Detailed Explanation of Binder Jetting 3D Printing TechnologyBinder Jetting technology (BJ) is an important additive manufacturing technology in the field of 3D printing.

Detailed Explanation of Binder Jetting 3D Printing TechnologyBinder Jetting technology (BJ) is an important additive manufacturing technology in the field of 3D printing.

This article provides a comprehensive analysis from working principles, material selection, post-processing techniques, equipment composition, technical advantages, application cases, and technical challenges and future trends in seven aspects:

1. Working Principle

1. Binder Jetting |

2. Heating and Curing |

3. Printing the Green Body |

4. Sintering and Shaping |

Principle of Binder Jetting 3D Printing Technology

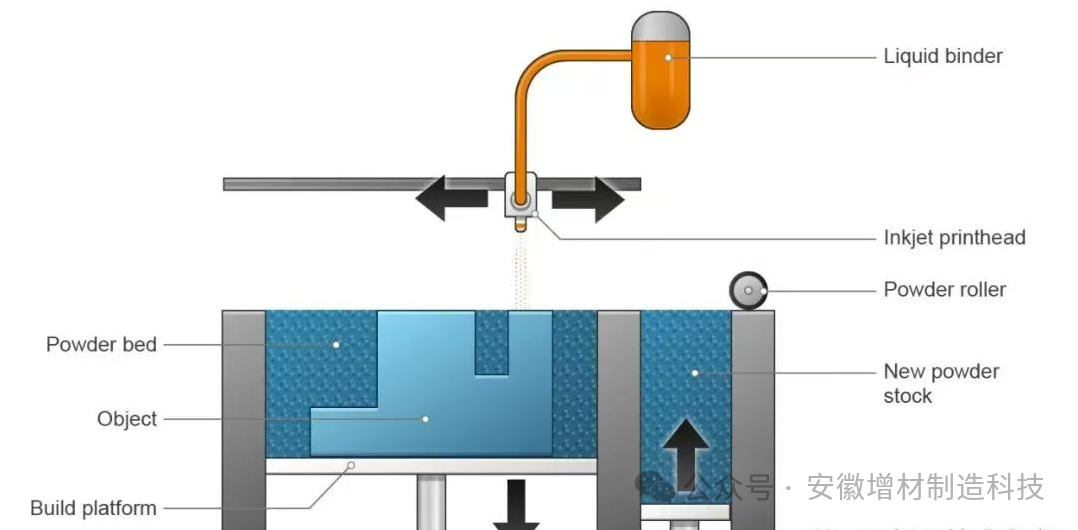

Binder Jetting technology (BJ) is an additive manufacturing technology with the following working principles:

- Powder Spreading A thin layer of powder is evenly spread on the build platform, which can be made of metal, ceramic, polymer, or sand.

- Binder Jetting The print head selectively sprays liquid binder droplets onto the powder layer according to the CAD model, binding specific areas of the powder particles.

- Layer Stacking The build platform descends by one layer thickness, the powder system lays down a new layer of powder, and the binder jetting process is repeated until the entire print is completed.

- Post-Processing The printed green body requires post-processing such as debinding and sintering to improve its density, strength, and mechanical properties.

2. Material Selection and Application Cases

Binder Jetting technology is compatible with various materials, and the choice of materials depends on the intended application:

-

Metal Materials:

- Common Materials include stainless steel, titanium alloys, chromium-nickel iron alloys, copper alloys, aluminum alloys, etc.

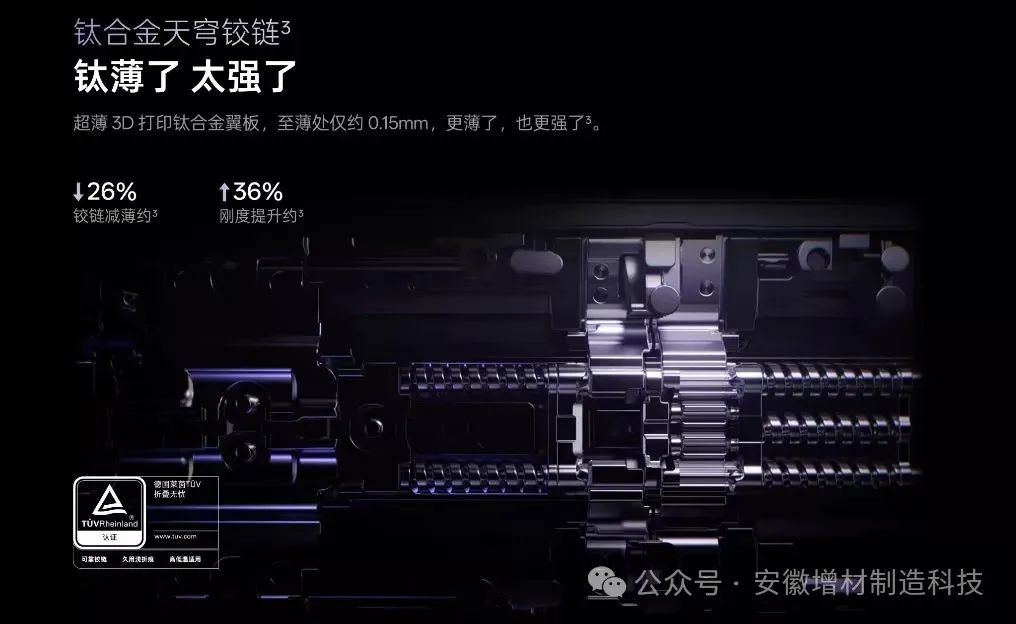

- Application Cases Lightweight brackets and heat exchangers in aerospace; gears and turbochargers in automotive manufacturing; titanium alloy phone frames in consumer electronics, etc.

- Breakthrough Advances For example, Desktop Metal has successfully tackled the binder jetting 3D printing of Ti64 titanium alloy and C18150 copper alloy.

△Cobra golf clubs collaborated with HP to mass-produce putters using metal binder jetting technology

△Cobra golf clubs collaborated with HP to mass-produce putters using metal binder jetting technology △Metal binder jetting 3D printing involves spraying liquid binder onto a layer of metal powder to solidify the shape

△Metal binder jetting 3D printing involves spraying liquid binder onto a layer of metal powder to solidify the shape

Ceramic Materials:

- Common Materials include oxide ceramics, nitride ceramics, etc.

- Application Cases Chamber components in the semiconductor field, high-temperature heat exchangers in aerospace, high-temperature valve pipelines, etc.

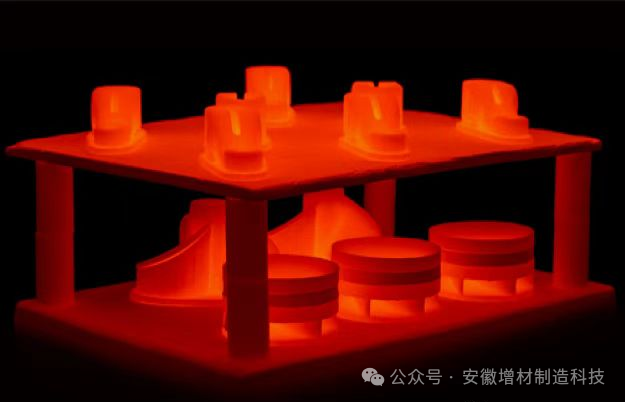

Polymer Materials:

- Common Materials include plastic powders, etc.

- Application Cases Full-color models, plastic parts, etc. Plastic parts usually do not require further processing but have lower structural strength.

Sand:

- Common Materials include gypsum, sand, etc.

- Application Cases Sand molds and cores in the casting industry, used to shorten production cycles and improve production efficiency.

3. Post-Processing Techniques

Debinding and Sintering Process of Metal Binder Jetting

The post-processing techniques are crucial for the final product performance of binder jetting technology, mainly including the following steps:

-

Debinding:

- Purpose Remove the binder from the printed part.

- Methods Solvent debinding, thermal debinding, thermal catalytic debinding, etc. Care must be taken to avoid damaging the parts and ensure effective debinding.

Sintering:

- Purpose Heat the printed part to a high temperature to melt and bond the powder particles, increasing the density and strength of the printed part.

- Process Divided into initial sintering stage, intermediate stage, and final stage, requiring control of temperature and time.

- Challenges Parts may shrink during sintering, requiring compensation to address distortion issues.

4. Equipment Composition

Binder jetting equipment typically consists of the following components:

- Powder Bin For storing powder materials.

- Print Head Precisely sprays binder at designated locations based on digital design files.

- Build Platform Supports powder materials and printed parts.

- Material Container For storing the binder.

- Powder Coater For evenly spreading powder materials on the build platform.

The equipment design aims to improve printing efficiency and accuracy to meet large-scale production demands. For example, the equipment from SanTi Technology integrates advanced technologies such as bidirectional high-speed sand spreading and wide-format efficient printing.

5. Technical Advantages

Binder jetting technology has the following advantages:

- Low Cost High material utilization, reusable powder, no need for expensive laser equipment.

- Fast Printing Surface forming technology, forming efficiency depends on the number of nozzles, suitable for mass production.

- No Support Structures No need for dedicated supports, powder self-supports to achieve complex geometric designs.

- Material Diversity Compatible with various materials to meet different needs.

- Large-Scale Manufacturing Supports large build volumes, suitable for industrial-grade part production.

6. Application Cases

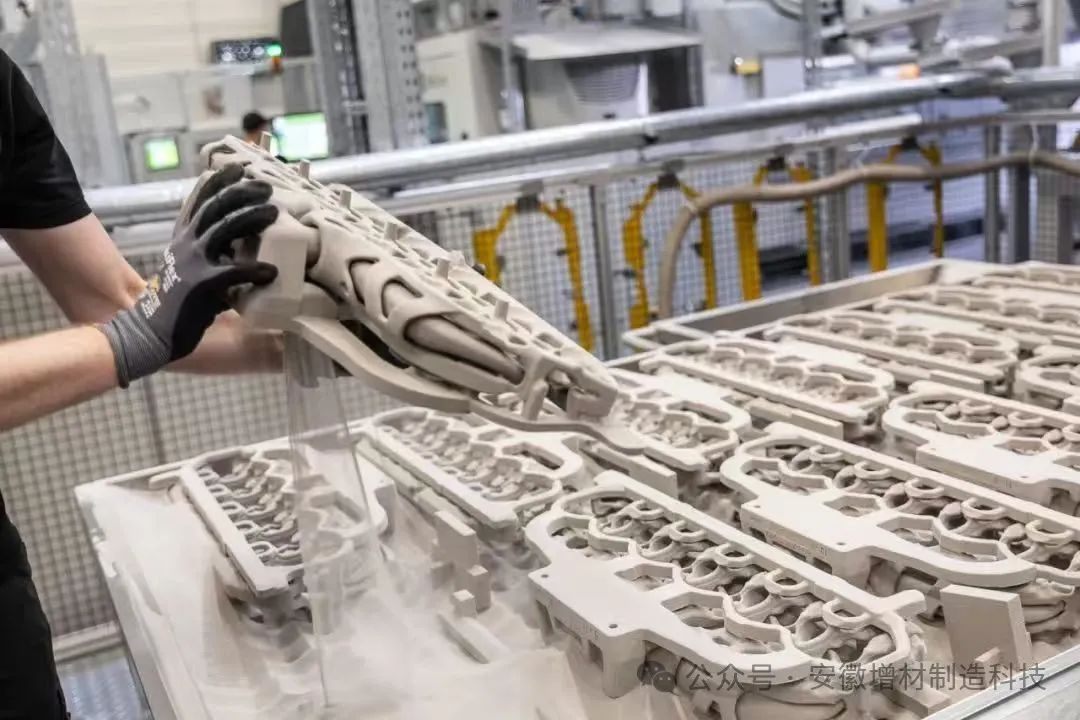

Binder jetting technology is applied in multiple industries, with typical application cases including:

- Aerospace Producing complex metal parts to enhance aircraft performance and efficiency.

DM uses binder jetting 3D printing to manufacture high-temperature alloy blades

DM uses binder jetting 3D printing to manufacture high-temperature alloy blades - Automotive Manufacturing Producing high-performance components, reducing vehicle weight, and improving fuel efficiency.

- Consumer Electronics Producing complex structural parts to enhance product aesthetics and durability.

- Medical Devices Custom surgical tools, dental models, etc., improving surgical precision and safety.

- Casting Industry Sand printing for casting molds, shortening production cycles, and improving casting efficiency.

- Art Creation Full-color models, ceramic artworks, etc., expanding forms and possibilities of artistic creation.

7. Technical Challenges and Future Trends

Technical Challenges:

- Material Limitations Metal parts require post-processing to enhance performance, and the structural performance of polymer parts needs improvement.

- Precision and Surface Quality Surface roughness is relatively high, requiring post-processing optimization; printing precision is affected by various factors.

- Equipment Complexity Multi-nozzle systems increase equipment costs and R&D difficulty, and equipment stability and reliability need improvement.

Future Trends:

- New Material Development Developing high-strength, high-temperature materials to expand application scenarios; researching new binders to improve printed part precision and performance.

- Equipment Improvement Enhancing printing precision and print head lifespan, supporting multi-material printing; optimizing equipment structure to improve printing efficiency and stability.

- Automation and Information Technology Integrating smart production lines to optimize the entire casting process; utilizing big data and AI technology to enhance production efficiency and product quality.

- Environmental Protection and Sustainability Exploring recyclable materials and eco-friendly binders to reduce environmental impact; promoting green manufacturing for sustainable development.

Binder jetting technology, with its efficiency, low cost, and flexibility, is driving the manufacturing industry towards intelligent and green transformation. With continuous technological advancements and innovations, it is expected to achieve industrial applications in more fields, injecting new vitality into the development of the manufacturing industry.