✅ Author Profile: A Matlab simulation developer passionate about scientific research, skilled in data processing, modeling simulation, program design, obtaining complete code, reproducing papers, and scientific simulation.

🍎 Previous reviews, follow the personal homepage:Matlab Research Studio

🍊 Personal motto: Investigate things to gain knowledge, complete Matlab code and simulation consultation content via private message.

Intelligent Optimization Algorithms Neural Network Prediction Radar Communication Wireless Sensors Power Systems

Signal Processing Image Processing Path Planning Cellular Automata Unmanned Aerial Vehicles

Physical Applications Machine Learning Series Workshop Scheduling Series Filtering and Tracking Series Data Analysis Series

Image Processing Series

🔥 Content Introduction

With the rapid development of information technology and the increasing popularity of electronic products, printed circuit boards (PCBs) are core components of electronic products, and their quality directly affects the performance and reliability of the entire system. Traditional PCB inspection mainly relies on manual visual inspection, which suffers from inefficiency, susceptibility to subjective factors, and high missed detection rates. To improve inspection efficiency and accuracy while reducing production costs, intelligent detection systems for circuit boards based on computer vision have emerged and gradually become a trend in the industry. This article will delve into the theoretical basis, key technologies, advantages, and development prospects of intelligent detection systems for circuit boards based on computer vision.

1. Advantages of Computer Vision in PCB Inspection

Computer vision is a scientific field that uses computers and image processing technology to simulate human visual functions. Applying it to PCB inspection can bring the following significant advantages:

- High Efficiency and Automation: Computer vision systems can achieve round-the-clock, high-speed, continuous inspection, significantly improving inspection efficiency, reducing manual intervention, and enabling automated production.

- High Precision and Consistency: Computer vision systems can detect minute defects through precise image processing and pattern recognition algorithms, maintaining consistency in inspection results and effectively reducing false positive and missed detection rates.

- Objectivity: Computer vision systems are not influenced by human factors, allowing for an objective assessment of PCB quality, avoiding subjective biases that may occur in manual inspections.

- Traceability: Computer vision systems can record and store inspection results, facilitating data analysis and quality traceability, providing a basis for improving production processes.

- Cost Reduction: Although the initial investment is high, in the long run, due to reduced labor costs and defect rates, computer vision-based inspection systems can effectively lower production costs.

2. Key Technologies of Intelligent PCB Inspection Systems

Building an efficient and reliable intelligent PCB inspection system based on computer vision requires the integration of various key technologies:

-

Image Acquisition and Preprocessing:

- Image Enhancement: Improving the visual quality of images by adjusting parameters such as contrast and brightness.

- Noise Reduction: Using filters (e.g., Gaussian filter, median filter) to reduce noise in images.

- Image Correction: Correcting image distortions caused by camera distortion, shooting angles, etc.

- Image Segmentation: Segmenting images into different regions, such as background, components, and circuits, for separate processing.

- Image Acquisition: High-quality images are the foundation of inspection. It is necessary to select appropriate industrial cameras, lenses, light sources, and image acquisition cards to ensure clear, stable, high-resolution images while avoiding uneven lighting and noise issues. Different lighting schemes may be required for different types of PCBs, such as backlighting, ring lighting, and coaxial lighting.

- Image Preprocessing: The purpose of image preprocessing is to enhance image quality, laying the groundwork for subsequent feature extraction and defect detection. Common preprocessing techniques include:

Feature Extraction:

Feature extraction refers to extracting representative information from preprocessed images to distinguish between defective and normal areas. Common feature extraction methods include:

- Edge-based Features: Using edge detection algorithms (e.g., Canny operator, Sobel operator) to extract edge information from images for detecting defects such as circuit breaks and missing components.

- Texture-based Features: Using texture analysis methods (e.g., gray-level co-occurrence matrix, Gabor filter) to extract texture features from images for detecting surface scratches and stains.

- Color-based Features: Using color space transformations and color histograms to extract color features from images for detecting color errors in components.

- Shape-based Features: Using shape descriptors (e.g., Hu moments, shape context) to extract shape features from images for detecting deformations and positional shifts of components.

Defect Detection and Classification:

Defect detection and classification are the core processes of the system. The goal is to determine whether defects exist in the image based on the extracted features and classify the defects. Common methods for defect detection and classification include:

- Rule-based Methods: Using predefined rules, such as component size, position, and color, to determine whether defects exist in the image. This method is simple but struggles with complex defect types.

- Statistical Methods: Using statistical models, such as Gaussian mixture models and hidden Markov models, to determine whether defects exist in the image. This method is robust to noise but requires a large amount of training data.

- Machine Learning Methods: Using machine learning algorithms, such as support vector machines (SVM), decision trees, and neural networks, to learn the features of defective and normal areas and perform classification. This method has high accuracy but requires substantial training data and computational resources. Deep learning methods, such as convolutional neural networks (CNN), have shown strong feature learning capabilities and classification performance in PCB defect detection, gradually becoming mainstream. Common CNN architectures include AlexNet, VGGNet, ResNet, etc.

- Template Matching: Using images of standard PCBs as templates to match with the images of the PCBs to be inspected, detecting defects by comparing the differences between the two. This method is suitable for detecting defects in fixed positions.

Defect Localization and Annotation:

The purpose of defect localization and annotation is to determine the location and type of defects in the image, providing information for subsequent repairs and quality analysis. Common methods include:

- Bounding Box Annotation: Using rectangular boxes or other shapes to enclose defect areas.

- Pixel-level Annotation: Classifying each pixel to distinguish between defect pixels and normal pixels.

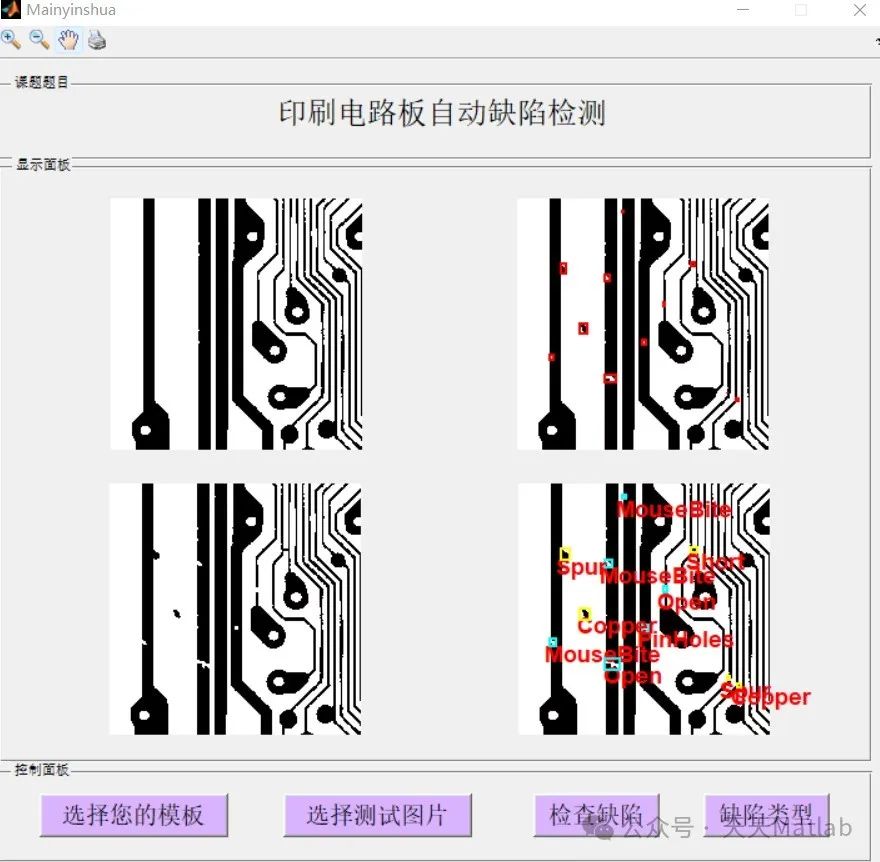

⛳️ Operation Results

🔗 References

📣 Partial Code

🎈 Some theoretical references from online literature, please contact the author for removal if there is any infringement.

👇 Follow me to receive a wealth of Matlab e-books and mathematical modeling materials

🏆 The team specializes in guiding customized MATLAB simulations in various research fields, helping to realize research dreams:

🌈 Various intelligent optimization algorithm improvements and applications

Production scheduling, economic scheduling, assembly line scheduling, charging optimization, workshop scheduling, departure optimization, reservoir scheduling, 3D packing, logistics site selection, cargo location optimization, bus scheduling optimization, charging pile layout optimization, workshop layout optimization, container ship loading optimization, pump combination optimization, medical resource allocation optimization, facility layout optimization, visual domain base station and drone site selection optimization, knapsack problem, wind farm layout, time slot allocation optimization, optimal distributed generation unit allocation, multi-stage pipeline maintenance, factory-center-demand point three-level site selection problem, emergency material distribution center site selection, base station site selection, road lamp post arrangement, hub node deployment, transmission line typhoon monitoring devices, container scheduling, unit optimization, investment optimization portfolio, cloud server combination optimization, antenna linear array distribution optimization, CVRP problem, VRPPD problem, multi-center VRP problem, multi-layer network VRP problem, multi-center multi-vehicle VRP problem, dynamic VRP problem, two-layer vehicle routing planning (2E-VRP), electric vehicle routing planning (EVRP), oil-electric hybrid vehicle routing planning, hybrid flow shop problem, order splitting scheduling problem, bus scheduling optimization problem, flight shuttle vehicle scheduling problem, site selection path planning problem, port scheduling, port shore bridge scheduling, parking space allocation, airport flight scheduling, leak source localization

🌈 Time series, regression, classification, clustering, and dimensionality reduction in machine learning and deep learning

2.1 BP time series, regression prediction, and classification

2.2 ENS voice neural network time series, regression prediction, and classification

2.3 SVM/CNN-SVM/LSSVM/RVM support vector machine series time series, regression prediction, and classification

2.4 CNN|TCN|GCN convolutional neural network series time series, regression prediction, and classification

2.5 ELM/KELM/RELM/DELM extreme learning machine series time series, regression prediction, and classification

2.6 GRU/Bi-GRU/CNN-GRU/CNN-BiGRU gated neural network time series, regression prediction, and classification

2.7 Elman recurrent neural network time series, regression prediction, and classification

2.8 LSTM/BiLSTM/CNN-LSTM/CNN-BiLSTM long short-term memory neural network series time series, regression prediction, and classification

2.9 RBF radial basis function neural network time series, regression prediction, and classification

2.10 DBN deep belief network time series, regression prediction, and classification

2.11 FNN fuzzy neural network time series, regression prediction

2.12 RF random forest time series, regression prediction, and classification

2.13 BLS broad learning system time series, regression prediction, and classification

2.14 PNN pulse neural network classification

2.15 Fuzzy wavelet neural network prediction and classification

2.16 Time series, regression prediction, and classification

2.17 Time series, regression prediction, and classification

2.18 XGBOOST ensemble learning time series, regression prediction, and classification

2.19 Transform various combinations time series, regression prediction, and classification

Directions cover wind power prediction, photovoltaic prediction, battery life prediction, radiation source identification, traffic flow prediction, load prediction, stock price prediction, PM2.5 concentration prediction, battery health status prediction, electricity consumption prediction, water body optical parameter inversion, NLOS signal recognition, precise prediction of subway stops, transformer fault diagnosis

🌈 In image processing

Image recognition, image segmentation, image detection, image hiding, image registration, image stitching, image fusion, image enhancement, image compressed sensing

🌈 In path planning

Traveling salesman problem (TSP), vehicle routing problem (VRP, MVRP, CVRP, VRPTW, etc.), UAV three-dimensional path planning, UAV collaboration, UAV formation, robot path planning, grid map path planning, multimodal transport problems, electric vehicle routing planning (EVRP), two-layer vehicle routing planning (2E-VRP), oil-electric hybrid vehicle routing planning, ship trajectory planning, full path planning, warehouse patrol

🌈 In UAV applications

UAV path planning, UAV control, UAV formation, UAV collaboration, UAV task allocation, UAV secure communication trajectory online optimization, vehicle collaborative UAV path planning

🌈 In communication

Sensor deployment optimization, communication protocol optimization, routing optimization, target localization optimization, Dv-Hop localization optimization, Leach protocol optimization, WSN coverage optimization, multicast optimization, RSSI localization optimization, underwater communication, communication upload and download allocation

🌈 In signal processing

Signal recognition, signal encryption, signal denoising, signal enhancement, radar signal processing, signal watermark embedding and extraction, electromyography signals, electroencephalography signals, signal timing optimization, electrocardiogram signals, DOA estimation, encoding and decoding, variational mode decomposition, pipeline leakage, filters, digital signal processing + transmission + analysis + denoising, digital signal modulation, bit error rate, signal estimation, DTMF, signal detection

🌈 In power systems

Microgrid optimization, reactive power optimization, distribution network reconstruction, energy storage configuration, orderly charging, MPPT optimization, household electricity

🌈 In cellular automata

Traffic flow, crowd evacuation, virus spread, crystal growth, metal corrosion

🌈 In radar

Kalman filter tracking, trajectory association, trajectory fusion, SOC estimation, array optimization, NLOS recognition

🌈 Workshop scheduling

Zero-wait flow shop scheduling problem (NWFSP) , Permutation flow shop scheduling problem (PFSP) , Hybrid flow shop scheduling problem (HFSP) , zero idle flow shop scheduling problem (NIFSP), distributed permutation flow shop scheduling problem (DPFSP), blocking flow shop scheduling problem (BFSP)

👇