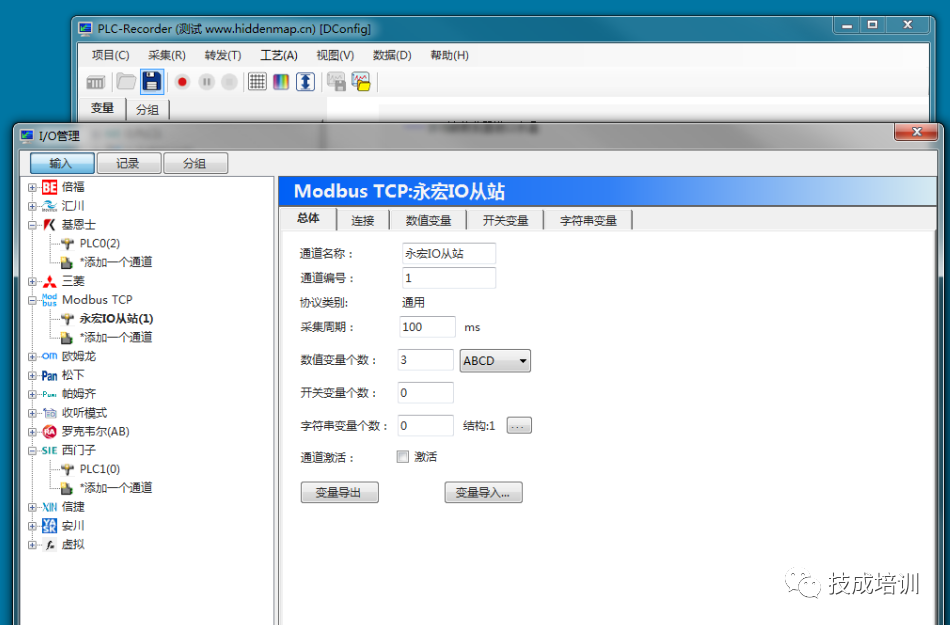

3) PLC-Recorder is a professional wave recording software widely used in various industrial scenarios. It supports the Modbus TCP protocol and can connect to various smart devices, and its parameter configuration is also quite rich and adaptable to various changes.

Disclaimer: This article is reproduced from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us in time for deletion. Thank you!

Complete question bank for the 2022 electrician junior examination (including answers)

3 must-have tools for electricians, available for one-click use on WeChat!

【Collection】 The “path” for a ten-year veteran electrician, the secret to earning over ten thousand a month!

The five major electrical drawing software (CAD, Eplan, CADe_simu…), which one do you pick?

The latest electrical CAD drawing software, with a super detailed installation tutorial!

The latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common issues for beginners using S7-200 SMART programming software (includes download link)

Comprehensive electrical calculation EXCEL spreadsheet, automatically generated! No need to ask for electrical calculations!

Bluetooth headphones, electrician/PLC introductory books available for free? Come and claim your electrical gift!

Basic skills in PLC programming: Ladder diagrams and control circuits (includes 1164 practical cases of Mitsubishi PLC)

Still can’t understand electrical diagrams? Take the basics of electrician diagram recognition and simulation software, theory and practice quickly!

12 free electrician video courses, 10GB software/e-book materials, and 30 days of free electrician live classes are being given away!