Currently, there are five mainstream metal 3D printing technologies: Nano Particle Jetting (NPJ), Selective Laser Melting (SLM), Selective Laser Sintering (SLS), Laser Metal Deposition (LMD), and Electron Beam Melting (EBM).1.NPJ (Nano Particle Jetting)NPJ (Nano Particle Jetting) technology is the latest metal 3D printing technology developed by the Israeli company Xjet. Compared to conventional laser 3D printing, it usesnano liquid metal, deposited in ainkjet manner, achieving a printing speedfive times faster than conventional laser printing, and hasexcellent precision and surface roughness.

Below is the working process of Xjet equipment:

Metal particle refinement

Metal particles distributed in droplets

Droplet jetting forming process

Liquid phase discharge process

Sintered parts

2. SLM (Selective Laser Melting)

SLM, or Selective Laser Melting technology, is currently the most common technology in metal 3D printing,which uses finely focused laser beams to rapidly melt pre-placed metal powder, directly obtaining parts of any shape with complete metallurgical bonding, achieving a density of over 99%.

The laser scanning system is one of the key technologies of SLM. Below is the working diagram of the scanning system from SLM Solutions:

Laser transmission

Laser emission

Scanning galvanometer

Laser scanning and melting

Metal powder melting process

During the metal 3D printing process, due to the complexity of the parts, support materials are usually required. After the parts are completed, the supports need to be removed, and the surface of the parts needs to be treated.

Removing the parts

Removing supports

Post-processing

This technology features high precision and excellent surface quality, greatly saving material and machining costs, reducing manufacturing costs by 20%-40%, and significantly shortening production cycles.

3. SLS (Selective Laser Sintering)

SLS, or Selective Laser Sintering technology,is similar to SLM technology, with the main difference being the laser power, and is typically used for 3D printing of polymer materials.

Below is the process of preparing plastic parts using SLS:

Model slicing

Laser sintering process

Removing the parts

Post-processing

SLS can also be used to manufacture metal or ceramic parts, but the resulting parts have low density and require subsequent densification treatment before use.

SLS manufacturing metal parts

4. LMD (Laser Metal Deposition)

LMD, or Laser Metal Deposition technology, has many names as different research institutions have independently studied and named it. Common names include:LENS, DMD, DLF, LRF, etc. The main difference from SLM is that its powder is gathered to the work surface through a nozzle, where it converges with the laser at a point, and after melting and cooling, a deposited solid is obtained..

Below is the working process of LENS technology:

Coaxial powder feeding

Building process

LENS technology enables mold-free manufacturing of metal parts, saving costs and shortening production cycles. This technology also addresses a series of issues such as the difficulty of machining complex curved parts in traditional manufacturing processes, large material removal, and severe tool wear.

5. EBM (Electron Beam Melting)

EBM, or Electron Beam Melting technology, has a process very similar to SLM, with the difference being thatthe energy source used in EBM is an electron beam. The output energy of the electron beam in EBM is typically an order of magnitude greater than the laser output power in SLM, and the scanning speed is also much higher than that of SLM. Therefore, during the construction process,the entire build platform needs to be preheated to prevent excessive temperature during the forming process, which can lead to significant residual stress.

Below is the working process of EBM:

Overall preheating

Forming process

Changes in powder during melting

The energy conversion efficiency of the electron beam is much higher than that of the laser, leading to faster material melting and thus faster object formation. The combination of EBM and vacuum technology can further enhance efficiency and material performance.

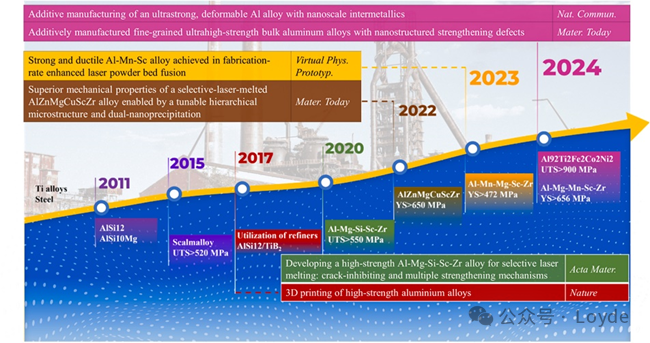

Additive Manufacturing (AM) technology has evolved from the stereolithography apparatus (SLA) technology pioneered by Charles Hull in 1984. This innovative manufacturing method constructs objects by adding materials layer by layer, contrasting sharply with traditional subtractive manufacturing methods such as cutting and milling. The development of AM technology can be divided into four stages: the nascent stage, early stage, mid-stage, and rapid development stage. Figure 1 outlines the historical development of AM technology in aluminum alloys. From the first application of aluminum alloys in 3D printing in 2011, to the development of Scalmalloy® alloys and the application of grain refinement agents, to the development of Al-Mg-Si-Sc-Zr alloys with yield strengths exceeding 550 MPa, and the recent successful reports of ultra-high-strength aluminum alloys.

Aluminum alloy AM technology is mainly divided into three types based on energy sources: Laser AM (LAM), Electron Beam AM (EBAM), and Arc AM (WAAM). LAM technology specifically includes SLM, SLS, and LMD processes, EBAM technology includes EBPBF, EBF3, and DED electron beam variants, while WAAM technology includes GMAW, GTAW, and PAW, with specific classifications and processes shown in Figure 2.

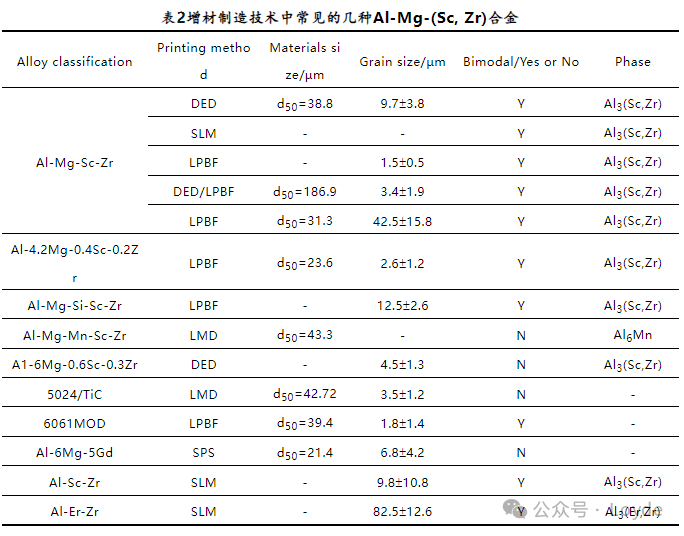

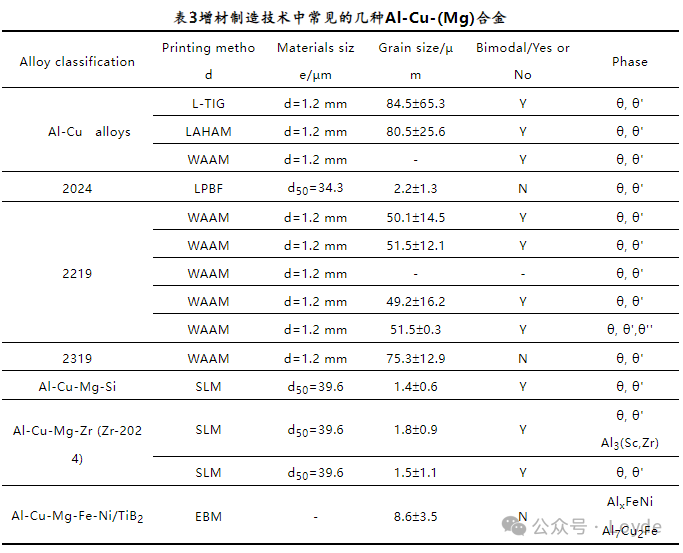

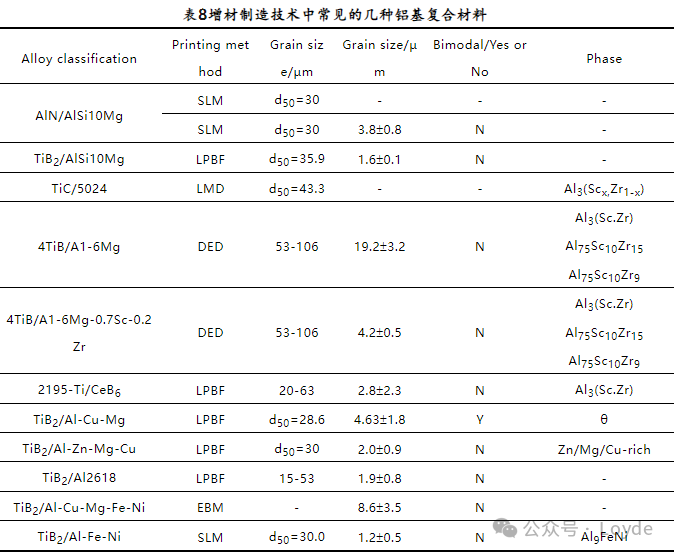

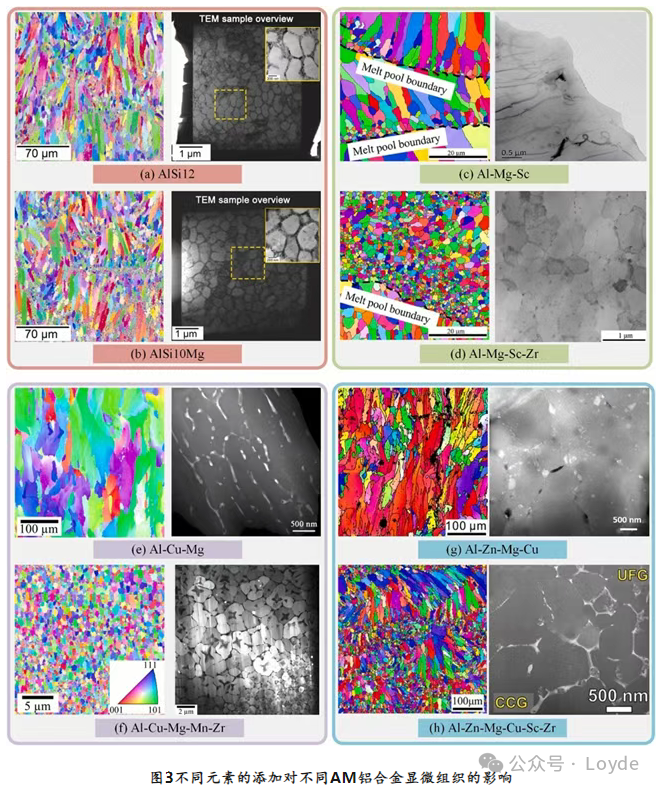

Al-Si, Al-Mg, Al-Cu-Mg, and Al-Zn-Mg-Cu alloys are among the earliest alloys used in the AM field, and subsequent developments have led to other alloys. Common types of additive manufacturing aluminum alloys are shown in Tables 1-8. However, these alloys have a significant drawback: their mechanical properties are limited (usually with tensile strengths below 400 MPa), making them insufficient to meet the requirements of the aerospace industry. Therefore, there is an urgent need to develop new aluminum alloys. Scandium (Sc) and Zirconium (Zr) modified aluminum-magnesium alloys are excellent alternatives for these high-performance aluminum alloys. Aluminum-magnesium alloys are known for their good corrosion resistance, excellent weldability, and moderate strength, and have been widely used in aerospace and maritime fields. Adding small amounts of Sc and Zr to Al-Mg alloys can significantly refine grain size, forming high-density nanoscale Al3(Sc, Zr) phases. These changes significantly improve the mechanical properties and thermal stability of the alloys.

Al-Cu-(Mg) series alloys represent heat-treated aluminum alloys, known for their high specific strength, good corrosion resistance, and low density. These characteristics make them widely used in automotive and aerospace fields. In recent years, Al-Cu-(Mg) alloys have often been prepared and processed using WAAM methods, achieving good results. This method leverages the inherent advantages of these alloys to effectively produce components that utilize their strength and lightweight characteristics. The successful integration of WAAM technology with Al-Cu-(Mg) alloys not only emphasizes the versatility of AM but also enhances the innovative potential for producing critical high-performance components in these demanding industries.

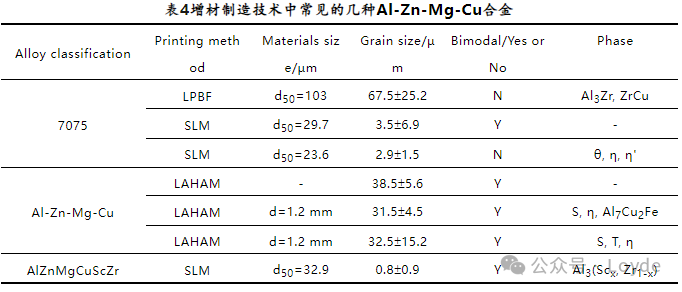

In the field of aluminum alloys, Al-Zn-Mg-Cu alloys have gained widespread attention from academia and industry due to their extremely high strength, good machinability, and excellent corrosion resistance. However, traditional casting and deformation processes struggle to manufacture Al-Zn-Mg-Cu alloy parts with complex shapes and ultra-fine grain structures, greatly limiting their broader market applications.

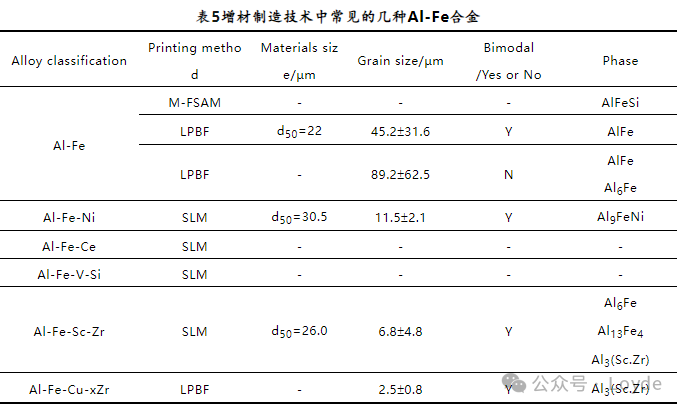

Al-Fe alloys are gaining attention for their lightweight, high strength, wear resistance, creep resistance, and cost-effectiveness. The addition of iron promotes the formation of Al-Fe intermetallic compounds, thereby enhancing the performance of these aluminum alloys at room and high temperatures. For example, the Al-Fe-V-Si series alloys developed by Allied Signal have a body-centered cubic (BCC) Al12(Fe, V)3Si phase, whose precipitation strengthening mechanism allows for a tensile yield strength of 407 MPa. Lockheed California has achieved a tensile strength of 422 MPa in Al-Fe-Ce alloys. Recently, researchers have also emphasized that the nano-stable Al6Fe phase has a good microstructure that helps improve the mechanical properties of Al-Fe alloys manufactured using LPBF.

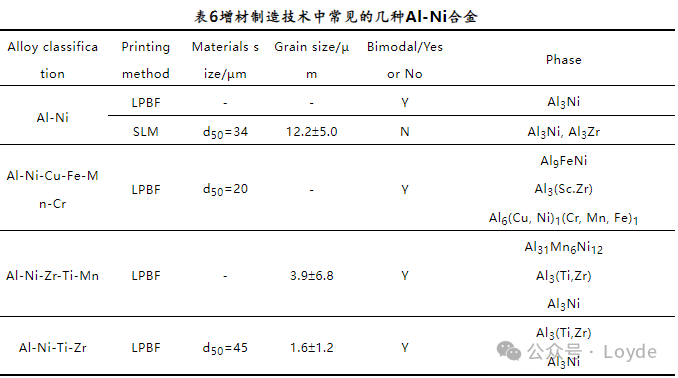

Al-Ni and Al-Mn alloys have been widely applied in the field of additive manufacturing due to their excellent mechanical properties and corrosion resistance. With the rapid development of additive manufacturing technology, the application of aluminum-manganese alloys has expanded from simple prototype manufacturing to the production of complex functional components. Researchers have been able to significantly improve the strength and precision of printed parts by precisely controlling temperature and speed during the printing process. Furthermore, new printing technologies such as SLM and EBM have further broadened the application of Al-Mn alloys in industries such as aerospace, automotive, and medical devices. These technological advancements not only expand the range of material applications but also drive innovation and technological revolution in the field of materials science.

Metal matrix composites have been a significant advancement in the field of materials science and manufacturing technology in recent years. Due to their good machinability and excellent mechanical properties, they have garnered increasing interest in the AM industry. Advances in powder metallurgy and traditional metal forming technologies indicate that the presence of reinforcing particles plays a crucial role in precipitation kinetics and the synergistic strengthening effect between the reinforcing particles and the precipitated phase.

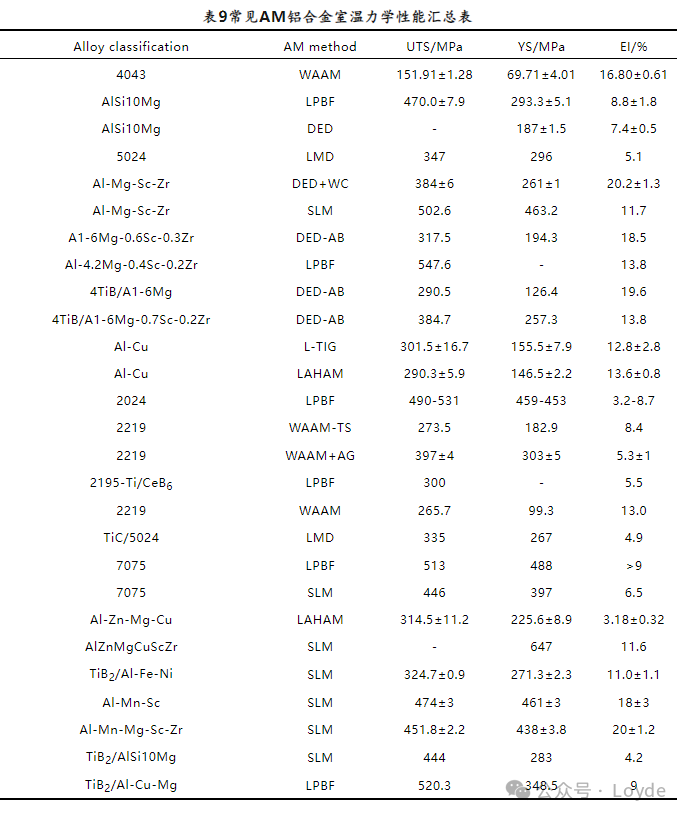

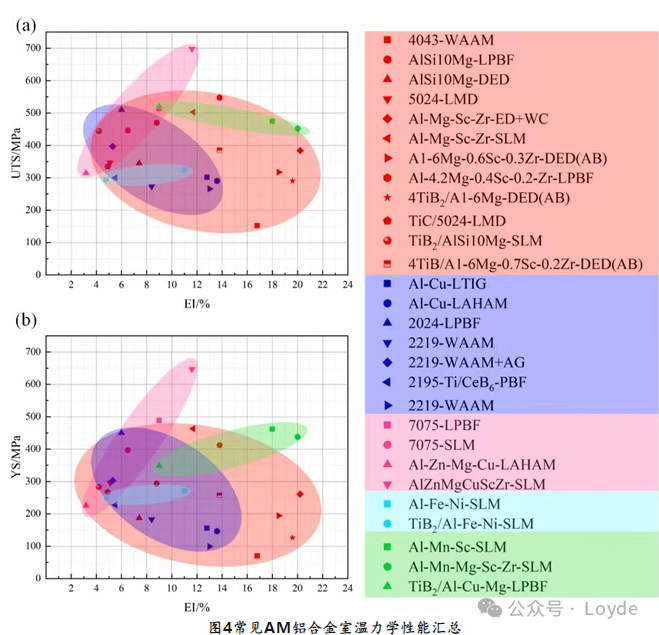

Next, a detailed and comprehensive overview of the static performance, thermal performance, fatigue performance, creep performance, corrosion performance, impact performance, and wear performance of common AM aluminum alloys will be provided. Among them, the mechanical properties of common AM aluminum alloys at room temperature are summarized in Table 9, and the data in the table is plotted into a clustering diagram, allowing for a more intuitive observation of the mechanical property distribution of alloys under different types and additive manufacturing methods, as shown in Figure 4.

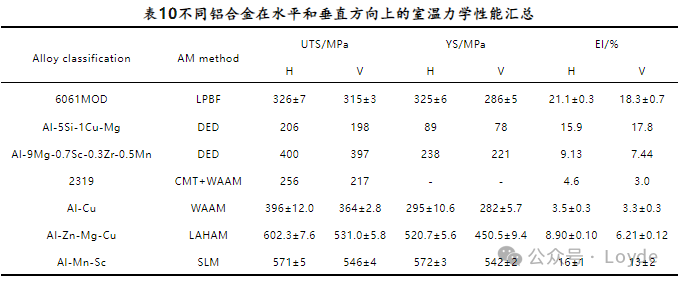

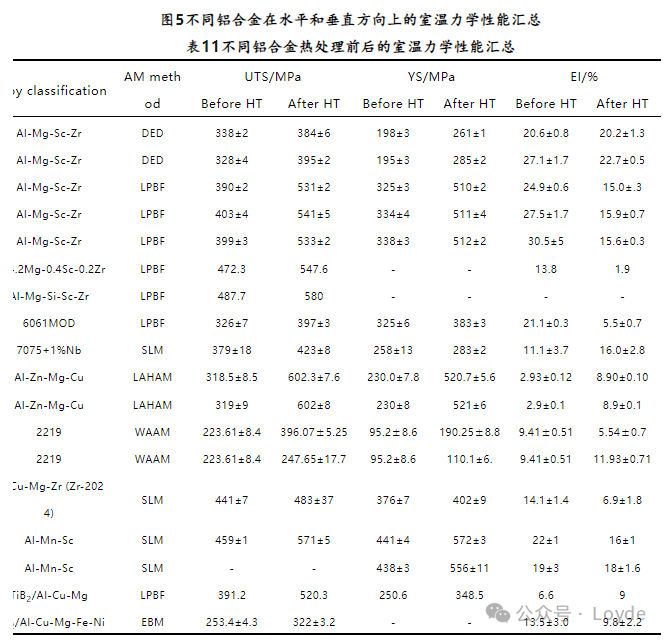

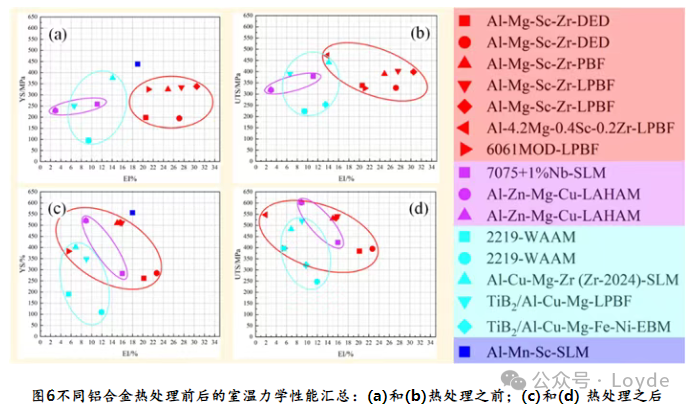

Tables 10-12 summarize the mechanical properties of several common aluminum alloys in both horizontal and vertical directions, the mechanical properties at room temperature before and after heat treatment, and the thermal performance summary, respectively. These are plotted into scatter plots, as shown in Figures 5-7, providing a more intuitive observation of the alloy performance distribution.

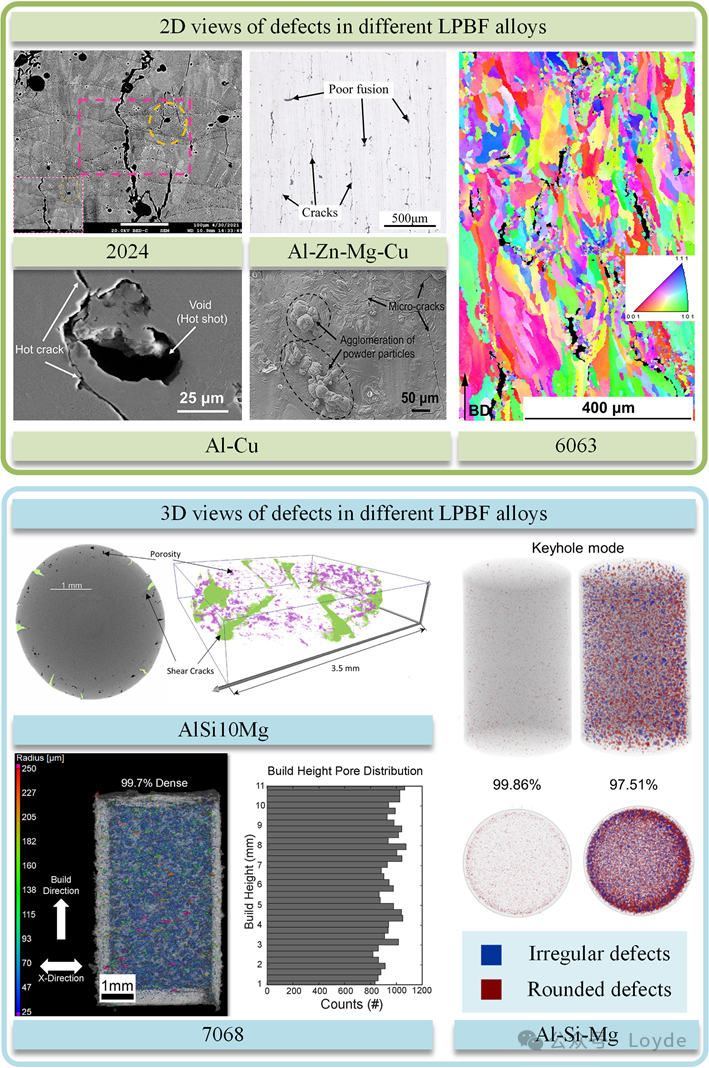

Research in the field of defects such as porosity, cracks, and sphericity in additive manufacturing aluminum alloys has greatly expanded. Enhanced analytical techniques have deepened the understanding of these defects and facilitated detailed examinations, as shown in the microstructural images of various alloys in Figure 8. Defects such as porosity, as well as insufficiently melted particles and residual powders, often act as nucleation points for internal microcracks, thereby reducing the mechanical properties of the alloys. The emergence of computed tomography (CT) technology has revolutionized our ability to visualize these defects in three dimensions, showcasing their complex structures and morphologies. This technological advancement provides a more thorough and detailed perspective on the occurrence and development of these defects and their micro-mechanical behavior in the alloys.

Figure 8 SEM images of various defects formed in aluminum alloy samples manufactured by LPBF

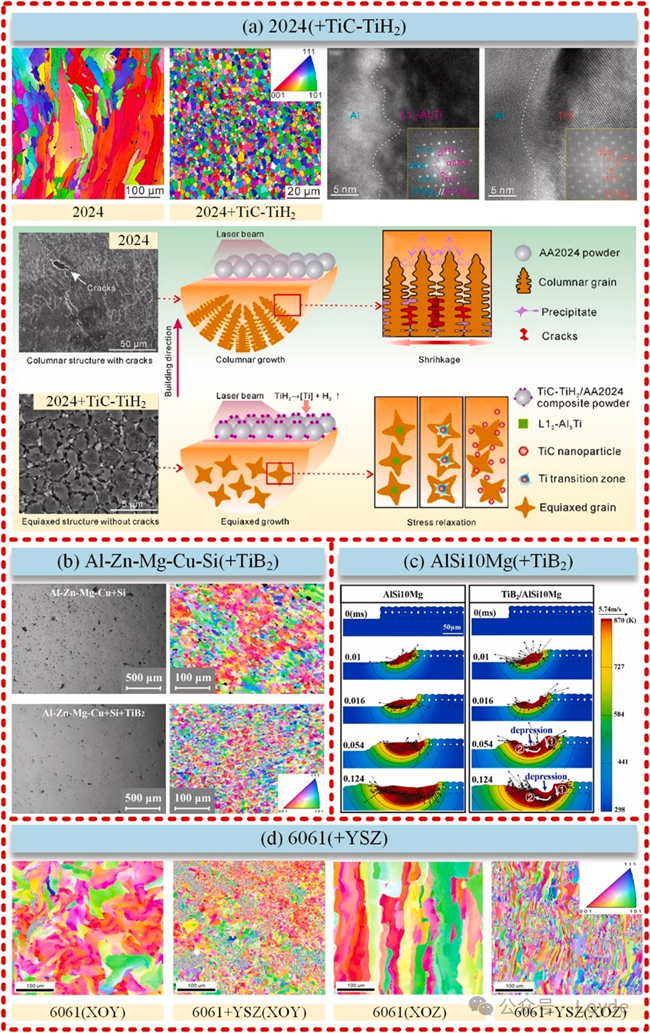

Next, to enhance the performance of AM aluminum alloys, a summary of the effects of powder raw materials, optimization of printing parameters, grain refinement agents, and different post-processing on the internal grain refinement and uniformity of AM aluminum alloys will be provided. The addition of trace elements and ceramic particles significantly improves the mechanical properties of the alloys, including strength and toughness. Furthermore, grain refinement agents help stabilize the melt pool, thereby reducing defects such as porosity and cracks during the manufacturing process, while optimizing the surface quality and geometric accuracy of the final product. Therefore, the reasonable selection and use of grain refinement agents is a key strategy for designing and optimizing aluminum alloy additive manufacturing processes, ultimately improving manufacturing efficiency and product quality. Figure 9 illustrates the improvement effects and mechanisms of different ceramic particles on the microstructure of AM aluminum alloys.

Figure 9 Improvement of microstructure of additive manufacturing aluminum alloys by different ceramic particles

With the rapid development of AM aluminum alloys, a series of commercial aluminum alloy powders have emerged, and components manufactured from these alloy powders are increasingly being applied in industries such as aerospace and rail transportation. Figure 10 showcases the practical applications of AM aluminum alloy components, including: turbine compressor wheels produced from 7075-TC4 materials, a rocket propulsion engine developed by ©SLM Solutions and Cellcore, various components of the Unimog series produced by Mercedes-Benz using LPBF, engine cylinder blocks made from 6061 aluminum alloy, LPBF manufactured Al6061-RAM2 heat exchangers, bionic partitions made from Scalmalloy® alloy by APWorks, piston heads made from A2024-RAM2, and 3D printed aluminum alloy honeycomb material heat exchangers.

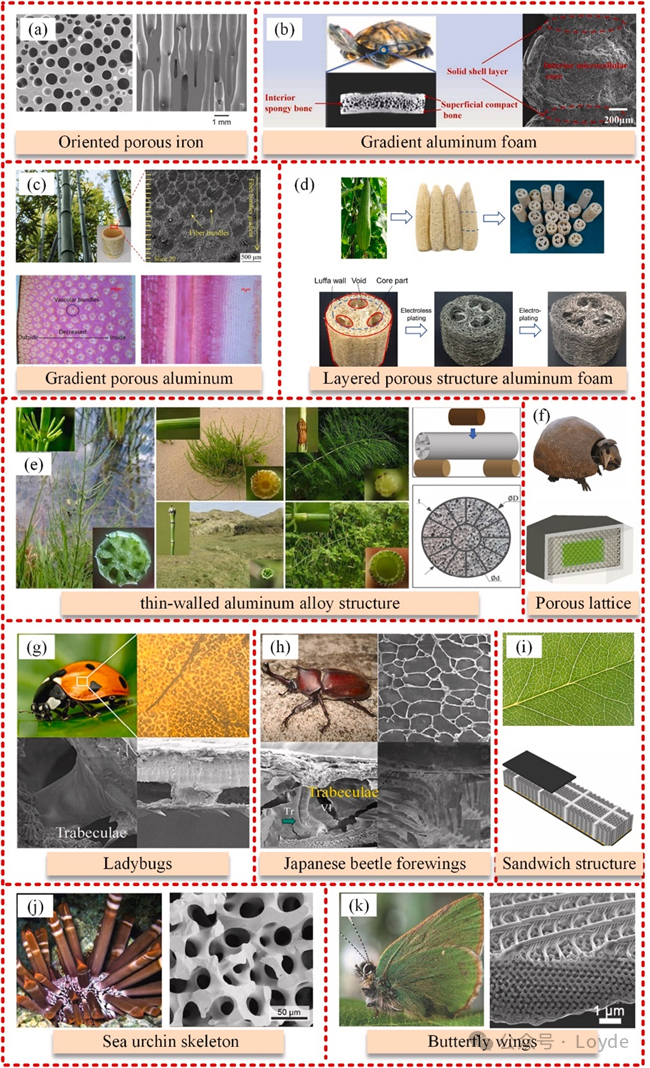

Figure 10 Practical applications of AM aluminum alloy components Inspired by the ingenious designs of nature,

researchers have developed various new structures known for their special energy absorption capabilities, as illustrated. These examples include porous iron structures mimicking the internal structure of lotus roots, gradient foam aluminum inspired by the sturdy shell of turtles, and gradient porous aluminum square tubes mimicking the elastic structure of bamboo. Other designs include layered porous foam aluminum, inspired by the sponge-like structure of loofah, and dense layered porous lattice core structures modeled after armadillos, which help combine strength with high energy absorption. Additionally, two new types of bionic multicellular tubes have been developed based on the internal structures of ladybugs and Japanese beetles. The porous vascular structure in the blades increases the ability of the blades to withstand mechanical stress. These bio-inspired innovations highlight the fusion of natural wisdom with advanced engineering to create materials and structures with outstanding performance in harsh environments.

Figure 11 Bionic structures designed inspired by natural structures

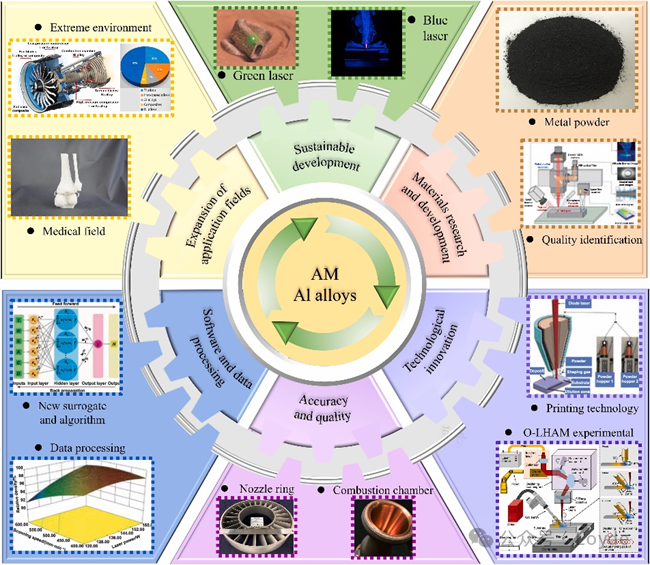

Since significant developments in the 1980s, AM technology has been widely applied in various fields, including aerospace, medical, construction, automotive, and consumer goods. Despite its widespread application, the technological maturity of AM still has room for improvement compared to traditional processing methods such as machining, casting, forging, and welding. They face some limitations, including slow processing speeds, size constraints on parts, and a limited variety of available materials. However, with continuous technological advancements, these challenges are expected to be gradually resolved. Therefore, the article concludes by emphasizing six highly promising development directions in aluminum alloy additive manufacturing technology, as shown in Figure 12.

Figure 12 Key development directions in aluminum alloy additive manufacturing technology

Note: The above content is sourced from the Yangtze River Delta G60 Laser Alliance

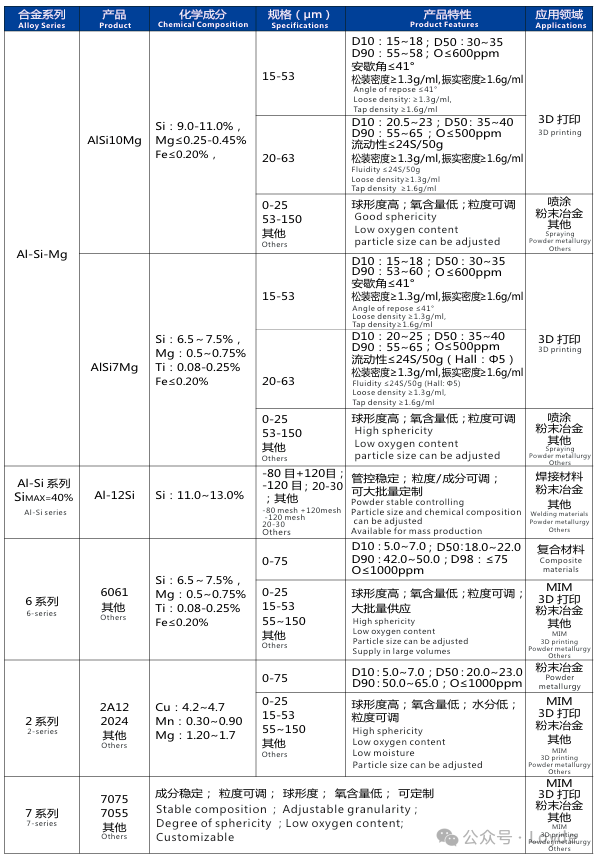

3D printing related metal materials:

1. Aluminum alloy powder series:

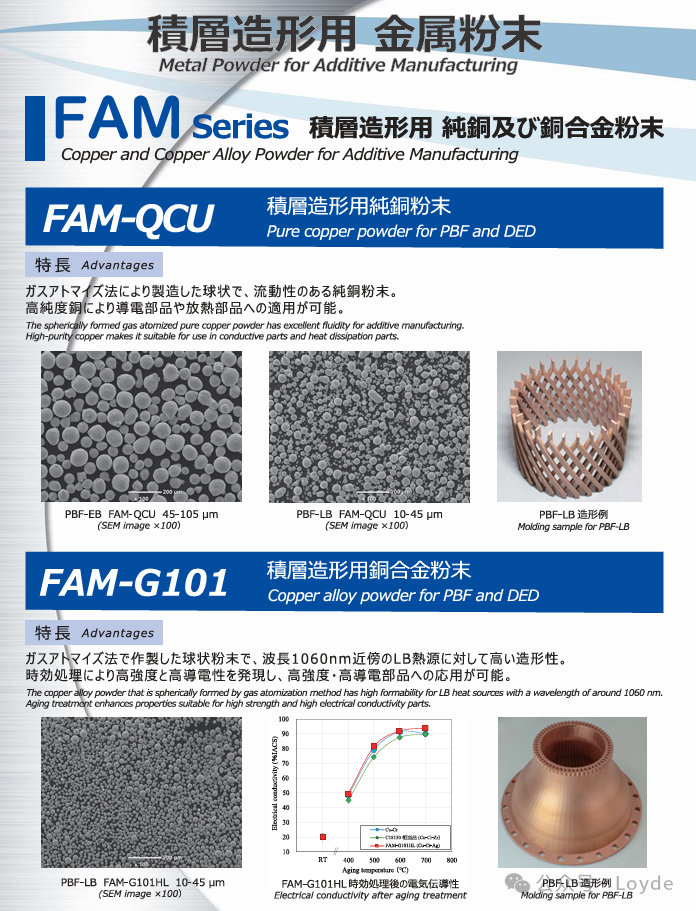

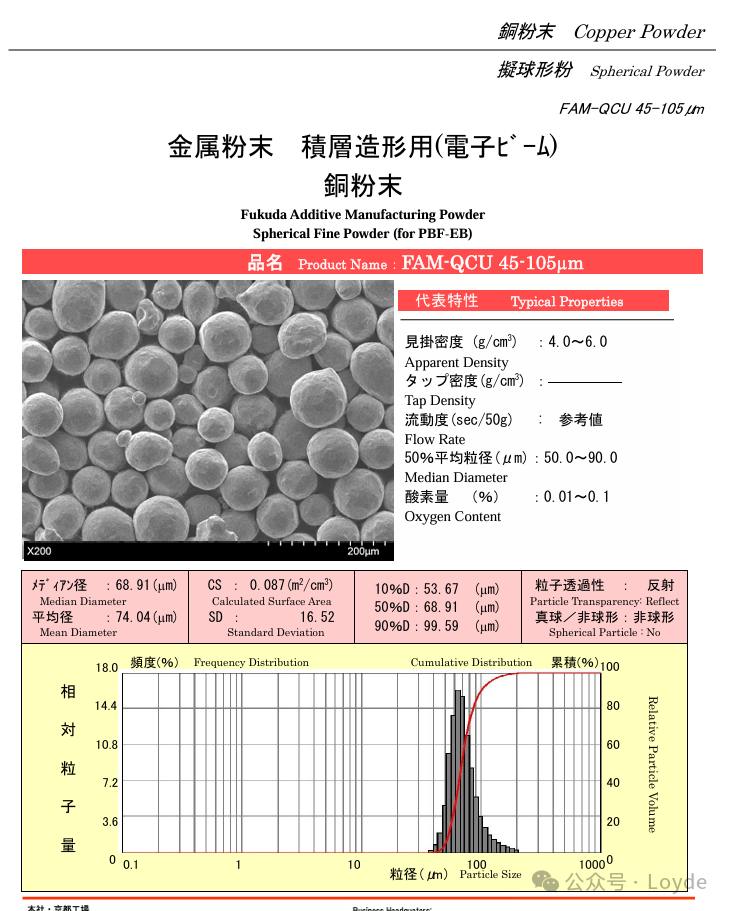

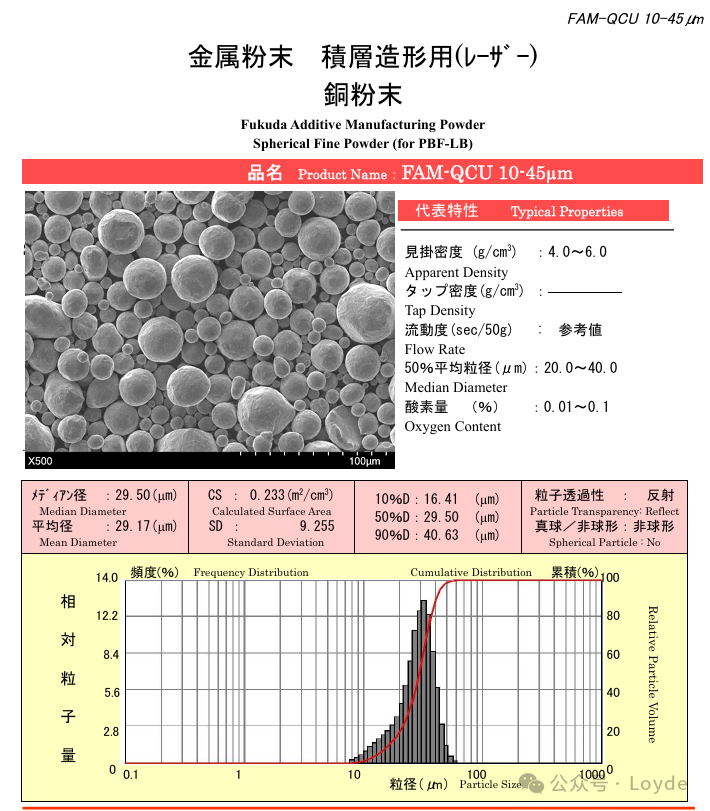

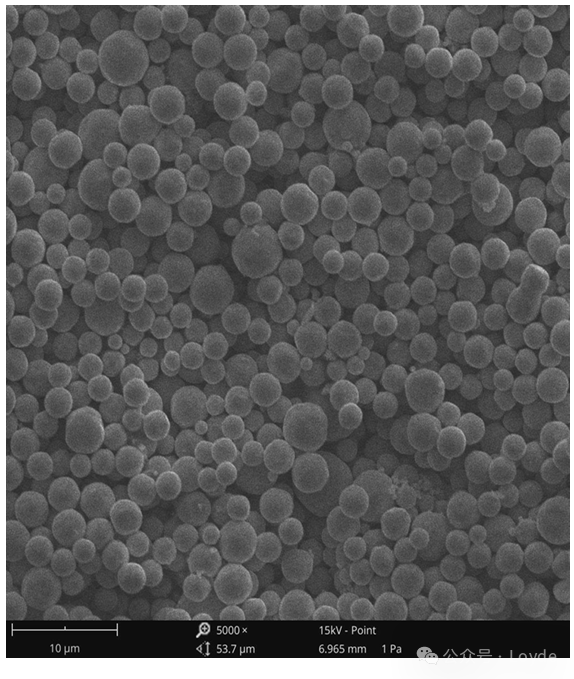

2. Copper-basedalloy powder series

3. Pure copper powder series

Compared to high-energy beam thermal source 3D printing technologies such as PBF and DED, BJAM technology has unique advantages such as low cost, a wide range of material systems, good surface quality, and no need for support structures. Factors affecting the quality of BJAM printed metal parts can be divided into material and process.

Material factors include the properties of the powder and binder. The properties of the powder determine the quality of the powder bed, the initial green density, and the densification effect, while the geometry and strength of the initial green body are influenced by the binder. This article focuses solely on the binder system.

In the BJAM process, the liquid binder fills the gaps between each layer of powder, bonding the powder to form the desired shape. Selecting a suitable binder is key to BJAM technology. First, the binder must be printable; only if the binder has an appropriate viscosity can it ensure the formation of individual droplets and their detachment from the nozzle.

The selection of binder viscosity is related to the use and the print head. To achieve good jetting performance, the viscosity of the binder must be maintained between 8-12 mPa·s to match the piezoelectric print head. Additionally, the binder must have sufficient bonding strength to ensure the integrity of the printed green body structure. Furthermore, it should exhibit good binder-powder interaction, clean combustion characteristics, and a long shelf life with no environmental pollution risks.

For example, the required ink parameters for the Star 1024 print head are a viscosity of 8-12 cps, a particle size of less than 10 um, and a surface tension of around 35 mN/m.

Types of binders

Binders used in BJAM technology can be divided into two types: organic and inorganic binders. Organic binders bond the powder through curing, while inorganic binders form bonds through colloidal gel formation. Binders can also be classified into acid-base binders, metal salt binders, and solvent binders. Acid-base binders bond the powder through acid-base chemical reactions, while metal salt binders form bonds between powders through salt recrystallization, salt crystallization reduction, or salt displacement reactions.

Solvent binders primarily act on polymer powders, dissolving the deposition area and forming specific structures after the solvent evaporates. Additionally, based on different bonding mechanisms, there are powder bed binders, phase change binders, and sintering inhibiting binders. Powder bed binders differ from general liquid binders, as most binders mixed with the powder bed will spray liquid to interact with the powder to create bonds. Phase change binders bond the powder together through the curing of the binder, while sintering inhibiting binders can control the sintering area by selectively spraying insulating materials. The types of binders, available materials, and their advantages and disadvantages are shown in Table 2.

During the binder jetting process, the interaction between the binder and the powder bed directly affects the geometric accuracy, green strength, and surface roughness of the printed parts. After the liquid binder is sprayed from the nozzle, a series of penetration behaviors occur, such as impact, spreading, and wetting. The impact is influenced by the droplet volume, initial velocity, viscosity, and roughness of the powder bed; wetting is affected by different droplet speeds, viscosity, contact angles, and the penetration time of the droplet in the powder bed (usually 0.1-1.0 s). The binder-powder interaction during binder jetting is shown in Figure 5, illustrating the interaction between the binder and powder in BJAM.

△Binder-powder interaction during binder jetting

When the binder droplet strikes the powder surface, the binder wets the powder, forming a contact angle at the binder-powder interface. Once the binder contacts the powder, the pores between the powder particles act as capillaries, drawing the binder into the powder. The contact angle decreases, and as the binder droplet wets and penetrates the powder bed, it forms an initial nucleus, saturating the entire pore space with binder (100% saturation). The binder also affects the debinding temperature, sintering temperature, and residue characteristics.

Most binders need to decompose completely before sintering, so there must be a certain interval between the binder decomposition temperature and the sintering temperature of the printed part. Residues left by binder decomposition can affect the performance of the final parts; residues rich in carbon or oxygen can form carbides or oxides, thereby reducing the mechanical properties of materials such as stainless steel and Ni 625. Therefore, after selecting a new binder-powder system, thermal gravimetric analysis can be performed to obtain the characteristics of binder decomposition and powder sintering, allowing for the formulation of reasonable debinding and sintering processes.

Improvement directions for the binder system in metal BJAM technology

In recent years, metal BJAM technology has received increasing attention, with commercial BJAM printers continuously being launched and successful applications being reported. However, metal BJAM technology still has shortcomings that need to be optimized, and the optimization and improvement of the binder system is an important aspect of this.

In terms of mechanism research, the interaction between the binder and powder particles significantly affects the geometric shape, strength, and quality of the final parts. The mechanism of binder-powder interaction is not yet clear, and it is necessary to clarify the impact of binder deposition and migration behavior on powder bed quality and develop predictive models for the process.

On the material development side, there are relatively few mature binders currently used for metal BJAM technology, and there are prominent issues such as clogging, low strength, and difficulty in removal. Moreover, most binders are not suitable for printing various powders. Additionally, existing binders are mostly organic polymers, and the residues after debinding have a significant adverse effect on the performance of printed parts. Therefore, developing new binders that are suitable for multi-type metal printing, resistant to clogging, high strength, easy to remove, or even do not require removal is crucial for advancing and applying metal BJAM technology. For example, Changsha Mokerui launched an environmentally friendly water-based binder in May 2021; in March 2022, they successfully developed a second-generation zero-residue water-based binder suitable for BJAM processes with metal and ceramic powders.

Low-residue carbon water-based inks are a major direction for the future development of BJAM, as the new environmentally friendly water-based inks have extremely low residual carbon content, making them suitable for mass production of carbon-sensitive metal materials. Of course, in addition to the binder system, metal powder materials, printing processes, and post-processing are equally important and need to be emphasized.

Future development directions for metal BJAM binders:

1) Water-based

Currently, most binders used in BJAM are organic binders, and organic solvents pose environmental pollution risks. It is foreseeable that with the promotion of BJAM and the large-scale use of binders, the issue of environmental pollution will become more prominent. The use of water-based binders will dominate.

2) Neutral

Acidic or basic inks will react with metal powders; only neutral or near-neutral inks can be suitable for BJAM printing of various metal powders.

3) Low residue

The green body printed by metal BJAM requires subsequent sintering treatment. The subsequent sintering is essentially a metallurgical process that requires a clean metal powder surface. If the binder is not completely debound, residues such as carbon, nitrogen, and sulfur will exist; the presence of these residues will sensitively affect the performance of the final metal metallurgical parts.

4) High solid low viscosity

Water-based inks with high polymer content will increase the shaping strength of the green body; if the green body has high strength, it will help in printing thin-walled and complex parts, and reduce the risk of breakage during the transfer of the green body. However, high solid content will increase the viscosity of the ink, which can cause nozzle clogging and even prevent it from being ejected. Balancing this contradiction and developing inks with high solid content and low viscosity is a key consideration.

5) Nano inks

The biggest issue with the sintering of BJAM green bodies is shrinkage and asymmetric deformation. There are two main approaches to solve this: one is to use low-temperature infiltration sintering methods (such as copper infiltration, brazing, etc.), which can avoid or reduce shrinkage deformation by simultaneously performing copper infiltration and brazing during solid-phase sintering; the other approach is to use inks containing metal nanoparticles (or metal nanoparticle precursors), which can precipitate metal nanoparticles at a lower sintering temperature, serving both to bond the metal powder and to fill the gaps between powders, thus achieving the goal of reducing shrinkage deformation.

Using nano inks will inevitably increase the viscosity of the ink, making it unsuitable for conventional nozzles. Conventional nozzles are only suitable for low-viscosity inks. Therefore, it is imperative for BJAM equipment manufacturers, especially nozzle manufacturers, to develop nozzles suitable for high-viscosity inks.