“The reason for this is that the solid-state drives (SSDs) provided with the computers at my workplace have been failing in batches. After testing, I found that some failures were due to interface issues, while others were due to problems with the storage chips. I can’t do anything about the damaged storage chips, but if it’s just the interface that’s broken, can I replace it? This way, I can turn the SSD replacement into an SSD repair, reducing costs to less than one-tenth, and I can also practice my soldering skills, achieving two goals at once. However, the results were not as ideal as I hoped, so let’s take a closer look.”

01

Introduction

I had already done some work on this last year, as referenced below:

First time using a soldering iron to repair an SSD

Just a novice coder, WeChat public account: Liang’s Little Electronic Space – Failed case of repairing SSD hard drive interface

Last year, when I used the soldering iron, I initially set the temperature to 250°C, and then gradually increased it to 300°C. However, the results were not good. I then looked up the melting point of solder on general circuit boards and found that it typically ranges from 300°C to 350°C. So today, I adjusted the soldering iron temperature to 350°C and tried again:

02

Main Content

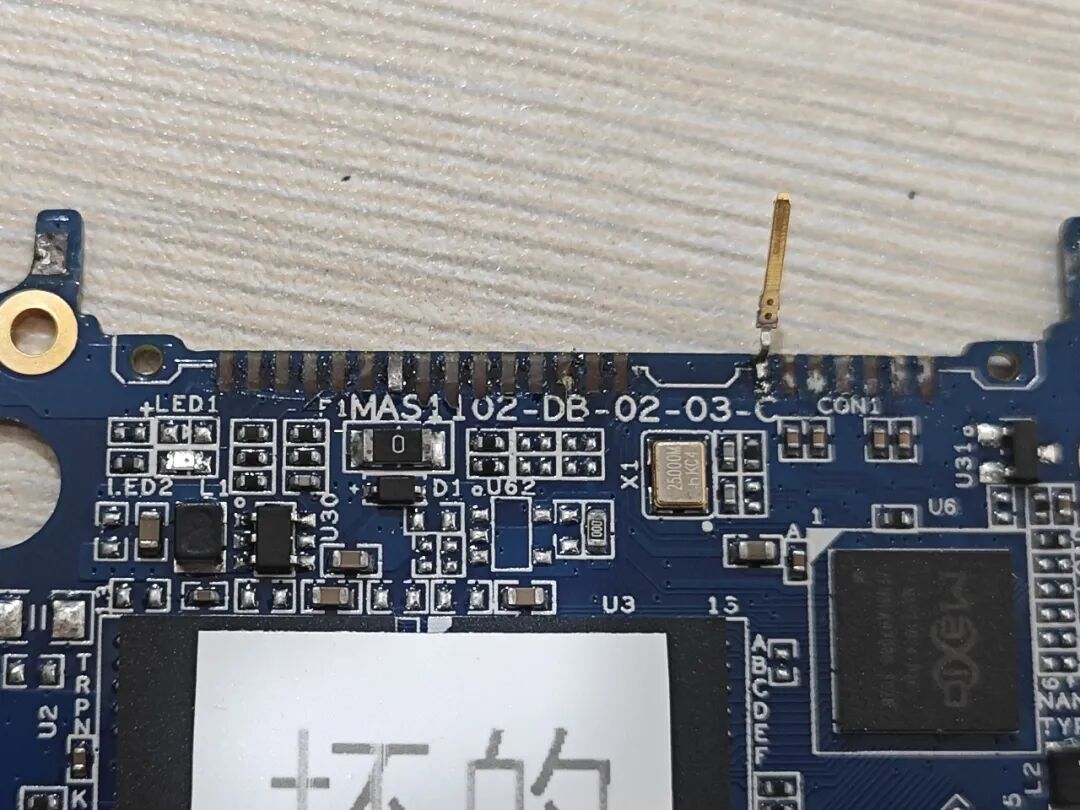

The hard drive in question is a standard Hikvision SSD;

This board is fine; only the plastic mounting plate on the interface has broken;

Continuing from the previous work, the simplest idea is to swap the interface from the board with the damaged storage chips to the board with intact chips:

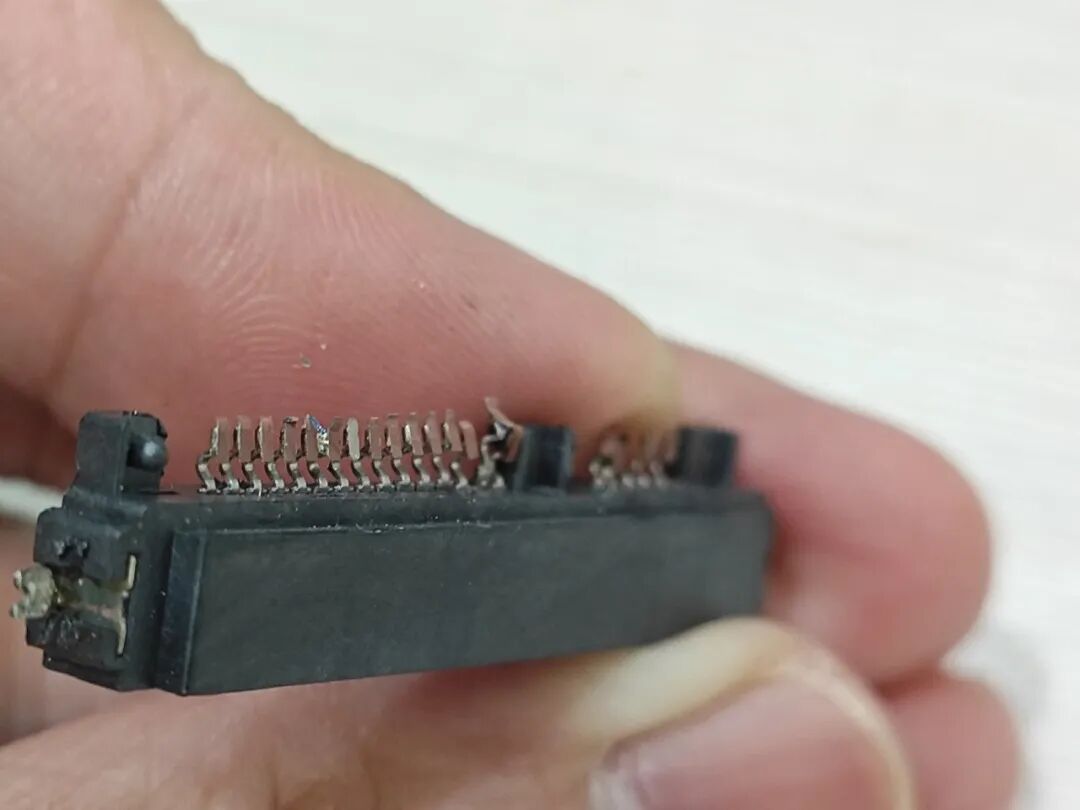

Alright, with the soldering iron set to 350°C, I managed to remove the interface with a bit of effort. Now, let’s see what issues we have with the details:

Well, I managed to get all the contact points off the board. Why did this happen? Because when I heated the second and third points, the temperature of the first point had already dropped. By the time I finished heating the last point, almost all the previous points had re-adhered (facepalm);

Now, let’s reconsider the initial idea of swapping the damaged interface onto the good board:

However, using a soldering iron is clearly not suitable, as it will remove the solder points from the board;

So how should this module be disassembled? I estimate that I need to use a heating gun like the ones used for repairing mobile phones, which heats the entire contact module evenly, allowing all contact points to warm up simultaneously, preventing the solder points on the board from being removed as well.

03

Conclusion

The conclusion is simple: do not use a soldering iron to disassemble circuit boards; it is inappropriate. Use a heating gun instead;

Well, today’s practical lesson was quite simple. Thank you all for watching, ( ^_^ )/~~ Goodbye.

Feel free to follow my public account for mutual growth: