#AM易道 News

The U.S. Department of Energy’s Office of Basic Energy Sciences released research on June 6, introducing a novel real-time defect detection method for 3D printing.

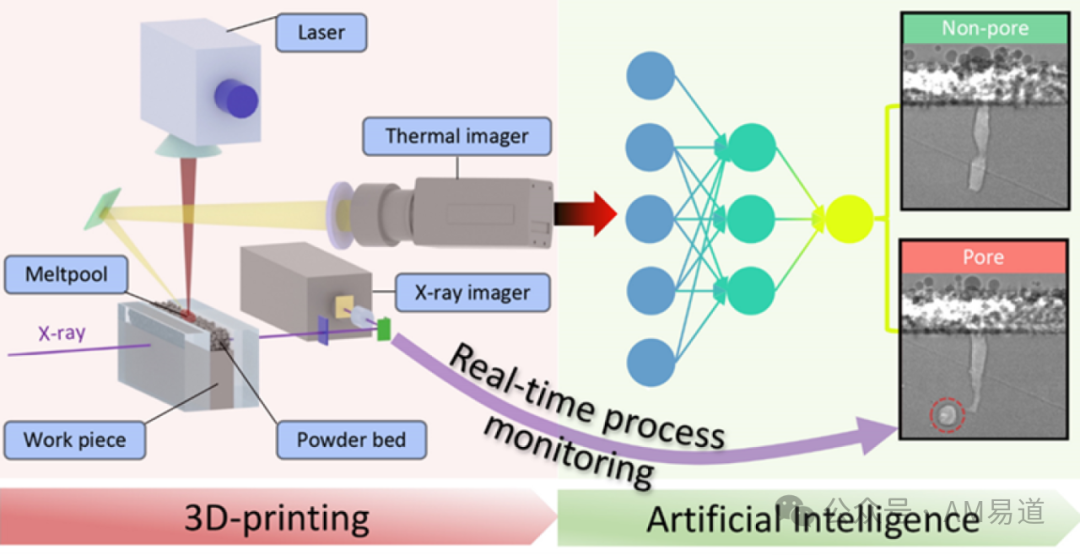

This AI-driven technology utilizes advanced X-ray and thermal imaging characterization techniques to monitor and accurately detect the typical printing defect of keyhole porosity in real-time during the 3D printing process, achieving near-perfect detection accuracy.

In metal additive manufacturing, the formation of structural defects has been a significant barrier to the promotion of this technology in certain critical application areas.

The research developed a new method capable of detecting and predicting defects in 3D printed materials through the combination of diagnostic tools and machine learning techniques, which is expected to revolutionize the 3D printing process.

This method employs various imaging and machine learning technologies to achieve real-time detection of pore generation with near-perfect accuracy.

The research team stated that the next step will be to develop sensing technologies capable of detecting other types of defects during the additive manufacturing process, with the ultimate goal of creating a complete system that not only detects defects but also enables repairs during 3D printing.

Technical Summary

A major defect issue in laser powder bed fusion technology is the formation of keyhole porosity. These pores or structural defects can severely impact the performance of printed parts.

Although many 3D printing devices are equipped with thermal imaging sensors to monitor the build process, they may still miss the formation of keyholes.

The primary method for directly detecting pores within dense metals is X-ray imaging, which requires the use of high-intensity beams, such as those provided by the Advanced Photon Source at the U.S. Department of Energy’s Office of Science.

The researchers correlated X-ray images of the sample’s interior with thermal images of the melt pool, discovering that the formation of pores generates unique signals on the material’s surface that can be detected by thermal imaging cameras.

The research team first trained a machine learning model using X-ray images to predict the formation of pores solely based on thermal images.

Subsequently, they tested the model’s ability to interpret complex thermal signals and predict pore generation in unmarked samples.

The research results showed that this method could detect the exact moment of pore formation within milliseconds.

This groundbreaking technological foundation actually stems from an important research paper published by Professor Tao Sun’s team in 2023 in the journal Science. Let us delve into the core principles and implementation details of this technology.

Ingenious Design of the Dual Imaging System

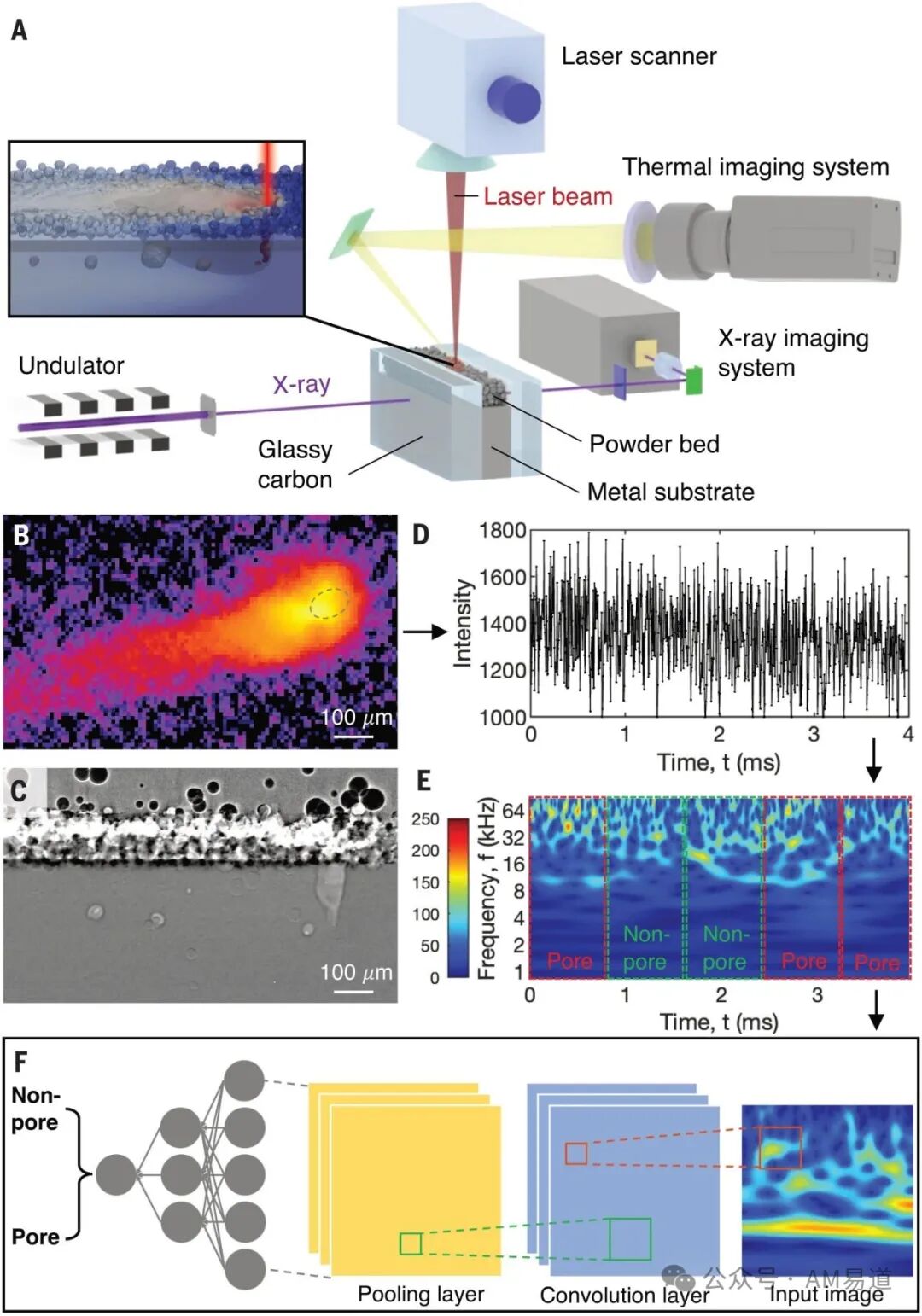

As seen in Figure 1 of the Science paper, the research team constructed an extremely precise synchronous detection system.

In the laser melting experiment of Ti-6Al-4V titanium alloy, they simultaneously deployed synchrotron X-ray and thermal imaging technologies.

The X-ray penetrates the material from the side, allowing direct observation of the dynamic changes of internal keyholes, while the thermal imaging camera records the temperature distribution on the surface of the melt pool from above.

This dual-view experimental design is the core of the entire technological system.

The researchers extracted the average emission intensity time series data from the keyhole region and performed wavelet analysis on this data, converting complex thermal signals into a spectral form that machine learning algorithms can process.

The innovation of this data processing method lies in its ability to capture subtle signal variation patterns that are not visible to the naked eye, laying the foundation for subsequent intelligent recognition.

Key Breakthrough in Oscillation Mode Recognition

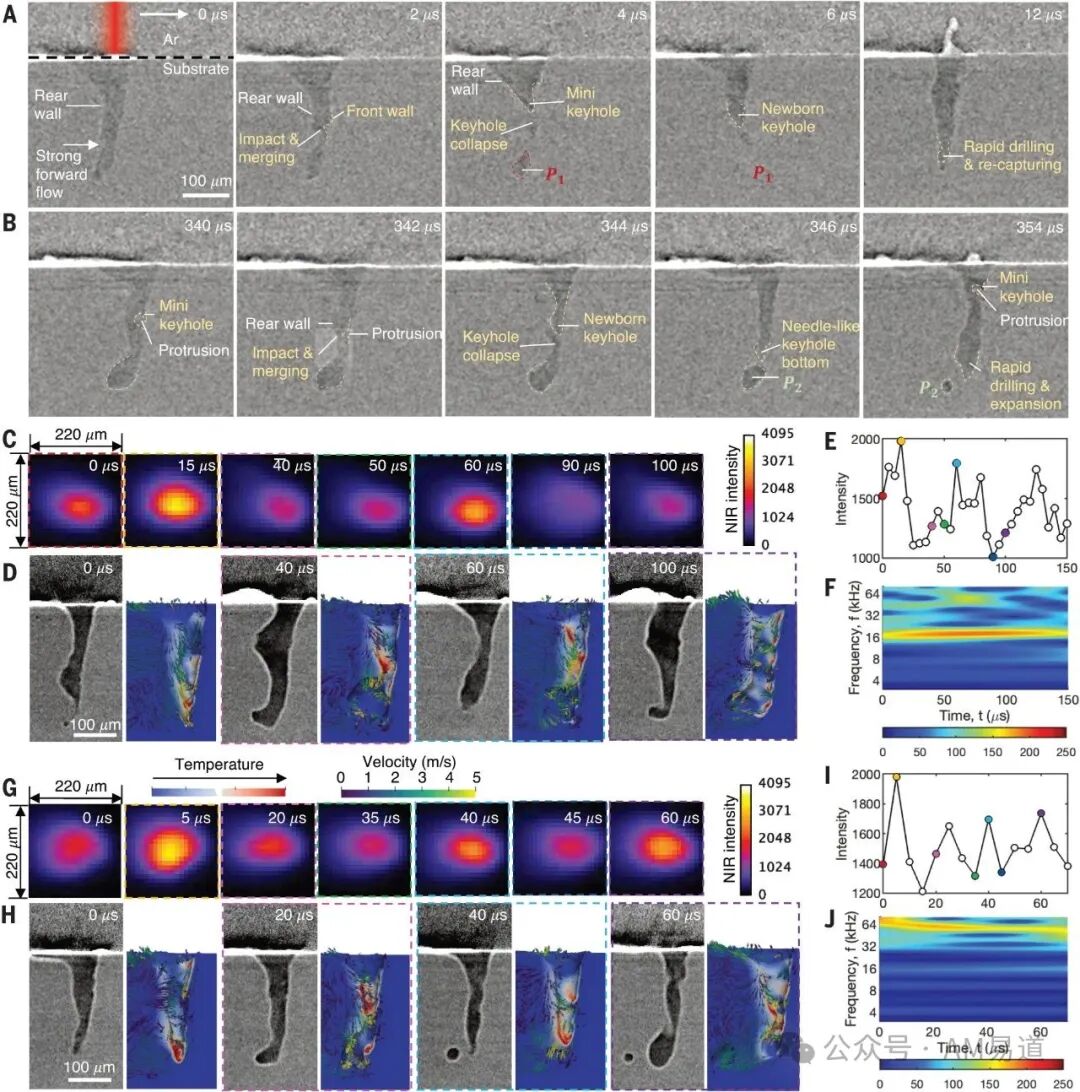

Figure 2 showcases the most significant scientific discovery of the research.

The research team successfully identified two completely different types of keyhole oscillation modes: intrinsic oscillation and disturbed oscillation.

Intrinsic oscillation is a normal physical phenomenon during the laser powder bed fusion process; although the shape of the keyhole undergoes periodic changes, these changes do not lead to pore defects.

In contrast, disturbed oscillation is the root of the problem; this abnormal oscillation mode directly leads to the formation of keyhole porosity.

Through high-speed X-ray imaging and corresponding multiphysics simulation analysis, the researchers found that these two oscillation modes exhibit distinctly different characteristics in thermal imaging signals.

From the corresponding spectral analysis, it can be seen that the signals generated by disturbed oscillation have unique frequency domain characteristics.

Although this difference is almost imperceptible in the original thermal imaging, it becomes clear in the spectral graph after wavelet transformation.

This discovery provides a reliable and stable basis for the machine learning model’s discrimination.

This article does not delve deeply into the technical details of machine learning/AI; interested readers can refer to the relevant content in Science via the link:

https://www.science.org/doi/10.1126/science.add4667

The Deep Impact of Annotation Accuracy on Algorithm Performance

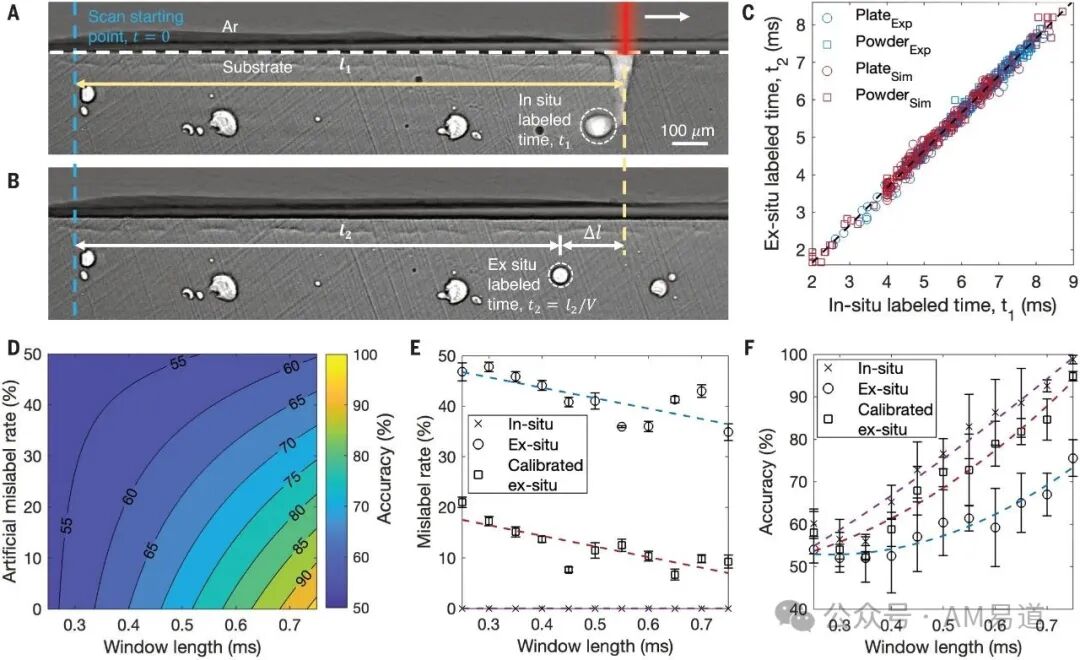

Figure 3 explores a crucial issue in practical engineering applications: how the accuracy of data annotation affects the detection performance of machine learning models.

The research team systematically compared three different data annotation strategies: on-site real-time annotation, offline post-annotation, and calibrated offline annotation.

On-site real-time annotation refers to accurately determining the moment of pore formation during the X-ray imaging process; this method, while the most accurate, is costly to implement.

Offline post-annotation infers the formation time by analyzing the spatial position of the final pores; this method has some time bias but is more practical.

The research results clearly demonstrate the impact of annotation error rates on model prediction accuracy.

When the mislabeling rate is kept low, the model can maintain excellent detection performance, but when the mislabeling rate exceeds the critical threshold of 30%, the prediction accuracy sharply declines.

AM易道 Interpretation

This research demonstrates significant innovative value on multiple levels.

From a technical implementation perspective, the research team successfully transformed complex physical phenomena into computable mathematical models.

Through wavelet transformation technology, they converted time-domain thermal signals into frequency-domain representations, enabling machine learning algorithms to more effectively recognize the essential characteristics of different oscillation modes.

From a scientific value perspective, the most important contribution of this research is establishing a quantitative correlation between observable surface signals and hidden internal defects.

This discovery breaks the traditional notion that internal defect detection can only rely on expensive X-ray equipment, providing a new implementation path for real-time quality monitoring.

In Conclusion

With the continuous advancement of algorithm optimization and the decreasing costs of computing hardware, this real-time defect detection technology is expected to achieve commercial application in the coming years.

The research team’s next development goal includes expanding the detection range to cover more types of manufacturing defects and ultimately building an intelligent manufacturing system that integrates detection and repair functions.

The realization of this closed-loop quality control capability will mark a fundamental shift of 3D printing technology from traditional manufacturing tools to intelligent manufacturing systems, laying a solid technical foundation for the large-scale promotion of additive manufacturing in high-end application fields.

Note: This article is based on official information released by the U.S. Department of Energy and related research papers from the journal Science.

Further Reading:

AI’s Transformer Technology First Applied to 3D Printing Quality Monitoring!

Say Goodbye to Destructive Sampling, New In-Situ Surface Detection Technology for Metal 3D Printing

Corporate Partner Program: Become a partner in the additive industry with AM易道 and gain free access to resources for clients, financing, overseas expansion, and industry-academia-government collaboration.Reader Reminder: Add amyidao to join the reader group (note to join), to obtain original source links or content that is inconvenient to publish, and discuss everything about 3D printing with fellow readers of AM易道,AM易道 also suggests readers star the public account to receive updates from AM易道 promptly.Disclaimer:AM易道 has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in this article.AM易道 ImageVideo clips are sourced from the internet and are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original author; if there are any infringement issues, please contact the rights holder promptly, and we will delete it immediately. The copyright of the images in this article belongs to the copyright holder, and the AM易道 watermark is automatically added for auxiliary reading and does not represent ownership of the image; for image usage, please consult the relevant copyright parties. AM易道 articles do not constitute any investment advice, and AM易道 is not responsible for any direct or indirect losses caused by the use of the information in this article.Original Statement: This article is a secondary creation based on the interpretation and analysis of relevant research papers. The narrative text, technical explanations, and opinions expressed in the article are original expressions of AM易道, aimed at providing readers with a different perspective on technical interpretation. Except for necessary data citations and chart explanations, the direct quotation or paraphrasing of the original text is relatively low. The language organization, structural arrangement, viewpoint elaboration, and industry analysis in this article are all original content, hereby declared..