The protection techniques for circuit boards in industrial applications are essential. Proper protection of circuit boards ensures that products operate reliably and stably in harsh environments. Below are several commonly used protection techniques for circuit boards.1. Nano Coating

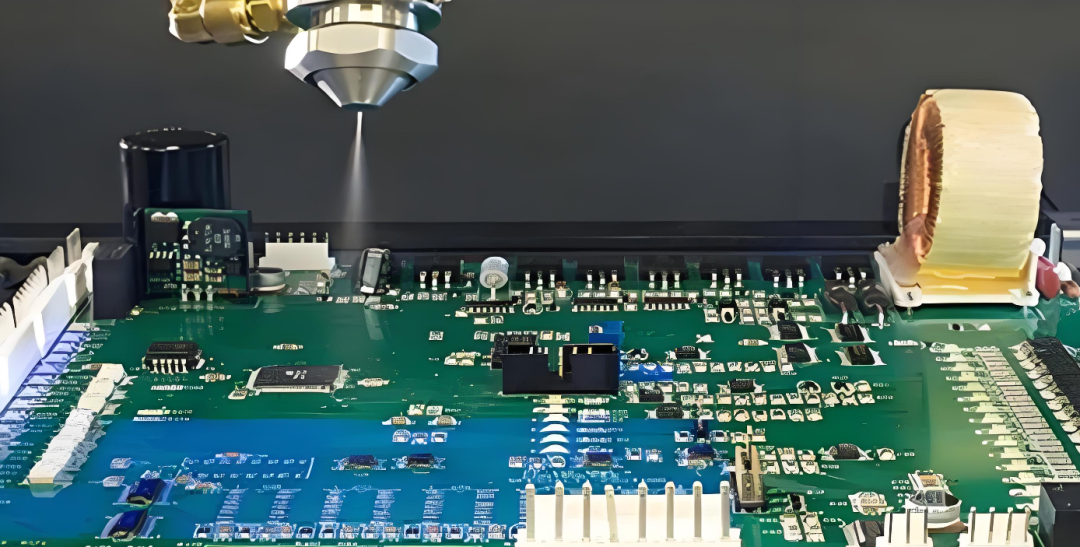

The protection techniques for circuit boards in industrial applications are essential. Proper protection of circuit boards ensures that products operate reliably and stably in harsh environments. Below are several commonly used protection techniques for circuit boards.1. Nano Coating Nano coating uses fluorinated solvents as a medium, containing fluorinated compounds that provide waterproof and oil-proof functions. It exhibits colorless, transparent, non-toxic, harmless, and non-flammable liquid properties, allowing it to penetrate into the tiny gaps of electronic components through immersion, achieving comprehensive waterproofing effects. Nano coatings have advantages such as ultra-thin (2-4μm), hydrophobic lotus leaf effect, no impact on heat dissipation, easy to repair, and can be directly soldered. Generally, immersion, brushing, dripping, and spraying methods can be used.Application Scenarios: Consumer electronics (headphones/mobile phones), automotive electronics, smart home devices.2. Conformal Coating

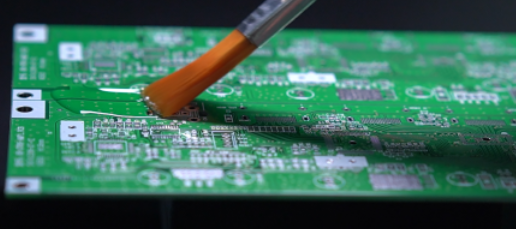

Nano coating uses fluorinated solvents as a medium, containing fluorinated compounds that provide waterproof and oil-proof functions. It exhibits colorless, transparent, non-toxic, harmless, and non-flammable liquid properties, allowing it to penetrate into the tiny gaps of electronic components through immersion, achieving comprehensive waterproofing effects. Nano coatings have advantages such as ultra-thin (2-4μm), hydrophobic lotus leaf effect, no impact on heat dissipation, easy to repair, and can be directly soldered. Generally, immersion, brushing, dripping, and spraying methods can be used.Application Scenarios: Consumer electronics (headphones/mobile phones), automotive electronics, smart home devices.2. Conformal Coating Conformal coatings typically use traditional acrylic/polyurethane/silicone coatings, providing moisture and salt mist protection, but have poor heat dissipation and are not suitable for scenarios requiring good heat dissipation. Additionally, the conformal coating leaves a noticeable layer on the circuit board, which must be removed during equipment maintenance. Generally, spraying, brushing, and immersion methods are used, and some processes may require 2 to 3 repetitions to ensure good protection.Application Scenarios: Typically used for industrial equipment, outdoor electronics, and low-cost scenarios.3. Epoxy Resin Encapsulation

Conformal coatings typically use traditional acrylic/polyurethane/silicone coatings, providing moisture and salt mist protection, but have poor heat dissipation and are not suitable for scenarios requiring good heat dissipation. Additionally, the conformal coating leaves a noticeable layer on the circuit board, which must be removed during equipment maintenance. Generally, spraying, brushing, and immersion methods are used, and some processes may require 2 to 3 repetitions to ensure good protection.Application Scenarios: Typically used for industrial equipment, outdoor electronics, and low-cost scenarios.3. Epoxy Resin Encapsulation As the name suggests, epoxy resin encapsulation is a method of protecting circuit boards by encapsulating them. It features complete PCB encapsulation, strong impact resistance, but is completely non-repairable and has extremely poor heat dissipation.Application Scenarios: Typically used for underwater equipment, high-vibration environments, outdoor chargers, and high-requirement waterproof scenarios.Precautions: 1. Ensure safety precautions; safety is paramount. Although many protective coatings claim to be safe and non-toxic, safety measures should still be taken during use. 2. Avoid coating circuit board sockets, buttons, and other movable components, as this may lead to poor contact or functional failure. 3. Follow the recommended application methods for the selected coating.

As the name suggests, epoxy resin encapsulation is a method of protecting circuit boards by encapsulating them. It features complete PCB encapsulation, strong impact resistance, but is completely non-repairable and has extremely poor heat dissipation.Application Scenarios: Typically used for underwater equipment, high-vibration environments, outdoor chargers, and high-requirement waterproof scenarios.Precautions: 1. Ensure safety precautions; safety is paramount. Although many protective coatings claim to be safe and non-toxic, safety measures should still be taken during use. 2. Avoid coating circuit board sockets, buttons, and other movable components, as this may lead to poor contact or functional failure. 3. Follow the recommended application methods for the selected coating.