1. Overview of FPC Flexible Printed Circuit Boards

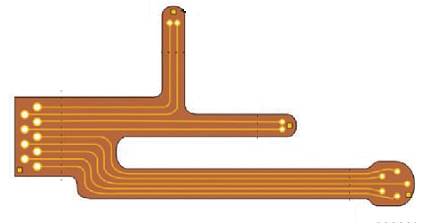

Printed circuit boards are fundamental products in the electronics industry, widely used in communication devices, computers, automotive electronics, industrial equipment, and various household appliances. Their main function is to support circuit components and interconnect circuit elements.FPC flexible printed circuit boards are a major category of printed circuit boards, as shown in Figures 1 and 2. Based on the structure of FPC flexible printed circuit boards, they can be classified into single-sided, double-sided, and multi-layer boards according to the number of conductor layers.

Figure 1 FPC Flexible Printed Circuit Board

Figure 2 FPC Flexible Printed Circuit Board (Assembled Components)

2. Main Raw Materials for Manufacturing FPC Flexible Printed Circuit Boards (Physical and Chemical Materials)

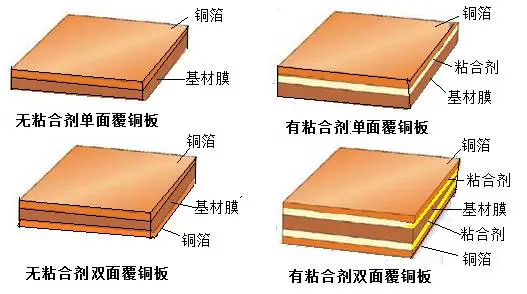

(1) Flexible Copper Clad Laminate (FCCL): It is classified as single-sided or double-sided copper clad laminate based on whether it has copper foil on one side or both sides; it is classified as adhesive or non-adhesive copper clad laminate based on whether there is an adhesive between the copper foil and the substrate film. The structure of flexible copper clad laminate is shown in Figure 3. Common substrate films for flexible copper clad laminates include polyimide (PI), polyester (PET), polyethylene naphthalate (PEN), and liquid crystal polymer (LCP). The copper clad laminate primarily serves three functions: conductivity, insulation, and support throughout the printed circuit board. The performance, quality, processability during manufacturing, manufacturing cost, and manufacturing level of the printed circuit board largely depend on the performance of the copper clad laminate.

Figure 3 Structure of Flexible Copper Clad Laminate (FCCL)

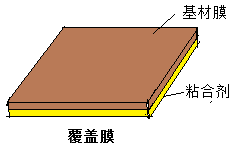

(2) Cover Film: It consists of an organic film and adhesive, as shown in Figure 4. The purpose of the cover film is to protect the completed flexible circuit conductor parts. The adhesive film comes in various substrate films, adhesive types, and thickness specifications. Some FPC flexible printed circuit boards do not use cover films but instead use a coating of solder mask to reduce costs.

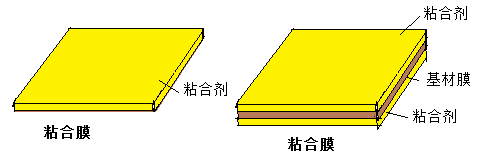

(3) Adhesive Film: It is formed by pouring adhesive on one or both sides of a substrate film, and there are also adhesive films that consist solely of adhesive without a substrate, as shown in Figure 5. Adhesive films come in various adhesive types and thickness specifications. The adhesive film is used for bonding and insulating between layers in multi-layer boards.

Figure 4 Composition of Cover Film

Figure 5 Composition of Adhesive Film

(4) Copper Foil: It includes electrolytic copper foil and rolled copper foil, as well as different thickness specifications of copper foil. Copper foil is used for the two surface conductor layers in the production of multi-layer printed circuit boards.

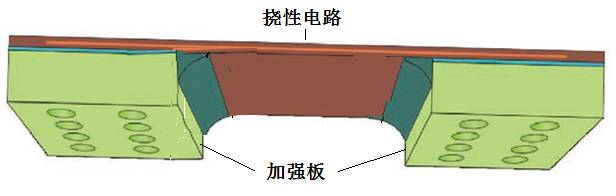

Additionally, some FPC flexible printed circuit boards use stiffener materials, such as metal sheets, plastic sheets, resin films, and epoxy glass substrates. The role of stiffening materials is to reinforce specific areas of the flexible circuit board for support and fixation, as shown in Figure 6. Since not all FPC flexible printed circuit boards use them, they are not included in the single consumption standards.

Figure 6 FPC Flexible Printed Circuit Board with Stiffener

3. Processing Technology of FPC Flexible Printed Circuit Boards

Sheet by Sheet processing: Similar to rigid boards, processed in a step-by-step manner.

FPC flexible printed circuit board processing adopts the same process and similar equipment conditions as rigid boards. In terms of processing form, there is Sheet by Sheet processing, similar to rigid boards processed step by step, or Roll to Roll processing, which is continuous processing of a roll of substrate.

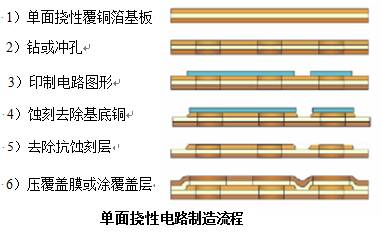

(1) Manufacturing Process of Flexible Single-Sided Printed Circuit Board (Figure 7)

Figure 7 Manufacturing Process of Single-Sided Flexible Printed Circuit Board

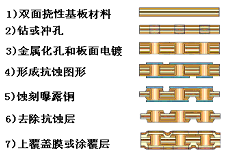

(2) Manufacturing Process of Flexible Double-Sided Printed Circuit Board (Figure 8)

Figure 8 Manufacturing Process of Double-Sided Flexible Printed Circuit Board

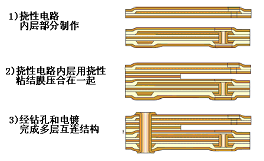

(3) Manufacturing Process of Flexible Multi-Layer Printed Circuit Board (Figure 9)

Figure 9 Simplified Process of Manufacturing Flexible Multi-Layer Printed Circuit Board

Some Screenshots from Electronic Books

【Complete Set of Hardware Learning Materials Collection】