Introduction

The interview with XianGong Intelligent was initiated by capital recommendations. Many investors mentioned and praised XianGong Intelligent when discussing the topic of mobile robots, with some capital insiders directly stating that the company’s future market value may far exceed people’s expectations.

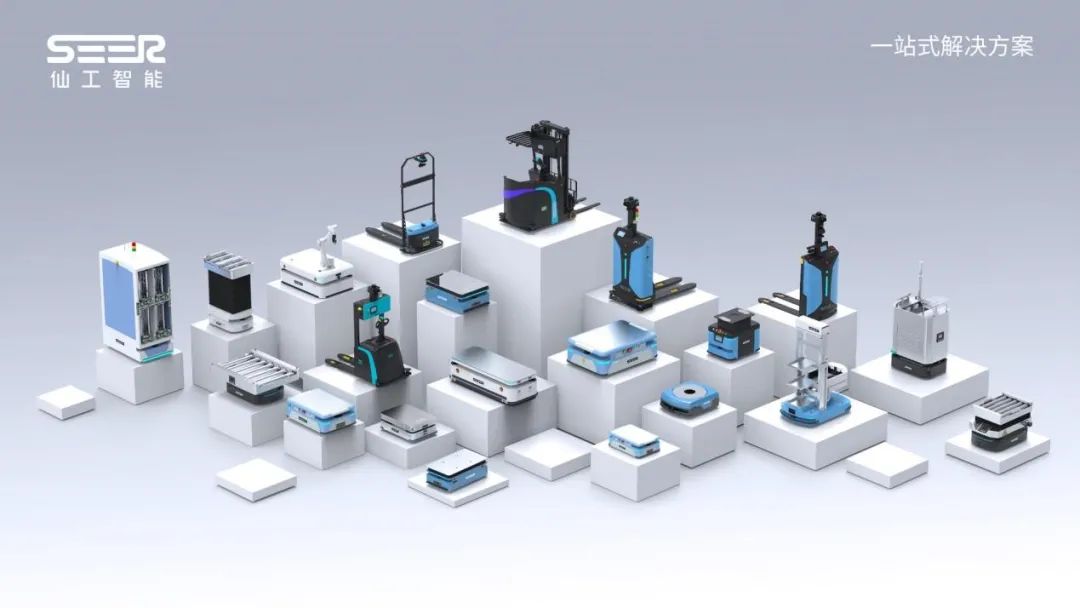

Capital has shown great interest and attention to XianGong Intelligent. In January 2021, XianGong Intelligent secured A+ round financing from IDG, and earlier investments were made by Huachuang Capital, Qianchen Investment, Ecovacs, Yingshan Capital, and Hanchuan Intelligent. The Robotics Lecture Hall learned that XianGong Intelligent’s latest round of financing has also been completed and will be officially announced soon. At the same time, XianGong Intelligent is preparing for its IPO. However, this is a very low-key company, and financing news is rarely disclosed. But by visiting XianGong Intelligent’s very international website, one can glimpse the company’s strength through the diverse range of products displayed, including automated forklifts, AMR-based rotating lifting robots, SLAM multi-layer material box robots, lurking towing robots, and even composite robots. It seems that XianGong’s product library is equipped with all types of mobile robots that can be seen and thought of in the market.

▍Not Just Robots

Upon visiting the Shanghai headquarters of XianGong Intelligent and viewing the dazzling array of robotic products, when asked about the core business of XianGong Intelligent, the reporter received an unexpected answer from Ye Yangsheng, the 1993-born co-founder of the company: controllers.

In Ye Yangsheng’s view, robots and other automation devices are the foundation of intelligent manufacturing and intelligent logistics, but after robots and other automation products reach a certain deployment stage, future controller solutions will bring broader market boundaries.

“Currently, both domestically and internationally, we are still in the early automation replacement phase of intelligent manufacturing. We believe that as robots develop to the next stage of intelligent manufacturing, controllers will gradually replace the original PLCs on production lines, achieving smarter control of the entire factory. XianGong Intelligent’s future goal is to become a motion control enterprise similar to Siemens,” Ye Yangsheng told the reporter.

Generally speaking, industrial automation is divided into three segments: perception, control, and execution. Perception relies on various sensors, control relies on controllers and servos, while robots and some equipment operation devices are considered execution. However, Ye Yangsheng believes that delving deep into the control layer is essentially an abstract form of execution. Simply put, different types of interconnected controllers can directly run execution processes, achieving infrastructure scheduling for the entire smart factory.

(SRC Controller)

For example, in automated production lines, roller lines and belt lines may originally use traditional PLC devices for control. Due to the rigidity of programming, the flexibility of production lines has always been low, and many dynamic changes cannot be handled in a timely manner. However, intelligent controllers can often directly communicate with the protocols of other devices, achieving unified control through comprehensive scheduling of the entire factory, thereby increasing production flexibility.

Based on the control capabilities of various underlying products, controllers can also be seen as directly integrated into many business systems. On the basis of equipment automation, they can also connect to electrification, information technology, etc. For example, business systems can extend to more modules like vision, allowing companies to collect more data and analyze and optimize based on this, improving the efficiency of the entire smart logistics, continuously optimizing and upgrading key links, ultimately achieving the intelligentization of the overall business process of intelligent manufacturing. “The essence of controllers is still automation, but as automation accumulates to a certain extent, it will naturally develop towards intelligence,” Ye Yangsheng said.

The various product lines aim to better enable smarter operations in factories, ultimately forming synergy. Under multiple product categories, XianGong Intelligent has always centered around controllers, providing one-stop solutions for intelligent manufacturing and smart logistics.

Under this concept, XianGong Intelligent is gradually forming four major solutions, including controllers, robots, enterprise digitization, and visual AI, hoping to continuously create more cost-effective and intelligent solutions centered around controllers, optimizing and solving some issues that arise in traditional PLC solutions, ultimately achieving intelligent manufacturing.

Therefore, it is reasonable that XianGong Intelligent’s future challenge is Siemens, which has PLC + software systems as its core product.

▍Standardization Compatibility in Non-Standard Products

“In the future, robots will definitely not be the main direction for XianGong. After thoroughly understanding the control of all models, we may not focus on making complete machines, but rather output overall solutions, with the core of the solution being the controller and the accompanying software system,” Ye Yangsheng explained.

However, the development direction of the company and individuals was not initially like this. Initially, Ye Yangsheng was engaged in software and robot control system R&D in the company, but for the better development of the entire company, he began to think about how to shift from a company that pursued extreme R&D and did not sell products much to one that could generate more business and revenue. As someone who knows the company and its technical strength best, Ye Yangsheng believes that in the stage of automation development, R&D must be more aligned with market demands.

To this end, XianGong Intelligent’s R&D path began to shift from being R&D-oriented to being customer demand-oriented, with R&D consistently stemming from customer needs. Ye Yangsheng personally led this process of choosing R&D and firmly promoted its execution. Various robots that could be quickly commercialized began to emerge at XianGong Intelligent.

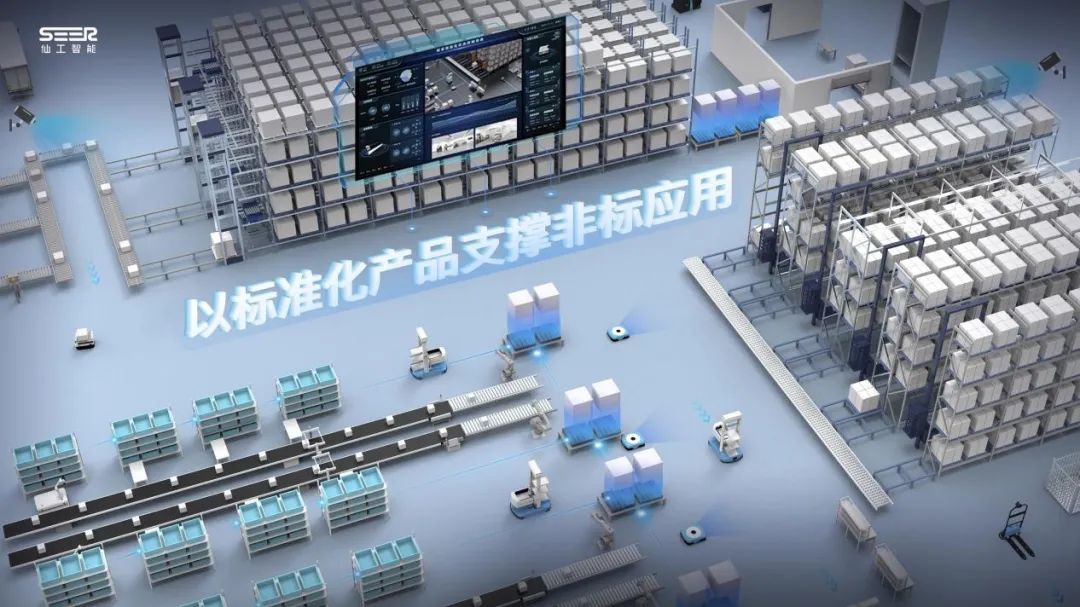

However, customer demands are very diverse, and to address most needs, it is essential to find a better, more universal method.“Supporting applications with standardized products” is a feasible route that XianGong Intelligent has summarized.

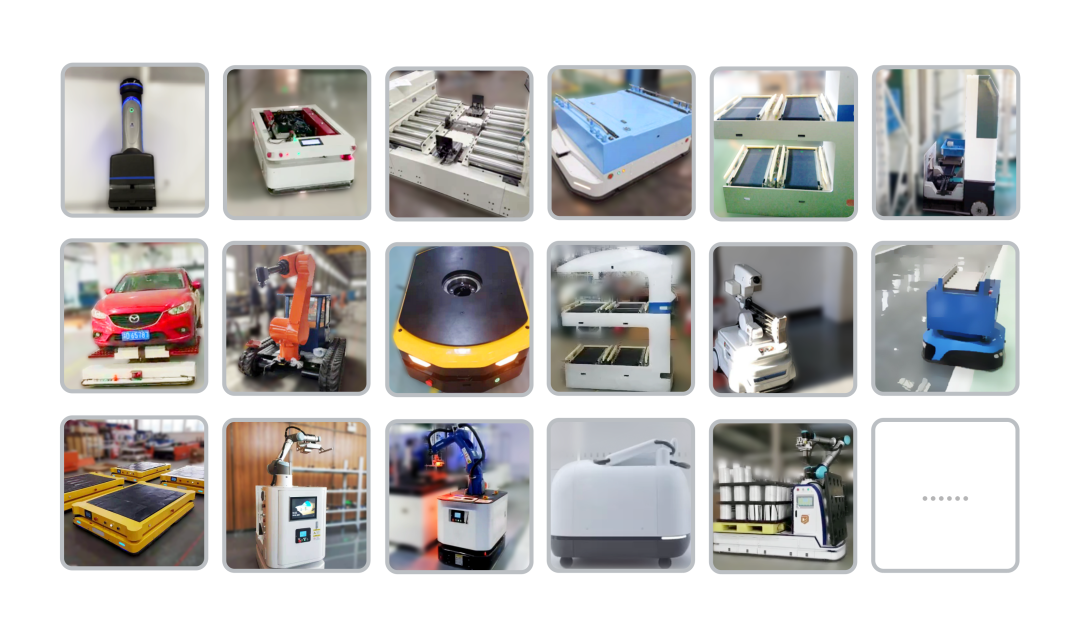

By collecting customer demands from the market, XianGong Intelligent’s EPC department abstracts and generalizes these demands, transforming processes into standardized functions through API calls, script writing, and other methods. At the same time, these non-standard demands are output in standardized forms of various robots through the controller as a standardized product. For example, XianGong has gradually formed robots of different load types or load forms, turning non-standard demands into standardized products, which can often meet the vast majority of needs.

However, diverse robots are still more of a non-standard product compared to controllers. A large product line also brings significant R&D pressure, and based on having a rich vehicle library and ecological platform, on one hand, expanding the business scope, on the other hand, XianGong Intelligent is gradually narrowing its core focus, concentrating R&D on the controller, attempting to find more universal solutions and establishing ecosystem cooperation has become the choice for the new era of XianGong Intelligent.

For some industries with high non-standard robot demands, XianGong Intelligent has gradually begun to let this market be handled by more experienced partners, allowing partners to conduct non-standard designs based on XianGong’s chassis to complete customer project deliveries. Due to the high standardization of controller products, many partners can even easily create a completely non-standard or relatively standard chassis based on XianGong Intelligent’s technical guidance.Through the controller, XianGong Intelligent has begun to shift towards being a standard setter and outputter.

Currently, XianGong Intelligent has undergone a more comprehensive transformation from a purely robotic business. The initial idea of firmly grasping the robotic business, which was the core of the business, has evolved into“how to help ecosystem customers also do well in robotics” in a new stage.

This undoubtedly requires more caution and detail. As the founder, Ye Yangsheng currently serves as the product director of the robotics division in the company.

Internally, XianGong Intelligent is divided into four major modules: the controller division, robotics division, systems division, and visual division. Ye Yangsheng believes that to help customers create a good product, one must have hands-on experience and be satisfied to gain greater trust from customers. This is the deepest level of dedication a researcher can have towards technology.

“To better help customers create robots, more mature experience is needed to refine these experiences into drawings and technical details to output to partners,” Ye Yangsheng said.

The robot business, which occupies a large share of revenue, is like XianGong Intelligent’s past and present, but with the continuous expansion of customer base, the controller business that has begun to emerge is more likely to become the future.

This choice has also brought many changes to XianGong. The downstream customers of XianGong Intelligent can be direct enterprise terminals or downstream partner partners. Centering on the controller business actually provides XianGong Intelligent with more advantageous choices.

▍Technical Development and Moat

If the core technology of robots lies in components like controllers, then what exactly reflects the technical advantages of controllers? Ye Yangsheng mentioned the term “fact standard” to the reporter. Just like Siemens’ initial development path, when quantitative changes lead to qualitative changes, standards naturally form. And to get the market to pay, technology and application volume are the biggest barriers and moats.

XianGong Intelligent’s controllers achieve abstraction of all actuators, allowing for simple product parameter configuration and model editing on the controller, graphical configuration through software mapping, motion mode judgment, and matching sensor models, thus enabling control of various models, with a very detailed level of granularity.

This allows XianGong Intelligent’s control system to achieve universal compatibility for both AGVs and robotic arm joint drives, and can be precisely configured to various details such as site, path, speed, and deceleration. In addition, XianGong Intelligent also has some scripted programming that can define complex mechanisms of non-standard institutions, making non-standard customization simpler.

With standardized products—controllers that master core technology, XianGong Intelligent is continuously attempting various non-standard business scenarios, providing more comprehensive one-stop solutions for intelligent manufacturing and smart logistics. For example, XianGong Intelligent’s controllers are no longer just core control components for mobile robots. According to Ye Yangsheng, the controllers that XianGong Intelligent is about to launch can also control the overall granularity of warehouses, such as achieving ladder control, door control, vertical storage, RGV, elevators, industrial floor scrubbers, etc. As long as the underlying software architecture or hardware architecture is ensured, the controller can easily possess strong universality.

The controller-centric model can be quickly replicated in bulk. When all devices in a factory can be equipped with XianGong’s controllers, with better system management capabilities, the integration of large logistics projects becomes more advantageous, with less restriction from distributors.

According to Ye Yangsheng, currently, the business volume of XianGong Intelligent’s controller division accounts for about 50%.“Last year, we sold about 1,000 controllers, but only one-third were used in our own robots. The AGVs built by customers actually outnumber those we built ourselves,” Ye Yangsheng said with a smile. “I hope that in a few years, we will not be seen as a company that makes AGVs, but more like Siemens, a motion control enterprise covering more segmented industries and fields.”

Challenging top global companies like Siemens is not just a hollow statement for this group of young people at XianGong Intelligent.

▍Conclusion

As we were leaving, it was already after work hours, and we noticed a group of young people coming out one after another to pick up takeout. Next to the XianGong Intelligent takeout rack was a small bowl, and not far away, a few stray cats were lazily basking in the sun. The young people casually petted the cats before heading upstairs with their takeout. Ye Yangsheng told the reporter that they had another meeting later.

Before leaving, the reporter asked Ye Yangsheng, as a young entrepreneur, whether his original intention had changed since starting the business. He candidly admitted that he had also wavered. “Like many entrepreneurs, I initially had no clear goal. I worked on service robots, inspection robots, and non-standard customization projects. In this process, we accumulated some understanding and concepts of controllers and chassis, and gradually moved towards standardization, which eventually led to the XianGong Intelligent we see today.”

In the new technological context of intelligent manufacturing and intelligent logistics, whether entrepreneurs or followers, everything has already become youthful. Youth often serves as the best annotation for intelligent manufacturing entrepreneurial teams. Understanding technology, summarizing through continuous experimentation, having keen insight, strong opportunity capture ability, and relentless execution power—perhaps this is what a successful intelligent manufacturing entrepreneur should look like.

END

More Exciting Content

*Breaking through bottleneck technologies, thoughts and directions for developing core components of collaborative robots

*The first machine dog from young people has arrived!

*Songling New Product丨The world’s first multi-modal® ROS development platform LIMO is here, in collaboration with Guyueju to create premium courses

*Working at a height of 20 meters, efficiency increased by 10 times! Can the God’s perspective accelerate the unlocking of the 27 billion new market for warehouse automation?

*The “rebirth” from manufacturing to intelligent manufacturing, the innovative practices of Elite Robotics with customers

*Foreign brands dominate the high-end market? How can domestic robots achieve brand reversal? These points are crucial!

*National-level! Luoshi Robotics has been awarded the title of “Little Giant” enterprise by the Ministry of Industry and Information Technology

*“The future development space of mobile composite robots, even ABB is envious?”

*The printing industry is constantly “involution,” collaborative robots break out of the encirclement

*Seizing the intelligent manufacturing market, a case analysis of the essence of semiconductor industrial logistics

*What if I have a stroke and become paralyzed? Please help me up!

*Artificial intelligence empowers thousands of industries, collaborative robots welcome a blue ocean market

*New Product丨Outdoor unmanned waypoint navigation development platform AutoPilot Kit, efficiently empowering the industry

Join the Community

Welcome to join the 【Robotics Lecture Hall】 reader discussion group, to discuss topics related to robotics, sharing cutting-edge technology and industry dynamics.

Discussion groups for educational robots, medical robots, legged robots, industrial robots, service robots, special robots, drones, soft robots, etc. are recruiting. Follow the Robotics Lecture Hall public account and send “discussion group” to get the joining method!

Recruiting Authors

The Robotics Lecture Hall is recruiting 【part-time content creators】. If you are interested in writing articles related to robotics 【technology】 or 【industry】, please send your resume and original works to the email:[email protected]

We have no requirements for profession, location, etc., and welcome friends to join!

Feeling tired? Click “Looking” to support us!