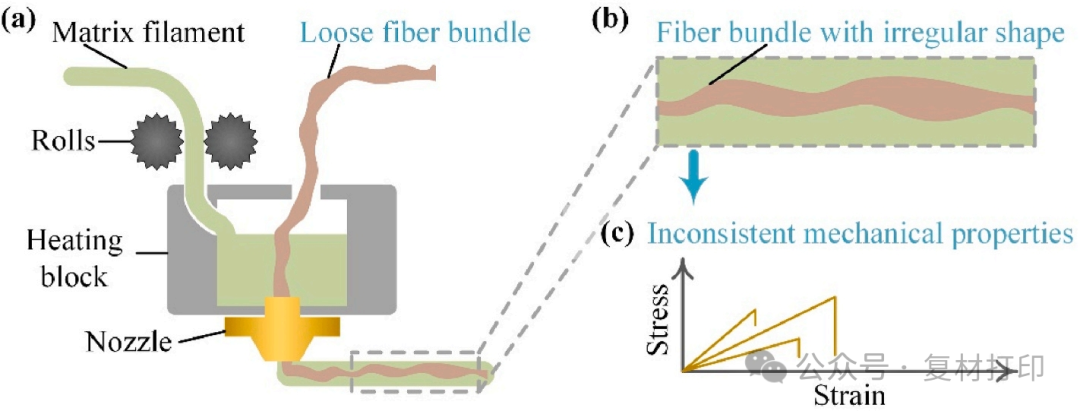

1 Paper InformationIn 2025, the journal “Composites Communications” in the field of composites published a research paper from Central South University on the 3D printing process of continuous fiber-reinforced composites with high uniformity, titled “3D printed continuous fiber-reinforced composites with high fiber bundle shape uniformity, mechanical performance consistency, and fiber content”. 2 Background SignificanceAlthough Fused Deposition Modeling (FDM) technology can achieve 3D printing of Continuous Fiber Reinforced Composites (CFRCs), traditional in-situ impregnation processes have defects such as uneven fiber bundle shapes and unstable impregnation quality. Loose fiber bundles lead to discrete width/thickness distributions, and randomly distributed unimpregnated areas cause stress concentration, resulting in significant fluctuations in mechanical properties (especially tensile strength), making it difficult to meet engineering application requirements. This study proposes a groove-assisted impregnation process that optimizes fiber tension control and resin penetration mechanisms to achieve uniform fiber bundle shapes, improved mechanical performance consistency, and high fiber content (40 vol%), filling the gap in the research on the correlation between fiber bundle morphology and mechanical properties.3 Main ContentThe nozzle impregnation method passively impregnates fiber bundles within the nozzle, where fluctuations in resin pressure can lead to uneven morphology. Figure 1a illustrates the principle of a 3D printer based on nozzle impregnation. Figure 1b shows that loose fiber bundles lead to randomly distributed unimpregnated areas, causing interface defects. Figure 1c indicates that the stress-strain curve of such composites exhibits significant fluctuations, suggesting inconsistency in mechanical performance.

2 Background SignificanceAlthough Fused Deposition Modeling (FDM) technology can achieve 3D printing of Continuous Fiber Reinforced Composites (CFRCs), traditional in-situ impregnation processes have defects such as uneven fiber bundle shapes and unstable impregnation quality. Loose fiber bundles lead to discrete width/thickness distributions, and randomly distributed unimpregnated areas cause stress concentration, resulting in significant fluctuations in mechanical properties (especially tensile strength), making it difficult to meet engineering application requirements. This study proposes a groove-assisted impregnation process that optimizes fiber tension control and resin penetration mechanisms to achieve uniform fiber bundle shapes, improved mechanical performance consistency, and high fiber content (40 vol%), filling the gap in the research on the correlation between fiber bundle morphology and mechanical properties.3 Main ContentThe nozzle impregnation method passively impregnates fiber bundles within the nozzle, where fluctuations in resin pressure can lead to uneven morphology. Figure 1a illustrates the principle of a 3D printer based on nozzle impregnation. Figure 1b shows that loose fiber bundles lead to randomly distributed unimpregnated areas, causing interface defects. Figure 1c indicates that the stress-strain curve of such composites exhibits significant fluctuations, suggesting inconsistency in mechanical performance.

Figure 1 (a) Schematic diagram of a 3D printer based on nozzle impregnation technology, (b) Defective fiber bundles, (c) Mechanical response of 3D printed composites

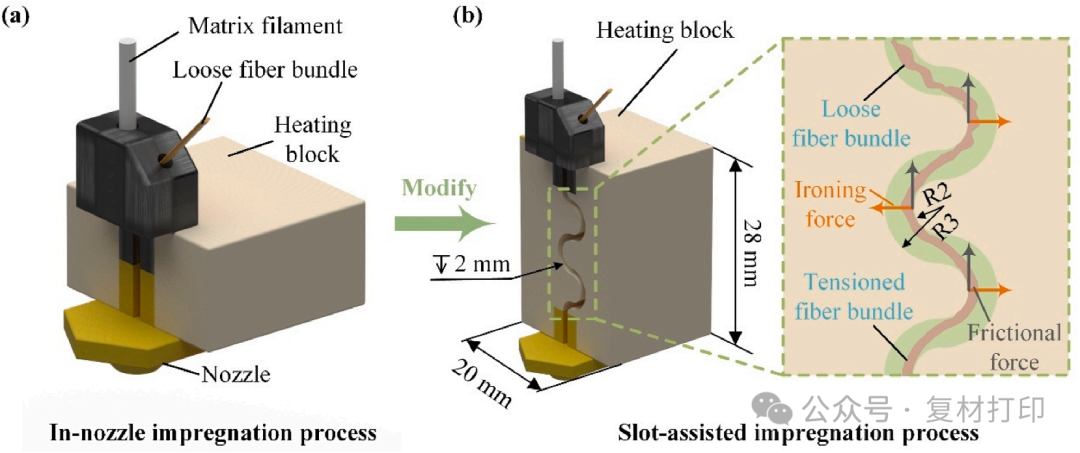

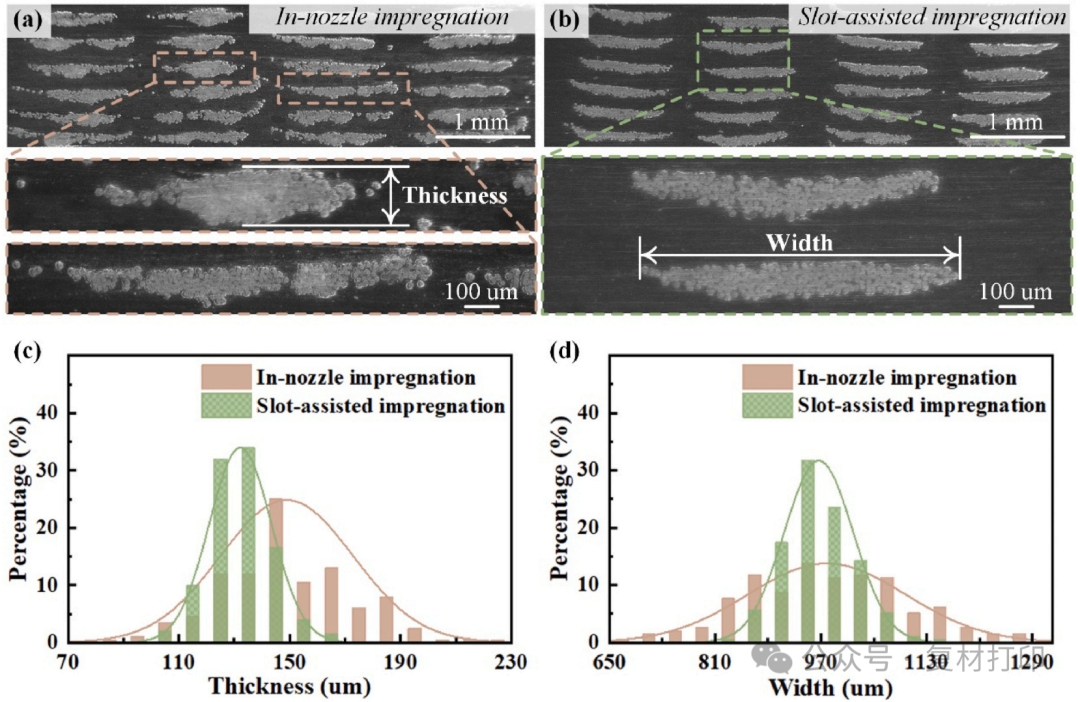

Comparing the principles of the two impregnation processes. Figure 2a is a schematic of nozzle impregnation, where resin only penetrates the fiber bundles during nozzle extrusion. Figure 2b illustrates the core innovation of groove-assisted impregnation: inspired by the unidirectional tape (UD-tape) groove molding process, an S-shaped channel heating mold is designed. The protruding structure tightens the fiber bundles through friction, while the pressing force on both sides promotes resin penetration, significantly improving impregnation uniformity. Figure 2 (a) Schematic of nozzle impregnation and (b) groove-assisted impregnation process for stretching fibersFigure 3a shows significant differences in fiber bundle shapes in the cross-section of CFRCs produced by nozzle impregnation (thickness 70–230 μm, width 650–1290 μm). Figure 3b confirms that the fiber bundle morphology in the groove-assisted process is highly uniform (thickness 100–170 μm, width 810–1170 μm). Figures 3c-d quantitatively compare: the groove-assisted process reduces the thickness distribution range by 58.3% (230→70 μm) and the width distribution range by 37.2% (640→360 μm), with the thickness peak shifting from 140–150 μm to 130–140 μm, which is beneficial for improving impregnation quality.

Figure 2 (a) Schematic of nozzle impregnation and (b) groove-assisted impregnation process for stretching fibersFigure 3a shows significant differences in fiber bundle shapes in the cross-section of CFRCs produced by nozzle impregnation (thickness 70–230 μm, width 650–1290 μm). Figure 3b confirms that the fiber bundle morphology in the groove-assisted process is highly uniform (thickness 100–170 μm, width 810–1170 μm). Figures 3c-d quantitatively compare: the groove-assisted process reduces the thickness distribution range by 58.3% (230→70 μm) and the width distribution range by 37.2% (640→360 μm), with the thickness peak shifting from 140–150 μm to 130–140 μm, which is beneficial for improving impregnation quality.

Figure 3 Cross-sectional morphology of CFRP based on (a) nozzle impregnation and (b) groove-assisted impregnation 3D printing processes; (c) Thickness and width distribution of fiber bundles in CFRP based on the two 3D printing processes

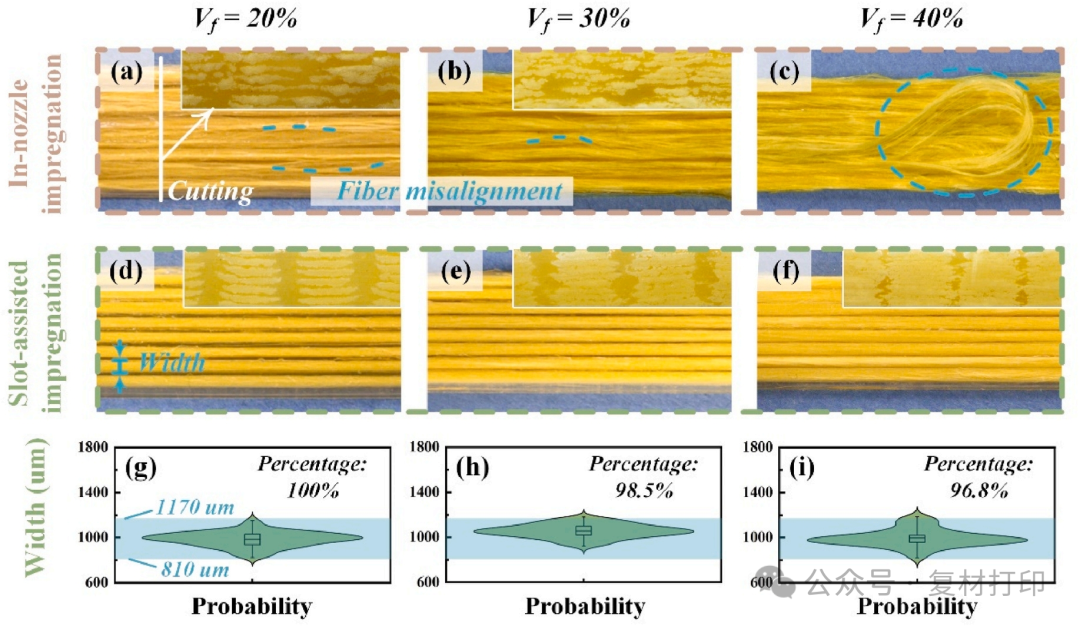

Figures 4a-c show that traditional processes experience fiber bundle misalignment (Figures 4a-b) or even failure to form (Figure 4c) when fiber content exceeds 30%. In contrast, the groove-assisted process maintains fiber bundle alignment even at 40 vol% (Figures 4d-f). Figures 4g-i quantitatively indicate that even as fiber content increases from 10.2% to 40%, 96.8% of fiber bundle widths remain stable at 810–1170 μm (consistent with the low content time distribution range), breaking the traditional process’s fiber content limit (<30%). Figure 4 CFRC printed using (a-c) nozzle impregnation and (d-f) groove-assisted impregnation processes; (g–i) Width distribution of fiber bundles in CFRP based on the groove-assisted impregnation process4 Main Conclusions1. Process Innovation: The groove-assisted impregnation process achieves active tensioning of fiber bundles and bidirectional resin penetration through S-shaped channel design, addressing the issue of uneven morphology caused by loose fibers in traditional processes.2. Performance Improvement: The distribution ranges of fiber bundle thickness/width are reduced by 58.3% and 37.2%, respectively, with significantly improved impregnation uniformity; tensile strength is increased by 10.6%, and mechanical performance consistency meets engineering application standards.3. Technical Breakthrough: Stable printing of CFRCs with high fiber content of 40 vol% is achieved, with a fiber bundle width qualification rate exceeding 96.8%, providing a new solution for manufacturing high-load structural components.Original TitleXiang J, Lin H, Wang D, et al. 3D printed continuous fiber-reinforced composites with high fiber bundle shape uniformity, mechanical performance consistency, and fiber content[J]. Composites Communications, 2025, 58: 102499.Original Link

Figure 4 CFRC printed using (a-c) nozzle impregnation and (d-f) groove-assisted impregnation processes; (g–i) Width distribution of fiber bundles in CFRP based on the groove-assisted impregnation process4 Main Conclusions1. Process Innovation: The groove-assisted impregnation process achieves active tensioning of fiber bundles and bidirectional resin penetration through S-shaped channel design, addressing the issue of uneven morphology caused by loose fibers in traditional processes.2. Performance Improvement: The distribution ranges of fiber bundle thickness/width are reduced by 58.3% and 37.2%, respectively, with significantly improved impregnation uniformity; tensile strength is increased by 10.6%, and mechanical performance consistency meets engineering application standards.3. Technical Breakthrough: Stable printing of CFRCs with high fiber content of 40 vol% is achieved, with a fiber bundle width qualification rate exceeding 96.8%, providing a new solution for manufacturing high-load structural components.Original TitleXiang J, Lin H, Wang D, et al. 3D printed continuous fiber-reinforced composites with high fiber bundle shape uniformity, mechanical performance consistency, and fiber content[J]. Composites Communications, 2025, 58: 102499.Original Link

https://www.sciencedirect.com/science/article/pii/S2452213925002529?via%3Dihub