|

|

|

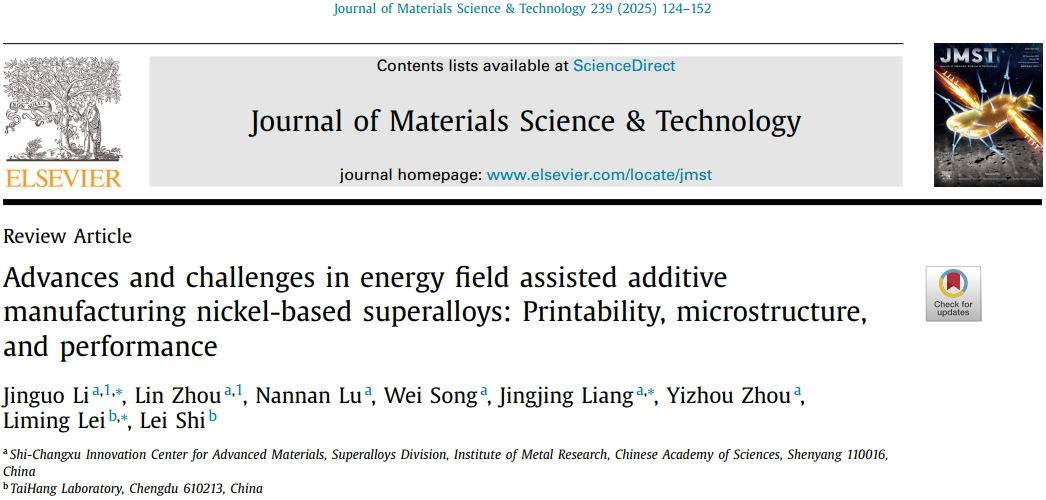

Article Overview: Nicholas-based superalloys are the backbone of core components in aerospace engines. However, the microstructural inhomogeneity, cracks, and porosity defects caused by thermal cycling in traditional additive manufacturing severely limit their performance and application. The team led by Li Jinguo at the Institute of Metal Research, Chinese Academy of Sciences, proposed a revolutionary solution—by introducing thermal fields, ultrasonic fields, magnetic fields, and multi-field coupling technology, they precisely control the dynamics of the melt pool and solidification behavior. This article deeply analyzes how energy fields can suppress element segregation, refine grains, and eliminate cracks, achieving integrated optimization of the “formability-structure-performance” of high-temperature alloys, and also looks forward to the disruptive potential of multi-field synergy in the remanufacturing of aerospace engines! |

|

|

|

Journal Name:《Journal of Materials Science & Technology》 Article DOI:10.1016/j.jmst.2025.03.010 First Corresponding Author’s Institution:Institute of Metal Research, Chinese Academy of Sciences (Shenyang) |

|

Research Background: |

|

Key components such as turbine discs and blades in aerospace engines must operate in extreme environments. Nickel-based superalloys are the preferred materials due to their excellent high-temperature strength. However, the rapid cooling during traditional additive manufacturing processes leads to significant temperature gradients, causing microstructural heterogeneity (such as columnar grain growth and element segregation) and cracks/porosity defects, severely limiting their application in aerospace. Single process optimization or heat treatment cannot fundamentally solve these issues, necessitating innovative manufacturing strategies to break through the bottleneck. |

|

Interpretation of Some Content: |

|

|

|

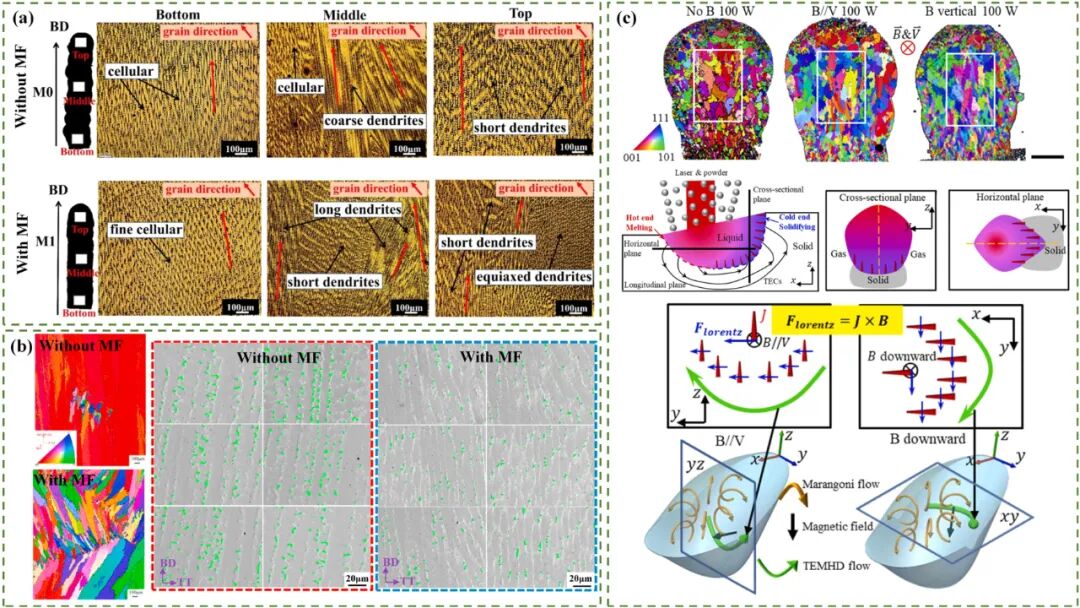

The above figure reveals the innovative framework of “performance-mechanism-energy field-mixed manufacturing.” The thermal field (TF) reduces thermal stress by lowering the temperature gradient; the ultrasonic field (UF) utilizes cavitation effects to break dendrites and accelerate bubble escape; the magnetic field (MF) suppresses the instability of melt pool flow through Lorentz force. Each of these fields regulates the solidification process from thermodynamic, mechanical, and electromagnetic dimensions, laying a theoretical foundation for multi-field synergy. |

|

|

|

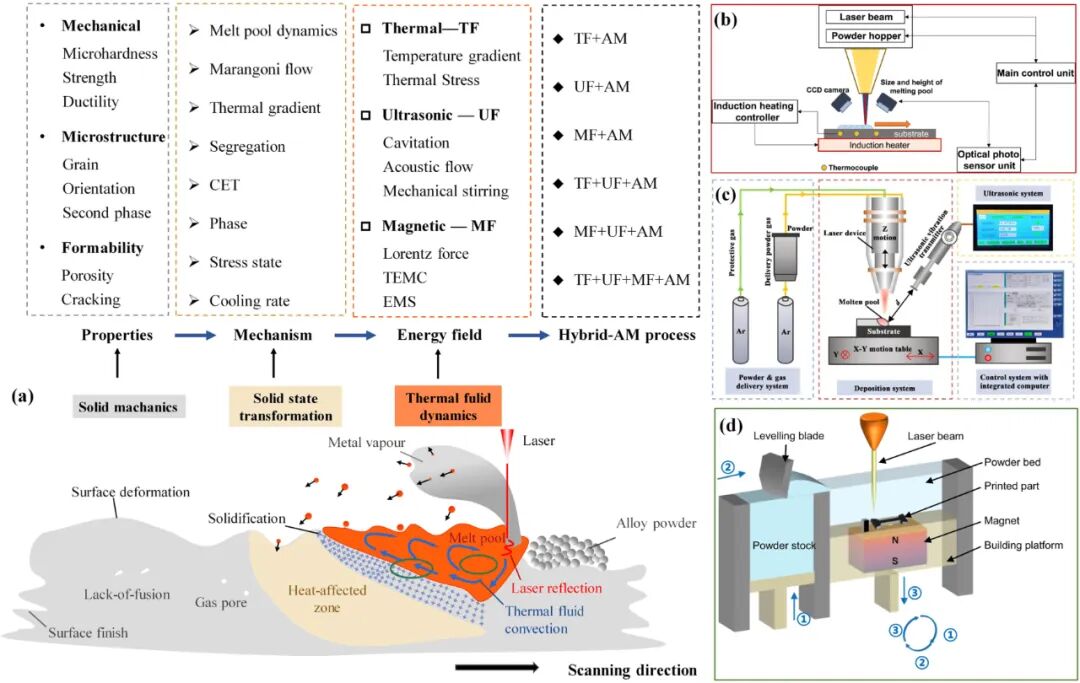

The above figure compares the crack morphology of high-temperature alloys at different preheating temperatures. When the preheating temperature is raised to 1100°C (such as IN738LC alloy), the temperature gradient of the melt pool is significantly reduced, the precipitation rate of the γ′ strengthening phase slows down, and the crack length is reduced by more than 70%. High-temperature preheating broadens the process window, allowing high crack-sensitive alloys (such as CM247LC) to achieve defect-free forming. |

|

|

|

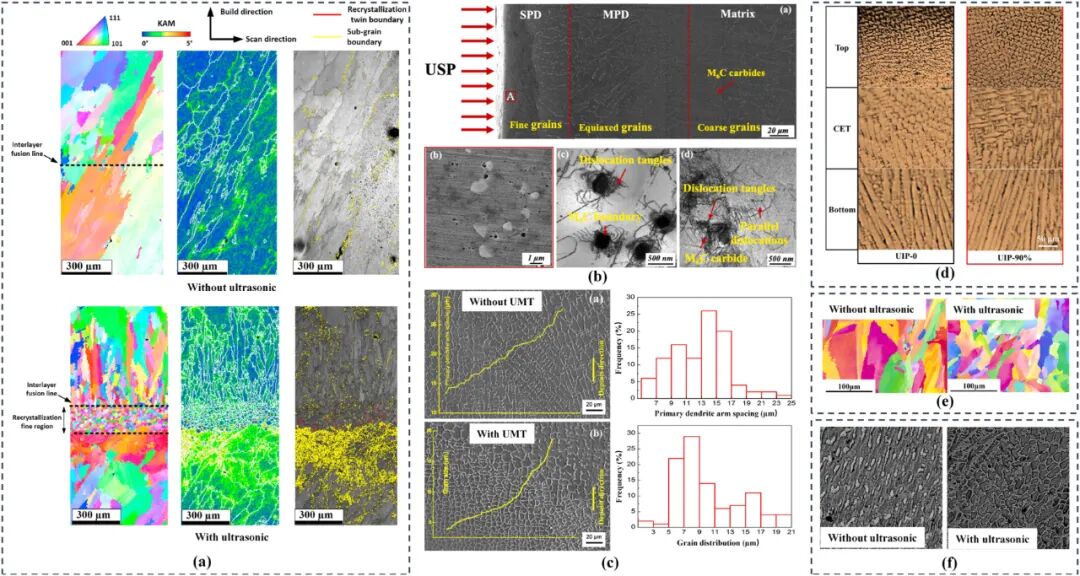

The above figure demonstrates the effect of ultrasonic impact treatment on the microstructure of IN718 alloy. The ultrasonic cavitation effect generates instantaneous high pressure (>1000 atm) within the melt pool, promoting heterogeneous nucleation; simultaneously, the acoustic flow effect drives the melt to convect, reducing the size of the Laves phase by 40% and decreasing the porosity by 50% (Figure f). Non-contact ultrasound can also optimize Marangoni flow by adjusting the incident angle, enhancing defect escape. |

|

|

|

The above figure reveals the directional control of dendrite growth by the magnetic field. When the static magnetic field is parallel to the scanning direction (B//V), thermoelectromagnetic convection (TEMC) homogenizes the diffusion of Nb and Mo elements, transforming the Laves phase from chain-like to granular (Figure b); the alternating magnetic field reduces the primary dendrite arm spacing to 11μm through electromagnetic stirring (EMS), significantly weakening the <001> texture and enhancing the isotropy of mechanical properties. |

|

|

|

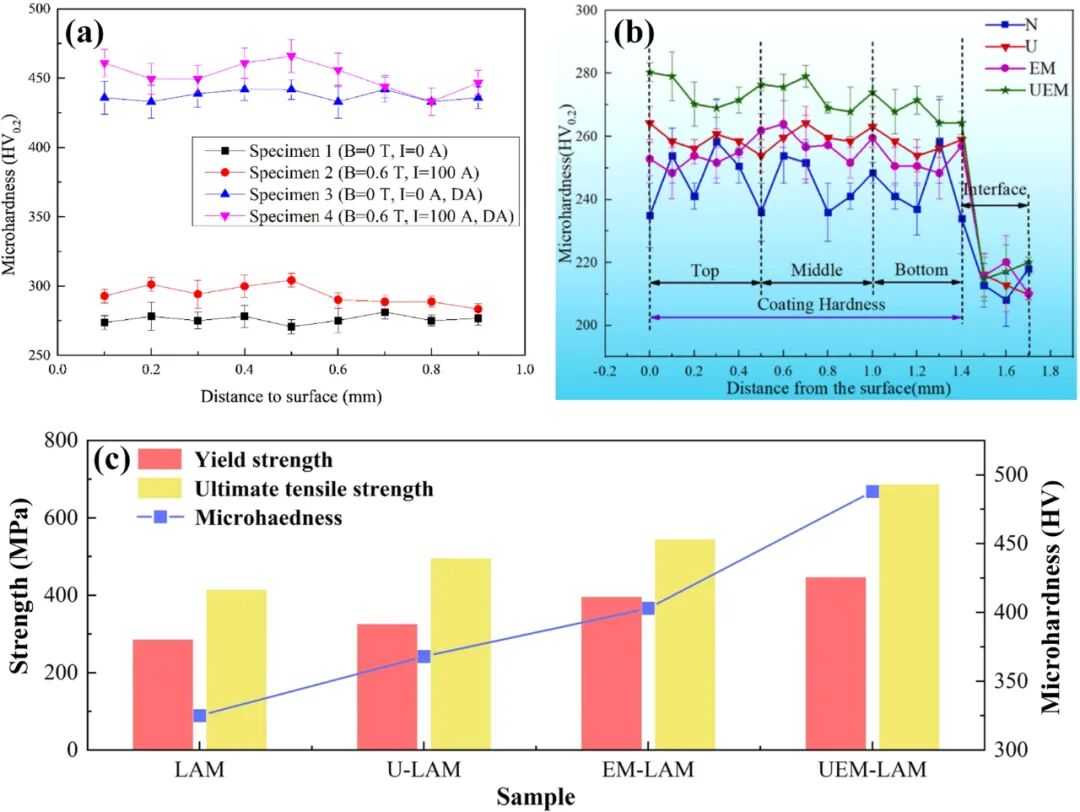

The above figure verifies the synergistic advantages of ultrasonic-electromagnetic multi-field coupling. The composite energy field simultaneously enhances the cavitation effect through Lorentz force, bringing the porosity of IN625 alloy close to zero (Figure c), while hardness and tensile strength increase by 15%. The multi-physical field coupling model further indicates that the downward Lorentz force can guide bubbles to escape directionally, achieving integrated optimization of “defect suppression-structure customization-performance control.” |

|

Main Content of the Review: |

|

1. Thermal field dominates crack control: Preheating above 900°C reduces the crack rate of high-sensitive alloys (IN738LC/CM247LC) by 70% by lowering the temperature gradient and regulating the precipitation of γ′ phase; 2. Ultrasonic field optimizes density: Cavitation effect (20–40 kHz) drives micro-bubble migration, reducing porosity by 50% and refining grain size to 10μm; 3. Magnetic field customizes microstructure: Static magnetic field suppresses melt pool turbulence, while alternating magnetic field promotes uniform distribution of elements, reducing the Laves phase content by 2% and decreasing mechanical anisotropy; 4. Multi-field synergy breaks bottlenecks: Thermal-acoustic-magnetic coupling achieves near-zero porosity and synergistic enhancement of high-temperature performance through effects such as “Lorentz force enhancing cavitation” and “preheating reducing acoustic pressure attenuation,” providing a new paradigm for the remanufacturing of aerospace components. |

Your support is our greatest motivation for creation. We welcome you to share and follow us, and we will continue to create more great content!