Click the blue text to follow us

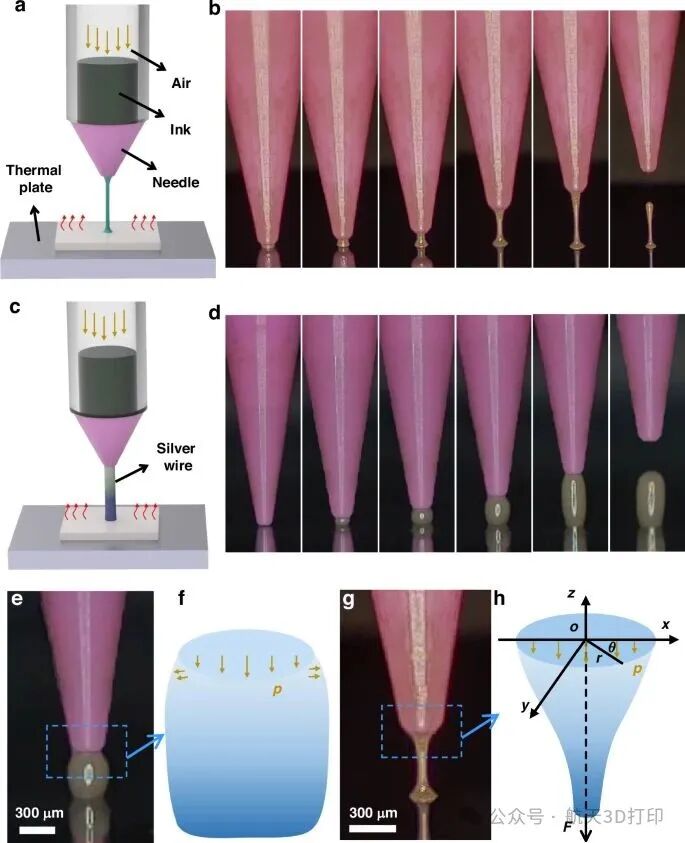

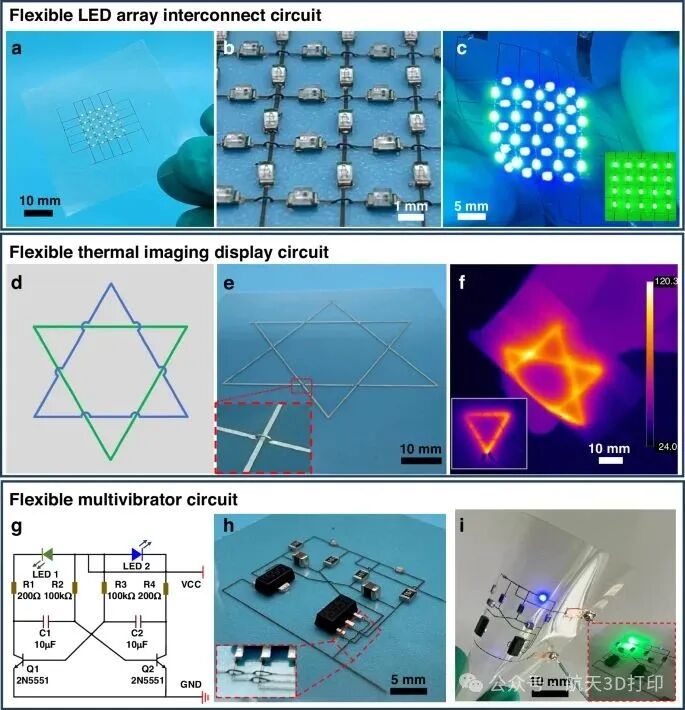

In the wave of rapid development of global flexible electronics technology, the research team led by Wang Dazhi and Wang Tiesheng at Dalian University of Technology has recently made a significant breakthrough by successfully developing the “tension-driven fluid-stretching 3D printing technology” with independent intellectual property rights. This innovative technology has improved the manufacturing precision of conductive structures to sub-10 micron levels, opening new avenues for the development of the next generation of flexible electronic devices.The core innovation of this technology completely overturns the principles of traditional extrusion printing. The research team cleverly utilizes the characteristics of high-viscosity silver nano-ink (viscosity exceeding 10,000 cP) and precisely controls the air pressure (0.1-0.5 bar) and stretching speed (0.1-10 mm/s) to form a stable “liquid bridge” effect between the needle and the substrate. Combined with a real-time solvent evaporation curing mechanism, it achieves a unique printing method of direct “air-drawing” without support. This innovative technological path not only breaks through the limitations of nozzle size on resolution in traditional methods but also achieves an ultra-high printing precision of 4 microns, equivalent to 1/20 of the diameter of a human hair. Comparison of traditional extrusion and tension-driven printing structuresIn terms of performance, this technology has created several industry-leading indicators. The printed conductive structures exhibit excellent conductivity close to that of pure silver bulk materials (with a resistivity as low as 2.5×10⁻⁷ Ω·m), and after 200 bending cycles, the resistance change remains within 5%, demonstrating outstanding mechanical durability. Notably, its printing efficiency is 8-10 times higher than that of conventional direct writing molding processes, significantly improving production efficiency while ensuring precision.The research team has successfully applied this technology in several cutting-edge fields. In flexible displays, they developed a three-dimensionally addressable LED mesh array that maintains 100% brightness output even under a minimal bending radius of 3mm. In the smart sensing field, the ultra-thin thermal imaging devices manufactured achieved a high precision temperature resolution of 50mK on a mica substrate. Additionally, the team successfully fabricated self-oscillating multi-resonator circuit with a working frequency of 2.4GHz, demonstrating the technology’s potential in high-frequency electronic devices.

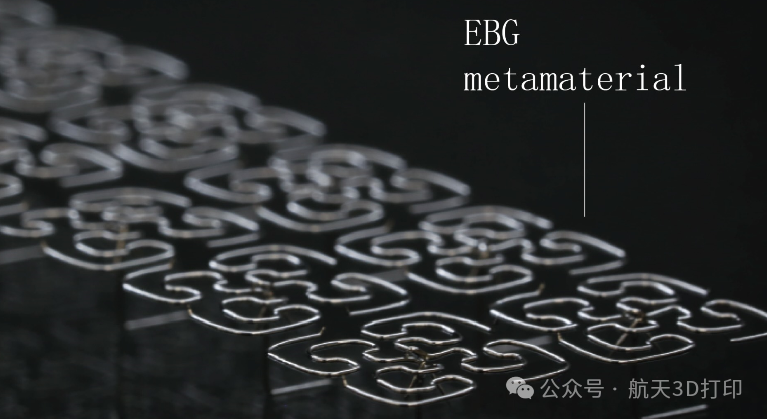

Comparison of traditional extrusion and tension-driven printing structuresIn terms of performance, this technology has created several industry-leading indicators. The printed conductive structures exhibit excellent conductivity close to that of pure silver bulk materials (with a resistivity as low as 2.5×10⁻⁷ Ω·m), and after 200 bending cycles, the resistance change remains within 5%, demonstrating outstanding mechanical durability. Notably, its printing efficiency is 8-10 times higher than that of conventional direct writing molding processes, significantly improving production efficiency while ensuring precision.The research team has successfully applied this technology in several cutting-edge fields. In flexible displays, they developed a three-dimensionally addressable LED mesh array that maintains 100% brightness output even under a minimal bending radius of 3mm. In the smart sensing field, the ultra-thin thermal imaging devices manufactured achieved a high precision temperature resolution of 50mK on a mica substrate. Additionally, the team successfully fabricated self-oscillating multi-resonator circuit with a working frequency of 2.4GHz, demonstrating the technology’s potential in high-frequency electronic devices. Compared to other advanced electronic printing technologies internationally, Dalian University’s solution demonstrates unique advantages. Compared to the National University of Singapore’s CHARM3D metal alloy printing technology and ioTech’s laser-assisted deposition technology, this technology not only supports a multi-ink system from nano-silver to conductive polymers but also offers greater structural freedom, capable of fabricating complex topological configurations such as suspended spirals and vertical interconnections. In terms of cost-effectiveness, it is significantly advantageous, with equipment investment only 1/20 of that of traditional photolithography processes.

Compared to other advanced electronic printing technologies internationally, Dalian University’s solution demonstrates unique advantages. Compared to the National University of Singapore’s CHARM3D metal alloy printing technology and ioTech’s laser-assisted deposition technology, this technology not only supports a multi-ink system from nano-silver to conductive polymers but also offers greater structural freedom, capable of fabricating complex topological configurations such as suspended spirals and vertical interconnections. In terms of cost-effectiveness, it is significantly advantageous, with equipment investment only 1/20 of that of traditional photolithography processes. Professor Wang Dazhi, the team leader, stated: “Our technology essentially microcosmizes the traditional macroscopic wire drawing process. This ‘top-down’ manufacturing philosophy provides a new approach for cross-scale manufacturing of electronic devices.” Currently, the research team is collaborating deeply with leading companies such as Huawei and BOE to jointly promote the industrial application of this technology in fields such as three-dimensional circuits for foldable smartphones and implantable medical sensors.Industry experts generally believe that this groundbreaking technology will expand the manufacturing dimension of printed electronics from two-dimensional to three-dimensional, and its excellent precision and efficiency performance is expected to redefine the design rules for flexible electronic products. With the rapid growth of demand for three-dimensional integrated circuits in the 5G/6G era, this original technology from Chinese universities is bound to occupy an important position in the global high-end electronic manufacturing field, giving China a head start in the development of next-generation electronic manufacturing technologies.

Professor Wang Dazhi, the team leader, stated: “Our technology essentially microcosmizes the traditional macroscopic wire drawing process. This ‘top-down’ manufacturing philosophy provides a new approach for cross-scale manufacturing of electronic devices.” Currently, the research team is collaborating deeply with leading companies such as Huawei and BOE to jointly promote the industrial application of this technology in fields such as three-dimensional circuits for foldable smartphones and implantable medical sensors.Industry experts generally believe that this groundbreaking technology will expand the manufacturing dimension of printed electronics from two-dimensional to three-dimensional, and its excellent precision and efficiency performance is expected to redefine the design rules for flexible electronic products. With the rapid growth of demand for three-dimensional integrated circuits in the 5G/6G era, this original technology from Chinese universities is bound to occupy an important position in the global high-end electronic manufacturing field, giving China a head start in the development of next-generation electronic manufacturing technologies.

Note: This article is organized and edited by Aerospace 3D Printing. Unauthorized reproduction is prohibited.