The security of industrial automation systems is a key focus in the modern industrial control field, especially for industrial control systems involving Siemens PLCs. How to implement level protection (referred to as “level protection”) has become an unavoidable topic for engineers.This article will interpret how to implement level protection requirements in Siemens PLC systems from basic concepts, hardware design, software configuration to practical cases, and provide best practice recommendations, helping readers quickly get started and avoid common issues.

—

What is Level Protection for Industrial Control Systems?

In industrial control systems, level protection refers to the classification of the security protection level of industrial control systems according to national cybersecurity regulations and standards (such as the “Cybersecurity Law” and the “Basic Requirements for Information Security Level Protection”), and implementing corresponding technical and management measures for different levels.

In simple terms, level protection is like “scoring” the system; the higher the score, the stricter the requirements. For example, your PLC control system is equivalent to the “main switch” at home, and level protection is like setting up multiple protective measures such as a password lock, firewall, and anti-tampering alarm for the switch.

Level protection for industrial control systems is divided into five levels:

1. Level 1: Autonomous protection level, applicable to general systems, with the lowest security requirements.

2. Level 2: Guiding protection level, applicable to small industrial control systems.

3. Level 3: Supervisory protection level, applicable to medium-sized industrial control systems or situations involving important production.

4. Level 4: Mandatory protection level, applicable to key national units or systems related to national economy and people’s livelihood.

5. Level 5: Special control protection level, applicable to systems involving national security.

Most industrial control systems (especially Siemens PLC systems) need to meet the requirements of level 2 or level 3, and we will discuss these levels below.

—

Hardware Security: How to Select and Configure PLC Hardware?

1. Basic Hardware Design

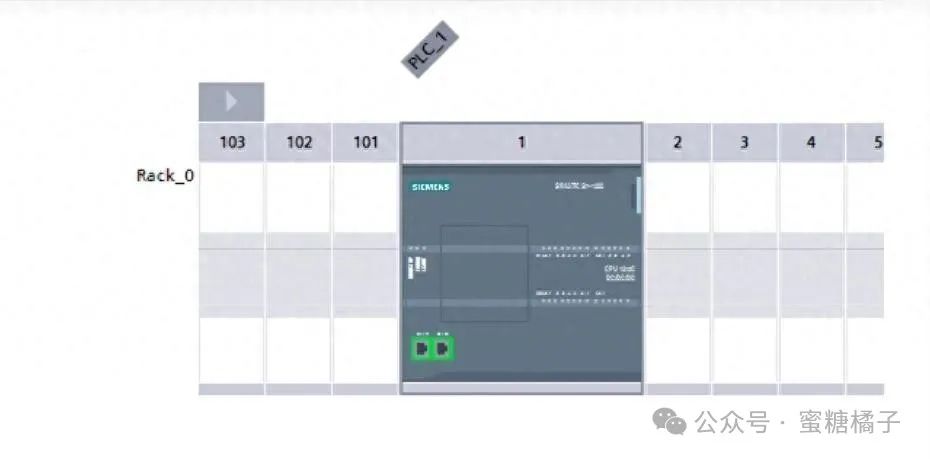

When implementing level protection, hardware design is the first step. Taking the Siemens S7-1200 series PLC as an example, here are the key hardware protection measures:

– Physical Isolation: Physically isolate the PLC control cabinet to prevent unauthorized access.

– Redundant Design: For critical production equipment, it is recommended to use redundant PLCs (such as S7-1500 redundant systems) to ensure system reliability.

– Network Isolation: Isolate the PLC from other devices using industrial switches (such as the SCALANCE series), and use firewalls when necessary.

2. Wiring Diagram Example

The following is a typical PLC hardware wiring diagram, demonstrating how to achieve basic security protection at the hardware level.

+————————-+ | Control Cabinet External | +————————-+ | | | | | +—-> Operator Panel (HMI) | +———–> Input Devices (Sensors/Buttons) +——————-> Output Devices (Relays/Motors) | +————————-+ | Control Cabinet Internal | +————————-+ | +————————-+ | Siemens PLC | +————————-+ | +————————-+ | Industrial Switch | +————————-+ | +————————-+ | Firewall Module | +————————-+ | Enterprise Network

Notes:

– Ensure that the wiring of the PLC’s input/output modules and power supply modules is secure to avoid loose connections.

– For external interfaces (such as RS485, PROFINET), use shielded cables and ground them to prevent signal interference.

—

Software Security: How to Configure Security Features in Siemens PLC?

1. User Permission Management

Siemens PLC supports multi-level user permission configuration. Taking the TIA Portal software as an example:

– Administrator Permission: For system configuration and maintenance.

– Operator Permission: Only allows operation of devices (such as start/stop).

– Guest Permission: Can only view operational status.

Configuration Steps:

1. Open the TIA Portal project.

2. Go to “Device Configuration” -> “User Management”.

3. Add users and assign permissions.

2. Communication Encryption Configuration

In level 3 requirements, communication encryption is essential. Siemens PLC supports encrypted communication via the TLS protocol:

– Configuration Method: In TIA Portal, go to “Communication Settings”. Enable the “Encrypted Communication” option. Configure certificates and keys.

1. In TIA Portal, go to “Communication Settings”.

2. Enable the “Encrypted Communication” option.

3. Configure certificates and keys.

Notes:

– Use the latest version of TIA Portal to access the latest encryption features.

– For PROFINET communication, it is recommended to enable device authentication.

—

Typical Case: Level 3 Implementation in a Chemical Plant

A chemical plant uses Siemens S7-1500 series PLCs to control the production line, needing to meet level 3 requirements. The implementation plan is as follows:

1. Hardware Level: Install physical locks on the control cabinet. Use SCALANCE industrial switches to isolate the production network from the office network. Configure redundant modules for critical equipment.

2. Software Level: Configure user permissions to restrict operators’ modification rights to the program. Enable encrypted communication to prevent data eavesdropping. Regularly update PLC firmware to fix known vulnerabilities.

3. Management Level: Develop emergency plans and conduct regular drills. Check system logs monthly for abnormal login records.

Hardware Level::

– Install physical locks on the control cabinet.

– Use SCALANCE industrial switches to isolate the production network from the office network.

– Configure redundant modules for critical equipment.

Software Level::

– Configure user permissions to restrict operators’ modification rights to the program.

– Enable encrypted communication to prevent data eavesdropping.

– Regularly update PLC firmware to fix known vulnerabilities.

Management Level::

– Develop emergency plans and conduct regular drills.

– Check system logs monthly for abnormal login records.

—

Common Problems and Solutions

1. Problem: PLC operation interrupted, unable to recover? Reason: Redundant system not configured, hardware failure occurred. Solution: Configure hot redundant PLCs for critical equipment.

2. Problem: Communication delay too high? Reason: Network topology not optimized or switch configuration improper. Solution: Use Siemens network diagnostic tools (such as PRONETA) to detect network bottlenecks.

3. Problem: HMI screen cannot load? Reason: Network firewall settings block communication. Solution: Check firewall rules to allow communication between HMI and PLC.

Problem: PLC operation interrupted, unable to recover?

– Reason: Redundant system not configured, hardware failure occurred.

– Solution: Configure hot redundant PLCs for critical equipment.

Problem: Communication delay too high?

– Reason: Network topology not optimized or switch configuration improper.

– Solution: Use Siemens network diagnostic tools (such as PRONETA) to detect network bottlenecks.

Problem: HMI screen cannot load?

– Reason: Network firewall settings block communication.

– Solution: Check firewall rules to allow communication between HMI and PLC.

—

Practical Recommendations

– Regular Maintenance: Check PLC hardware and network devices quarterly, clean dust and test performance.

– Log Auditing: Enable system log functionality and regularly check for abnormal operation records.

– Security Training: Provide basic security training for operators to avoid system paralysis due to operational errors.

– Backup Data: Regularly back up PLC programs through TIA Portal and store them in a secure location.

Implementing level protection is not a one-time effort but a continuous optimization and improvement process. In practical engineering, combining hardware, software, and management measures to form a comprehensive security protection system is essential to truly ensure the stability and security of industrial control systems.