1. Core Fault Analysis of ECU Anomalies

1. Program Corruption: The “Amnesia” of Digital Neurons

-

Typical Triggers:

-

Unofficial ECU tuning (e.g., aggressive first/second-order program flashing leading to checksum failure)

-

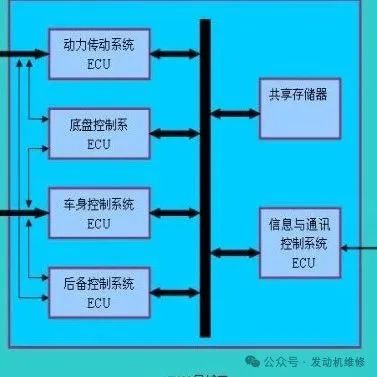

CAN bus signal conflicts (devices occupying diagnostic protocol IDs, such as permanent devices on the OBD interface)

-

OTA upgrade interruptions (voltage fluctuations causing packet loss rate > 5%)

-

Failure Symptoms:

-

Loss of throttle baseline learning values

-

Abnormal fuel injection pulse width calculation (deviation > ±15%)

-

False triggering of the anti-theft system (IMEI code not matching BCM)

2. Moisture Damage to Circuit Boards: The “Rheumatism” of Electronic Components

-

Testing Standards:

Test Item Normal Value Fault Determination Insulation Resistance (between layers) >100MΩ <10MΩ Electrolytic Capacitor ESR Value <1Ω >5Ω Oxidation Area of Solder Joints <5% >30% -

High-Risk Areas:

-

Bottom of ECU pins (prone to condensation accumulation)

-

Surroundings of DC-DC conversion module (large fluctuations in operating temperature)

3. Unstable Power Supply Voltage: The “Arrhythmia” of Energy Supply

-

Key Parameters:

-

Steady-state voltage range: 13.5V±0.5V (during engine operation)

-

Instantaneous voltage drop: >9.6V during startup (must be >10.5V for vehicles with start-stop systems)

-

Ripple voltage: <200mV (measured peak-to-peak with an oscilloscope)

2. Symptom Diagnosis and Quick Response

1. Multiple Fault Indicator Warnings (Christmas Tree Phenomenon)

-

Diagnosis Priority:

-

Read freeze frame data (lock the first triggered fault code)

-

Check CAN bus termination resistance (standard 60Ω±2%)

-

Inspect power supply to the gateway module (fuses SB10/SC20)

2. Diagnostic Protocol Failure (Unable to Communicate)

-

Physical Layer Testing:

-

Protocol Layer Testing:

-

K-Line wake-up signal (>7V pulse)

-

ISO-TP frame response time (<100ms)

| Pin | Test Point | Standard Value |

|---|---|---|

| OBD-16 | Power Voltage | 12-14V |

| OBD-6 | CAN-H Voltage | 2.6-2.8V |

| OBD-14 | CAN-L Voltage | 2.2-2.4V |

3. Chaotic Power Output (Random Fluctuations)

-

Data Stream Analysis Focus:

-

Intake pressure sudden changes (>±10kPa/second)

-

Ignition advance angle oscillation (amplitude >±8°)

-

A/F ratio λ value jumps (irregular fluctuations between 0.8-1.2)

3. Systematic Repair Solutions

▌ Phase One: Basic Reset Operations1. Battery Disconnection for Forced Reset

-

Standardized Process:

-

Turn off all vehicle electrical devices (including dash cams)

-

Disconnect negative cable → wait 10 minutes → disconnect positive cable

-

Short-circuit the terminals for 30 seconds (to release residual charge)

-

Reconnect positive terminal first → then negative terminal (torque 4-6N·m)

Notes:

-

Vehicles equipped with intelligent start-stop systems require additional reset of the BSM module

-

High-end models must disable transport mode before disconnection (VAS5054 operation)

▌ Phase Two: ECU Program Refresh1. Device Selection Standards

| Device Type | Applicable Scenario | Refresh Speed |

|---|---|---|

| Original Factory Diagnostic Tool (VAS6154) | Bootloader Repair | Low-speed mode (19.2kbps) |

| Third-party Device (Autel IM608) | Calibration Data Writing | High-speed mode (500kbps) |

| Chip Programmer (PCMFlash) | Low-level Data Repair | Parallel Writing (8 channels) |

2. Flashing Operation Specifications

-

Environmental Requirements:

-

Stable Voltage: Connect to a regulated power supply (13.5V±0.1V)

-

Temperature Control: 20-30℃ (if out of range, use a temperature chamber)

-

Data Verification:

-

Cyclic Redundancy Check (CRC32)

-

Hash Value Comparison (SHA-256)

▌ Phase Three: In-Depth Hardware Inspection1. Circuit Board Repair Process

-

Moisture Treatment:

-

Ultrasonic Cleaning (40kHz, 60℃ pure water)

-

Vacuum Drying (50℃/12 hours, vacuum degree -0.08MPa)

-

Three-proof Paint Spraying (thickness 0.1-0.3mm)

Component-Level Repair:

-

Replace bulging capacitors (low ESR capacitors from the KMQ series)

-

Wire repair for broken connections (0.1mm gold wire bonding)

2. Power System Rectification

-

Main Relay Testing:

Parameter Standard Value Replacement Threshold Pull-in Voltage ≤9V >11V Contact Resistance ≤50mΩ >200mΩ -

Fuse Selection:

-

Main Power Supply for ECU: Slow-blow type (Littelfuse 0SPT series)

-

Sensor Circuit: Fast-blow type (Bussmann ATM series)

4. Preventive Maintenance Strategies

1. Environmental Protection Upgrades

-

Add waterproof ECU protective sleeves (IP69K rating)

-

Install shock-absorbing bases (silicone cushioning pads, shock absorption rate >70%)

2. Power System Reinforcement

-

Parallel supercapacitor modules (16V 300F)

-

Upgrade generator regulators (output fluctuations <±0.3V)

3. Software Health Management

-

Perform full system diagnostic scans monthly (generate health reports)

-

Establish an ECU software fingerprint database (record MD5 values of each version)

5. Classic Fault Case Library

| Case Features | Fault Root Cause | Solution |

|---|---|---|

| ECU failure after water immersion | Pin oxidation causing CAN line short to ground | Replace TE 2280913-1 gold-plated connector |

| Power interruption after xenon light modification | Electromagnetic interference causing ECU restart | Add TDK ZJYS51R5 filter magnetic ring |

| Unable to start after long-term parking | Static current draining battery causing EEPROM data loss | Use XPROG-M to rewrite 93C86 chip |

Technical Summary The essence of ECU control anomalies is a dual failure of “digital-physical,” requiring a layered repair strategy:

-

Software Layer: Retrieve original factory reference data via VIN (force overwrite abnormal parameters)

-

Hardware Layer: Execute three-level circuit testing (visual inspection → thermal imaging → X-ray tomography)

-

System Layer: Rebuild power integrity (ripple suppression ratio >60dB)

It is recommended to equip a dedicated repair platform:

-

ESD workstation (surface resistance 10^6-10^9Ω/sq)

-

Inert gas welding station (nitrogen environment, oxygen content <50ppm)

-

Automatic three-proof paint spraying equipment (thickness accuracy ±0.02mm)

Through systematic maintenance, the failure rate of ECU-related issues can be reduced by 75%, and the stability of the power system can be improved by 40%. For smart vehicles post-2020, it is necessary to additionally monitor OTA upgrade logs to prevent cloud-pushed abnormal program packages from causing systemic risks.