“PLC Automation Testing: Scripted Solutions, Efficiency Soars by 80%! Say Goodbye to Overtime!”

Hello everyone! Today, let’s talk about a problem that makes engineers’ heads hurt—PLC testing that goes on until the wee hours, and still ends up with unexpected issues. Are you also on the verge of collapse? Don’t panic! Today’s trick, “scripted testing,” is like installing autopilot on your PLC, allowing you to say goodbye to manual operations and directly boost your efficiency!

Bloody lessons: How pitiful is manual testing?

A real-life account from an auto parts factory: Missing a signal point during manual testing caused the entire production line to stop for 8 hours, resulting in a direct loss of 150,000! The boss’s face was redder than the PLC alarm light.

A series of tragedies in a food factory: A worker mistakenly entered the wrong parameters, causing the filling line to spray yogurt everywhere, with cleaning costs exceeding equipment repair costs… (Don’t ask, just know the workshop turned into a yogurt bath.)

A midnight scare in an electronics factory: A tester stayed up late modifying code, and with a shaky hand, wrote “0” instead of “1,” burning three PLC mainboards, enough repair costs to buy a Wuling Hongguang!

Three-tier rocket-style scripting solution: Even the lazy can master testing

First layer: Basic script library (a must-see for beginners)

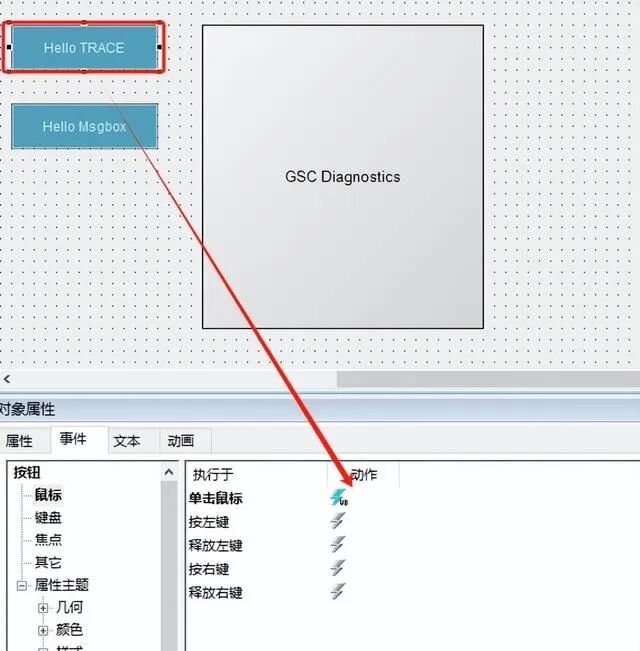

VBS script toolkit: Just copy the homework! For example, using HMIRuntime.Trace to output debug logs is 100 times easier than staring at the screen counting signal lights.

Universal C script template: printf(“Current pressure value: %f”, pressure variable), real-time data monitoring without even blinking!

Second layer: Variable simulator (the cheat tool)

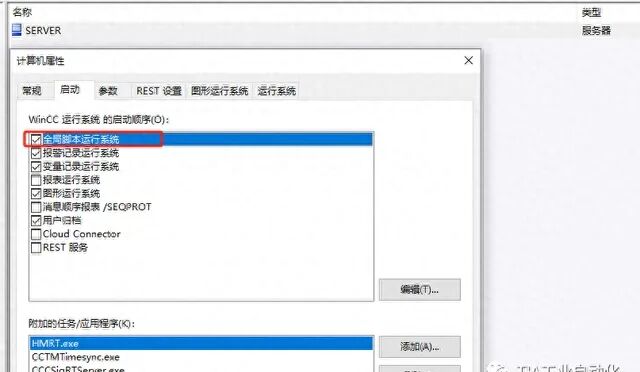

The built-in simulator in WinCC is your “stand-in actor”! No need to connect real devices, directly simulate thousands of variables, saving even the PLC boot time.

Secret: Check “Quality Code” to simulate abnormal states, practicing communication interruptions and data overflows in advance!

Third layer: Automated testing framework (exclusive for experts)

Three-piece set: script + simulator + automated work order, a complete testing assembly line.

For example:

Scripts automatically generate test cases (no need to open Excel)

Simulators can push extreme values (create anything from -100℃ to 200℃)

The work order system automatically sends reports (can even include the line graphs that the boss loves!)

Pitfall guide: Avoid these traps!

❗ Bloody case 1: A factory used UDP protocol to transmit data, resulting in packet loss due to workshop WiFi interference, making test results more random than rolling dice! 👉 Solution: TCP protocol + heartbeat packet detection, stable as a rock!

❗ Bloody case 2: An engineer forgot to close the debug window, causing alarms to pop up wildly during production, almost leading to a computer being smashed! 👉 Remember: Before formal operation, disable Msgbox and switch to log files!

Let’s do the math: The boss exclaimed it was truly fragrant

(Data from a major appliance manufacturer: Fault diagnosis time reduced from 2 hours a day to 10 minutes, allowing engineers to finally leave work on time!)

Five-step roadmap to get started

Baseline test: Thoroughly analyze the existing testing process (list out pain points!)

Tool selection: If VBS is sufficient, don’t switch to C#, fully utilize the built-in features of WinCC!

Small trial: Choose a simple workstation for a pilot test (like testing the start and stop of a conveyor belt)

Copy and paste: Directly apply successful cases to other production lines

Continuous optimization: Add new skills to the script library every week (just like leveling up in a game!)

Three soul-searching questions

Is your production line still using the “manual testing method”?

Haven’t you had enough of changing scripts at 3 AM?

Does the boss even know how much money you secretly saved by using scripts?

End of article benefit: The top 3 likes will receive the “PLC Script Testing Handbook” (including 50 ready-made scripts + pitfall checklist)! By the way, what funny stories did you have when you first wrote a test script? Share your black history in the comments!

Golden quote to conclude: If machines can do the work, why waste your hair? When the script runs, gold flows in!