1.

What is VX1000?

The VX1000 system is a high-performance measurement and calibration hardware that enables high bandwidth and high-frequency acquisition of internal ECU variables through high-speed debugging interfaces of the MCU (such as DAP, JTAG, SWD, Aurora, TPIU, etc.), with minimal or no CPU resource consumption. Additionally, the VX1000 system offers a wide range of functionalities, including DAQ acquisition during the first cycle after power-up, uninterrupted DAQ acquisition during ECU reset, dynamic Flash Overlay, code bypass, functional stimulation, Flash programming, and more.

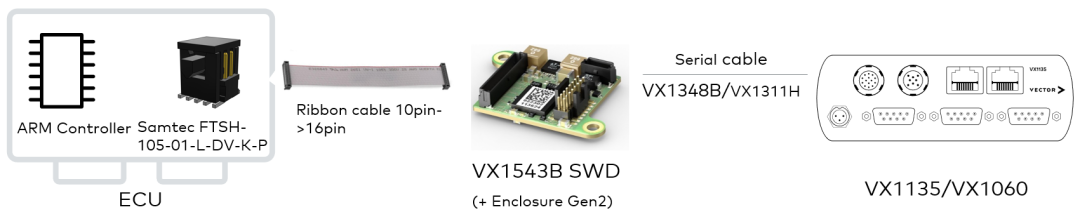

The VX1000 system consists of two parts: the base module and the POD (Plug-On-Device). One end of the POD connects to the microcontroller’s debug port, while the other end connects to the base module (such as VX1060, VX1135, VX1161, etc.), and finally, a computer running CANape is connected to the base module via Ethernet.

Combined with the powerful measurement and calibration tool CANape, the VX1000 can be used for complex measurement configurations of thousands of signals and can measure event rates of 100 microseconds or even faster. Depending on the user’s objectives, measurement rates of up to 100 MBytes per second can be achieved.

In recent years, the VX1000 has strengthened its support for domestic chips. Through end-users or chip manufacturers, Vector has adapted several domestic chips. For information on domestic chips compatible with the VX1000, please contact us. For the latest list of supported domestic chips, please click the end of the article“Read the original text” to view.

2.

Usage Scenarios of VX1000

In chassis applications, such as ABS/ESP/EMB, it is necessary to measure thousands of signals simultaneously; in electric vehicle measurements, such as inverters, measurement time accuracy can reach 10 microseconds or even faster; for radar sensor measurements, a large amount of raw data and 1D/2D FFT data or XCP data must be collected; in advanced driver-assistance systems, for perception, fusion, and control data, at least thousands of signals need to be collected. The VX1000 perfectly supports all of these measurement scenarios.

All measurement data from the VX1000 is timestamped, and precise time synchronization for simultaneous measurements from multiple controllers can be achieved through the IEEE 1588 PTP protocol.

3.

VX1000 Measurement and Calibration Solutions for ARM M/R Cores

a.

SWD Interface Solution

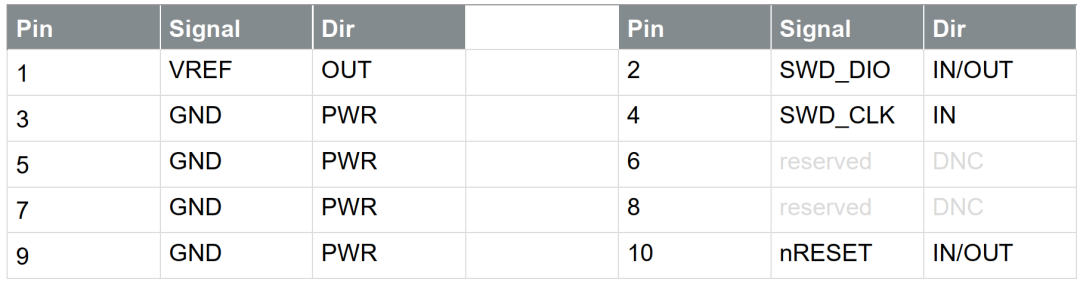

ARM SWD (Serial Wire Debug) is a dual-wire debugging protocol proposed by ARM, serving as a simplified alternative to JTAG for debugging, programming, and diagnosing ARM Cortex series processors. The POD model of VX1543B supports the SWD interface, connecting to the SWD connector of the ARM chip via a 10-pin ribbon cable. To ensure testing stability, Vector provides enclosures and harnesses rated IP60/67. The communication frequency of the SWD interface is generally within 50 MHz, and when used with either the VX1060 or VX1135 base module, the achievable measurement bandwidth is typically within 1.5 MB/s.

VX1000 SWD Interface Solution

10 Pin SWD Interface Definition

b.

TPIU Trace Interface Solution

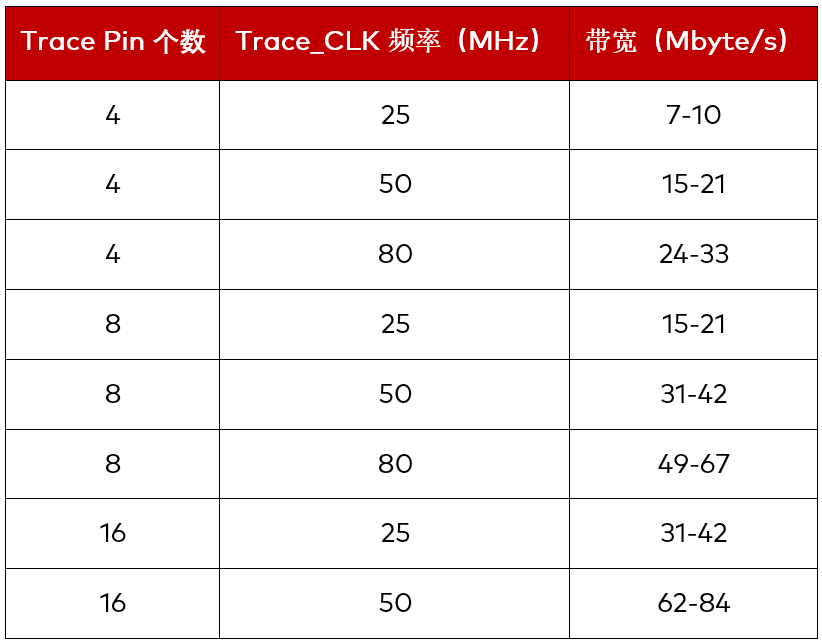

TPIU is a parallel interface defined by ARM, part of the ARM CoreSight debugging architecture, used to output internal chip trace data to the outside, facilitating real-time program tracing and analysis for developers. The TPIU interface is often referred to as the Trace-Pin-Interface or ETM-Trace-Interface. The TPIU interface is a unidirectional interface, allowing data to be transmitted only from the target controller to the debugger or measurement hardware; it cannot be used alone and must be combined with JTAG or SWD interfaces in calibration application scenarios. Depending on the number of trace pins used and the frequency, the TPIU interface can achieve high measurement bandwidth.

Since Trace Pin pins are generally multiplexed with other peripheral pins, users need to reserve the relevant pins during ECU hardware design, and real vehicle testing scenarios also need to consider the fixation and packaging of the POD.

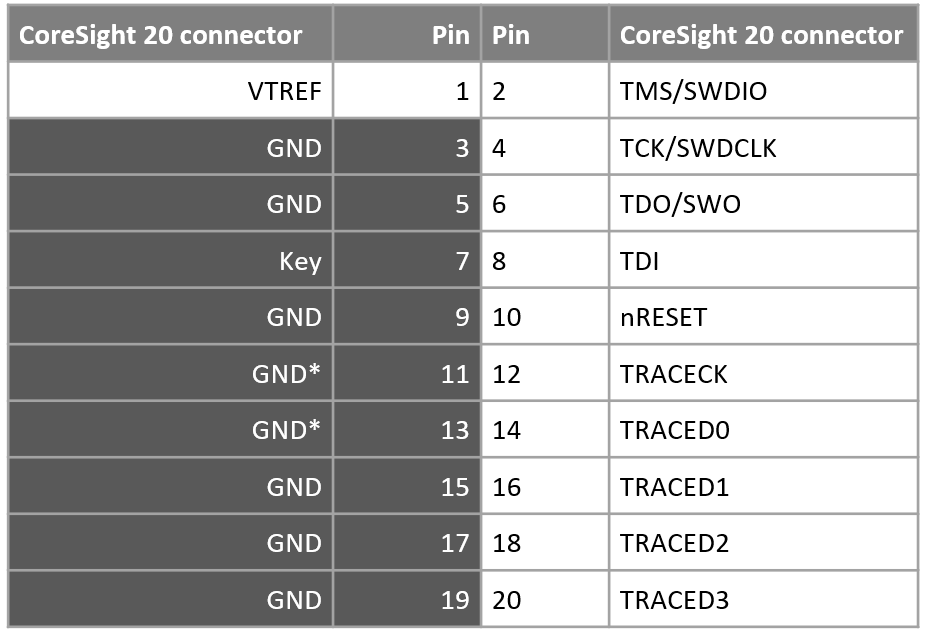

The VX1453 POD supports TPIU interface measurements and offers three types of Trace connectors: 20 Pin (including 4 Trace Data), 28 Pin (including 8 Trace Data), and 44 Pin (including 16 Trace Data). The POD end has a 60 Pin connector, and Vector provides a 44 Pin to 60 Pin adapter board VX1902.09 for connecting the ECU and POD. The VX1453 POD enclosure is not waterproof; for automotive applications, users are advised to create their own enclosure. The interface between the VX1453 POD and the base module is HSSL or HSSL2, requiring the selection of either the VX1135 or VX1161 base module..

VX1000 TPIU Interface Solution

20Pin (4Pin Trace Data) TPIU Interface Definition

The advantage of this solution over the SWD interface solution is that it offers higher acquisition bandwidth; the DAQ (Data Acquisition) bandwidth of SWD is generally within 1.5 Mbyte/s, while the 4 Pin Trace solution can easily achieve 7~10 Mbyte/s. Additionally, compared to the Ethernet XCP acquisition solution, the TPIU acquisition solution consumes very low CPU load, approximately 0.4%~5% for 1 MByte/s.

4.

Conclusion

The application of ARM chips in automotive electronics is becoming increasingly widespread, occupying a core position in key systems such as automotive control, infotainment, and autonomous driving due to their high performance and flexible architecture. The ARM SWD and TPIU acquisition solutions supported by the VX1000 offerhigh bandwidth and low system load, providing efficient and reliable data acquisition capabilities for automotive electronics development, effectively simplifying the development process and accelerating project validation.

END

Recent Online Seminar

Vector China

WeChat ID|Vector维克多

Bilibili | Vector Automotive Technology

021-2283 4688

Click“Read the original text” to view the supported chip types.