Tianjin Economic and Technological Development Zone: 3D Printing Technology Applied in Marine Engineering

On June 14, China National Radio published an article titled “Tianjin: High-end Marine Equipment Gathers to Support Shipping Industry Upgrade,” highlighting that the Tianjin Economic and Technological Development Zone has gathered numerous research forces and innovative enterprises. Liu Changmeng’s research group from the School of Mechanical Engineering and Vehicle Engineering at Beijing Institute of Technology introduced their team’s innovative achievements in the application of 3D printing technology in the marine engineering field. Their support-free lattice structure printing technology can achieve the printing of suspended structures, and the lattice sandwich panel they developed exhibits excellent performance in explosion-proof, compressive, and fatigue resistance, and can further enhance performance through concrete infusion, providing new ideas for marine infrastructure.

Guohe Baotai Zirconium Industry:Zirconium Niobium Joint Additive Manufacturing Project Approved

On June 12, the Baoji Science and Technology Bureau’s website published news about the high-quality development of Guohe Baotai Zirconium Industry Co., Ltd., mentioning that the company zirconium niobium joint additive manufacturing project has been approved. The company focuses on the research, production, and sales of nuclear-grade zirconium materials, while also involving zirconium material applications in the medical and chemical fields.

Zirconium Niobium Alloy has good biocompatibility, excellent mechanical properties, and wear resistance, with its elastic modulus significantly lower than that of medical titanium alloys and medical stainless steel, effectively reducing stress shielding phenomena between joints and extending the lifespan of implants.Additive manufacturing technology provides a new avenue for the preparation of zirconium niobium alloy joints. According to references on 3D printing technology, on February 8, 2025, a national key research and development project titled “Key Technologies for High Compatibility Zirconium Niobium Alloy Knee Joint Additive Manufacturing Prosthetics and Surface Functional Modification” jointly applied by Peking University Third Hospital, Guohe Baotai Zirconium Industry and others was approved by the Ministry of Science and Technology.

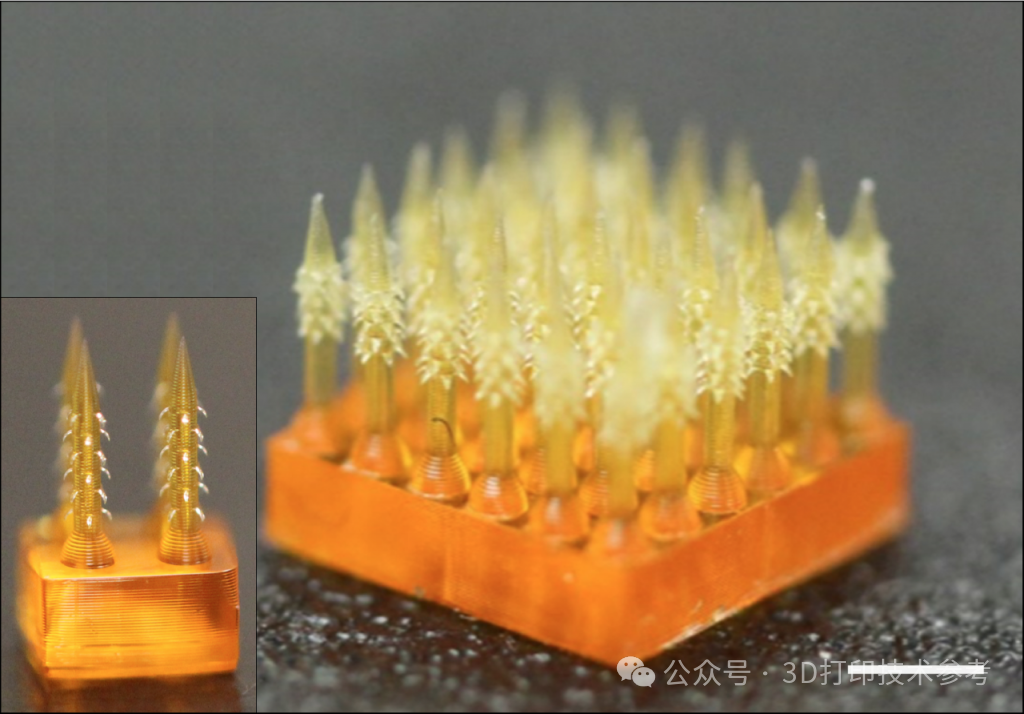

This image is for display purposes only and is not related to Guohe Baotai Zirconium Industry

This image is for display purposes only and is not related to Guohe Baotai Zirconium Industry

Huagong Technology:3D Printing Business Breakthrough, Already Has Good Cooperation with Globally Renowned End Brands

On June 12, Huagong Technology participated in the online collective reception day for investors of listed companies in Hubei on June 12, where it accepted investor research. The company achieved a scale breakthrough in its precision micro-nano business in 3D printing, semiconductors, and green agriculture fields. In the field of 3D printing, the company closely focuses on the structural opportunities in the global additive manufacturing market, deeply cultivating metal additive manufacturing equipment, with a focus on 3C electronics and new energy vehicles, forming a series of products, and actively exploring 3DPrint smart factory service processing business with strategic partners, quickly forming new growth points. In terms of 3D printing business, the joint venture established with Likai is based on successful long-term cooperation experience, providing complementary resource advantages in each link, enhancing comprehensive competitiveness in the field of 3D printing. The company has already established good cooperation with globally renowned end brands, and some products have been validated, all meeting customer specifications. Domestic leading 3C brand customers are also actively cooperating, with some products already entering the validation testing phase, showing good performance indicators.

Zhonghui Pharmaceutical: Completed Two Rounds of Financing of Tens of Millions, Accelerating Dual Breakthroughs in 3D Printed Hollow Microneedles and Exosomes Industrialization

On June 9, news reported that Shaanxi Yungu Zhonghui Biopharmaceutical Co., Ltd. has completed seed round and angel round financing, totaling approximately 50 million yuan. Zhonghui Pharmaceutical has been deeply engaged in needle design and production for many years, developing a mass production, full-chain production platform through independent microneedle design, micro-nano 3D printing, and photopolymerization, achieving a leap from laboratory technology to industrial production, reserving numerous mass production processes, engineering equipment, and other technical patents, breaking foreign monopolies, and plans to complete the construction of the first domestic automated production line by September 2025.

Pawoo Mart: Launches 3D Printed Collaborative Blind Box

Recently, Pawoo Mart launched the new Labubu series blind box, with reports of long queues in various locations to purchase this blind box. Unverified news indicates that Jinyun Laser collaborated with Pawoo Mart to develop an innovative category of blind boxes, launching 3D printed collaborative blind boxes, enabling users to design their own C2M (Customer-to-Manufacturer).

Inno Laser: 3D Printing Business Revenue Averages About 27 Million Yuan

On June 12, news reported that Inno Laser stated on the investor interaction platform that 3D printing, traceability identification, engraving, etc., are downstream applications of lasers, and the company supports laser equipment customers in exploring related applications in consumer electronics, cultural and creative toys, oral medical care, food and consumer goods, semiconductors, etc. In recent years, the company’s 3D printing business revenue averages about 27 million yuan.

Weihai High-tech Zone: 3D Printing Service Project Officially Launched, Orders Extended to Two Years Later

On June 9, news reported that Weihai Mice 3D Technology Co., Ltd. has officially launched its 3D printing service project, with the company’s 650 3D printers capable of accurately printing parts with an error margin of within 0.01 millimeters. General Manager Feng Weipeng stated that despite just starting production, they have already received orders for two years later. The company provides FDM technology 3D printing services, including self-designed products and offering OEM and ODM services to customers. This project is invested by Korea’s M4X Corporation, a subsidiary of BMT Corporation, providing one-stop services for globally renowned enterprise clients.Note: This article is created by 3D printing technology reference and is not authorized for reproduction without contact..Welcome to share

Industry Expert Communication Group QQ Group:248112776

Further Reading:

1. Xietong High-tech will showcase multiple continuous fiber 3D printing devices at SAMPE China 2025 Annual Conference

2. Overview of Research on High Strength Plasticity of Magnesium Alloy in 3D Printing

3. San Di Technology 3DP+SLS Composite 3D Printing Technology Assists in Manufacturing Key Components of High-end Equipment

4. Plutotech Participates in Remote Sensing Satellite Project and Achieves Phase Breakthrough, Supporting HarmonyOS to Complete On-orbit Verification!