1. What Are the Inspection Standards for PCBA Boards? First, let us understand the introduction of quality inspection standards: 1. Critical Defects (denoted as CR): Any defect that can cause harm to humans or machines or endanger life safety, such as non-compliance with safety regulations, burning machines, electric shock, etc. 2. Major Defects (denoted as MA): Defects that may cause product damage, functional abnormalities, or affect the product’s lifespan due to materials. 3. Minor Defects (denoted as MI): Defects that do not affect product functionality and lifespan, including minor aesthetic flaws and slight assembly discrepancies. What Items Should Be Inspected on PCBA Boards and What Are the Inspection Standards2. Inspection Conditions for PCBA Boards: 1. To prevent contamination of components or assemblies, gloves or finger cots with full EOS/ESD protection must be selected, and static rings should be worn during operations. The light source should be white daylight lamps, with light intensity above 100 Lux, clearly visible within 10 seconds. 2. Inspection Method: Place the item to be inspected about 40 cm from the eyes, checking visually or with a threefold magnifying glass at angles of 45º up, down, left, and right. 3. Inspection Determination Standards: (Sampling based on QS9000 C=0 AQL=0.4%; if the customer has special requirements, determine according to customer acceptance standards) 4. Sampling Plan: MIL-STD-105E LEVEL II normal single sampling 5. Determination Standards: Critical Defects (CR) AQL 0% 6. Major Defects (MA) AQL 0.4% 7. Minor Defects (MI) AQL 0.65%

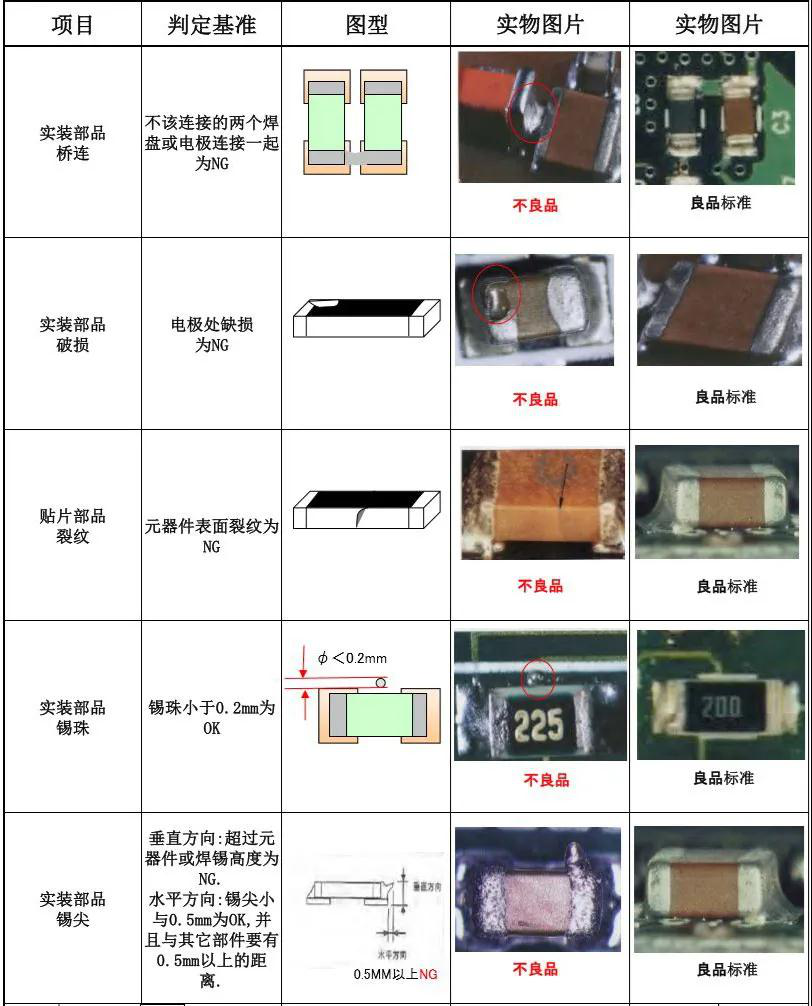

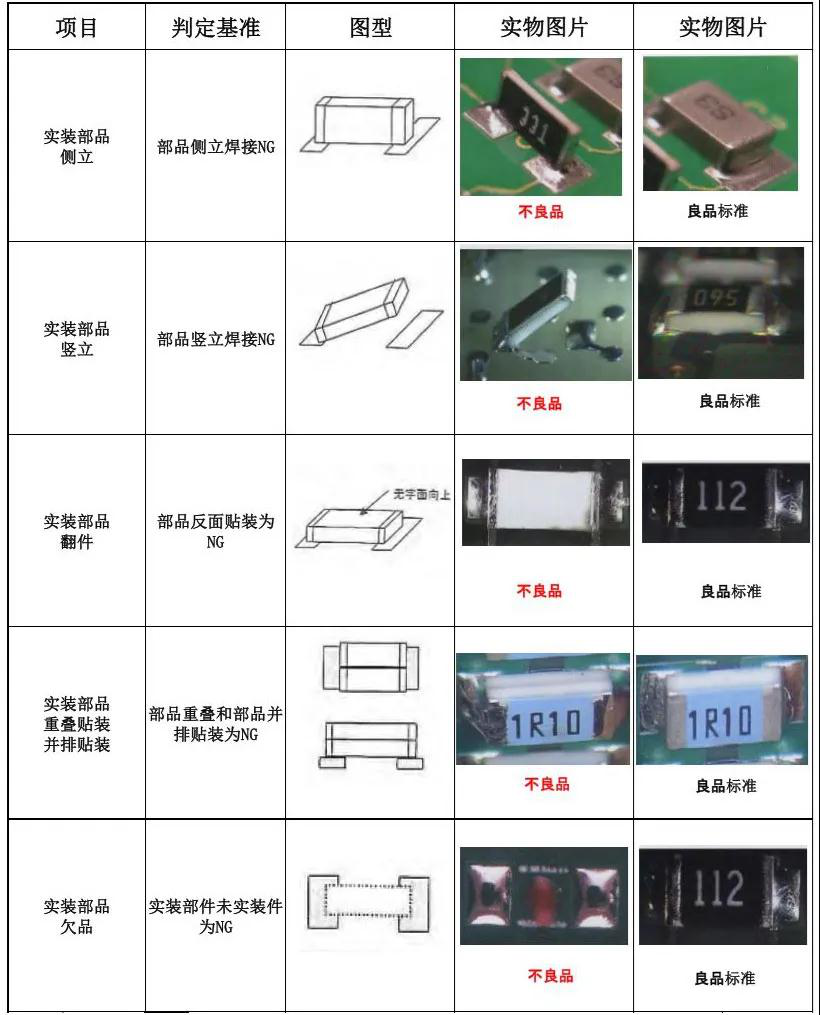

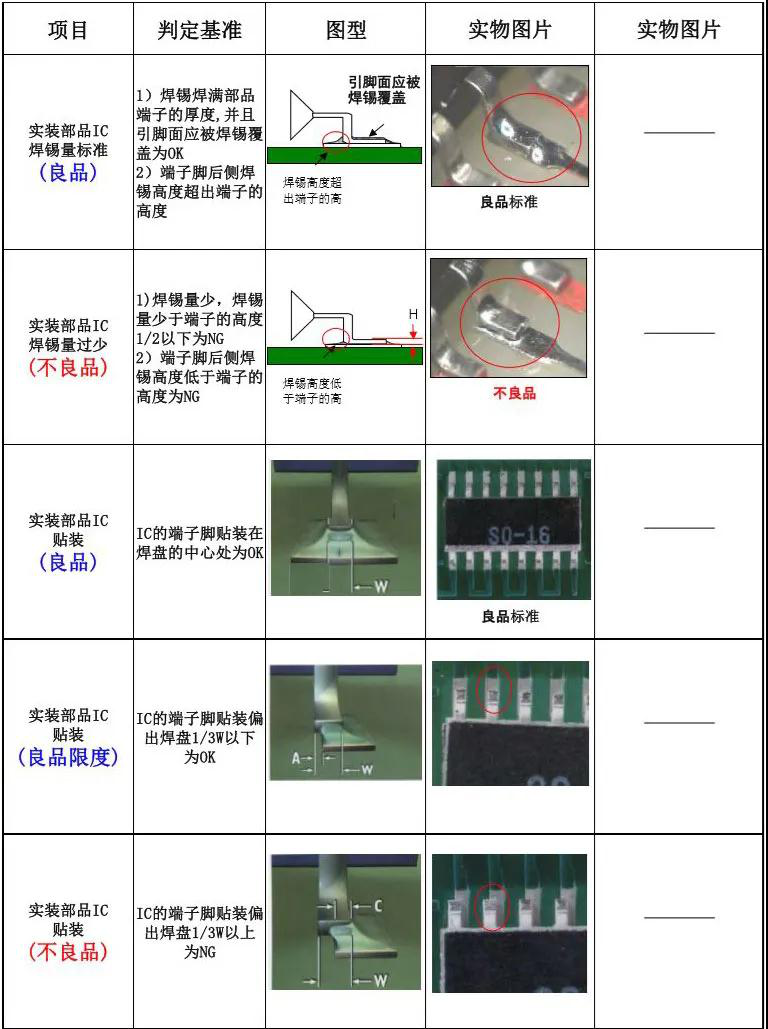

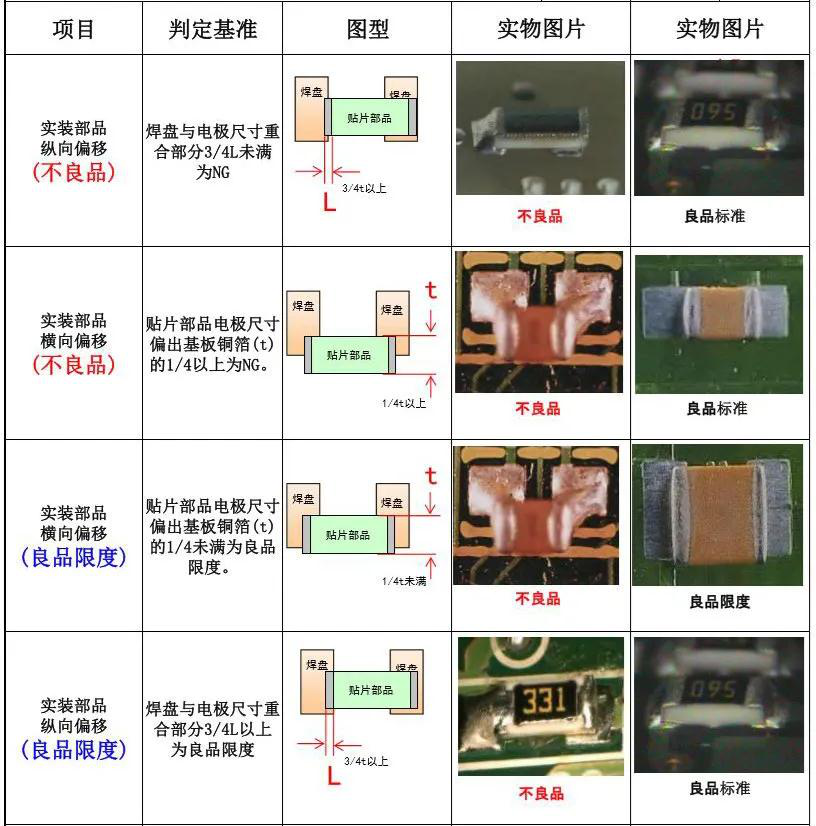

What Items Should Be Inspected on PCBA Boards and What Are the Inspection Standards2. Inspection Conditions for PCBA Boards: 1. To prevent contamination of components or assemblies, gloves or finger cots with full EOS/ESD protection must be selected, and static rings should be worn during operations. The light source should be white daylight lamps, with light intensity above 100 Lux, clearly visible within 10 seconds. 2. Inspection Method: Place the item to be inspected about 40 cm from the eyes, checking visually or with a threefold magnifying glass at angles of 45º up, down, left, and right. 3. Inspection Determination Standards: (Sampling based on QS9000 C=0 AQL=0.4%; if the customer has special requirements, determine according to customer acceptance standards) 4. Sampling Plan: MIL-STD-105E LEVEL II normal single sampling 5. Determination Standards: Critical Defects (CR) AQL 0% 6. Major Defects (MA) AQL 0.4% 7. Minor Defects (MI) AQL 0.65% Inspection Standards for PCBA Boards in SMT Assembly Workshops3. Inspection Standards for PCBA Boards in SMT Assembly Workshops 01. SMT component solder joint open solder 02. SMT component solder joint cold solder: If the component pin can be moved with a toothpick, it is considered cold solder 03. SMT component (solder joint) short circuit (solder bridge) 04. Missing SMT components 05. Incorrect SMT components 06. SMT component polarity reversed or incorrect, causing burning or explosion 07. Multiple SMT components 08. SMT component flipped: text facing down 09. SMT component standing sideways: for chip components, length ≤ 3mm, width ≤ 1.5mm, no more than five (MI) 10. SMT component tombstone: end of chip component lifted 11. SMT component pin offset: side offset less than or equal to 1/2 of the solderable end width 12. SMT component floating high: distance between component bottom and substrate < 1mm 13. SMT component pin high lift: height lifted greater than the thickness of the component pin 14. SMT component pin not flat: pin not soldered 15. SMT component not identifiable (printing unclear) 16. SMT component pin or body oxidized 17. SMT component body damaged: capacitor damaged (MA); resistor damaged less than 1/4 of the component width or thickness (MI); IC damaged in any direction length < 1.5mm (MI), exposing internal material (MA) 18. SMT component using non-designated suppliers: according to BOM, ECN 19. SMT component solder joint solder tip: solder tip height greater than component body height 20. SMT component insufficient solder: minimum solder joint height less than solder thickness plus solderable end height of 25% or solder thickness plus 0.5mm, whichever is smaller (MA) 21. SMT component excessive solder: maximum solder joint height exceeding the pad or creeping to the top of the metal plating end cap is acceptable, solder touching the component body (MA) 22. Solder balls/solder dross: more than 5 solder balls or solder splashes (0.13mm or smaller) per 600mm2 is (MA) 23. Solder joint has pinholes/blowholes: one solder joint has one (or more) is (MI) 24. Crystallization phenomenon: white residue on the PCB surface, solder terminals, or around terminals, white crystallization on the metal surface 25. PCB surface not clean: uncleanliness not discovered within 30 seconds at arm’s length is acceptable 26. Poor glue dispensing: adhesive located in the solder area, reducing the width of the solderable end by more than 50% 27. PCB copper foil peeling 28. PCB exposed copper: width of exposed copper on the line (gold finger) greater than 0.5mm is (MA) 29. PCB scratches: scratches not reaching the substrate 30. PCB yellowing: PCB has burnt yellowing after passing through the reflow oven or repair, differing from the PCB color 31. PCB bending: any direction bending deformation exceeding 1mm (300:1) for every 300mm is (MA) 32. PCB inner layer separation (bubbles): areas with bubbling and layering not exceeding 25% of the distance between plated holes or internal wires (MI); bubbling between plated holes or internal wires (MA) 33. PCB contaminated with foreign matter: conductive (MA); non-conductive (MI) 34. PCB version error: according to BOM, ECN 35. Gold finger soldering: soldering position falling within 80% from the edge of the board is (MA)

Inspection Standards for PCBA Boards in SMT Assembly Workshops3. Inspection Standards for PCBA Boards in SMT Assembly Workshops 01. SMT component solder joint open solder 02. SMT component solder joint cold solder: If the component pin can be moved with a toothpick, it is considered cold solder 03. SMT component (solder joint) short circuit (solder bridge) 04. Missing SMT components 05. Incorrect SMT components 06. SMT component polarity reversed or incorrect, causing burning or explosion 07. Multiple SMT components 08. SMT component flipped: text facing down 09. SMT component standing sideways: for chip components, length ≤ 3mm, width ≤ 1.5mm, no more than five (MI) 10. SMT component tombstone: end of chip component lifted 11. SMT component pin offset: side offset less than or equal to 1/2 of the solderable end width 12. SMT component floating high: distance between component bottom and substrate < 1mm 13. SMT component pin high lift: height lifted greater than the thickness of the component pin 14. SMT component pin not flat: pin not soldered 15. SMT component not identifiable (printing unclear) 16. SMT component pin or body oxidized 17. SMT component body damaged: capacitor damaged (MA); resistor damaged less than 1/4 of the component width or thickness (MI); IC damaged in any direction length < 1.5mm (MI), exposing internal material (MA) 18. SMT component using non-designated suppliers: according to BOM, ECN 19. SMT component solder joint solder tip: solder tip height greater than component body height 20. SMT component insufficient solder: minimum solder joint height less than solder thickness plus solderable end height of 25% or solder thickness plus 0.5mm, whichever is smaller (MA) 21. SMT component excessive solder: maximum solder joint height exceeding the pad or creeping to the top of the metal plating end cap is acceptable, solder touching the component body (MA) 22. Solder balls/solder dross: more than 5 solder balls or solder splashes (0.13mm or smaller) per 600mm2 is (MA) 23. Solder joint has pinholes/blowholes: one solder joint has one (or more) is (MI) 24. Crystallization phenomenon: white residue on the PCB surface, solder terminals, or around terminals, white crystallization on the metal surface 25. PCB surface not clean: uncleanliness not discovered within 30 seconds at arm’s length is acceptable 26. Poor glue dispensing: adhesive located in the solder area, reducing the width of the solderable end by more than 50% 27. PCB copper foil peeling 28. PCB exposed copper: width of exposed copper on the line (gold finger) greater than 0.5mm is (MA) 29. PCB scratches: scratches not reaching the substrate 30. PCB yellowing: PCB has burnt yellowing after passing through the reflow oven or repair, differing from the PCB color 31. PCB bending: any direction bending deformation exceeding 1mm (300:1) for every 300mm is (MA) 32. PCB inner layer separation (bubbles): areas with bubbling and layering not exceeding 25% of the distance between plated holes or internal wires (MI); bubbling between plated holes or internal wires (MA) 33. PCB contaminated with foreign matter: conductive (MA); non-conductive (MI) 34. PCB version error: according to BOM, ECN 35. Gold finger soldering: soldering position falling within 80% from the edge of the board is (MA) Inspection Standards for PCBA Boards in DIP Post-Soldering Workshops4. Inspection Standards for PCBA Boards in DIP Post-Soldering Workshops 01. DIP component solder joint open solder 02. DIP component solder joint cold solder: If the component pin can be moved with a toothpick, it is considered cold solder 03. DIP component (solder joint) short circuit (solder bridge) 04. Missing DIP components 05. DIP component lead length: Φ≤0.8mm→lead length less than or equal to 1.5mm; Φ>0.8mm→lead length less than or equal to 2.0mm, except for special lead cutting requirements 06. Incorrect DIP components 07. DIP component polarity reversed or incorrect, causing burning or explosion 08. DIP component pin deformation: pin bent more than 50% of pin thickness 09. DIP component floating high or high lift: refer to IPC-A-610E, depending on assembly and special circumstances 10. DIP component solder joint solder tip: solder tip height greater than 1.5mm 11. DIP component not identifiable (printing unclear) 12. DIP component pin or body oxidized 13. DIP component body damaged: surface damage without exposing the internal metal material of the component 14. DIP component using non-designated suppliers: according to BOM, ECN 15. PTH hole vertical filling and surrounding wetting: at least 75% vertical filling, pin and hole wall at least 270º wetting 16. Solder balls/solder dross: more than 5 solder balls or solder splashes (0.13mm or smaller) per 600mm2 is (MA) 17. Solder joint has pinholes/blowholes: one solder joint has three (or more) is (MI) 18. Crystallization phenomenon: white residue on the PCB surface, solder terminals, or around terminals, white crystallization on the metal surface 19. PCB surface not clean: uncleanliness not discovered within 30 seconds at arm’s length is acceptable 20. Poor glue dispensing: adhesive located in the solder area, reducing the width of the solderable end by more than 50% 21. PCB copper foil peeling 22. PCB exposed copper: width of exposed copper on the line (gold finger) greater than 0.5mm is (MA) 23. PCB scratches: scratches not reaching the substrate 24. PCB yellowing: PCB has burnt yellowing after passing through the reflow oven or repair, differing from the PCB color 25. PCB bending: any direction bending deformation exceeding 1mm (300:1) for every 300mm is (MA) 26. PCB inner layer separation (bubbles): areas with bubbling and layering not exceeding 25% of the distance between plated holes or internal wires (MI); bubbling between plated holes or internal wires (MA) 27. PCB contaminated with foreign matter: conductive (MA); non-conductive (MI) 28. PCB version error: according to BOM, ECN 29. Gold finger soldering: soldering position falling within 80% from the edge of the board is (MA)

Inspection Standards for PCBA Boards in DIP Post-Soldering Workshops4. Inspection Standards for PCBA Boards in DIP Post-Soldering Workshops 01. DIP component solder joint open solder 02. DIP component solder joint cold solder: If the component pin can be moved with a toothpick, it is considered cold solder 03. DIP component (solder joint) short circuit (solder bridge) 04. Missing DIP components 05. DIP component lead length: Φ≤0.8mm→lead length less than or equal to 1.5mm; Φ>0.8mm→lead length less than or equal to 2.0mm, except for special lead cutting requirements 06. Incorrect DIP components 07. DIP component polarity reversed or incorrect, causing burning or explosion 08. DIP component pin deformation: pin bent more than 50% of pin thickness 09. DIP component floating high or high lift: refer to IPC-A-610E, depending on assembly and special circumstances 10. DIP component solder joint solder tip: solder tip height greater than 1.5mm 11. DIP component not identifiable (printing unclear) 12. DIP component pin or body oxidized 13. DIP component body damaged: surface damage without exposing the internal metal material of the component 14. DIP component using non-designated suppliers: according to BOM, ECN 15. PTH hole vertical filling and surrounding wetting: at least 75% vertical filling, pin and hole wall at least 270º wetting 16. Solder balls/solder dross: more than 5 solder balls or solder splashes (0.13mm or smaller) per 600mm2 is (MA) 17. Solder joint has pinholes/blowholes: one solder joint has three (or more) is (MI) 18. Crystallization phenomenon: white residue on the PCB surface, solder terminals, or around terminals, white crystallization on the metal surface 19. PCB surface not clean: uncleanliness not discovered within 30 seconds at arm’s length is acceptable 20. Poor glue dispensing: adhesive located in the solder area, reducing the width of the solderable end by more than 50% 21. PCB copper foil peeling 22. PCB exposed copper: width of exposed copper on the line (gold finger) greater than 0.5mm is (MA) 23. PCB scratches: scratches not reaching the substrate 24. PCB yellowing: PCB has burnt yellowing after passing through the reflow oven or repair, differing from the PCB color 25. PCB bending: any direction bending deformation exceeding 1mm (300:1) for every 300mm is (MA) 26. PCB inner layer separation (bubbles): areas with bubbling and layering not exceeding 25% of the distance between plated holes or internal wires (MI); bubbling between plated holes or internal wires (MA) 27. PCB contaminated with foreign matter: conductive (MA); non-conductive (MI) 28. PCB version error: according to BOM, ECN 29. Gold finger soldering: soldering position falling within 80% from the edge of the board is (MA)

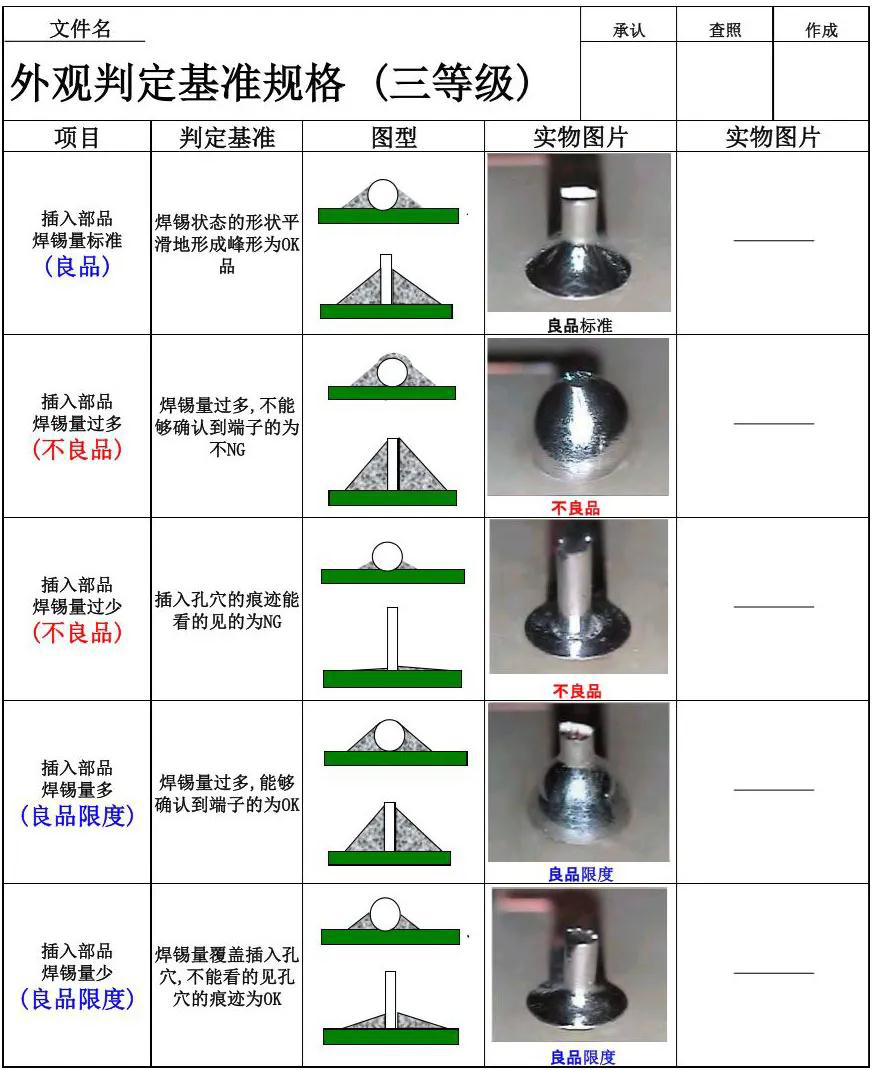

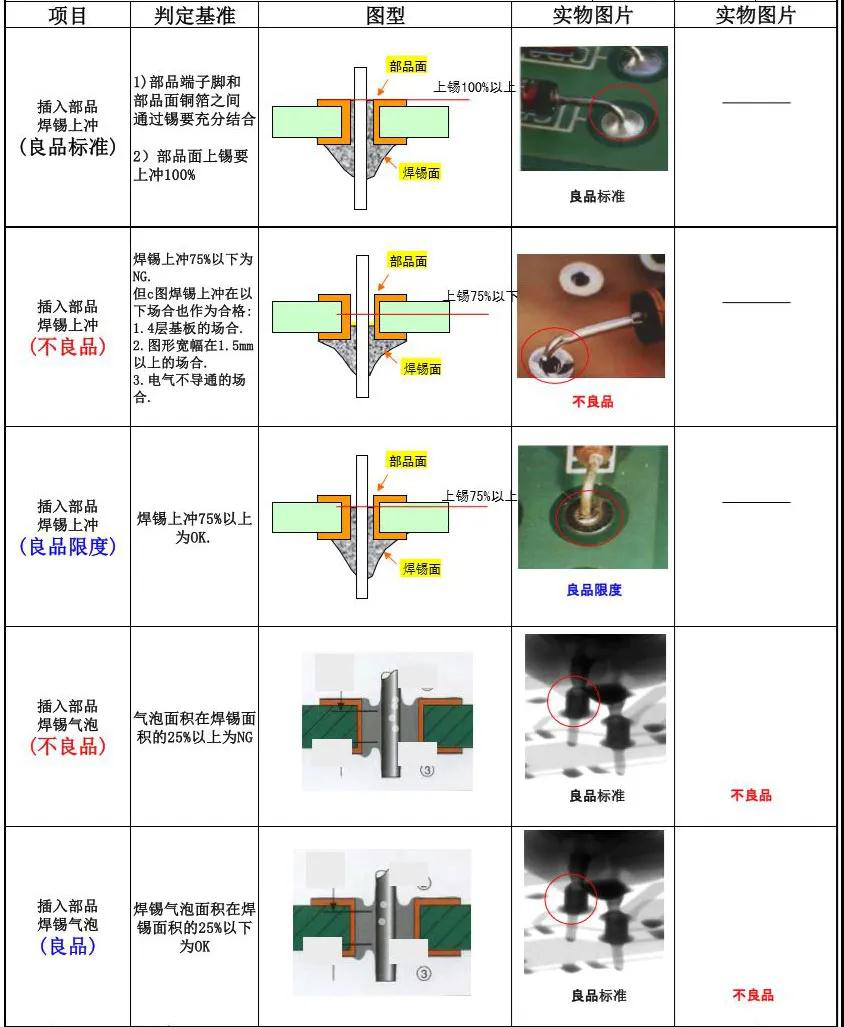

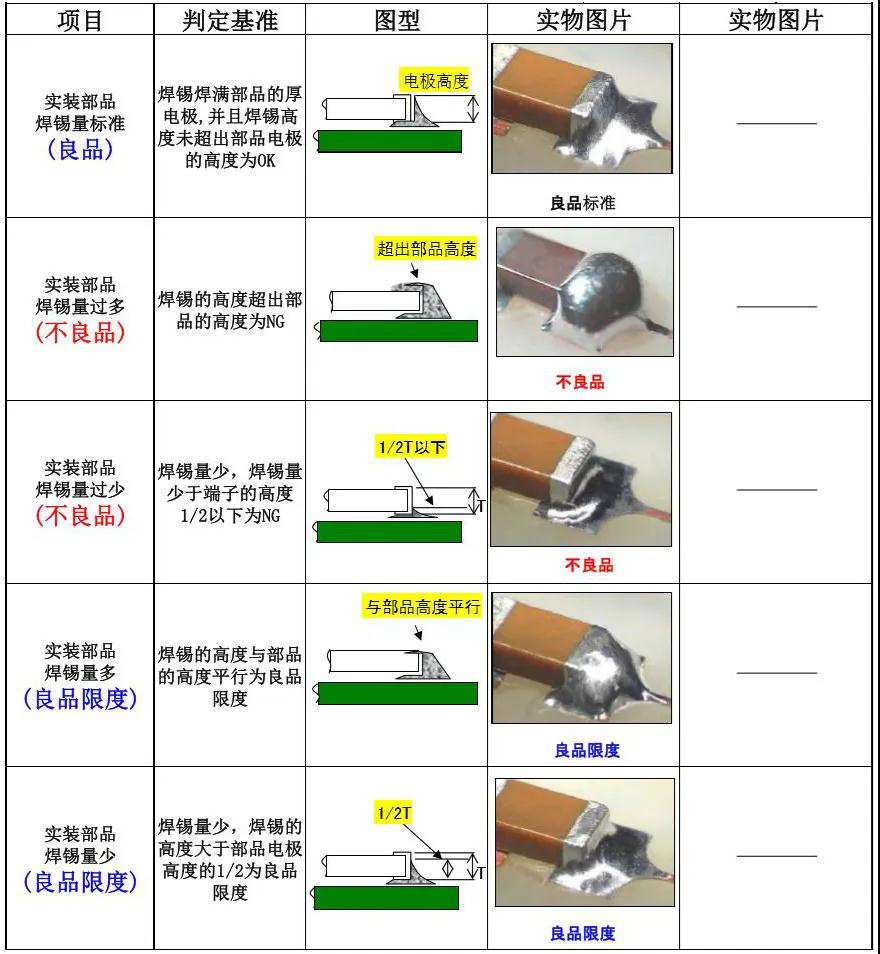

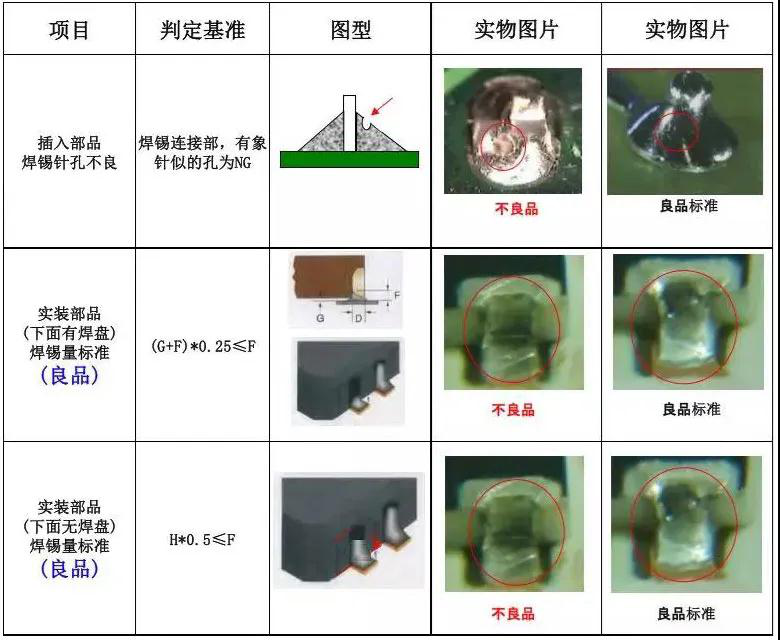

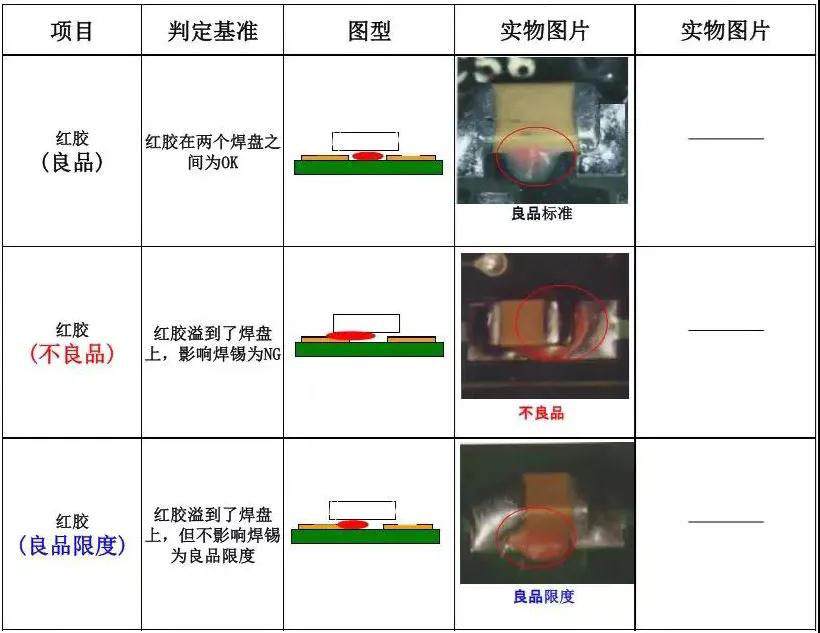

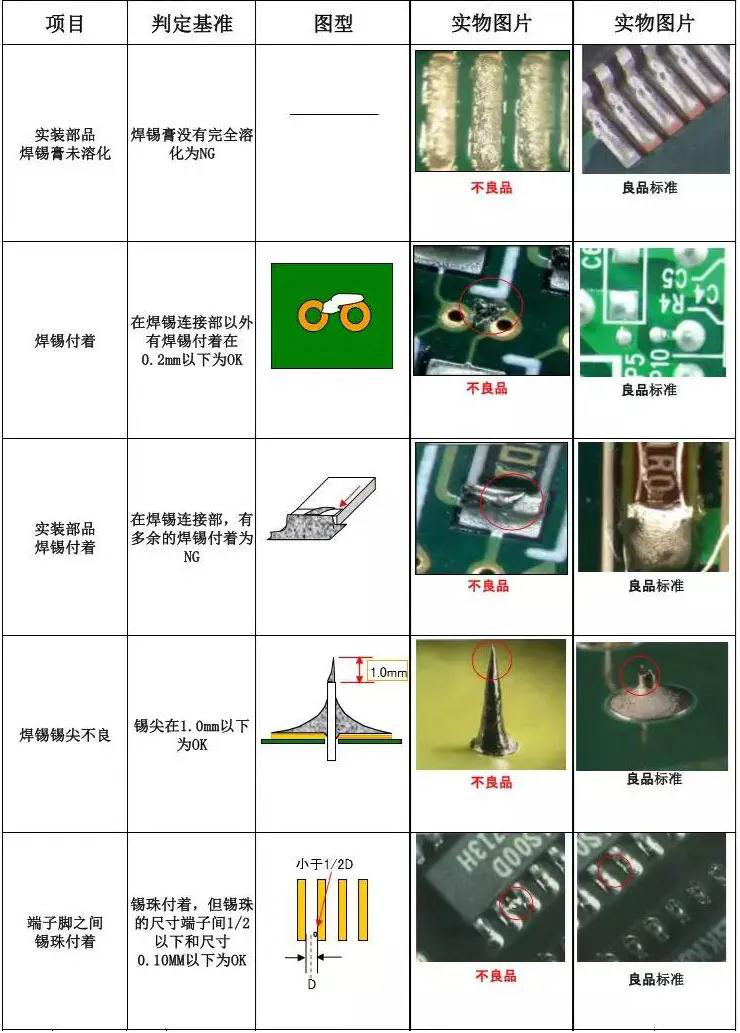

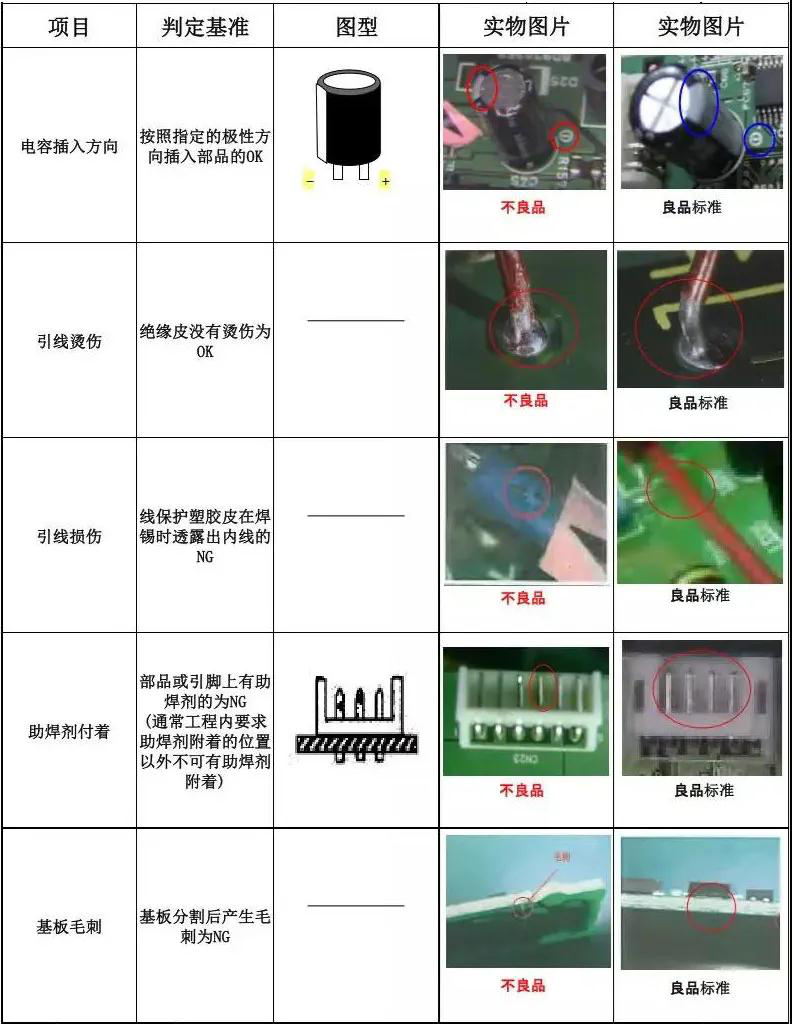

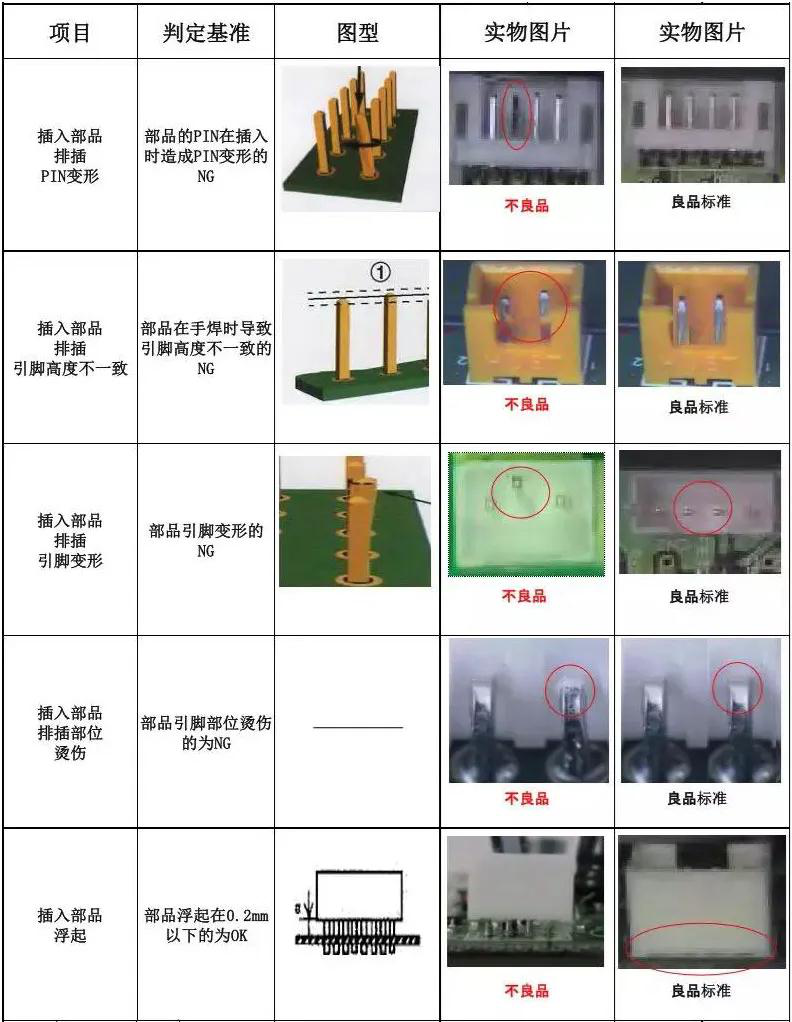

PCBA Appearance Determination Criteria Are as Follows:

Source: SMTJS News; Electronic Craft and Technology;

Editor’s Note Many readers have not yet developed the habit of liking after reading, and we hope everyone will click “ ” after reading and share it to your circle of friends to show encouragement! Persistence is a belief, and focus is an attitude!Disclaimer: The articles published by this public account are original or compiled and edited based on online sources, and the copyright of the articles belongs to the original author. If there are issues regarding the content, copyright, and other matters, please contact us! The content of the article represents the author’s personal views and does not represent the views of this public account. This public account reserves the final interpretation rights of this statement.

” after reading and share it to your circle of friends to show encouragement! Persistence is a belief, and focus is an attitude!Disclaimer: The articles published by this public account are original or compiled and edited based on online sources, and the copyright of the articles belongs to the original author. If there are issues regarding the content, copyright, and other matters, please contact us! The content of the article represents the author’s personal views and does not represent the views of this public account. This public account reserves the final interpretation rights of this statement.

Advertising Product Wealth Promotion Zone