Source: Toutiao Account – Fat Fu’s Little Cabin

First, let’s take a look at a video

The chip is continuously magnified

It resembles a huge city inside

With the continuous advancement of chip manufacturing processes, a chip can now contain over 10 billion transistors. How are so many transistors integrated?

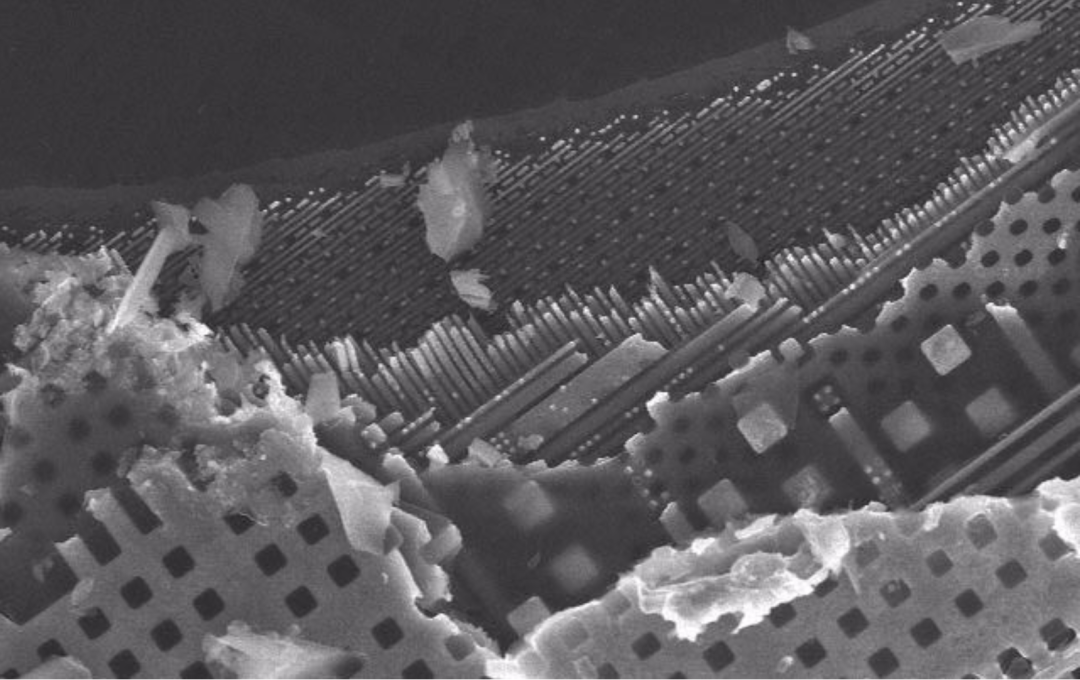

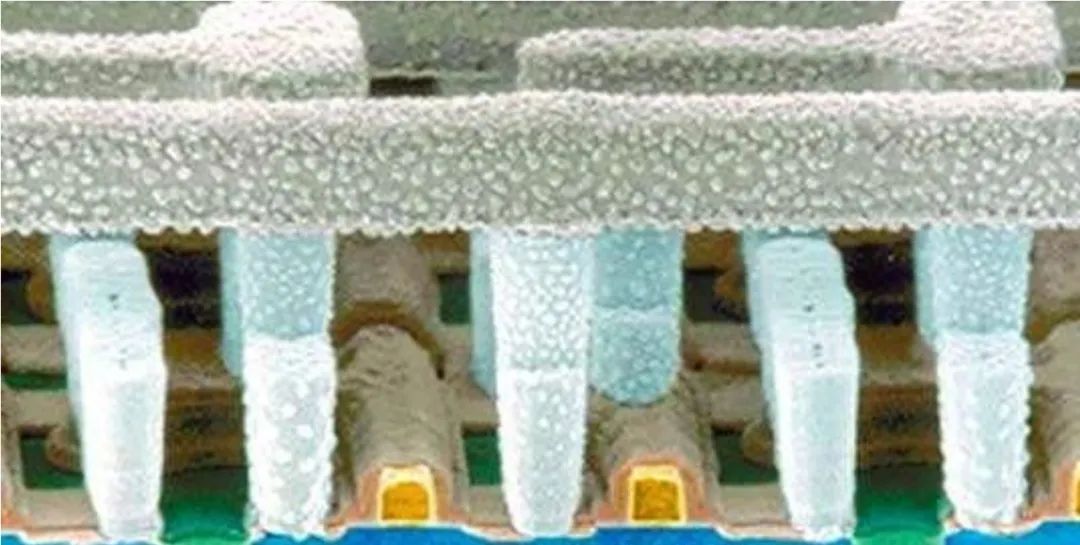

This is a Top-down View SEM image, which clearly shows the layered structure inside the CPU. The line width narrows as you go deeper, approaching the device layer.

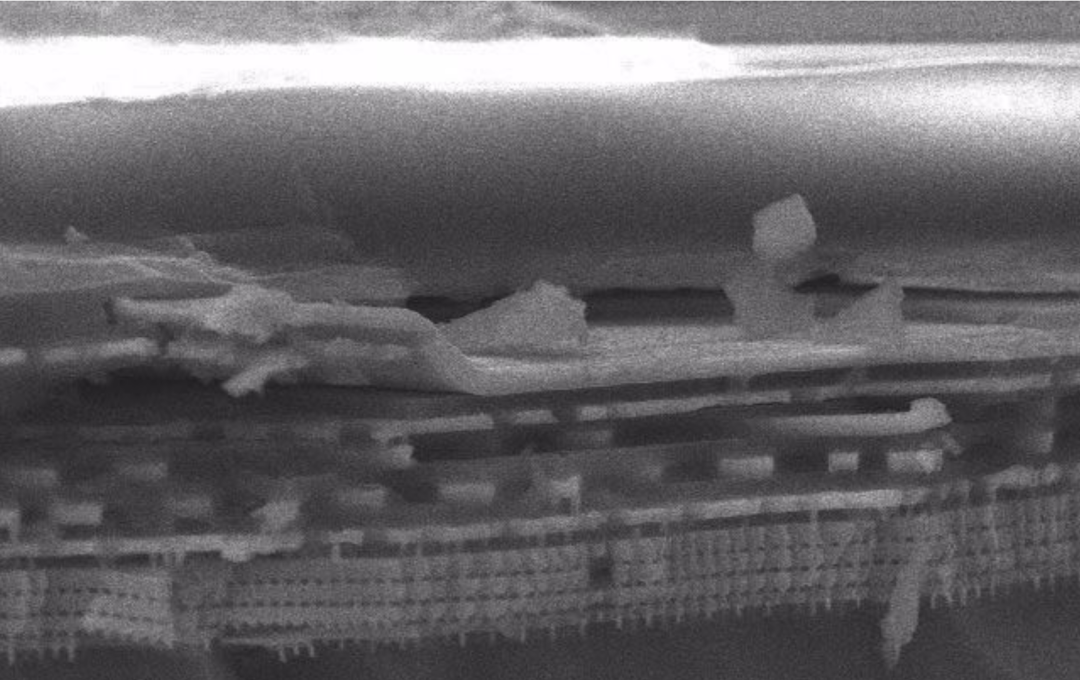

This is a cross-sectional view of the CPU, clearly showing the layered structure. The chip’s internal structure is arranged hierarchically, with approximately 10 layers in this CPU. The bottom layer is the device layer, which consists of MOSFET transistors.

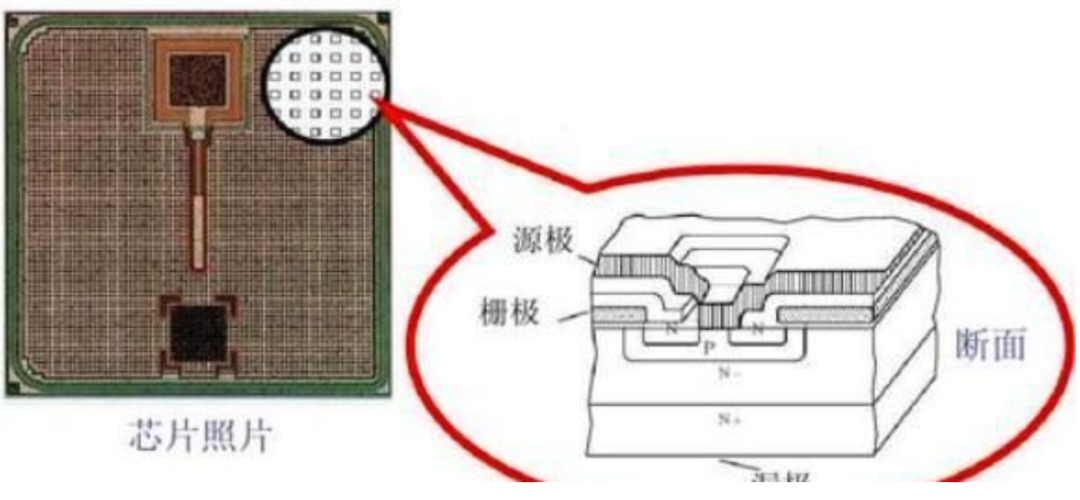

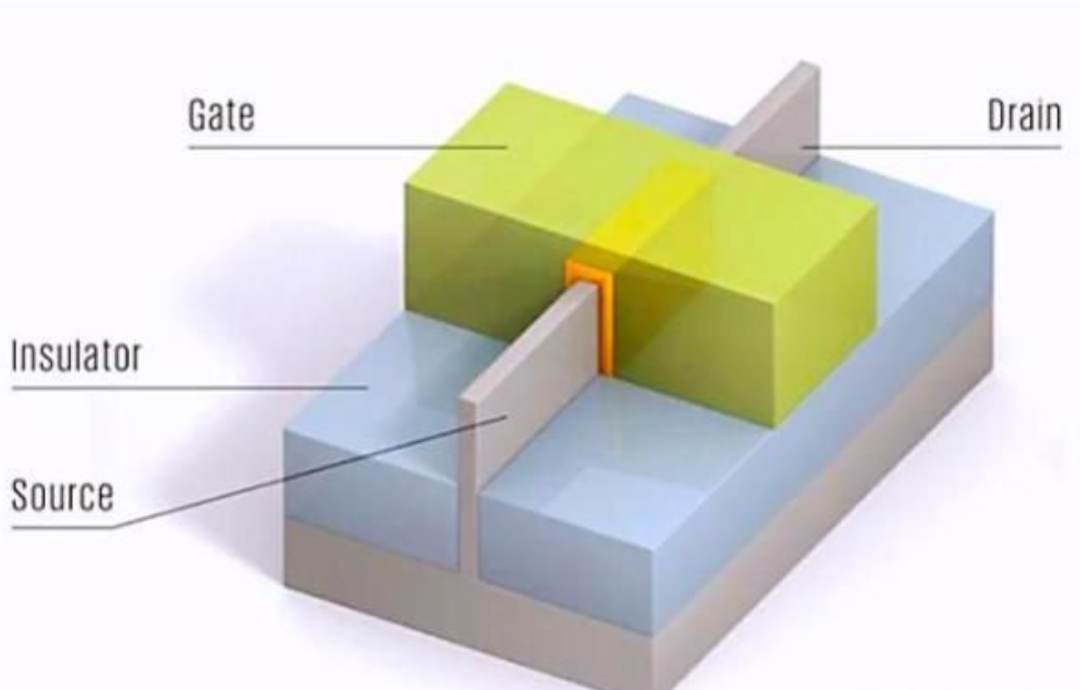

This is a cross-sectional view of the CPU, clearly showing the layered structure. The chip’s internal structure is arranged hierarchically, with approximately 10 layers in this CPU. The bottom layer is the device layer, which consists of MOSFET transistors. The MOSFETs in the chip can be seen as a three-dimensional structure resembling a “platform”. Transistors do not contain inductors or resistors, which are prone to generating heat. The top layer is a low-resistance electrode, separated from the platform below by an insulator, typically made of P-type or N-type polysilicon used as gate material, with silicon dioxide as the insulator below.The source and drain are formed by adding impurities to the sides of the platform, and their positions can be interchanged. The distance between them is the channel, which determines the characteristics of the chip.

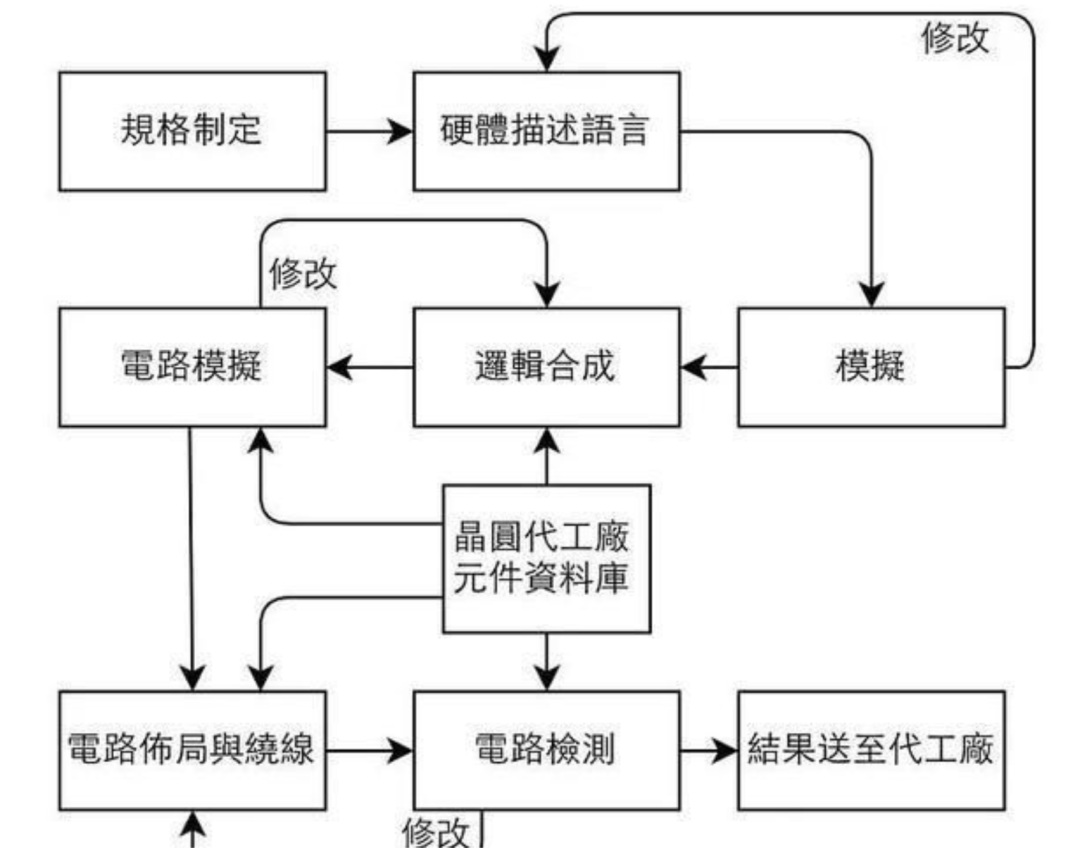

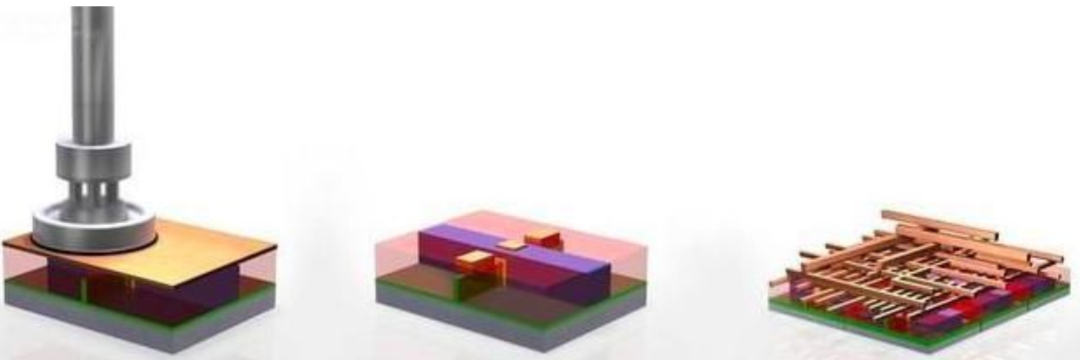

The MOSFETs in the chip can be seen as a three-dimensional structure resembling a “platform”. Transistors do not contain inductors or resistors, which are prone to generating heat. The top layer is a low-resistance electrode, separated from the platform below by an insulator, typically made of P-type or N-type polysilicon used as gate material, with silicon dioxide as the insulator below.The source and drain are formed by adding impurities to the sides of the platform, and their positions can be interchanged. The distance between them is the channel, which determines the characteristics of the chip. Of course, there are not only MOSFETs in the chip; there are also tri-gate transistors and others. Transistors are not simply installed; they are sculpted during the chip manufacturing process.During chip design, designers use EDA tools to plan the layout and routing of the chip.

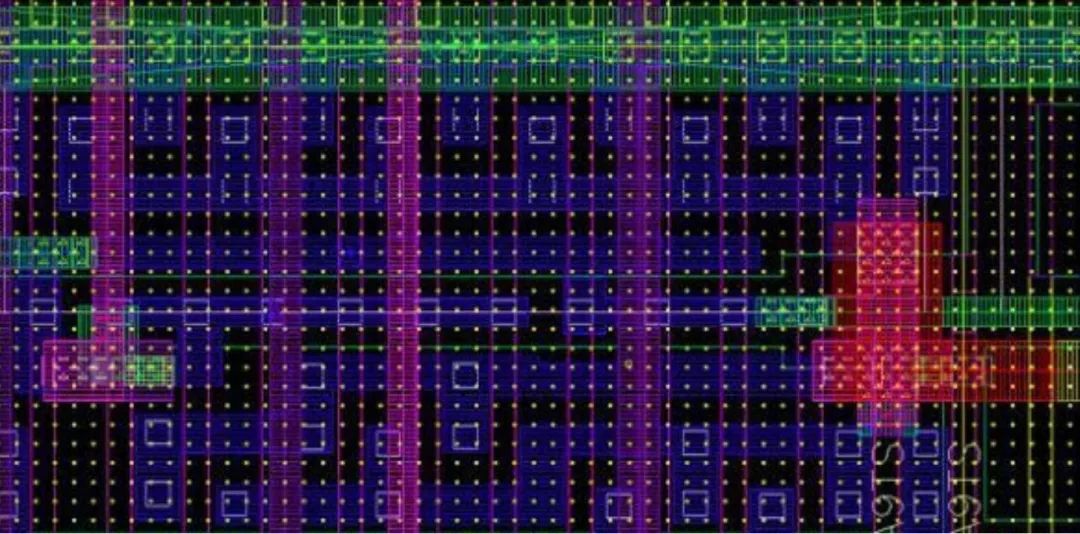

Of course, there are not only MOSFETs in the chip; there are also tri-gate transistors and others. Transistors are not simply installed; they are sculpted during the chip manufacturing process.During chip design, designers use EDA tools to plan the layout and routing of the chip. If we magnify the designed gate circuit, the white dots represent the substrate, and the green borders represent the doped layers.

If we magnify the designed gate circuit, the white dots represent the substrate, and the green borders represent the doped layers. Wafer foundries manufacture chips based on the physical layout designed by chip designers.There are two trends in chip manufacturing: one is that wafers are getting larger, allowing for more chips to be cut out, improving efficiency; the other is the chip process, which refers to the size of the gate, also known as gate length. In the transistor structure, current flows from the Source to the Drain, and the Gate acts as a gate, primarily responsible for controlling the on/off state between the source and drain.Current will dissipate, and the width of the gate determines the loss of current flow, which manifests as common heat and power consumption in mobile phones. The narrower the width, the lower the power consumption. The minimum width of the gate (gate length) is also referred to as the process.The purpose of shrinking the nanometer process is to fit more transistors into a smaller chip, preventing the chip from becoming larger due to technological advancements.However, if we make the gate smaller, the current flowing between the source and drain will increase, making the process more challenging.

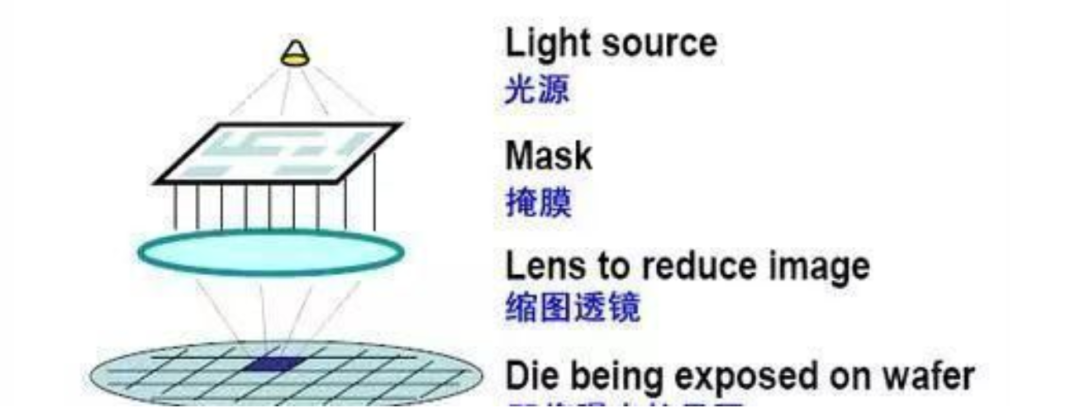

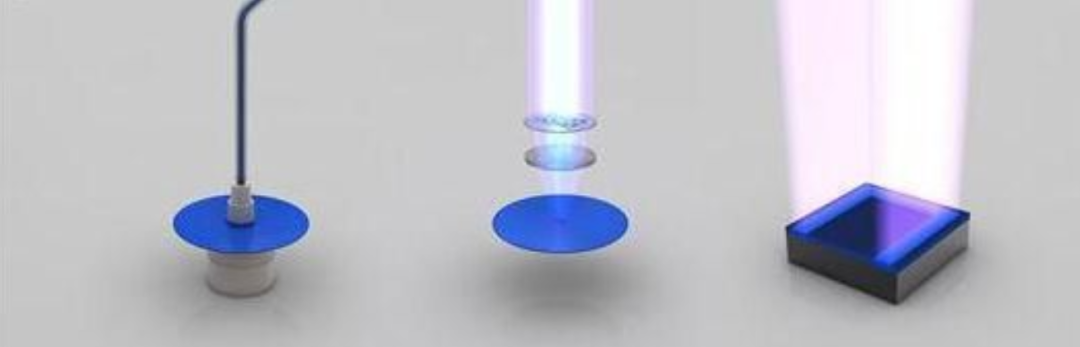

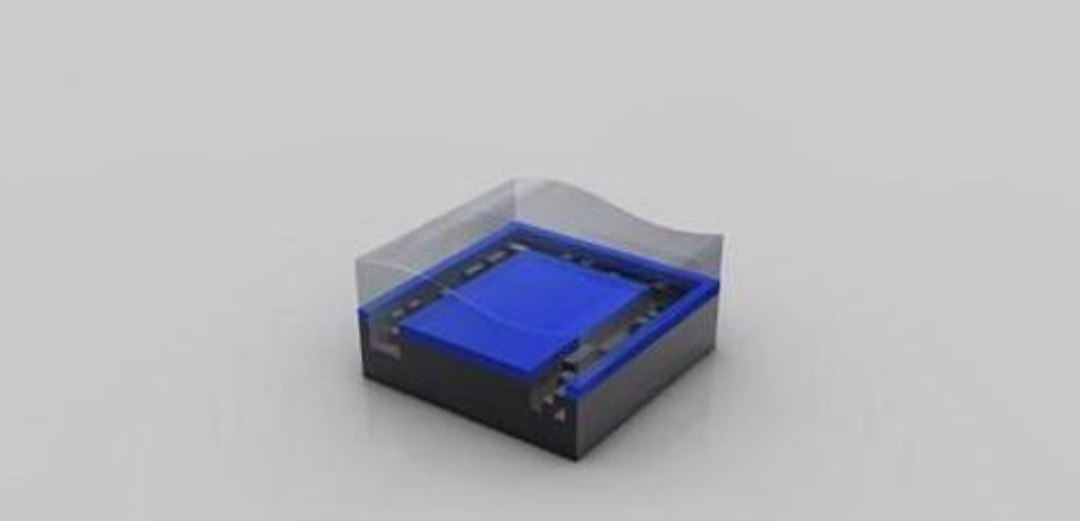

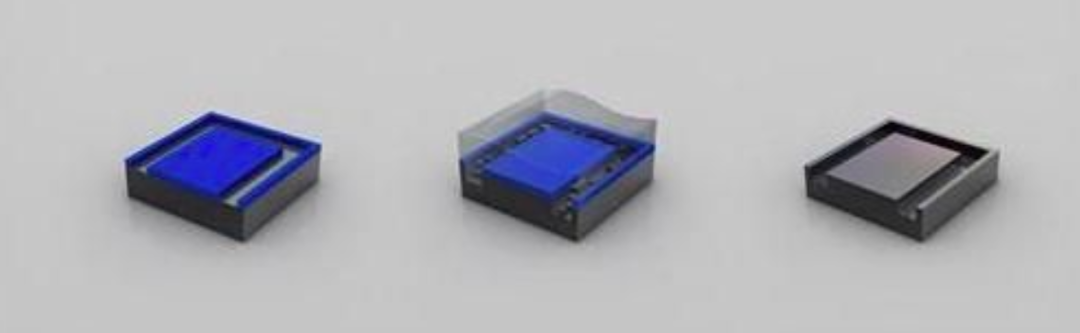

Wafer foundries manufacture chips based on the physical layout designed by chip designers.There are two trends in chip manufacturing: one is that wafers are getting larger, allowing for more chips to be cut out, improving efficiency; the other is the chip process, which refers to the size of the gate, also known as gate length. In the transistor structure, current flows from the Source to the Drain, and the Gate acts as a gate, primarily responsible for controlling the on/off state between the source and drain.Current will dissipate, and the width of the gate determines the loss of current flow, which manifests as common heat and power consumption in mobile phones. The narrower the width, the lower the power consumption. The minimum width of the gate (gate length) is also referred to as the process.The purpose of shrinking the nanometer process is to fit more transistors into a smaller chip, preventing the chip from becoming larger due to technological advancements.However, if we make the gate smaller, the current flowing between the source and drain will increase, making the process more challenging. The chip manufacturing process is divided into seven major production areas: diffusion, photolithography, etching, ion implantation, thin film growth, polishing, and metallization. Photolithography and etching are the two core steps.Transistors are sculpted through photolithography and etching. Photolithography is the process of creating the necessary circuits and functional areas for chip production.Using a photolithography machine, light is projected through a patterned photomask onto a wafer coated with photoresist. The photoresist undergoes a chemical change upon exposure to light, allowing the pattern from the photomask to be transferred onto the wafer, thus creating an electronic circuit diagram.This is the role of photolithography, similar to how a camera takes a picture. The photo taken by a camera is printed on film, while photolithography does not print a photo but rather a circuit diagram and other electronic components.

The chip manufacturing process is divided into seven major production areas: diffusion, photolithography, etching, ion implantation, thin film growth, polishing, and metallization. Photolithography and etching are the two core steps.Transistors are sculpted through photolithography and etching. Photolithography is the process of creating the necessary circuits and functional areas for chip production.Using a photolithography machine, light is projected through a patterned photomask onto a wafer coated with photoresist. The photoresist undergoes a chemical change upon exposure to light, allowing the pattern from the photomask to be transferred onto the wafer, thus creating an electronic circuit diagram.This is the role of photolithography, similar to how a camera takes a picture. The photo taken by a camera is printed on film, while photolithography does not print a photo but rather a circuit diagram and other electronic components. Etching is the process of selectively removing unwanted materials from the surface of the wafer using chemical or physical methods. In the typical wafer processing flow, the etching process follows photolithography, where the patterned photoresist layer is not significantly eroded by the etching source, thus completing the pattern transfer process. The etching step is crucial for replicating the mask pattern.

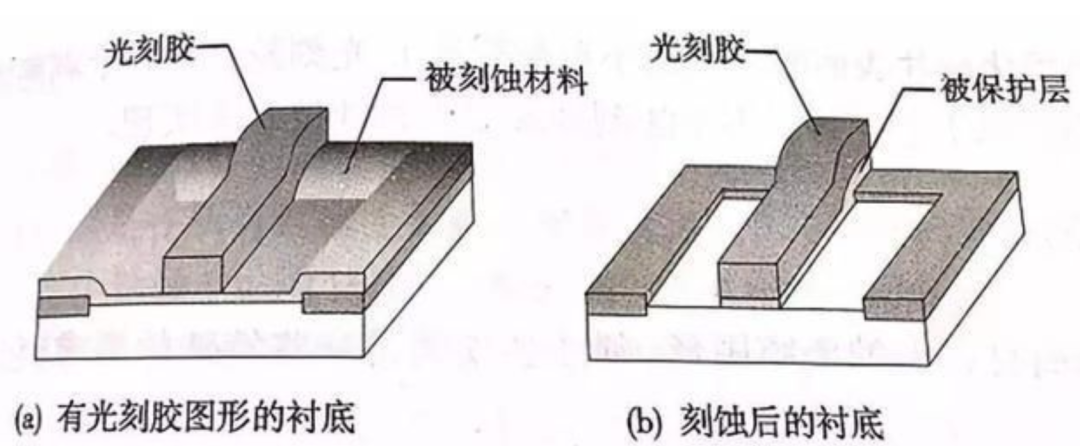

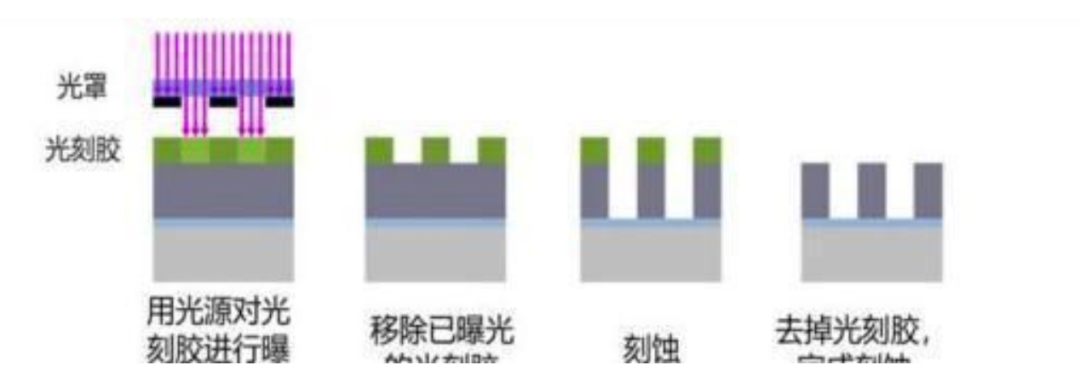

Etching is the process of selectively removing unwanted materials from the surface of the wafer using chemical or physical methods. In the typical wafer processing flow, the etching process follows photolithography, where the patterned photoresist layer is not significantly eroded by the etching source, thus completing the pattern transfer process. The etching step is crucial for replicating the mask pattern. Additionally, the material involved is photoresist. We need to understand that the circuit design is first written onto a photomask using a laser, and then the light source illuminates the surface of the wafer coated with photoresist through the photomask, causing a chemical effect in the exposed area of the photoresist. Afterward, developing technology dissolves and removes either the exposed or unexposed areas, transferring the circuit diagram from the photomask onto the photoresist, and finally using etching technology to transfer the pattern onto the wafer.

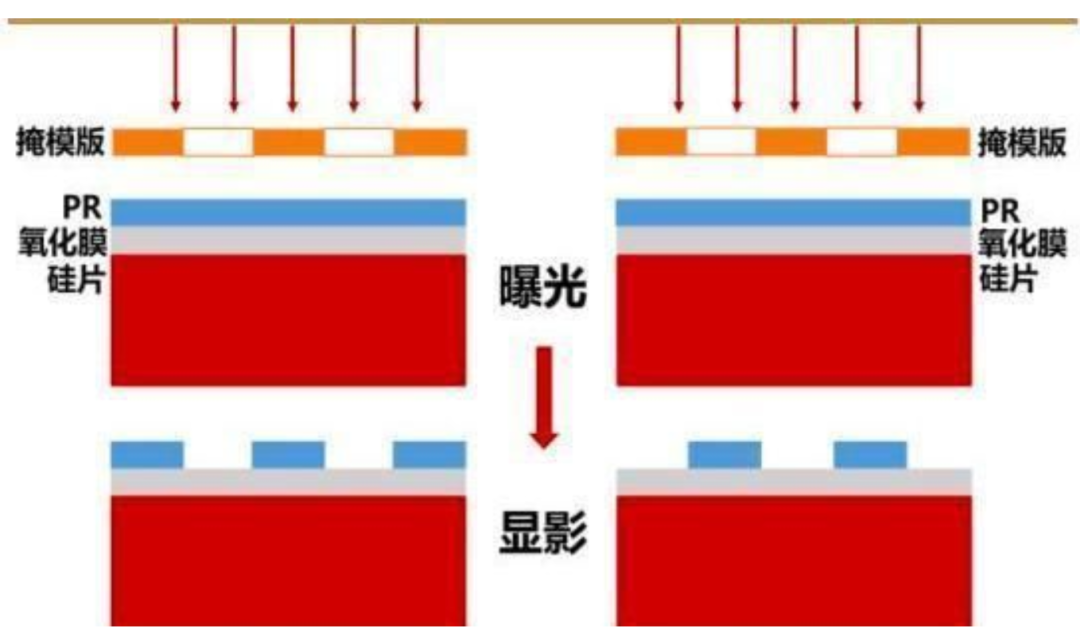

Additionally, the material involved is photoresist. We need to understand that the circuit design is first written onto a photomask using a laser, and then the light source illuminates the surface of the wafer coated with photoresist through the photomask, causing a chemical effect in the exposed area of the photoresist. Afterward, developing technology dissolves and removes either the exposed or unexposed areas, transferring the circuit diagram from the photomask onto the photoresist, and finally using etching technology to transfer the pattern onto the wafer. Photolithography is divided into positive and negative processes based on the type of photoresist used, categorized as positive photolithography and negative photolithography. In positive photolithography, the exposed part of the positive photoresist is destroyed and washed away by solvent, making the pattern on the photoresist identical to that on the mask. Conversely, in negative photolithography, the exposed part of the negative photoresist hardens and becomes insoluble, while the masked part is washed away by solvent, making the pattern on the photoresist opposite to that on the mask.

Photolithography is divided into positive and negative processes based on the type of photoresist used, categorized as positive photolithography and negative photolithography. In positive photolithography, the exposed part of the positive photoresist is destroyed and washed away by solvent, making the pattern on the photoresist identical to that on the mask. Conversely, in negative photolithography, the exposed part of the negative photoresist hardens and becomes insoluble, while the masked part is washed away by solvent, making the pattern on the photoresist opposite to that on the mask. We can briefly explain this step from a microscopic perspective.

We can briefly explain this step from a microscopic perspective. On a wafer (or silicon wafer) coated with photoresist, a pre-made photomask is placed on top, and ultraviolet light is used to irradiate the wafer for a certain period through the photomask. The principle is to use ultraviolet light to alter the photoresist, making it easier to etch.

On a wafer (or silicon wafer) coated with photoresist, a pre-made photomask is placed on top, and ultraviolet light is used to irradiate the wafer for a certain period through the photomask. The principle is to use ultraviolet light to alter the photoresist, making it easier to etch. Dissolving the photoresist: The photoresist exposed to ultraviolet light during the photolithography process is dissolved, leaving a pattern consistent with that on the mask.

Dissolving the photoresist: The photoresist exposed to ultraviolet light during the photolithography process is dissolved, leaving a pattern consistent with that on the mask. Etching is the process of using etching solution to remove the altered part of the photoresist (positive photoresist), revealing the semiconductor device and its connecting patterns on the wafer surface. Then, another etching solution is used to etch the wafer, forming the semiconductor device and its circuit.

Etching is the process of using etching solution to remove the altered part of the photoresist (positive photoresist), revealing the semiconductor device and its connecting patterns on the wafer surface. Then, another etching solution is used to etch the wafer, forming the semiconductor device and its circuit. Removing the photoresist: After etching is complete, the mission of the photoresist is over. Once fully removed, the designed circuit pattern can be seen.

Removing the photoresist: After etching is complete, the mission of the photoresist is over. Once fully removed, the designed circuit pattern can be seen. Over 10 billion transistors are sculpted in this manner, and transistors can be used for various digital and analog functions, including amplification, switching, voltage regulation, signal modulation, and oscillation.The more transistors there are, the greater the processing efficiency of the processor; furthermore, reducing the size can also lower power consumption; finally, as the chip size shrinks, it becomes easier to fit into mobile devices, meeting the future demand for thinner and lighter designs.

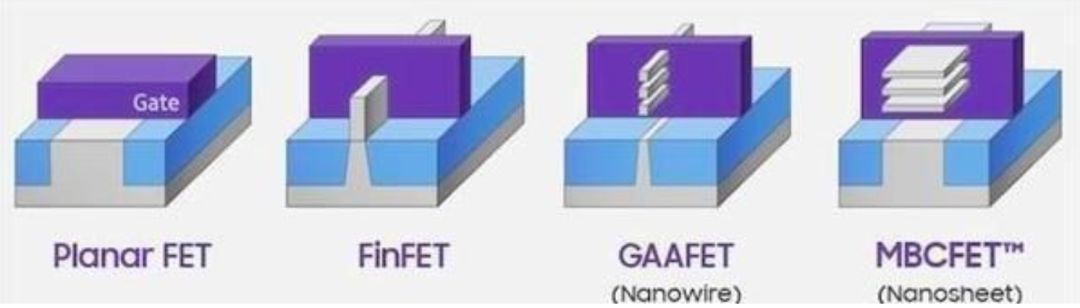

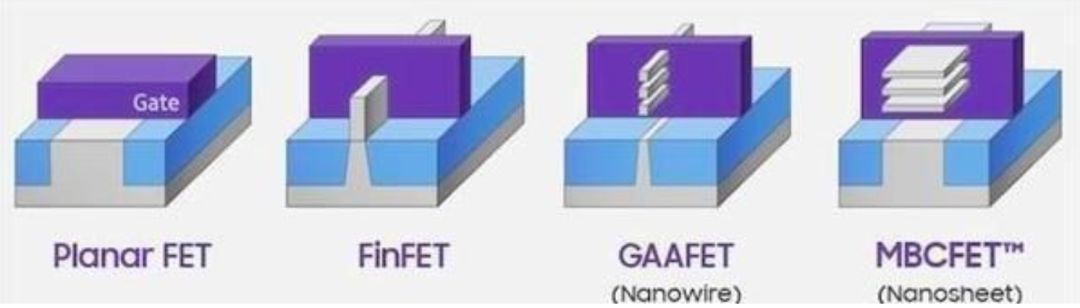

Over 10 billion transistors are sculpted in this manner, and transistors can be used for various digital and analog functions, including amplification, switching, voltage regulation, signal modulation, and oscillation.The more transistors there are, the greater the processing efficiency of the processor; furthermore, reducing the size can also lower power consumption; finally, as the chip size shrinks, it becomes easier to fit into mobile devices, meeting the future demand for thinner and lighter designs. Cross-section of chip transistorsAfter reaching 3nm, the current transistors are no longer applicable. Currently, the semiconductor industry is developing nanosheet FETs (GAA FETs) and nanowire FETs (MBCFETs), which are considered the future of today’s finFET technology.Samsung is betting on GAA surround-gate transistor technology, while TSMC has not yet disclosed its specific process details. Samsung was the first to announce GAA surround-gate transistors in 2019. According to Samsung, based on the new GAA transistor structure, they have manufactured MBCFETs (Multi-Bridge-Channel FETs) using nanosheet devices, which can significantly enhance transistor performance and replace finFET transistor technology.

Cross-section of chip transistorsAfter reaching 3nm, the current transistors are no longer applicable. Currently, the semiconductor industry is developing nanosheet FETs (GAA FETs) and nanowire FETs (MBCFETs), which are considered the future of today’s finFET technology.Samsung is betting on GAA surround-gate transistor technology, while TSMC has not yet disclosed its specific process details. Samsung was the first to announce GAA surround-gate transistors in 2019. According to Samsung, based on the new GAA transistor structure, they have manufactured MBCFETs (Multi-Bridge-Channel FETs) using nanosheet devices, which can significantly enhance transistor performance and replace finFET transistor technology. Additionally, MBCFET technology can also be compatible with existing finFET manufacturing processes and equipment, thereby accelerating process development and production.

Additionally, MBCFET technology can also be compatible with existing finFET manufacturing processes and equipment, thereby accelerating process development and production.

Disclaimer:All content provided by self-media sources is owned by the original authors. Please contact the original authors for permission to reprint.The views expressed in this article are solely those of the author and do not represent the position of Global Physics.

Global Physics

ID: huanqiuwuli

Global Physics focuses on the study of physics and is committed to spreading physics culture. Specializing in physics, we aim to inspire learners’ interest in physics, share the wisdom of physics, and encourage thinking through a physical lens, showcasing an interesting, rich, and magical world of physics.

For submissions, please contact [email protected]