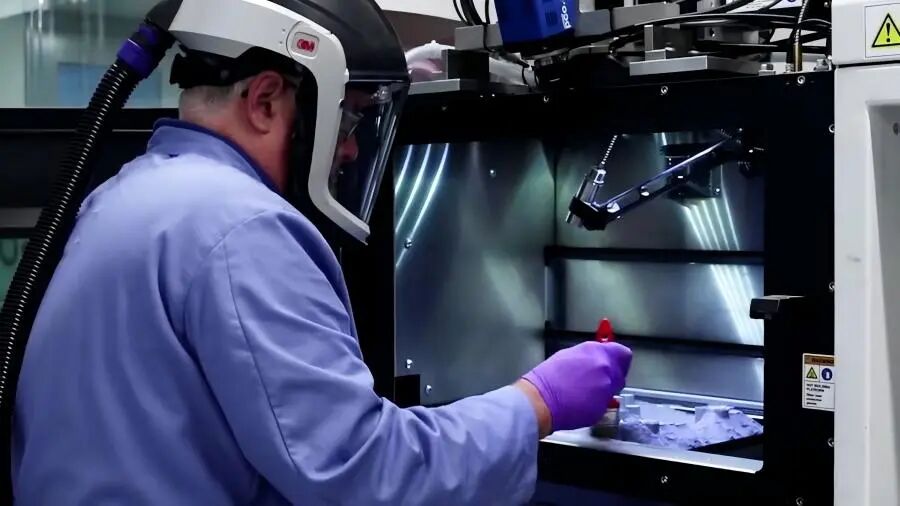

According to foreign media reports, American aircraft engine manufacturer Pratt & Whitney has announced that its rotating components of the TJ150 turbojet engine produced through additive manufacturing technology (3D printing) have completed their first test, marking the entry of military aviation power systems into a new era of “digital manufacturing.” The TJ150 is a small turbojet engine designed specifically for autonomous systems and weapons, capable of providing 150 pounds (approximately 68 kilograms) of thrust. In this test, Pratt & Whitney collaborated with the RTX Technology Research Center to reconstruct the engine turbine structure using a “modular” design concept, replacing traditional subtractive manufacturing with an additive process that layers metal powder, significantly enhancing component complexity and design freedom.

Chris Hughes, Executive Director of Pratt & Whitney’s GATORWORKS division, stated that the test results showed that the 3D printed turbine operated stably under full speed and high-temperature conditions, achieving the expected lifespan. He emphasized, “Previously, we validated the reliability of 3D printed static components, and the breakthrough with rotating components will open new pathways for expendable weapon systems.” According to corporate assessments, this technology can shorten production cycles by 50% and reduce costs by 30%, while simplifying the supply chain. The U.S. military has recently accelerated the promotion of additive manufacturing applications, with the Army planning to equip frontline troops with portable 3D printers for battlefield repairs; the Rock Island Arsenal Joint Manufacturing Center announced in May the expansion of 3D printed drone production capacity; additionally, the U.S. military established a special research center in Illinois this year, focusing on the rapid production and replacement of key components for large vehicles.