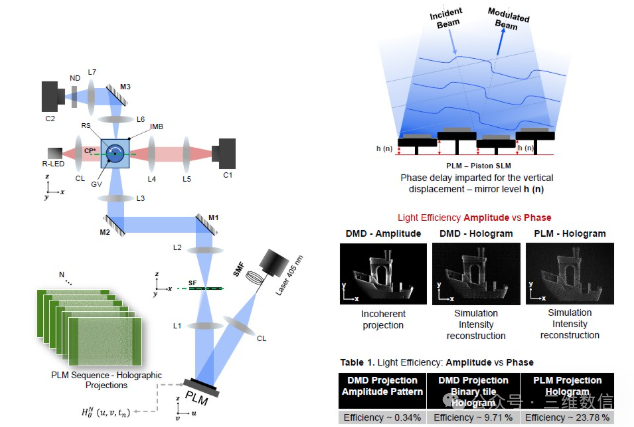

Researchers at the École Polytechnique Fédérale de Lausanne (EPFL) have introduced a compact and efficient holographic volumetric additive manufacturing (HT-VAM) system that achieves unprecedented energy efficiency and faster, higher-resolution printing using MEMS-based phase modulators. This technological advancement marks a significant progress in addressing the light transmission limitations associated with volumetric 3D printing. Combining Holographic Technology with Volumetric ManufacturingVolumetric additive manufacturing (VAM) is a layerless 3D printing technology that simultaneously cures an entire object by projecting light patterns onto a rotating vat of photoresin. Unlike layer-by-layer methods, VAM eliminates stair-stepping artifacts and supports the unsupported fabrication of complex geometries. EPFL’s approach, known as tomographic VAM (TVAM), employs computed tomography principles to generate dynamic light fields that polymerize the resin volumetrically.Traditional TVAM systems typically rely on digital micromirror devices (DMDs), which have limited optical efficiency (usually below 10%). The EPFL team replaced these devices with pure phase light modulators (PLMs), enabling precise wavefront control. This change resulted in a measured optical efficiency of 23.78% while also reducing imaging artifacts such as speckle noise.

Combining Holographic Technology with Volumetric ManufacturingVolumetric additive manufacturing (VAM) is a layerless 3D printing technology that simultaneously cures an entire object by projecting light patterns onto a rotating vat of photoresin. Unlike layer-by-layer methods, VAM eliminates stair-stepping artifacts and supports the unsupported fabrication of complex geometries. EPFL’s approach, known as tomographic VAM (TVAM), employs computed tomography principles to generate dynamic light fields that polymerize the resin volumetrically.Traditional TVAM systems typically rely on digital micromirror devices (DMDs), which have limited optical efficiency (usually below 10%). The EPFL team replaced these devices with pure phase light modulators (PLMs), enabling precise wavefront control. This change resulted in a measured optical efficiency of 23.78% while also reducing imaging artifacts such as speckle noise.

Phase Modulation: A Game Changer

Until recently, silicon-based liquid crystal on silicon (LCOS) spatial light modulators (SLMs) were the standard for phase modulation. However, LCOS has several limitations, including slow response times (60-120Hz), ultraviolet (UV) degradation, and polarization sensitivity.

In contrast, the MEMS-based PLM developed by EPFL in collaboration with Texas Instruments directly encodes phase using piston-driven micromirrors. It features 4-bit resolution (16 phase levels) for precise wavefront shaping and can achieve rapid graphical rendering at high speeds (1,440Hz frame rate), along with being polarization insensitive and UV stable, which is crucial for photopolymerization.

This architecture supports the use of low-power, single-mode 405nm lasers, reducing costs and system complexity while achieving near-theoretical diffraction efficiency.

Reducing Speckle and Print Quality

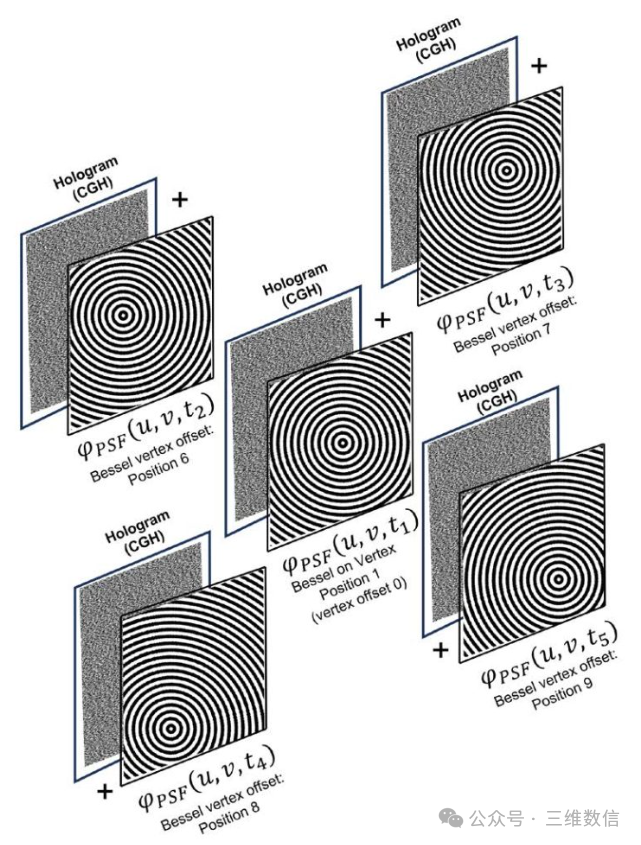

A key innovation of the system is the reduction of speckle through a pipeline. Speckle caused by coherent light interference is mitigated by time-multiplexed projection of holograms with nine lateral offsets at each angle. Combined with the phase of Bessel beam cone lenses, this significantly reduces speckle contrast (from 0.45 to 0.33) and expands the system’s depth of focus, ensuring consistent resolution across the entire printed volume.

Fast, High-Fidelity Printing

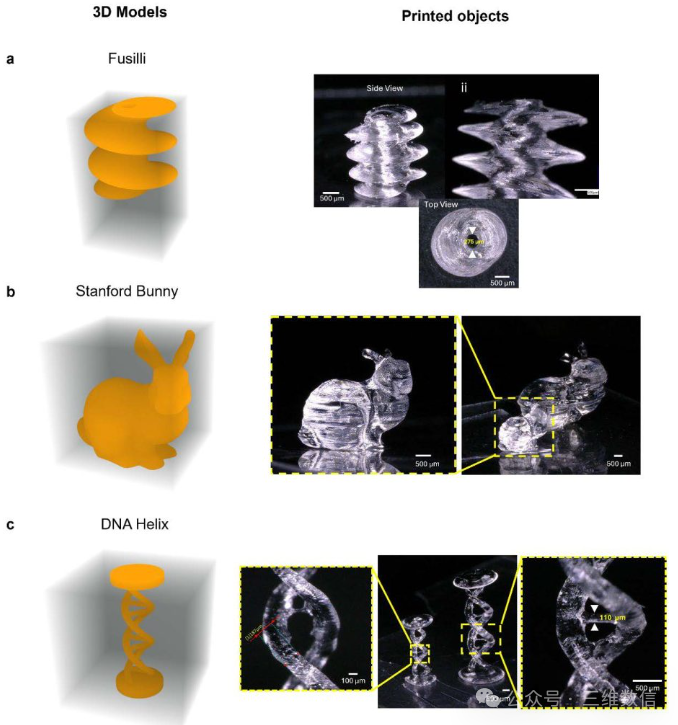

The system demonstrated rapid printing of complex models, such as a 4 mm pasta structure printed in 32 seconds (at 18mW laser power), the Stanford Bunny (8mm high) printed in 61 seconds (at 50mW), and DNA helices with micron-level surface smoothness. Potential applications include bioprinting, micro-optics, and aerospace, where speed, resolution, and material efficiency are critical.

Volumetric printing matures with innovations in light control and biomedical applicationsVolumetric additive manufacturing is a promising alternative to traditional layer-by-layer 3D printing, gaining momentum by enabling the simultaneous fabrication of entire objects with fewer limitations on geometry and speed. Recent advancements include automated exposure control systems for more precise light metering during tomographic projection and the use of light-converting nanoparticles for deeper and more controlled polymerization.

Volumetric printing matures with innovations in light control and biomedical applicationsVolumetric additive manufacturing is a promising alternative to traditional layer-by-layer 3D printing, gaining momentum by enabling the simultaneous fabrication of entire objects with fewer limitations on geometry and speed. Recent advancements include automated exposure control systems for more precise light metering during tomographic projection and the use of light-converting nanoparticles for deeper and more controlled polymerization.