GKN Aerospace has made significant strides in the industrialization of additive manufacturing, with its 3D printed fan case mounting rings (FCMR) project expected to achieve full-rate production by the end of 2025. The company has begun batch deliveries from its facility in Trollhättan, Sweden, with production expected to increase from the current approximately 30 units per month to 40 units per month by the end of the year.

“This is a turning point for the aerospace manufacturing industry,” said Joakim Andersson, President of GKN Aerospace’s Engine Business. “Through the industrial-scale FCMR project, we have not only demonstrated the technical capabilities of additive manufacturing but also its real impact on sustainability, delivery cycles, and costs, providing predictability to our supply chain. Our recent achievements highlight GKN Aerospace’s leadership in developing and certifying advanced manufacturing technologies for the next generation of engines—this is just the beginning of this transformative technology.”

Earlier this year, GKN Aerospace delivered its 200th batch of 3D printed “thermal size rings” (the core structure of FCMR) to its facility in Newington, USA for final processing. The company is on track to deliver mass-produced products to meet the growing market demand for the Airbus A220 and Embraer 195-E2 GTF engines.

With the 3D printed fan case mounting rings entering mass production, GE Aerospace’s key 3D printing technology work is also underway, with current results indicating that, compared to traditional manufacturing methods, material waste per part has been reduced by 40%. In the future, GKN Aerospace expects to save over 70% of materials while reducing the end-to-end delivery cycle from 9 months to 4 weeks.

In the past 12 months, GKN Aerospace has achieved several key milestones in additive manufacturing certification and technology. These include its first additive manufacturing critical structural component receiving approval from the Federal Aviation Administration (FAA), as well as the successful delivery of its largest fully additive manufactured component: a large titanium alloy engine casing for the CFMI RISE technology demonstrator. This structure was produced using fully automated direct energy deposition technology, meeting casting quality standards and showcasing the potential of large-scale additive manufacturing in design and construction.

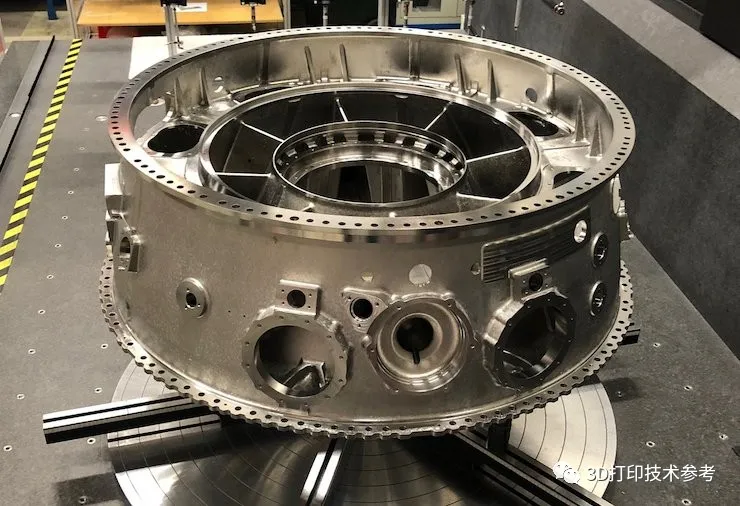

GKN for Rolls-Royce 3D printed UltraFan engine intermediate compressor casing

GKN for Rolls-Royce 3D printed UltraFan engine intermediate compressor casing

Prior to this capacity increase, GKN Aerospace had invested $50 million in 2024 to expand its sustainable additive manufacturing capabilities, focusing on increasing capacity and accelerating its industrial application in civil and military engine platforms. Thanks to the modular additive manufacturing production concept, this expansion plan will accelerate starting in 2026, enabling rapid deployment of the technology in other global facilities.

Note: This article was created by 3D Printing Technology Reference and is not authorized for reproduction without contact..Welcome to share

Industry expert communication group Q group: 248112776

Further reading:

1. Safran showcases a 1-meter diameter 3D printed integrated engine component at the Paris Air Show and shares experiences!

2. VDE simulation software | Predict + Optimize + Validate, easily cope with thin-walled 3D printing buckling

3. Two domestic companies fined due to quality risks in 3D printed denture products

4. 3D printing of alumina ceramic P surfaces with multi-level pore sizes and stepped pore structures