As the global manufacturing industry enters a critical stage of intelligent upgrading, how to break through the shackles of traditional production models through technological innovation has become a core proposition for enterprises to seize market opportunities. As a representative enterprise in the domestic industrial automation field, Yike, with decades of technical accumulation in the industry, provides comprehensive solutions for the transformation of intelligent manufacturing, reshaping the digital future of China’s manufacturing industry.

The overall solution from Yike Automation includes high-performance programmable logic controllers and high-precision servo motion control products.

The controller products can be divided intoX7 series advanced motion controllers based on X86 architecture, X3 series motion controllers, X1 series medium PLCs, and X0 series small PLCs, which can meet various control needs from high to low in the industry.

In terms of on-site network communication, Yike’s controller products support various communication methods such as ModbusTCP, OPC UA, Socket, and Codesys tags, and also support RS485/RS232-based ModbusRTU/custom communication, and CAN bus, supporting CANopen protocol, providing strong compatibility with various devices, allowing for quick and easy integration with various on-site equipment, and enabling the rapid establishment of stable network communication between different device systems.

In motion control, it supports EtherCAT, Profinet bus and pulse axis control methods, which can meet various motion control needs in different scenarios. The axis control capability of the EC bus supports the fastest bus update cycle of 0.5ms, with the ability to control up to 256 EC bus axes. Meanwhile, X1, X3, and X7 PLCs can support various advanced motion control functions, such as electronic cam/electronic gear. X3 and X7 can control axis motion using CNC code and can easily configure various robot models using the axis group function, greatly reducing programming time.

For high-precision and high-response applications in assembly, cutting, welding, handling, depalletizing, painting, and sorting processes, Yike can provide high-performance motion controller product solutions. A rich variety of IO expansion modules and its powerful backplane IO and remote IO expansion capabilities can meet the IO logic control needs of large process production lines.

Servo drive products can be divided into two main series: SA and SC.

SA is for economy, while SC is for standard type.The entire series includes two power supply modes: 220V and 380V, and includes three control methods: EtherCAT bus, Profinet bus, and pulse.The EtherCAT bus type covers a power range of 0.1KW-7.5KW; the pulse control type covers a power range of 0.1KW-3KW; the PN bus type covers a power range of 0.1KW-7.5KW.

Yike’s high-performance servo products are closely integrated with self-developed high-performance controllers to form a comprehensive automation manufacturing solution. With a certain advantage in solution capabilities on the fast track of technological innovation, it continues to take root and sprout in various niche fields.

Typical case of Yike PLC + Servo overall solution:

The solution model is a glass loading and unloading machine for the consumer electronics industry. It mainly realizes the loading/unloading function of mobile phone and tablet screens.

The solution configuration includes oneX1 series PLC and five sets of SA series servos, configured as shown in the following figure.

Yike product solution configuration:

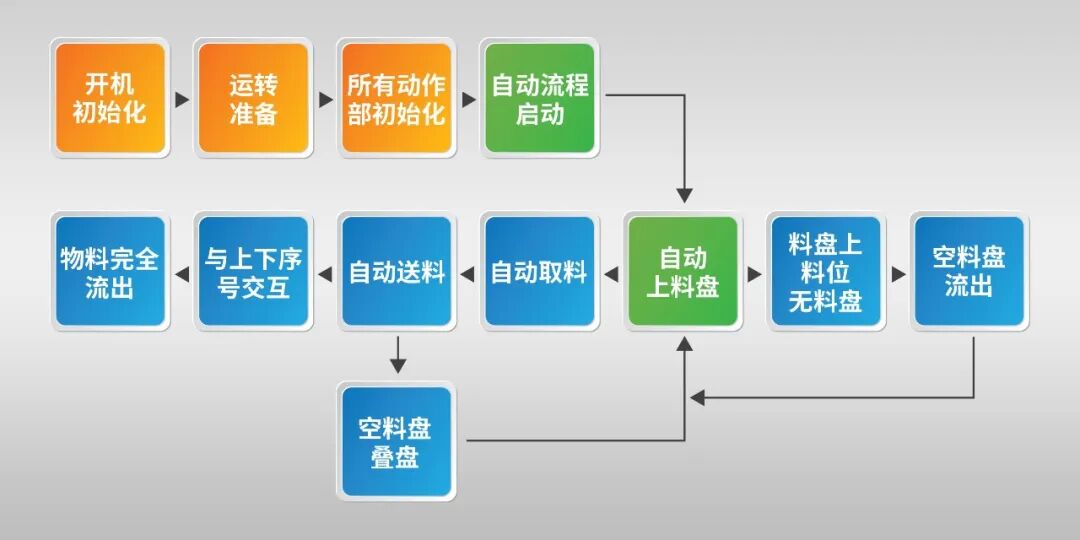

Principle of equipment operation control:

Device structure diagram – main process part:

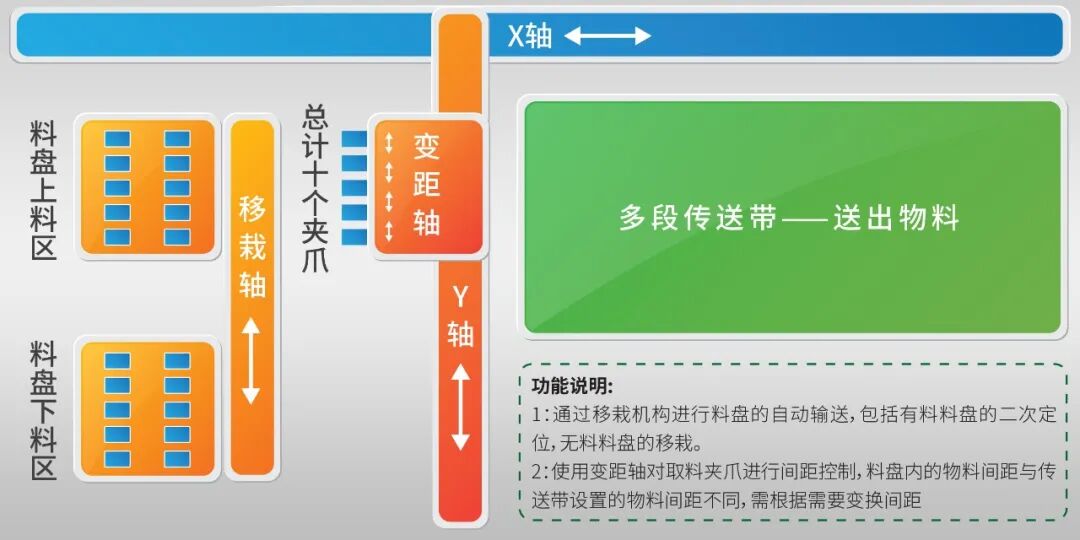

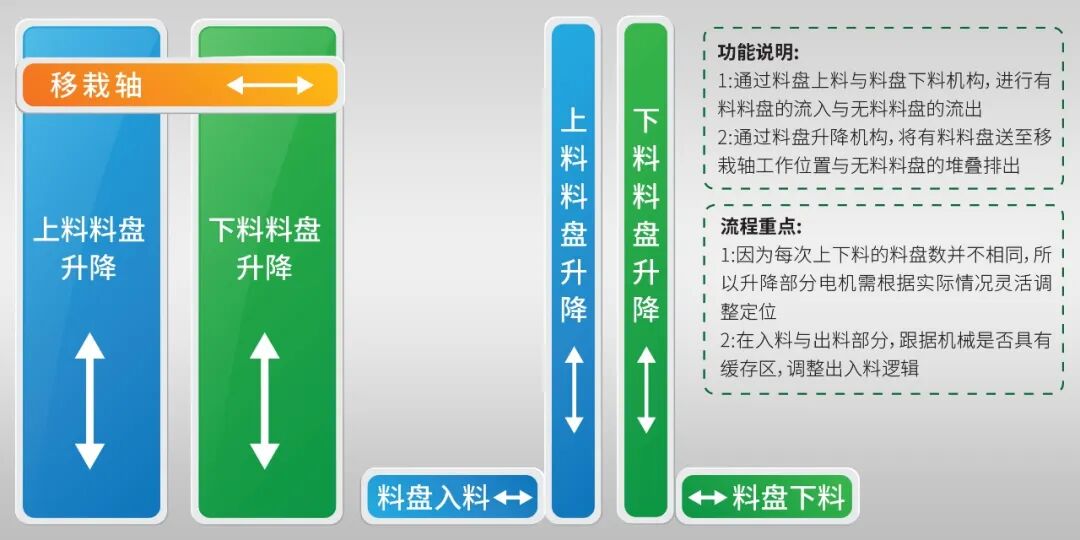

Device structure diagram – tray transplanting process part:

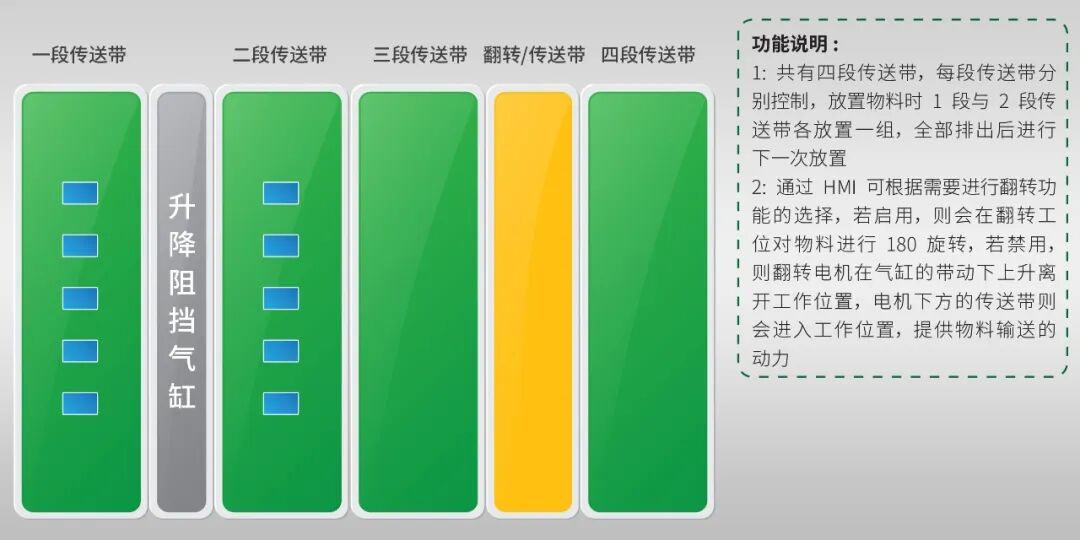

Device structure diagram – conveyor belt conveying process part:

Yike PLC + Servo not only provides enterprises with efficient and intelligent solutions but also promotes the innovative development of the intelligent manufacturing industry. In the future, Yike will continue to deepen its efforts in the field of industrial automation, driven by technological innovation, to assist more enterprises in achieving the upgrade and transformation of intelligent manufacturing.