Microrobots

Microrobots have been a focal point of extensive research, catalyzing various innovative developments. Their unique active motion behaviors provide distinct capabilities and advantages in different aqueous biological and environmental media, such as enhanced delivery, improved mass transfer, efficient repair, and access to small spaces. Appropriate material selection, structural design, and surface functionalization enable various propulsion mechanisms and motion control methods for microrobots, bringing unique capabilities to different applications. Microscale robots (Source: Internet)Material Considerations for the Development of MicrorobotsIn this review, Joseph Wang from the University of California, San Diego, and others outline the design principles and material selection for the propulsion and operation of microrobots. The authors first introduce the basic mechanisms for controlling the motion of microrobots, followed by material design strategies for achieving efficient and controllable propulsion. They emphasize the use of various reactive and responsive materials in realizing advanced functionalities of microrobots, covering representative biomedical and environmental applications, and discuss how future material innovations will impact the development of the next generation of microrobots.Related work titled “Materials consideration for the design, fabrication and operation of microscale robots” was published in Nature Reviews Materials.

Microscale robots (Source: Internet)Material Considerations for the Development of MicrorobotsIn this review, Joseph Wang from the University of California, San Diego, and others outline the design principles and material selection for the propulsion and operation of microrobots. The authors first introduce the basic mechanisms for controlling the motion of microrobots, followed by material design strategies for achieving efficient and controllable propulsion. They emphasize the use of various reactive and responsive materials in realizing advanced functionalities of microrobots, covering representative biomedical and environmental applications, and discuss how future material innovations will impact the development of the next generation of microrobots.Related work titled “Materials consideration for the design, fabrication and operation of microscale robots” was published in Nature Reviews Materials. 【Key Points】1. Material Considerations for Achieving Propulsion Functionality in MicrorobotsMaintaining effective motion at the microscale requires a constant driving force, which largely depends on the materials used. Designing asymmetric micro-motor structures is crucial for generating controlled motion. Achieving such asymmetric structures and non-reciprocal motion requires careful material selection, thoughtful motor structure design, and appropriate driving modes. Various propulsion mechanisms have been developed based on chemical and physical principles (such as acoustic, optical, electric fields, or magnetism) to provide microscale propulsion (Figure 1).

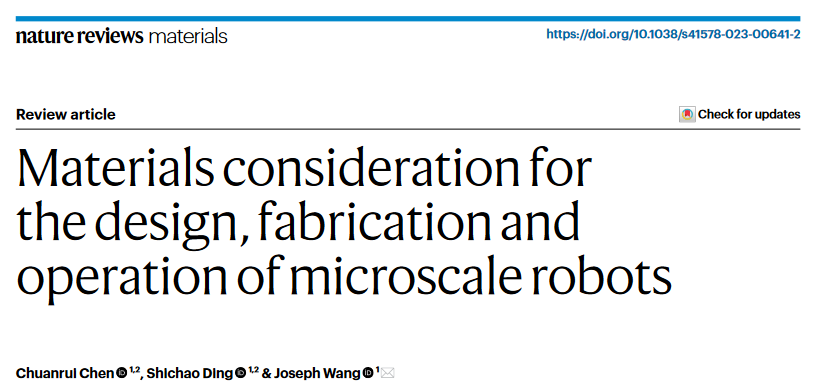

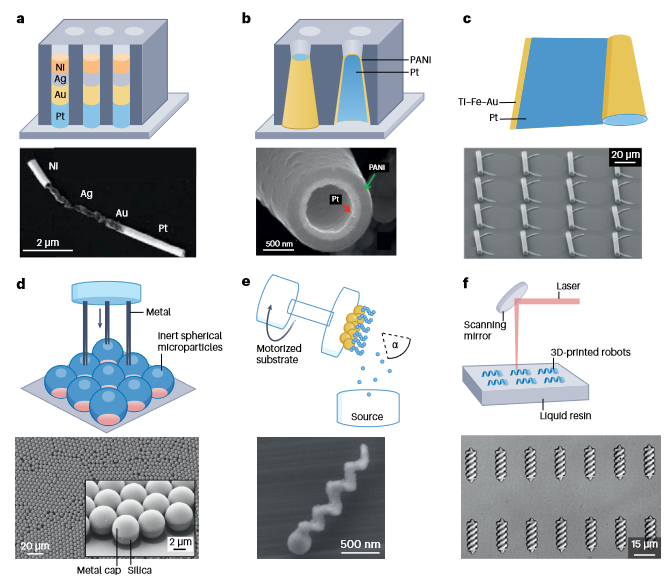

【Key Points】1. Material Considerations for Achieving Propulsion Functionality in MicrorobotsMaintaining effective motion at the microscale requires a constant driving force, which largely depends on the materials used. Designing asymmetric micro-motor structures is crucial for generating controlled motion. Achieving such asymmetric structures and non-reciprocal motion requires careful material selection, thoughtful motor structure design, and appropriate driving modes. Various propulsion mechanisms have been developed based on chemical and physical principles (such as acoustic, optical, electric fields, or magnetism) to provide microscale propulsion (Figure 1). Figure 1 Basic design principles of micro-nano robots2. Material Considerations for Achieving Motion ControlMicrorobots require precise spatial and temporal control of their direction and speed to perform complex operations and applications. Brownian (random) motion caused by thermal fluctuations poses significant challenges to controlling the trajectories of microrobots and adjusting their speeds. Therefore, extensive research has developed various strategies to overcome this Brownian dynamics—endowing microrobots with directionality—and to adjust their speeds to meet the demands of future applications. These motion control strategies are inspired to some extent by the superior motion control capabilities of biological motors. They rely on various stimuli to control motion activities and provide precise spatiotemporal operations (including on-demand ON/OFF driving) (Figure 2).

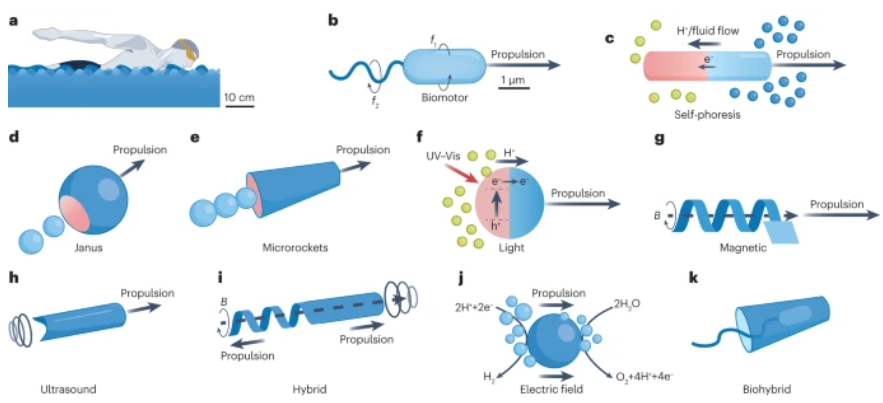

Figure 1 Basic design principles of micro-nano robots2. Material Considerations for Achieving Motion ControlMicrorobots require precise spatial and temporal control of their direction and speed to perform complex operations and applications. Brownian (random) motion caused by thermal fluctuations poses significant challenges to controlling the trajectories of microrobots and adjusting their speeds. Therefore, extensive research has developed various strategies to overcome this Brownian dynamics—endowing microrobots with directionality—and to adjust their speeds to meet the demands of future applications. These motion control strategies are inspired to some extent by the superior motion control capabilities of biological motors. They rely on various stimuli to control motion activities and provide precise spatiotemporal operations (including on-demand ON/OFF driving) (Figure 2). Figure 2 Various motion control strategies3. Manufacturing MicrorobotsAchieving propulsion at the microscale/nanoscale and imparting various functionalities to microrobot structures make the manufacturing of microrobots highly challenging. The design and fabrication of microrobots require careful consideration of several factors, such as the shape, composition, and distribution of active materials. The manufacturing of microrobots typically relies on bottom-up techniques; current technologies include template-assisted electrodeposition, rolled-up nanofilm fabrication, asymmetric surface modification, oblique deposition, 3D printing, and bio-robotic functionalization, among others (Figure 3).

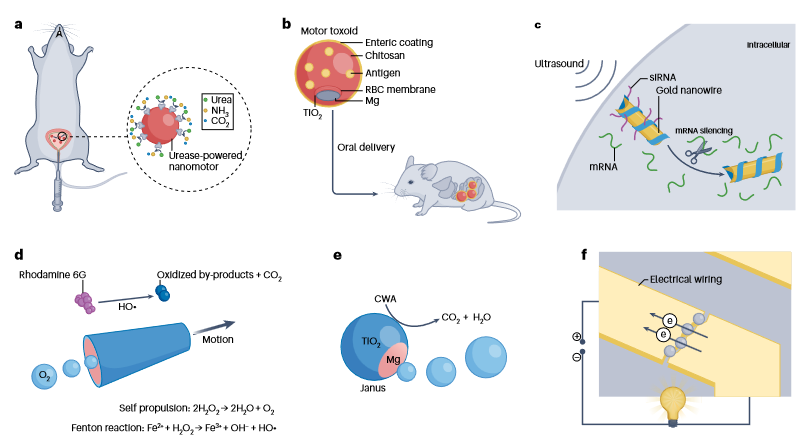

Figure 2 Various motion control strategies3. Manufacturing MicrorobotsAchieving propulsion at the microscale/nanoscale and imparting various functionalities to microrobot structures make the manufacturing of microrobots highly challenging. The design and fabrication of microrobots require careful consideration of several factors, such as the shape, composition, and distribution of active materials. The manufacturing of microrobots typically relies on bottom-up techniques; current technologies include template-assisted electrodeposition, rolled-up nanofilm fabrication, asymmetric surface modification, oblique deposition, 3D printing, and bio-robotic functionalization, among others (Figure 3). Figure 3 Typical manufacturing processes of micro-nano robots4. Applications of MicrorobotsFunctionalized microrobots have broad application appeal (Figure 4). In particular, microrobots can navigate in biological fluids and perform a wide range of biomedical tasks, such as microsurgery, drug delivery, separation of biological targets, biosensing, and operations within single living cells. The motion of microrobots in biological fluids or tissues increases their residence time and can further enhance targeted drug delivery. Additionally, microrobots can overcome diffusion-limited reactions by improving mass transfer and interactions between their active surfaces and target contaminants, thereby increasing the yield of decontamination reactions and shortening repair times. To this end, modifying the outer surface of microrobots with reactive repair materials can remove or degrade pollutants in contaminated environments through physical or chemical processes. Depending on the optical and electrical properties of the selected materials, microrobots can possess other unique functionalities for additional applications. For example, they can be used for high-resolution imaging, with swimming microrobots serving as a typical example of optical nanoscopy; while the electrical properties and active motion of nanorobots can be utilized for autonomous searching, detecting, and repairing microscale surface cracks on circuits.

Figure 3 Typical manufacturing processes of micro-nano robots4. Applications of MicrorobotsFunctionalized microrobots have broad application appeal (Figure 4). In particular, microrobots can navigate in biological fluids and perform a wide range of biomedical tasks, such as microsurgery, drug delivery, separation of biological targets, biosensing, and operations within single living cells. The motion of microrobots in biological fluids or tissues increases their residence time and can further enhance targeted drug delivery. Additionally, microrobots can overcome diffusion-limited reactions by improving mass transfer and interactions between their active surfaces and target contaminants, thereby increasing the yield of decontamination reactions and shortening repair times. To this end, modifying the outer surface of microrobots with reactive repair materials can remove or degrade pollutants in contaminated environments through physical or chemical processes. Depending on the optical and electrical properties of the selected materials, microrobots can possess other unique functionalities for additional applications. For example, they can be used for high-resolution imaging, with swimming microrobots serving as a typical example of optical nanoscopy; while the electrical properties and active motion of nanorobots can be utilized for autonomous searching, detecting, and repairing microscale surface cracks on circuits. Figure 3 Typical applicationsConclusion and OutlookFinally, the authors also list several significant challenges that remain: First, the energy conversion efficiency of microrobots is still low, and future material innovations are expected to improve the efficiency of synthetic microrobots compared to natural biological machines. Additionally, by adjusting the surface roughness and the distribution of catalytic sites, the efficiency of bubble-propelled microrobots can be further enhanced to promote bubble nucleation and growth; new materials that provide new chemical reaction pathways can also improve energy conversion efficiency. Secondly, scaling up the manufacturing of complex multifunctional microrobots is also crucial. Therefore, new manufacturing methods capable of handling advanced materials are needed to create complex 3D structures in a controllable and scalable manner to achieve new microrobot capabilities. Lastly, the biocompatibility of microrobots still has room for improvement, and further efforts are needed to better understand the immunogenicity and genotoxicity of microrobots at the tissue and cellular levels. Overall, material selection plays a significant role in the rapid development of microrobots and is a key factor in expanding applications. This research on the materials for controlling the propulsion and operation of microrobots has endowed these micromachines with powerful capabilities. In the future, computational technologies are expected to play an important role in the selection of materials for microrobot development. In particular, artificial intelligence technologies hold considerable promise in screening, selecting, and designing new materials for specific microrobot operations and applications. Advanced machine learning algorithms are expected to accelerate the discovery of new catalysts that power microrobots and new responsive materials that control their motion in rapidly changing environments. Therefore, the next generation of robotic technology is expected to rely heavily on significant breakthroughs in materials science. This material innovation is expected to further propel the development of microrobots and bring exciting future applications.

Figure 3 Typical applicationsConclusion and OutlookFinally, the authors also list several significant challenges that remain: First, the energy conversion efficiency of microrobots is still low, and future material innovations are expected to improve the efficiency of synthetic microrobots compared to natural biological machines. Additionally, by adjusting the surface roughness and the distribution of catalytic sites, the efficiency of bubble-propelled microrobots can be further enhanced to promote bubble nucleation and growth; new materials that provide new chemical reaction pathways can also improve energy conversion efficiency. Secondly, scaling up the manufacturing of complex multifunctional microrobots is also crucial. Therefore, new manufacturing methods capable of handling advanced materials are needed to create complex 3D structures in a controllable and scalable manner to achieve new microrobot capabilities. Lastly, the biocompatibility of microrobots still has room for improvement, and further efforts are needed to better understand the immunogenicity and genotoxicity of microrobots at the tissue and cellular levels. Overall, material selection plays a significant role in the rapid development of microrobots and is a key factor in expanding applications. This research on the materials for controlling the propulsion and operation of microrobots has endowed these micromachines with powerful capabilities. In the future, computational technologies are expected to play an important role in the selection of materials for microrobot development. In particular, artificial intelligence technologies hold considerable promise in screening, selecting, and designing new materials for specific microrobot operations and applications. Advanced machine learning algorithms are expected to accelerate the discovery of new catalysts that power microrobots and new responsive materials that control their motion in rapidly changing environments. Therefore, the next generation of robotic technology is expected to rely heavily on significant breakthroughs in materials science. This material innovation is expected to further propel the development of microrobots and bring exciting future applications.

「BioMed Technology」 focuses on cutting-edge research progress at the intersection of biomedicine and chemical materials! For communication and collaboration, please add Editor Yang’s WeChat!

Original link:

https://www.nature.com/articles/s41578-023-00641-2

Source: BioMed TechnologyDisclaimer: The views expressed are solely those of the author. The author’s level is limited, and if there are any scientific inaccuracies, please leave comments below for correction!