First Author: Xue Zhixin

Corresponding Author: Xu Guiyin

Affiliation: Donghua University

Summary of Results

Sodium-ion batteries (SIBs) are receiving widespread attention due to their low cost, low-temperature performance, and fast charging capabilities. The membrane is one of the essential key components of the battery, affecting the battery’s interface structure, internal resistance, capacity, cycle life, and safety performance. Therefore, the membrane must possess excellent wettability, mechanical properties, pore size distribution, ionic conductivity, and thermal stability. Currently, research on sodium-ion battery membranes mainly focuses on the modification of commercial PP and PE membranes and other new types of membranes, which exhibit excellent chemical stability and cycling stability. These membranes have good electrochemical stability and high mechanical strength, but their stability at high temperatures is relatively poor, and they suffer from poor electrolyte wettability. Thus, the membrane remains one of the significant challenges in the practical application of sodium-ion batteries.

Introduction

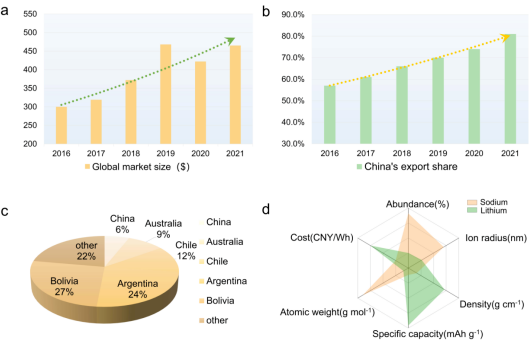

Lithium-ion batteries and sodium-ion batteries emerged in the late 1970s. Lithium-ion batteries have rapidly developed due to their electrochemical performance and currently dominate the market. They occupy a significant market share in many application scenarios, such as smartphones, electric vehicles, solar energy storage, and aerospace-related manufacturing fields. Meanwhile, the export ratio of lithium batteries has been increasing year by year (Figure 1a-b). However, this widespread use has led to a shortage of lithium, increasing costs. Statistical data shows that global lithium resources are mainly concentrated in South America and Australia, while China’s lithium resources account for only 6% of the global reserves (Figure 1c). The shortage of lithium will restrict its sustainable development.

Sodium has similar physical and chemical properties to lithium but is present in the Earth’s crust at a concentration 440 times that of lithium (Figure 1d). Sodium resources are widely distributed and easy to extract, making the cost of large-scale commercialization of sodium batteries significantly lower compared to lithium batteries. In recent years, with the development of the energy vehicle industry in our country and the increase in market demand, research and development of SIBs have also made steady progress. SIBs outperform lithium batteries in low-temperature performance, fast charging performance, and safety performance, but still have some shortcomings. SIBs have low energy density, low cycling stability, and rapid capacity decay, limiting their potential applications.

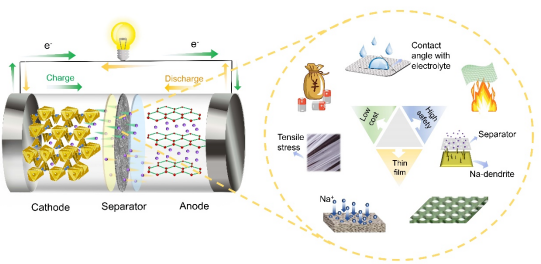

The structure of sodium-ion batteries is similar to that of lithium-ion batteries, mainly composed of positive electrode materials, negative electrode materials, electrolytes, and membranes. Sodium ions oscillate back and forth between the positive and negative electrodes, similar to a rocking chair. During charging, sodium ions are extracted from the positive electrode, pass through the electrolyte and membrane, and ultimately embed in the negative electrode. Electrons flow through the external circuit from the negative electrode to the positive electrode to balance the charge, with the discharge process being the reverse of the above (Figure 2). The membrane, as a crucial component of the internal structure, can isolate the positive and negative electrodes, store the electrolyte, and facilitate the free transport of sodium ions, significantly impacting the electrochemical performance of the battery. The ideal membrane for high-energy-density sodium batteries needs to have excellent chemical stability to resist organic electrolyte corrosion; high mechanical strength to prevent sodium dendrites from penetrating the membrane and causing internal short circuits; high wettability to expand the contact area between the membrane and electrolyte, thereby improving ionic conductivity and enhancing the battery’s charge-discharge performance and capacity; suitable pore size to promote the formation of uniform sodium ion channels, thus improving ionic transport efficiency; good thermal stability to maintain the membrane’s integrity, continue to isolate the positive and negative electrodes, and prevent short circuits; thin membranes can provide more space for the active materials of the positive and negative electrodes, thus increasing the battery’s energy density; and low production costs to allow for the widespread promotion and sustainable development of sodium-ion batteries.

Figure 1: (a-b) Global lithium battery market size and China’s lithium battery export volume; (c) Global lithium resource distribution; (d) Comparison of sodium and lithium properties.

Figure 2. Structure of sodium-ion batteries (left) and performance requirements of membranes (right).

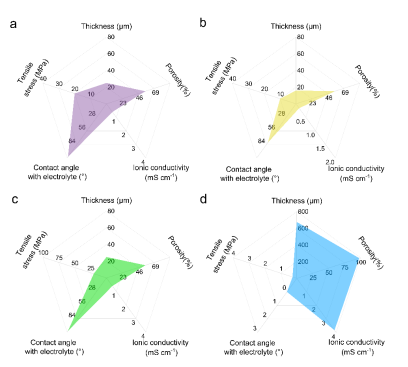

Currently, the primary materials for sodium-ion battery membranes are polyethylene, polypropylene membranes, and their composite membranes. Polyolefin membranes are low-cost, have strong mechanical properties, and good chemical stability, but they still have issues with thermal stability and electrolyte compatibility. Glass fibers have high porosity, excellent thermal stability, and high ionic conductivity, and are widely used as membranes for sodium-ion batteries in laboratories, but they still face problems such as large thickness and poor mechanical properties (Figure 3). To improve the thermal stability of the membranes without affecting the electrochemical performance of sodium batteries, researchers have coated inorganic ceramic powders with good thermal stability or polar polymers to enhance the thermal stability of the membranes, effectively improving the safety, high-power fast charging, and discharging performance of the battery. However, this may lead to reduced pore size and increased membrane thickness, negatively impacting battery performance. Additionally, cellulose, based on widely available raw materials, high wettability, good thermal stability, biocompatibility, and environmental friendliness, can meet the needs for sustainable development in the battery field. However, cellulose-based membranes are still in the laboratory research stage and require further exploration for commercialization. Furthermore, using interlayers that promote interfacial ionic transport, designing composite membranes that prevent sodium dendrite growth, or using inorganic solid electrolytes with low elastic modulus are also feasible options.

Conference Recommendations

The 2024 International Symposium on Energy Storage Materials and the 2024 Shenzhen International Graphene Forum will be jointly hosted by the Shenzhen Science and Technology Innovation Commission, the Nanshan District People’s Government, Tsinghua University Shenzhen International Graduate School, the Institute of Metal Research, Chinese Academy of Sciences, the Shenzhen Advanced Technology Research Institute Carbon Neutral Technology Institute, and the Shenzhen Game Graphene Center from April 10-13, 2024, at Tsinghua University Shenzhen International Graduate School.

Currently, 8 keynote speakers have been confirmed: Nobel Laureate Konstantin Novoselov, Academicians Liu Zhongfan, Dai Hongjie, Chen Jun, Patrice Simon, Professor Joachim Maier, Chair Professor Liu Zheng, and Young Scientist Li Xianfeng… More speakers will be updated continuously, please pay attention.

We warmly welcome global researchers, engineers, corporate representatives, and students working in the fields of energy storage materials, energy storage devices, graphene and other two-dimensional materials, as well as carbon nanomaterials to actively participate and submit papers.