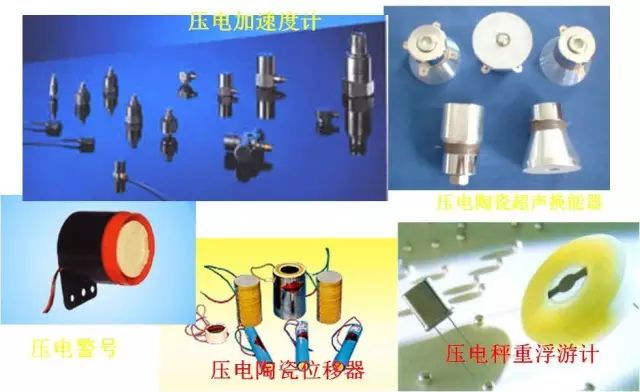

Piezoelectric sensors can measure various dynamic forces, mechanical impacts, and vibrations, and are widely used in acoustics, medicine, mechanics, and navigation. They are characterized by their small size, light weight, high frequency response, and large signal-to-noise ratio.

Piezoelectric Sensor

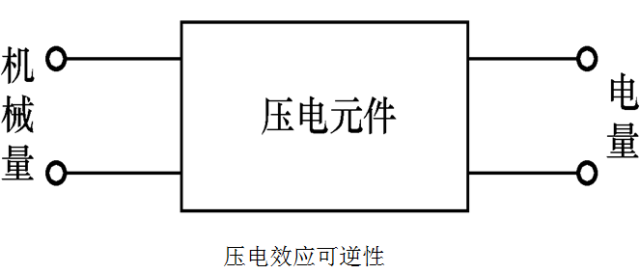

The working principle of piezoelectric sensors is based on the piezoelectric effect of certain dielectric materials, making them typical active sensors. When the material is deformed by applied force, electric charges are generated on its surface, enabling the measurement of non-electric quantities.

Piezoelectric Effect

Certain dielectrics, when subjected to force along a specific direction causing deformation, generate a polarization phenomenon within them, resulting in opposite charges on their two surfaces. When the external force is removed, they return to a non-charged state. This phenomenon is known as the piezoelectric effect. Conversely, when an electric field is applied in the direction of polarization, these dielectrics will also deform, a phenomenon known as the “inverse piezoelectric effect” (electrostriction).

Piezoelectric Materials

Quartz crystals, barium titanate, and lead zirconate titanate are excellent piezoelectric materials. The piezoelectric element materials used in piezoelectric sensors generally fall into three categories: piezoelectric crystals, polarized piezoelectric ceramics, and new piezoelectric materials.

All of them have a large piezoelectric constant, good mechanical properties, time stability, and temperature stability, making them ideal piezoelectric materials.

1. Piezoelectric Crystals

Natural quartz crystal shape

Quartz crystal slices and packaging

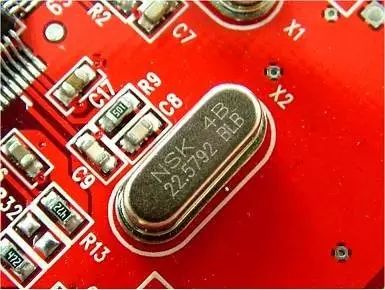

Quartz crystals work in oscillating circuits, where the piezoelectric effect and inverse piezoelectric effect alternate, producing a stable oscillation output frequency.

Quartz crystal oscillator (crystal oscillator)

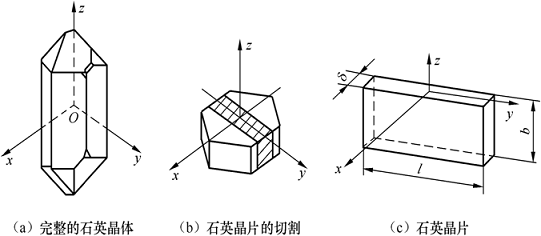

Quartz crystal is a widely used piezoelectric crystal. It is a single crystal of silicon dioxide and belongs to the hexagonal crystal system. It has a regular hexagonal prism shape. Quartz crystal has three crystal axes: the x-axis, y-axis, and z-axis. The vz-axis is also known as the optical axis, which aligns with the longitudinal axis of the crystal; the x-axis is known as the electric axis, which passes through the two edge lines of the hexagonal prism and is perpendicular to the optical axis; the y-axis is known as the mechanical axis, which is perpendicular to the two opposite pillar edge faces.

The piezoelectric effect of quartz crystal is related to its internal structure, and the mechanism of generating polarization can be explained. The chemical formula of quartz crystal is SiO2, which contains three silicon ions and six oxygen ions in each unit cell, with one silicon ion alternating with two oxygen ions (the oxygen ions appear in pairs). Viewed along the optical axis, it can be equivalently considered as a regular hexagonal arrangement.

In the figure, 1—Positive charge equivalent center 2—Negative charge equivalent center

(1) When there is no external force

(2) When the crystal is subjected to pressure along the electric axis (x-axis), the lattice deforms

(3) Similarly, when the crystal is subjected to pressure along the mechanical axis (y-axis), the lattice also deforms

(4) When the crystal is subjected to force along the optical axis (z-axis), due to the deformation of the lattice, there is no separation of positive and negative charge centers, thus no piezoelectric effect is generated.

When force is applied along the mechanical axis direction, the generated charge is related to the geometric size of the crystal surface, and the negative sign indicates that the charge polarity caused by pressure along the mechanical axis is exactly opposite to that caused by pressure along the electric axis.

2. Piezoelectric Ceramics

Piezoelectric ceramics are artificially manufactured polycrystalline piezoelectric materials. The internal grains of the material have many spontaneously polarized electric domains with a certain polarization direction, thus producing an electric field. In the absence of an external electric field, the electric domains are randomly distributed within the crystal, and their respective polarization effects cancel each other out, resulting in zero polarization strength within the piezoelectric ceramic. Therefore, original piezoelectric ceramics are neutral and do not exhibit piezoelectric properties.

When an external electric field is applied to the ceramic, the polarization direction of the electric domains rotates, aligning themselves in the direction of the external electric field, thereby polarizing the material. The stronger the external electric field, the more completely the electric domains align with the direction of the external electric field. When the external electric field is strong enough to saturate the material’s polarization, meaning all electric domains’ polarization directions are neatly aligned with the external electric field direction, once the external electric field is removed, the polarization direction of the electric domains remains largely unchanged, resulting in a significant remaining polarization strength, and the material then exhibits piezoelectric characteristics.

Polarization of piezoelectric ceramics (a) Unpolarized; (b) Polarized

The piezoelectric coefficient of piezoelectric ceramics is much larger than that of quartz crystals, so piezoelectric sensors made from piezoelectric ceramics have higher sensitivity. The remaining polarization strength and characteristics of polarized piezoelectric ceramic materials are temperature-dependent, and their parameters also change over time, which weakens their piezoelectric characteristics.

3. New Piezoelectric Materials

Piezoelectric Films

(1) Piezoelectric Semiconductor Materials

Piezoelectric semiconductor materials include ZnO, CdS (cadmium sulfide), CdTe (cadmium telluride), etc. These force-sensitive devices have advantages such as high sensitivity and short response time. Additionally, ZnO can be used as piezoelectric material for surface acoustic wave oscillators to detect parameters like force and temperature.

(2) Polymer Piezoelectric Materials

Certain synthetic polymer films, after being stretched and polarized by an electric field, exhibit some piezoelectric properties; these films are referred to as polymer piezoelectric films. Currently available piezoelectric films include polyvinylidene fluoride (PVF2), polyvinyl fluoride (PVF), polyvinyl chloride (PVC), and poly-γ-methyl-L-glutamate (PMG). Polymer piezoelectric materials are soft, not easily broken, can be mass-produced, and made into larger areas.

4. Main Characteristic Parameters of Piezoelectric Materials

1) Piezoelectric Constant: The piezoelectric constant measures the strength of the piezoelectric effect in materials, directly relating to the sensitivity of the piezoelectric output.

2) Elastic Constant: The elastic constant and rigidity of piezoelectric materials determine the inherent frequency and dynamic characteristics of piezoelectric devices.

3) Dielectric Constant: For piezoelectric elements of a certain shape and size, their inherent capacitance is related to the dielectric constant; the inherent capacitance also affects the frequency lower limit of piezoelectric sensors.

4) Mechanical Coupling Coefficient: In the piezoelectric effect, its value equals the square root of the ratio of output energy (such as electrical energy) to input energy (such as mechanical energy); it is an important parameter for measuring the energy conversion efficiency of piezoelectric materials.

5) Insulation Resistance of Piezoelectric Materials: Reducing charge leakage improves the low-frequency characteristics of piezoelectric sensors.

6) Curie Point: The temperature at which piezoelectric materials begin to lose their piezoelectric characteristics is called the Curie point.

Measurement Circuit of Piezoelectric Sensors

1. Equivalent Circuit of Piezoelectric Sensors

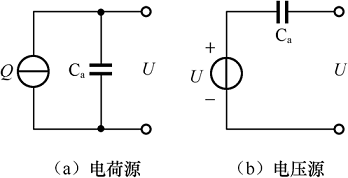

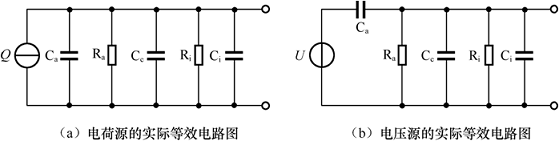

When the two crystal surfaces generating charge of the piezoelectric chip are encapsulated with metallic electrodes, it forms a piezoelectric element. When the piezoelectric element is subjected to force, charges will generate on the two electrodes, thus the piezoelectric element acts as a charge source; the two electrodes are insulated piezoelectric dielectrics, making it equivalent to a capacitor with piezoelectric material as the dielectric, with capacitance value Ca = εRε0A/δ

The piezoelectric element is equivalent to a charge source in parallel with a capacitor, or can also be equivalent to a voltage source in series with a capacitor.

Piezoelectric sensors cannot be used for static measurements. The piezoelectric element only generates continuous charges under alternating forces, providing a certain current to the measurement circuit, thus only suitable for dynamic measurements.

2. Measurement Circuit of Piezoelectric Sensors

Piezoelectric sensors have high internal resistance, requiring coordination with a high input impedance preamplifier circuit, connecting with general amplification, detection, display, and recording circuits to prevent rapid charge leakage, thereby reducing measurement errors.

The role of the preamplifier for piezoelectric sensors has two aspects: first, to convert the sensor’s high impedance output into low impedance output; second, to amplify the sensor’s weak signal.

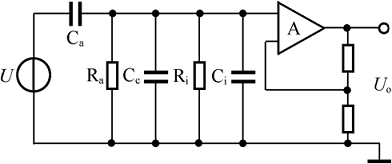

According to the working principle and equivalent circuit of piezoelectric sensors, their output can be either charge signals or voltage signals, thus the accompanying preamplifier can also be in the form of charge amplifiers or voltage amplifiers.

Due to the output voltage of voltage preamplifiers being related to cable capacitance, charge amplifiers are currently more commonly used.

(1) Charge Amplifier

Parallel output piezoelectric elements can be equivalent to a charge source. The charge amplifier is essentially a high-gain operational amplifier circuit with feedback capacitance Cf.

Charge amplifier schematic diagram

The output voltage of the charge amplifier is only related to the input charge and feedback capacitance, and the influence of cable capacitance and other factors can be ignored.

(2) Voltage Amplifier (Impedance Converter)

Series output piezoelectric elements can be equivalent to a voltage source, but due to the small capacitance caused by the piezoelectric effect, their equivalent internal resistance is very large. When connected to a voltage output measurement circuit, the preamplifier must not only have sufficient amplification but also a very high input impedance.

Applications of Piezoelectric Sensors

1. Glass Breakage Alarm Device

By attaching a polymer piezoelectric vibration film to glass, vibrations produced when the glass breaks can be detected, and the voltage signal transmitted to a centralized alarm system.

A PVDF film about 0.2mm thick is cut to a size of 10´20mm. Transparent tin oxide conductive electrodes are sprayed on both sides, and two flexible electrode leads are ultrasonically welded. Finally, a protective film is applied.

During use, it is glued to the glass with instant adhesive. When the glass is violently shattered, the piezoelectric film senses the intense vibration, generating charge Q and producing a narrow pulse alarm signal between the two output leads.

Piezoelectric sensors can only be used for dynamic measurements. The charge produced by the external force on the piezoelectric element can only be retained under conditions of no leakage, meaning the measurement circuit must have infinite input impedance, which is practically impossible. Therefore, piezoelectric sensors cannot be used for static measurements. The piezoelectric element can continuously replenish charge under alternating forces, providing a certain current to the measurement circuit, thus only suitable for dynamic measurements (generally must be above 100Hz, but sensitivity decreases above 50kHz).

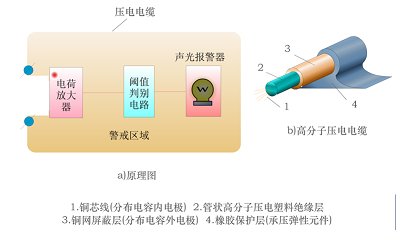

2. Piezoelectric Perimeter Alarm System

Long piezoelectric cables buried in the shallow soil can act as distributed underground microphones or listening devices, capable of detecting human footsteps within dozens of meters, and can also differentiate wheeled or tracked vehicles through a signal processing system. The following figure shows the output waveform of the measurement system.

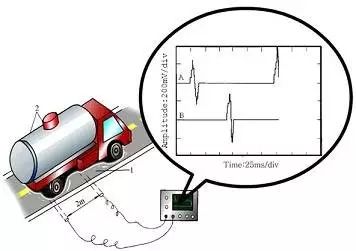

3. Traffic Monitoring

By burying polymer piezoelectric cables on the road, vehicle classification information (including axle count, wheelbase, track width, single or double tires), speed monitoring, weight measurement at toll booths, red-light violation photography, parking area monitoring, traffic data collection (road monitoring), and airport taxiway monitoring can be obtained.

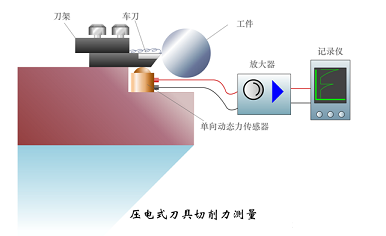

4. Piezoelectric Dynamic Force Sensors

Used in lathes for measuring dynamic cutting forces.

5. Piezoelectric Vibration Acceleration Sensors

Acceleration sensors can be used to determine vehicle collisions, allowing airbags to inflate rapidly, thus saving lives; they can also be installed on the side walls of cylinders to ensure that the ignition timing approaches the knock zone without causing knocking, while maximizing engine torque output.

The ignition timing of the cylinder in an automobile engine must be very precise. If the ignition timing is advanced correctly, there will be an advance angle, allowing the mixture of gasoline and air in the cylinder to burn fully, increasing torque and reducing emissions. However, if the advance angle is too large, the mixture can auto-ignite, creating shock waves and a sharp metallic knocking sound known as knocking, which can damage spark plugs, piston rings, and overload or deform components like cylinder heads, connecting rods, and crankshafts, which can be detected and controlled using piezoelectric sensors.

Toward Miniaturization and Intelligence

Current large precision systems pay great attention to quality and size. Traditional bulky piezoelectric sensors will gradually lose their market. With the development of new materials and processing technologies, silicon acceleration sensors made using laser and various micro-processing technologies, due to their very small size, interchangeability, and reliability, are gradually replacing traditional piezoelectric sensors.

The functions of piezoelectric sensors have surpassed traditional capabilities; their output is no longer a single analog signal, but a digital signal processed by microcomputers. Some piezoelectric sensors, such as integrated piezoelectric sensors, come with control functions, which are referred to as digital sensors.

As modern semiconductor technology becomes increasingly advanced and mature, future piezoelectric acceleration sensors will be integrated with subsequent processing circuits, resulting in smaller sizes and better performance.

Source: Sensor Technology

END

Hot Articles (Swipe Up to Read)

Article Recommendation | Zhang Zhen: Application of Industrial CT in Aviation Industry

Article Recommendation | Zhu Chen: Research on Improved Algorithm for SLAM Loop Detection Based on Binocular Cameras

Article Recommendation | Sun Yu: Application Research of New Fiber Optic Sensors in Pipeline Leakage Monitoring

Article Recommendation | Xiong Yunong: A Visual Measurement Technology Based on Target Recognition and Positioning Algorithm

Article Recommendation | Zhou Yitian: Bearing Fault Diagnosis Model Based on Feature-Extended CapsNet

Article Recommendation | Wang Hong: Embedded Online Monitoring Technology for Foreign Avionics Systems

Article Recommendation | Wang Bin: 3D Measurement of Ice Formation Based on Line Structured Light Scanning

Article Recommendation | Jia Funian: Design and Verification of High Altitude Air Inlet Device for Turbo Shaft Engine

Article Recommendation | Yan Bo: Research on Oxygen Partial Pressure of Al2O3 High-Temperature Insulating Films Based on Dual Ion Beam Sputtering

Article Recommendation | Wang Hong: Test and Measurement Technology System Architecture for Civil Aircraft

Article Recommendation | Zhang Shuai: Research on NARX Neural Network-Assisted Combined Navigation Method

Article Recommendation | Wu Zhen: Design of Autonomous Flight Path Planning Platform for Drones

Article Recommendation | Zhao Xiaoping: Gearbox Fault Diagnosis Method Based on Information Fusion and CNN

Article Recommendation | Shi Yucheng: Analysis of Shock Wave Pressure Measurement and Sensor Technology Status in Explosion Fields

Article Recommendation | Meng Chihua: Arc Simulation Research Based on Aviation Exchange Fault Arc Standard

Article Recommendation | Wu Zheming: Correlation Analysis of Component Failures in Multi-Electric Aircraft Starter Generator Systems Based on DEMATEL

Article Recommendation | Lü Zuopeng: Application of HHT Time-Frequency Analysis Method Based on Wavelet Packets and EMD in Bearing Fault Diagnosis of Aviation Test Equipment

Article Recommendation | Wang Hong: Intelligent Testing and Monitoring Technology for Aviation Onboard Systems

Article Recommendation | Xin Wenhui: Dual Closed-Loop Temperature Control System for Semiconductor Lasers

Article Recommendation | Li Dapeng: Atmospheric Parameter In Situ Detection System and Experiment Based on Airship

Article Recommendation | Jiao Xiaofeng: Overview of CO2 Detection Technology Based on TDLAS

Article Recommendation | Chen Haiming: Online Calibration Method for Magnetic Sensors in Backup Attitude Systems

Article Recommendation | Ren Dantong: Behavior Recognition Method for Workshop Personnel in Smart Factories Based on Dual Light Fusion

Article Recommendation | Li Shuhao: Application Research of Integrated Monitoring Technology in Bearing Fault Diagnosis

Article Recommendation | Zhuo Li: Multi-Attribute Collaborative Recognition Method for Pedestrians Based on ResNet50 and Channel Attention Mechanism

Article Recommendation | Liang Minjian: Research on Mechanical Fault Classification of Escalators Based on One-Dimensional Convolutional Neural Networks

Article Recommendation | Hou Qilin: Research on Remaining Useful Life Prediction of Aviation Lithium Batteries Based on Indirect Health Indicators and Echo State Networks

Article Recommendation | Chen Peng: An End-to-End Model for Text Detection and Recognition in Natural Scenes

Article Recommendation | Hou Feng: Remote Sensing Image Retrieval Based on Deep Feature Dictionary Learning and Largevis

Article Recommendation | Wang Xinyao: Global Inertial Navigation and Combined Navigation Method Based on Earth Coordinate System

Article Recommendation | Chen Lijing: Fault Diagnosis of Aviation Inverters Based on Multi-Class SVM

Article Recommendation | Li Mingfei: Discussion on Image Enhancement and Flow Field Density Processing of Blade Pattern Shadow Test

Article Recommendation | Liu Qiuyu: Flexible Pressure Sensor Based on Capacitive-Resistive Conversion Principle

Article Recommendation | Li Lei: Research on Data-Driven Fault Prediction Methods

Article Recommendation | Yan Junjie: Automated Precision Assembly Technology for Satellite Antenna Modules Based on Machine Vision

Article Recommendation | Yao Yanling: Research on Surge Diagnosis Model of Aviation Engines Based on CNN-Seq2Seq

Article Recommendation | Guan Li: Review of Electro-Hydraulic Actuation Technology for Aircraft Flight Control Systems

Article Recommendation | He Yunze: Analysis of Acoustic Emission Signals of Power Devices in Inverter Circuits

Article Recommendation | Xie Li: Circuit Board Component Defect Detection Based on Improved YOLOv4 Network

Article Recommendation | Wang Yizhou: Short Video Fingerprint Extraction Based on R(2+1)D Twin Networks

Article Recommendation | Han Han: Overview of No-Reference Image Quality Assessment Based on Deep Learning

Article Recommendation | Wang Jiulong: Research on Fatigue Testing Technology of Helicopter Tail Rotor Blades

Article Recommendation | Sun Weihong: Research on Portable ECG Monitoring System Based on Flexible Electrodes

Article Recommendation | Zhang Meiju: Research Status and Development Trends of Ceramic Substrate Thin Film Thermocouples

Article Recommendation | Ouyang Lin: Fatigue Driving Detection Algorithm Based on Driver’s Facial Temporal Data

Article Recommendation | Zhang Wenli: Multi-Target Tracking Algorithm Based on Improved Transformer with Anchor-Free Network

Article Recommendation | Liu Juanjuan: Research Progress of Silicon-Based and Graphene-Based Resonant Pressure Sensors

Article Recommendation | Jiang Chao: Overview of Image-Based Battlefield Situation Awareness Technology for Drones

Article Recommendation | Zhang Feiyang: Overview of Alertness Detection Research Based on Physiological Signals

Article Recommendation | Qiu Fang: Research on Autonomous Management Software Architecture for Spacecraft Control Systems in Deep Space Exploration

Article Recommendation | Wang Yanshan: Research Progress of Flexible Pressure/Strain Sensors Based on Graphene

Article Recommendation | Wang Hong: Research on Testing Technology System Architecture for Civil Aircraft

Article Recommendation | Liu Yawei: Overview of Digital Twin and Its Application Research for Structural Health Management of Aircraft

Journal Dynamics (Swipe Up to Read)

Notice for Contributions to “Measurement and Control Technology” Special Column on Gas Turbine Engine Measurement and Control Technology

“Measurement and Control Technology” continues to be selected as a “Core Journal of China Science and Technology”

Journal Directory (Swipe Up to Read)

2023 Issue 4 Special Issue on Force Tactile Technology

2023 Issue 3

2023 Issue 2

2023 Issue 1

2022 Issue 12

2022 Issue 11

2022 Issue 10 Special Issue on Intelligent Testing Technology for Onboard Systems

2022 Issue 9 Special Issue on Advanced Sensors and Atmospheric/Meteorological Measurement Technology

2022 Issue 8

2022 Issue 7

2022 Issue 6

2022 Issue 5

2022 Issue 4

2022 Issue 3

2022 Issue 2

2022 Issue 1