Wearable devices represented by smartwatches and head-mounted displays can now utilize flexible circuit boards. However, the next generation of wearable devices requires stretchability and conformability to flexibly follow body movements and collect various data from the body. This is the purpose of developing stretchable circuit boards.

Stretchable circuit boards need to possess mechanical properties that allow for contraction while maintaining their electrical characteristics during stretching. We will explain how to achieve these seemingly contradictory properties and the potential applications of stretchable circuit boards.

What is a “Stretchable Circuit Board”?

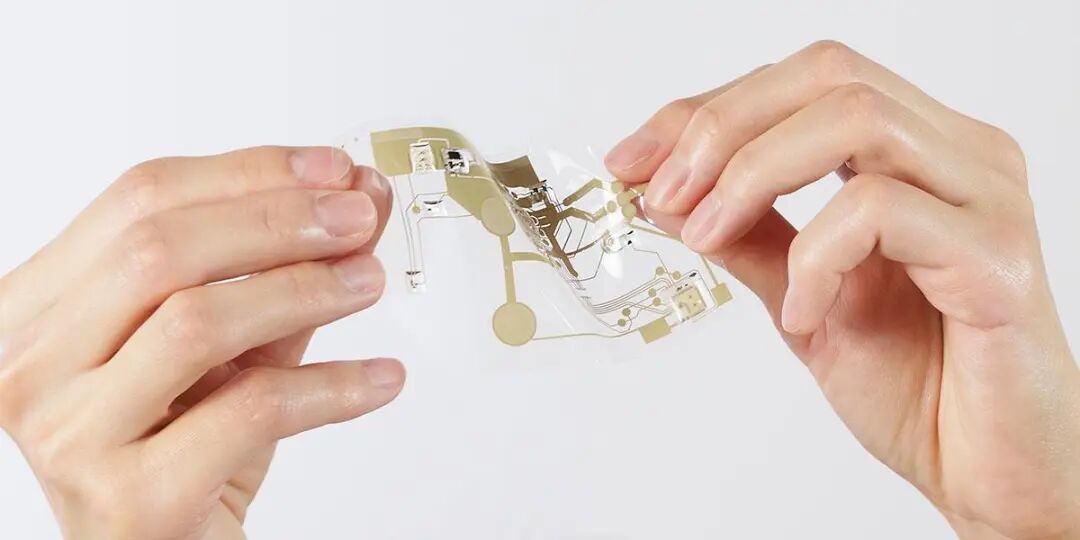

Stretchable circuit boards are circuit boards that form circuit patterns using stretchable circuit boards and conductive materials, utilizing the “printed electronics technology that applies conductive materials to circuit boards using printing techniques”. The circuit boards are made from elastomers such as stretchable polyurethane or silicone, with silver as the primary conductive material. They exhibit high stretchability and conformability, allowing circuits to be installed on joints such as knees and elbows, as well as on free-form surfaces like the neck and chest (Figure 1).

Figure 1: Stretchable Circuit Board

Previous stretchable circuit boards had some issues, such as significant changes in resistance and other electrical characteristics due to stretching, and applying voltage in high humidity environments could lead to migration.

Migration, also known as the migration phenomenon, is a phenomenon where wiring or electrodes move on an insulator or its interface due to the effects of electrolysis. After migration occurs, the insulation resistance value decreases, which can lead to short circuits between electrodes, causing electronic devices to fail. Electronic products at risk of migration face reduced long-term reliability and require heat dissipation measures when soldering electronic components.

In recent years, improvements in circuit board materials and conductive materials have enhanced electrical characteristics, implemented preventive measures against migration, improved wiring designs, and developed solder materials that can be soldered at low temperatures, leading to the practical application of stretchable circuit boards. Another feature of these circuit boards is their environmental friendliness, as they form circuit patterns directly printed onto the circuit board.

What is “Printed Electronics”?

Printed electronics is a technology that uses printing techniques to print conductive materials onto circuit boards to form electronic components or circuit patterns, enabling very thin coatings and high-precision wiring.

In the circuit board manufacturing process, a method called “photolithography” has traditionally been used, where conductive materials are coated over the entire surface of the circuit board and then dissolved with a chemical solution to remove unwanted parts and form circuit patterns, while printed electronics directly prints the circuit patterns onto the circuit board. Therefore, the process of dissolving with chemicals is not required, which saves resources and energy and allows for the use of various circuit board materials.

Electronic components using printed electronics

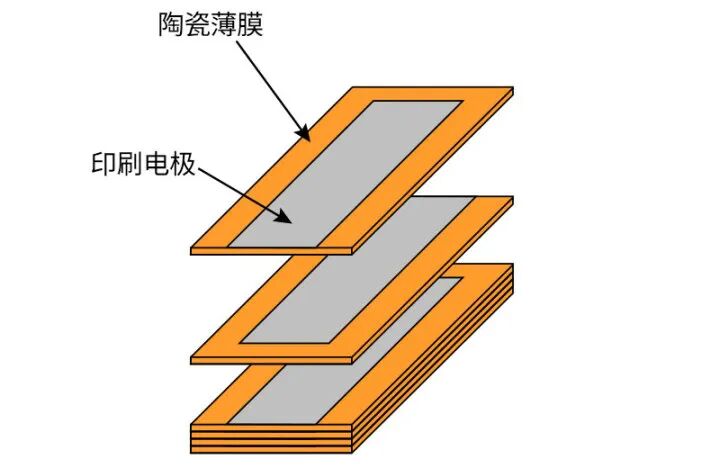

So far, printed electronics have been used as a means to achieve multilayer structures for multilayer ceramic capacitors (MLCC) and multilayer inductors. For example, in multilayer ceramic capacitors, a structure is used where thin ceramic films acting as dielectrics and metal electrodes are alternately stacked (Figure 2). The ceramic dielectric and binder are made into a slurry, which is coated onto a carrier film and dried to form a sheet, referred to as a green sheet. After repeatedly printing electrodes on its surface, further baking is done to harden it. The number of layers can sometimes reach several hundred.

Figure 2: Multilayer Structure of Multilayer Ceramic Capacitors (MLCC)

Applications of Printed Electronics in Circuit Boards

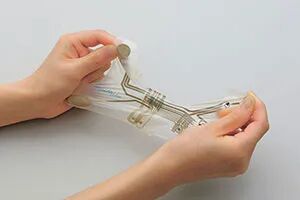

In printed electronics, in addition to using rigid circuit boards made of glass and resin, flexible conductive materials can also be used to form circuit patterns on films. Furthermore, by using stretchable conductive materials, circuit patterns can be formed on stretchable materials.

This allows for the production of bendable flexible circuit boards (Figure 3) and flexibly stretchable circuit boards (Figure 1).

Figure 3: Flexible Circuit Board

Potential of Stretchable Circuit Boards

Stretchable circuit boards have stretchability, allowing them to conform to joints such as knees and elbows, as well as free-form surfaces like the neck and chest. Additionally, by installing various electronic components on stretchable circuit boards, it is possible to develop devices that can be worn on the body to collect vital sign data such as brain waves and heart rates, which are essential for appropriate treatment and care, including heart rate, respiratory rate, pulse rate, body temperature, blood pressure, and blood oxygen saturation. They can also be used to monitor joints after surgery.

Examples of Applications in the Medical Field

Stretchable circuit boards are expected to be applied in various fields, and here we introduce examples in the medical field.

There have been the following issues in medical devices:

Patients cannot wear them continuously

Long-term wear can restrict physical activity. Additionally, the devices themselves pose a risk of damaging the skin.

Unable to obtain data with required accuracy

Traditional medical devices cannot obtain data with required accuracy due to external noise and body movement noise when collecting vital sign data.

Complicated to use

Wearing them takes time and can only be used by specialized medical personnel.

Below, we introduce examples of how stretchable circuit boards can solve these issues.

Electroencephalogram (EEG) Devices

Brain waves are weak electrical signals continuously emitted by the cerebral cortex. The frequency of these electrical signals changes according to mental state and brain activity, and measuring the frequency can provide insights into the brain’s condition. Brain waves are measured by placing 10 to 20 electrodes on the scalp (Figure 4).

Figure 4: Traditional Electroencephalogram (EEG) Device

When monitoring brain waves, it is necessary to install electrodes in precise locations. Installing electrodes is very cumbersome, making it difficult for non-professionals to use.

However, in recent years, stretchable circuit board-based band and cap-type EEG electrode array devices have been developed. By using stretchable circuit boards, they can adapt to the shape and size of the patient’s head, or the stretchable circuit board itself can be embedded in a cap. The cables connecting the electrodes can be hidden inside the device, reducing the risk of wiring detaching during installation or patient movement. Additionally, by embedding amplifiers or filters near the EEG electrodes, high-precision data can be obtained after noise elimination (Figure 5).

Figure 5: EEG Electrode Array Device with Stretchable Circuit Board

Monitoring of Joint Areas After Artificial Joint Replacement Surgery

Artificial joint replacement surgery is a procedure that replaces deformed joints due to osteoarthritis, rheumatoid arthritis, or trauma with artificial joints. This surgery targets joints such as shoulders, thighs, and knees, restoring important functions such as “pain-free,” “mobility,” and “supporting the body.” After artificial joint replacement surgery, rehabilitation treatment is necessary to restore the function of the joint area. Additionally, beyond rehabilitation, pain management and monitoring for complications such as fractures, dislocations, and infections are also required.

Currently, medical staff accompany patients during rehabilitation and observe and diagnose the affected areas, providing various types of care. Furthermore, wearable devices for joint areas currently under development are expected to detect and record movements during daily life and rehabilitation processes, conveying results to medical staff and patients, helping to determine postoperative rehabilitation strategies and maintain and enhance motivation for ongoing rehabilitation. They are also expected to be used for early detection of complications such as infections and dislocations.

Joints are areas of the body with a very large range of motion, requiring high mechanical durability. It is believed that by equipping stretchable circuit boards with various sensors, mechanical monitoring functions for joint range of motion and activity status, as well as physiological monitoring functions for the surgical site (temperature, swelling, etc.), it will be possible to grasp the patient’s condition and changes in status after artificial joint replacement surgery early, contributing to improving the patient’s quality of life (Figure 6).

Figure 6: Monitoring of Joint Areas with Stretchable Circuit Board

Vital Sign Monitoring for Neonatal Intensive Care

Premature or low-birth-weight newborns are physically fragile, requiring constant monitoring of their vital signs to take appropriate measures in a timely manner. However, due to the hardness of the sensors, the wires connecting the sensors, and the adhesives used to secure the sensors, current devices are not very suitable for newborns. For example, wires may interfere with kangaroo care (care provided directly by parents) and the newborn’s movements. Additionally, the hardness of the sensors and adhesives also poses a risk of skin damage.

Therefore, by installing sensors, batteries, microcontrollers, and BLE (Bluetooth Low Energy) on stretchable circuit boards, wireless devices can be realized that do not interfere with kangaroo care or the newborn’s movements. Furthermore, utilizing the flexibility of the circuit board itself allows for good conformability even on delicate skin, thus enabling monitoring devices that reduce the aforementioned risks (Figure 7).

Figure 7: Vital Sign Data Acquisition Without Interfering with Movement

Conclusion

Printed electronics is a technology used in products from Murata Manufacturing, such as multilayer ceramic capacitors (MLCC). By combining this technology with stretchable materials and conductive materials, stretchable circuit boards have been created.

Stretchable circuit boards represent a “flexible technology” that combines existing electronic component manufacturing technologies with the development of stretchable materials. Currently, in the medical field, there is hope that these devices will achieve conformability, comfortable wear, improved sensor accuracy, and long-term wearability. Furthermore, this technology is expected to be applied not only in the medical field but also in various fields such as industrial robotics and smart textiles.

Click the image to learn more about Murata’s Stretchable Circuit Board product details

Scan to follow

Scan to follow