The CNC system is the core of CNC machine tools. The speed of its upgrade and its ability to adapt to market demands directly affect the development of CNC machine tools. In today’s rapidly developing science and technology, CNC systems have gradually moved towards open, intelligent, and networked development directions. As a leading enterprise in the domestic independent research and development of CNC systems, GSK Technology Co., Ltd. (hereinafter referred to as “GSK Technology”) has combined its open-source CNC system with the open EtherCAT bus control, directly leading the development of CNC machine tools today.

Development of CNC Systems

Since the first experimental CNC system was successfully developed in 1952, CNC systems have gone through 66 years. In this more than sixty years of development, CNC systems have rapidly evolved from integrated circuit types to microcomputer types, from PLC to NC and then to CNC, achieving rapid development in terms of size, integration, functionality, and stability.

Modern CNC machine tools are electromechanical products that integrate mechanics, hydraulics, pneumatics, electronics, automation, sensing measurement, and computers. As a key foundational unit, the CNC system is mainly used to input digitized part programs, store input information, transform data, perform interpolation calculations, and achieve various controls. Therefore, the strength of its functions and the quality of its performance determine the market positioning and user experience of the entire product. In the increasingly complex manufacturing development process, CNC systems are also undergoing fundamental changes to adapt to development. The open architecture of CNC systems has better versatility, applicability, and expandability, and is currently recognized and applied by many well-known large enterprises. With the development of openness in CNC systems, intelligent and networked features are also gradually being developed and promoted.

Introduction and Features of GSK CNC System

Founded in 1999, GSK Technology is headquartered at the Hong Kong University of Science and Technology. In the research and application of industrial automation technologies such as motion control, servo drive research, and mechanical optimization design, GSK Technology has gathered a group of technological elites who have made remarkable achievements in the fields of motion control and electromechanical integration. GSK Technology’s CNC system products are widely used in industrial control fields such as CNC machine tools, robots, laser processing equipment, and production automation. The self-developed computer programmable motion controllers, PC-based open motion controllers, networked motion controllers, and embedded motion controllers have achieved international first-class performance, filling multiple gaps in the domestic industry.

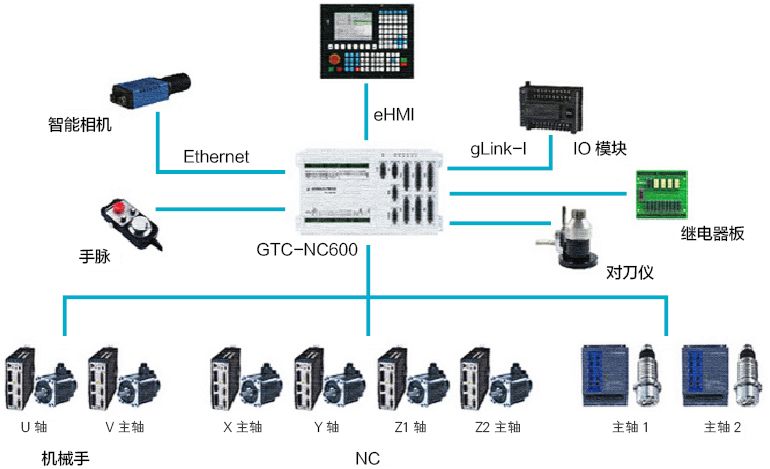

The GSK CNC system (Figure 1) is an open CNC system developed based on the CoDeSys platform. It supports six PLC programming languages of the IEC61131-3 international standard: IL, ST, FBD, LD, CFC, and SFC. Technicians can choose different languages to edit functional modules, subprograms, etc., within the same project. The GSK CNC system can run on the WINCE operating system, meeting the CNC system’s requirements for real-time performance, safety, and stability.

Figure 1 GSK CNC System

The core of the CNC system lies in its CNC processing capability, and the GSK CNC system decomposes the CNC processing into various execution actions at the end, achieving sub-functions such as movement, stop, parameter setting, and communication in a unique GT instruction form. Technicians only need to call different GT instructions according to their needs and combine them with corresponding logic instructions to ultimately realize different functions. Due to its high openness, the differences with the motion control products across the Asia-Pacific region had already emerged as early as 2000. At that time, most brand systems were purchased from Japan, leading to fixed functionalities in their platform products that could not be redeveloped. The longer the time, the more limited the equipment became. In contrast, GSK Technology adopted a DSP and FPGA control platform and self-developed compilers, allowing technicians to freely develop, modify, or add different functions based on process and functional requirements on this platform.

In addition to having a high degree of openness, the GSK CNC system also has the following features: 1) Modular platform functionality, configurable via parameters; 2) Customers can customize processing codes to achieve any desired specific function; 3) Can simultaneously support CNC and loading/unloading automation devices, with safety protection features; 4) Intelligent networking and tuning debugging functions; 5) Supports 5-axis interpolation and RTCP functions; 6) Features such as probing capture and fast I/O; 7) Tool compensation, pitch compensation, and trajectory optimization functions; 8) Supports gantry synchronous control; 9) Functions such as manual wheel-guided processing, breakpoint continuation, and segment skipping processing.

Development and Features of EtherCAT Bus

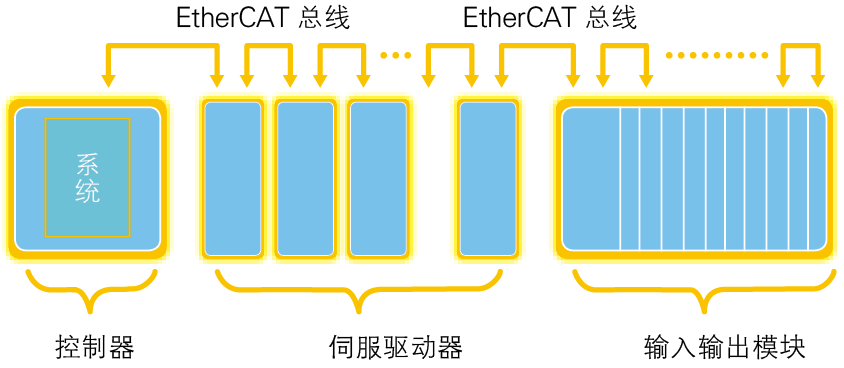

EtherCAT (Ethernet for Control Automation Technology) is an open architecture fieldbus system based on Ethernet, originally developed by Beckhoff Automation GmbH in Germany. It was introduced to the market in 2003 and became an international standard in 2007. Since entering the Chinese market in 2007, EtherCAT bus technology (Figure 2) has gained widespread acceptance and recognition in the Chinese market after ten years of development as a high-performance, low-cost, easy-to-use, and topologically flexible industrial Ethernet technology.

Figure 2 EtherCAT Bus Technology

Unlike other fieldbus control technologies, EtherCAT is an open technology that allows anyone to implement and apply it; it uses standard Ethernet data frames and complies with the Ethernet standard IEEE802.3 physical layer, reserving space for simple control architecture; at the same time, its system setup and configuration work is simple and easy, and the cost is even lower than that of fieldbus technology, thus allowing a smooth transition from fieldbus to EtherCAT bus control. In addition, EtherCAT also includes optional cable redundancy, functional safety protocols, and high-precision device synchronization features.

Application of GSK EtherCAT Bus

In 2007, with the entry of EtherCAT bus technology into the Chinese market, GSK Technology also began researching digital control systems suitable for EtherCAT bus control. The GSK EtherCAT bus CNC system, based on its mature analog control framework, added bus configuration files, bus establishment, bus communication, and bus monitoring commands, successfully developing a bus control system that passed the EtherCAT Technology Group (ETG) conformance certification. In 2016, it officially showcased related new products at the Industrial Expo.

The GSK EtherCAT bus CNC system can support up to 64 axes of motion control, with all 64 axes capable of being CNC axes. The CNC system can flexibly switch between interpolation and point motion modes as needed. Typically, other EtherCAT bus control systems require dedicated software platforms to communicate with execution components (such as servo drives) when configuring SDO and axis information, mapping and configuring each required SDO one by one. In contrast, the GSK EtherCAT bus CNC system can directly add the modified underlying configuration table to the corresponding axis, generate the eni file for bus communication configuration, and download it to the specified system execution directory to achieve SDO mapping and configuration. For PDO processing, other EtherCAT bus control systems also require one-by-one configuration like SDO, while the GSK EtherCAT bus CNC system can directly call a simple GT instruction at any time to obtain any desired PDO information, achieving functionality while greatly reducing CPU occupancy of the system.

Although EtherCAT bus features high speed and performance, communication frame loss and interruptions are common issues in EtherCAT bus technology, which can directly lead to machine tool downtime. To avoid this phenomenon, the GSK EtherCAT bus CNC system performs verification of EtherCAT bus communication in each cycle. When it detects suspected frame loss or data issues, the system automatically judges and processes based on the current state and data to ensure accurate communication and control of data.

After realizing the functionality of EtherCAT bus communication, open-source motion control has become a strong suit of the GSK CNC system. By combining different GT instructions such as mode setting instruction GT_PrfTrap, parameter definition instruction GT_GT_SetCrdPrm, position planning instruction GT_SetPos, buffer initialization instruction GT_InitLookAhead, and motion start instruction GT_GT_CrdStart, along with corresponding PLC logic, different requirements for point and interpolation motion can be achieved.

Conclusion

The EtherCAT bus CNC system developed by GSK Technology can meet the needs of the vast majority of users and provides an excellent user experience in terms of openness, intelligence, and convenience. Especially in its design for system versatility, it can almost meet all customer needs, achieving a smooth transition from other fieldbus control to EtherCAT bus control without significantly increasing workload.

To better adapt to the rapidly evolving scientific technology and meet different customer development needs, the GSK EtherCAT bus CNC system still needs to continue expanding its functions, implementing high-precision and efficient modules such as probing, gantry, and vibration suppression under the analog framework into the bus CNC system, striving to make domestic CNC systems larger and stronger.

——This article is selected from “Sheet Metal and Manufacturing” Issue 12, 2018