In the summer of 2025, as a group of graduates donned their bachelor’s robes and walked out of the gates of Xinxiang University, the first truly qualified 3D printing undergraduates trained by Chinese universities officially entered society. As the first university in the country to establish an “Additive Manufacturing Engineering undergraduate program,” the graduation report from the 3D Printing College of Xinxiang University not only reflects the achievements of the institution itself but also influences the future path of talent cultivation in China’s 3D printing sector.

In June 2025, Antarctic Bear interviewed Dean Qian Chunyan of the 3D Printing College at Xinxiang University to understand the training model, employment directions, and career trajectories of this group of “pioneers.” Their paths may lead them into the front lines of the industry, continue their studies and research, or become innovators and entrepreneurs. At the same time, Antarctic Bear is pondering: can their future truly leverage the next pivot of Chinese manufacturing?

△ Dean Qian Chunyan of the 3D Printing College at Xinxiang University

An “experiment” in breaking new ground for the discipline: The official establishment of the Additive Manufacturing undergraduate program

Xinxiang University began laying the groundwork for 3D printing undergraduate education in 2017. Without the backing of a national professional directory, it gradually integrated traditional engineering disciplines such as materials science, electrical engineering, software engineering, and mechanical design with 3D printing directions, adding content on 3D modeling, printing processes, and equipment operation to pilot the training of talent in additive manufacturing.

Dean Qian candidly stated that establishing the additive manufacturing program faced many challenges: “At that time, experts had differing opinions. Some believed that additive manufacturing (3D printing) is essentially a manufacturing technology, belonging to the application of manufacturing engineering or materials science, and should not be set up as an independent undergraduate program.” These doubts stem from the fact that additive manufacturing technology inherently integrates multiple disciplines, including mechanics, materials, control, computing, and software, making it difficult to categorize within traditional academic fields; at the same time, the lack of a mature theoretical system makes structural layout and curriculum design extremely challenging.

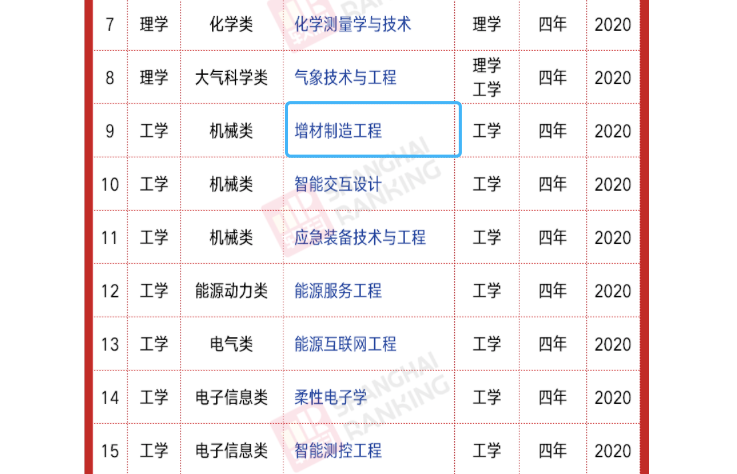

It wasn’t until 2021 that the “Additive Manufacturing Engineering” program finally received approval from the Ministry of Education, making Xinxiang University the only institution in the country to establish this program that year. This was a pilot exploration of a program outside the directory, meaning that these students embarked on a “non-typical” path when filling out their college applications, carrying the strategic mission of interdisciplinary integration in new engineering.

As Dean Qian Chunyan stated in an exclusive interview with Antarctic Bear: “Additive manufacturing is not simply an extension of mechanical engineering; it is essentially a typical interdisciplinary system that encompasses mechanics, materials, control, computing, and electrical engineering. Therefore, the training program must break through traditional disciplinary frameworks.”

Prioritizing breadth: The “additive thinking” in course design

The undergraduate curriculum for Additive Manufacturing Engineering at Xinxiang University adopts a “breadth-first + project-driven” hybrid structure, aiming to cultivate composite application-oriented engineering talents with foundational engineering thinking, process capabilities, material adaptation, modeling simulation, and equipment operation.

Its course design features include:

-

Five major knowledge dimensions covered: material properties (such as tensile strength, melting point), typical printing technologies (SLM, SLA, FDM, etc.), 3D modeling (including topology optimization and reverse design), industrial-grade equipment operation, and equipment hardware principles.

-

Project-based teaching implementation: Innovative practice projects for disassembling and assembling FDM printers, developing cultural and creative products, personalized design of 3D printed medical supports and rehabilitation aids, and conducting joint graduation projects with real enterprise problems, such as optimizing metal printing parameters and participating in entrepreneurial practice exhibitions.

△ Innovative practice teaching for FDM disassembly and assembly

△ Project teaching for assembling FDM printers

△ Project practice teaching for cultural and creative product development

-

Integration of industry and education training: The experimental platform covers metal, nylon, photopolymerization, polymer, ceramic, FDM printing, post-processing, and testing areas, with a total investment of over 30 million yuan and a platform area of 2,000 square meters.

It is particularly noteworthy that students in the Additive Manufacturing Engineering program must possess comprehensive abilities in rapid material selection, forming path planning, and equipment matching and debugging. As Dean Qian summarized: “I do not require undergraduate students to master theoretical knowledge to an extreme depth, but they must have a full-chain thinking in additive manufacturing—thinking (customer needs), selecting (materials, equipment), creating (3D modeling), using (equipment operation), and optimizing (process adjustments).”

Employment profile: Over 60 students pursue further studies, nearly 100 are favored by companies, and many are booked by enterprises before graduation, with an employment rate reaching 95% during graduation season.

As the first batch of undergraduates in the Additive Manufacturing Engineering program in China, the 3D Printing College of Xinxiang University has about 270 graduates this year, including students from rehabilitation engineering, biomedical engineering, and other majors, all of whom received training in basic 3D printing skills.

Antarctic Bear has learned that this year’s employment data is quite impressive:

(1) Over 60 students have successfully entered graduate programs. Some have been admitted to top universities such as Hebei University of Technology, Dalian University of Technology, Yanshan University, Zhengzhou University, and Henan University, with directions covering materials science and engineering, mechanical engineering, additive manufacturing design and processes, laser additive manufacturing, and biomedical engineering;

(2) Over 200 students have found employment.

Among them, nearly 50 students in the 3D printing-related medical engineering direction have joined local innovative leading enterprises—Henan Tuoren Medical Device Group Co., Ltd., empowering the healthcare industry with 3D printing.

Nearly 100 students have entered 3D printing-related companies, including:

-

Shanghai Fuzhi Technology, Shanghai Heiyan Medical, Xinjinghe Technology, Liantai Technology, Yijia 3D, Nanjing Enigma Industrial Automation Technology Co., Ltd., and other well-known companies in the industry, hiring varying numbers of graduates;

-

Traditional strong enterprises such as Huashu High-tech, Hart 3D, and AVIC Mate have also extended olive branches to the school;

-

Some students have joined local companies in Henan, such as Chao Kuo Electronics, Jinhang Testing, and Zhengzhou Kensai Technology Co., Ltd., injecting new vitality into the development of the 3D printing industry in Henan.

△ Graduates from the 3D Printing College at Xinxiang University who joined Shanghai Fuzhi

The “hardcore” achievements of students are backed by the school’s “accumulated strength” investment

From curriculum design, equipment procurement, faculty development, school-enterprise cooperation, graduate school guidance, to practical training platform construction, the 3D Printing College at Xinxiang University has embarked on a rare path of specialization among local undergraduate institutions:

-

In terms of faculty: Over 32.5% of the 40 teachers in the college hold doctoral degrees, and 8 industry mentors have been hired, forming an integrated team of teaching, research, and application;

-

Practical resources: Students can directly use metal printers on campus for SLM printing, with a full chain from modeling to printing, post-processing, and testing;

-

Project-driven: Students can complete 1-3 practical projects during their studies, accumulating over 3,000 hours of service, with self-assembled equipment fault intervals exceeding 500 hours;

-

Social recognition enhancement: The admission score line for the Additive Manufacturing Engineering program has risen for three consecutive years, with the 2024 admission rate for science students in Henan Province exceeding 120%, and the highest admission score reaching 536 points.

This high investment and high standard practical teaching has become the supporting force behind the “hard power” of talent employment.

Career pathways and challenges coexist: Where do undergraduates go from here?

Despite the overall positive employment situation, 3D printing undergraduates still face many real challenges:

-

Industry fragmentation and rapid technological updates: With numerous equipment models and constantly evolving processes, students are forced to continue learning and adapting after graduation;

-

Clear trend of “using without nurturing” in enterprises: Some companies do not yet have a complete technical training system, putting pressure on undergraduates who enter the workforce with weak foundations;

-

Heavy load of interdisciplinary courses: Integrating five major disciplines within 166 credits inevitably leads to limitations of “broad but not deep”;

-

Lack of composite teachers: Current faculty mainly come from traditional disciplines such as materials, mechanics, or computer science. Although there are PhDs in additive manufacturing from Harbin Institute of Technology and South China University of Technology employed in the 3D Printing College, they still cannot fully support teaching in software, hardware, and algorithm modeling, limiting students’ expansion into cutting-edge intelligent manufacturing fields;

-

Lack of a medium- to long-term professional certification system in the industry: Currently, there is no complete professional qualification system corresponding to “Additive Manufacturing Engineer.”

However, from another perspective, this group of students may be the “native generation” most suited to the future manufacturing ecosystem:

-

They possess full-process skills in modeling, forming, and equipment maintenance;

-

They have participated in real projects and have experience solving practical problems;

-

They are profoundly influenced by 3D printing, possessing a mindset of “structure equals function” and “on-demand manufacturing”;

-

Their growth paths are changing the traditional stereotype of “undergraduate = technical worker.”

Antarctic Bear’s commentary: Their future is not just about “finding a job”

Antarctic Bear believes that the 3D printing undergraduate education system represented by Xinxiang University is gradually becoming a key force in the upgrading of China’s manufacturing industry. Of course, this model is also being adopted by many universities across the country. By 2025, 23 universities will have opened the same program, with Xinxiang University’s advantages becoming even more apparent. The employment status of the first batch of additive manufacturing undergraduates has already sent three positive signals to the industry:

The “Additive Manufacturing Engineering” program is recognized by enterprises, not just a “virtual name,” but a real recruitment target;

“Versatile” talents are more favored, and students with composite abilities are more likely to secure core positions;

The integration of teaching, learning, research, and application is gradually forming a closed loop, with universities beginning to supply directly employable engineering talents to enterprises.

This marks the beginning of a generation of “printing natives.” They are not only the implementers of the 3D printing industry but also the pioneers of the future intelligent manufacturing era. In the future, will we see more “undergraduate” names in domestic metal printing, high-end medical devices, domestic aerospace components, and educational innovation fields? We shall see.

Conclusion: The era of cultivating application-oriented talents in China’s additive manufacturing has begun

Not every university dares to open an “Additive Manufacturing Engineering” program, nor is every student willing to be among the first to “take the plunge.” But it is this courage, investment, and persistence that have made China’s 3D printing undergraduate education no longer just a concept, but a force that can truly change the industrial landscape.

There are risks, but also opportunities!

Let us cheer for these young people stepping out of the school and into the front lines of the industry. In the future, they may build a smarter, greener, and more efficient “Made in China.”

“The 2025 college entrance examination results are out, and 23 universities have 3D printing majors [Additive Manufacturing Engineering] to choose from. What will the score lines be?”Recent hot articles from Antarctic Bear:“Members of the [Hong Kong 3D Printing Association] expressed amazement after visiting three 3D printing companies in Shenzhen: Can this really work?”“3D printing cars in the morning and 3D printing missiles in the afternoon! The U.S. pushes the “Commercial Reserve Manufacturing Network” bill, with additive manufacturing and AI technology becoming new pillars of defense manufacturing.”“Frequently featured on CCTV, the booming 3D printing farm is forming an ecosystem, and the second farm conference is now open for registration.”“Help: What is the English translation for ‘Antarctic Bear’?”“Yijia 3D impacts the Sci-Tech Innovation Board IPO, delivering over 100 ‘super-meter’ metal 3D printers in 2024.”“LABUBU infringement case verdict! 3D printing players should beware of ‘ten-thousand-dollar bills.'”“Notice: Chinese 3D printing farms/service factories may inadvertently receive foreign military orders.”“The ‘3D printing farm’ explosion has attracted attention from Xinhua News Agency and Shanghai Securities Journal.”“3D printed landmines cost less than $50, and Ukrainian soldiers are buying Chinese consumer-grade 3D printers in large quantities to produce them.”