9

Online Siemens TIA Portal PLC Training Camp Registration Open on August 7

Siemens PLC Practical Training Class in Qingdao on August 18

1. Overview of MODBUS Communication

2. Detailed Explanation of MODBUS Library Commands

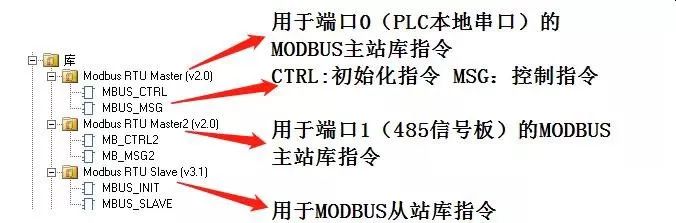

Library commands are divided into two types: master library and slave library.

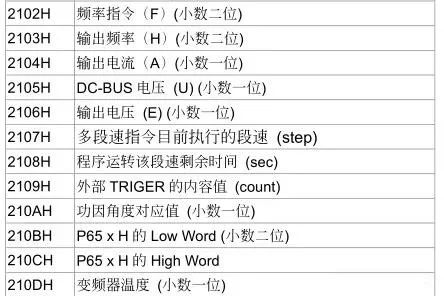

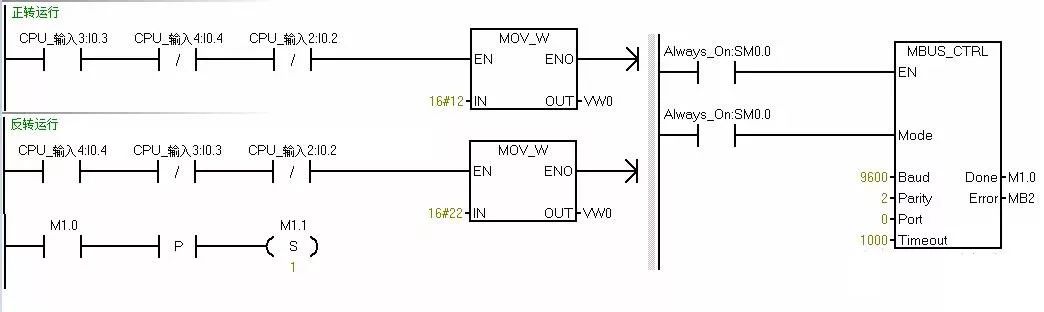

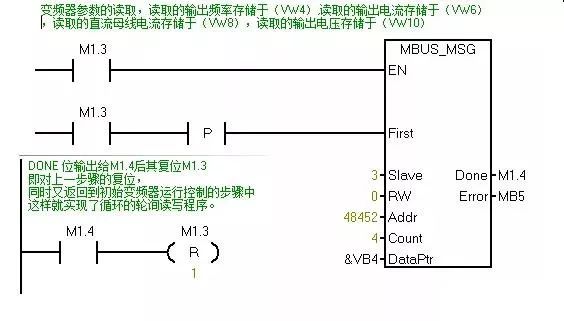

The master station is when the PLC acts as the MODBUS master to actively read data from other devices; the slave station is when the PLC acts as the MODBUS slave, and other devices read data. In this article, we share the scenario of the PLC as the master and the inverter as the slave.

STEP7-MinWIN SMART software comes with MODBUS communication library commands.

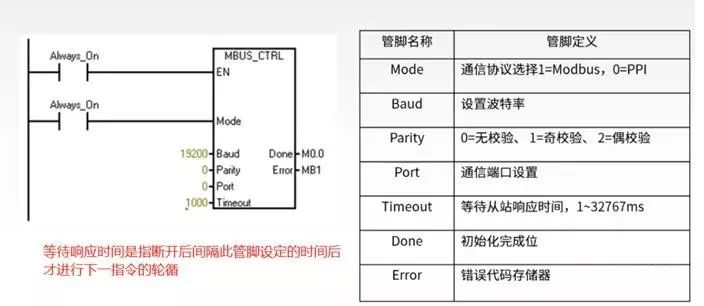

Initialization command:

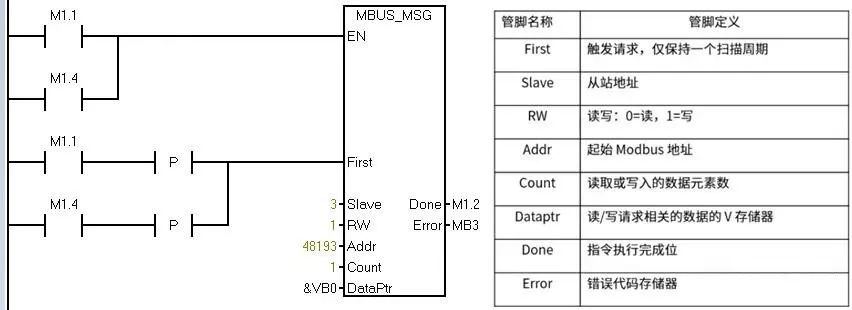

Control command:

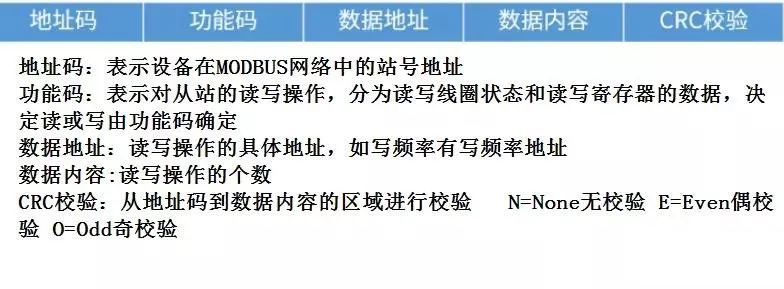

3. Communication Format (Protocol) of MODBUS RTU

The communication protocol consists of: station number, function code, data address, data content, checksum, and end character.

Checksum: N=None (no checksum), E=Even (even checksum), O=Odd (odd checksum).

Determine whether the number of bits with a value of 1 is odd or even (for even checksum, if the number of 1s in 16#03 is even, the checksum is 1; if odd, the checksum is 0. For odd checksum, if the number of 1s is even, the checksum is 0; if odd, the checksum is 1).

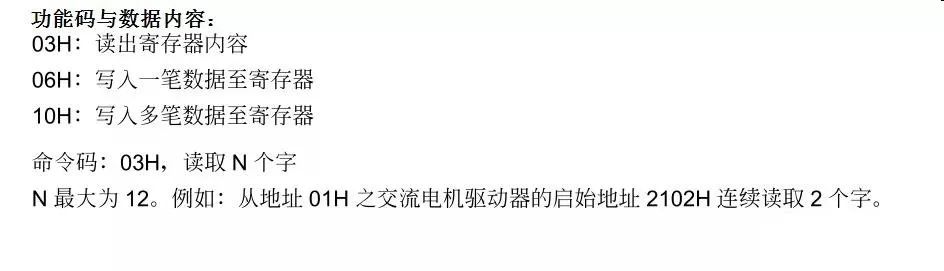

The function code specifies whether to read or write operations on the slave device, and also specifies the type of MODBUS register address. Common function codes include:

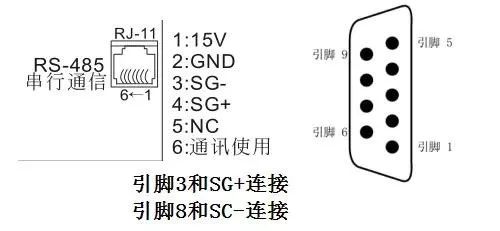

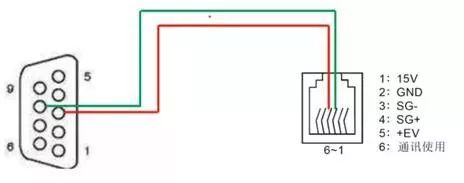

4. Hardware Connection for PLC and Inverter Communication

The communication terminals on the inverter are marked as A/B RS585+/RS485- or RJ11 port; find the relevant inverter manual to view the wiring definitions for the communication ports. Below is the wiring definition for the Delta VFD-M series inverter communication port.

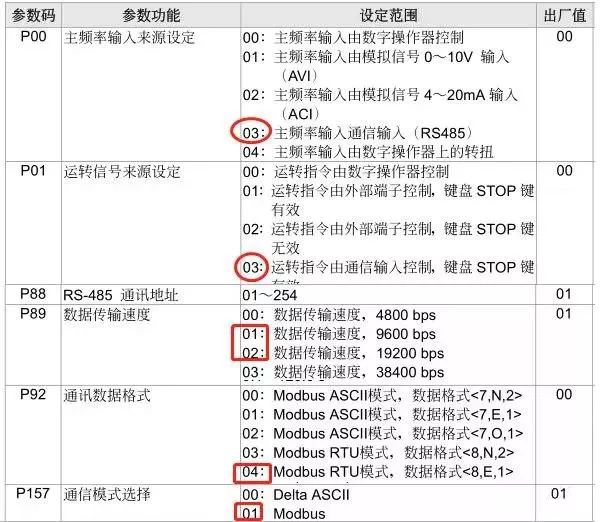

5. Setting Communication Parameters for the Inverter

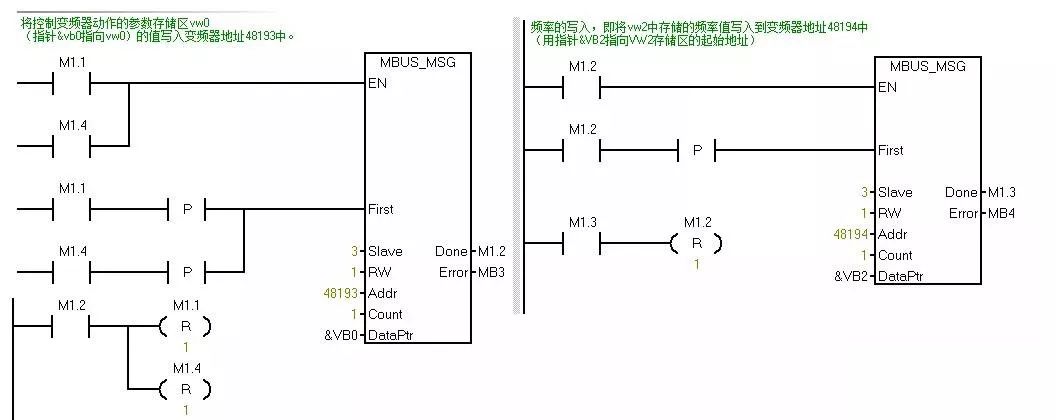

1. To achieve normal communication between the inverter or instrument and the PLC, their interfaces and protocols must be consistent, and the parameter settings must also be consistent.

Information frame format description

Information frame format description

Disclaimer: The article is sourced from the internet. If there are any infringements, please leave a message or directly contact the editor for deletion.

===Learning Courses===

Recent announcements of online and offline course arrangements.

Recently Recommended Courses

Online and offline course announcements

Online Siemens TIA Portal PLC Training Camp registration open on August 7

FANUC CNC Online Training Camp registration open on August 11

Siemens PLC Practical Training in Qingdao and Zhengzhou on August 18

Zhengzhou and Suzhou Hydraulic Technology Training on August 18

Nanjing Inverter Application and Common Fault Troubleshooting Practical Training Class on September 22

Zhengzhou Multi-axis CNC Processing Technology and UGNX Automatic Programming Training on August 26

Beidaihe Equipment Inspector National Vocational Qualification Certification on August 27

Shanghai Equipment Management Informationization Advanced Seminar on September 16

Suzhou Machine Tool Precision Adjustment Technical Training Class on September 14

Beijing FANUC System CNC Fault Diagnosis Technical Training on September 15

Suzhou Machine Tool Assembly and PMC Application Practical Training Class in September

Suzhou CNC FANUC Circuit Board Repair Practical Training Class on September 24

Shanghai SIEMENS System Programming Advanced Training Class on September 15

Shanghai FANUC Industrial Robot Technology Practical Training Class on August 26

Shanghai ABB Industrial Robot Application Technology Advanced Practical Training Class in September

Welcome to scan the QR code to add 24-hour online customer service.

I will dance for you, just give a thumbs up.