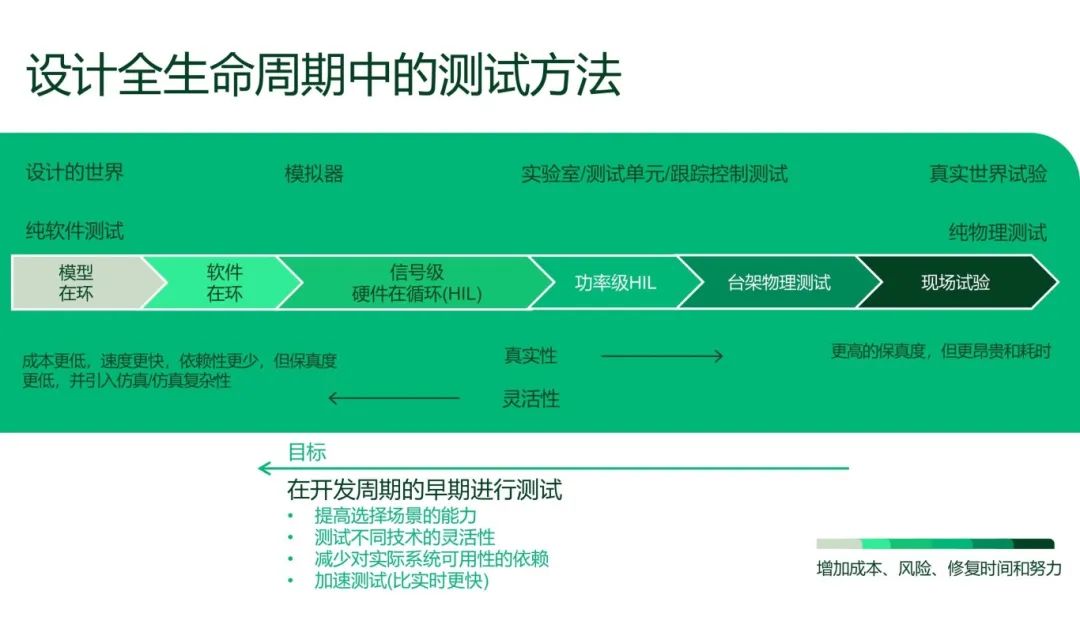

As technology continues to converge, we need a more agile and flexible development platform to support the full lifecycle testing of ECUs. The stages of ECU lifecycle testing are listed from left to right, representing the transition from pure software testing to pure physical testing.

The left side utilizes more model-based technologies, which provides higher flexibility and lower costs. As the process moves to the right, testing gradually approaches actual hardware and vehicle environments. Although the realism increases, flexibility decreases, and the requirements for personnel, facilities, equipment, and laboratory surroundings also increase, leading to higher costs and risks.

Therefore, we need to find a good balance in testing throughout the lifecycle, using Hardware-in-the-Loop (HIL) testing as early as possible to discover and solve problems, avoiding the exposure of numerous issues during later vehicle testing, which would require significant time and resources for redesign and development.

The core goal of HIL testing is to ensure logical correctness, especially focusing on complex conditions, extreme scenarios, and system performance under fault conditions during the early stages of ECU development, particularly at the software functionality level. By simulating these conditions, potential problems can be identified in advance, accelerating the iteration process and improving overall development efficiency.

In a recent seminar, NI experts extensively explained the NI HIL platform solution. This included the following content:

-

Trends in the development of electric control units for new energy vehicles and testing challenges

-

Basic concepts of HIL and application examples

-

How to reduce costs and improve efficiency using open HI architecture

HIL testing refers to connecting actual hardware (such as ECUs) with simulator devices (such as models, simulators) through interfaces to simulate the actual operating environment. This allows for testing and evaluation of the system running in real-time to ensure the performance and stability of automotive electronic control systems. The HIL testing system mainly consists of the device under test, real-time machine, system management, and other components.

To achieve efficient and stable HIL testing, the system must have high real-time performance. Moreover, the real-time system must minimize jitter to ensure consistency and stability in computation and response.

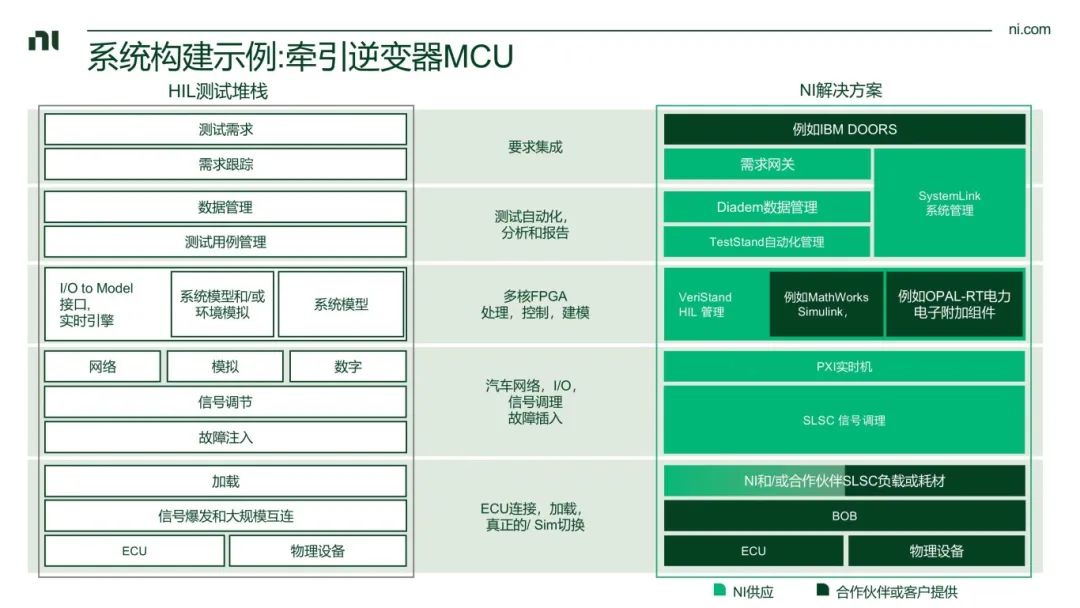

Taking the motor controller (MCU) as an example, building a HIL system requires the following steps:

-

Select the appropriate hardware interface: Collaborate with third-party suppliers or partners to determine the required hardware interfaces.

-

Configure the real-time machine: Ensure the real-time machine can simulate vehicle environments and interact with the ECU under test.

-

Import test models: Use Simulink or other specialized toolkits to import motor models.

-

Set up test management software: Deploy automated test case management and data management software.

-

Integrate system management: If multiple HIL systems are involved, integrate system management software to coordinate and supervise all test stations.

How to quickly familiarize oneself with these tools and break through the bottleneck of autonomous driving testing? The NI experts provided detailed answers during the seminar.

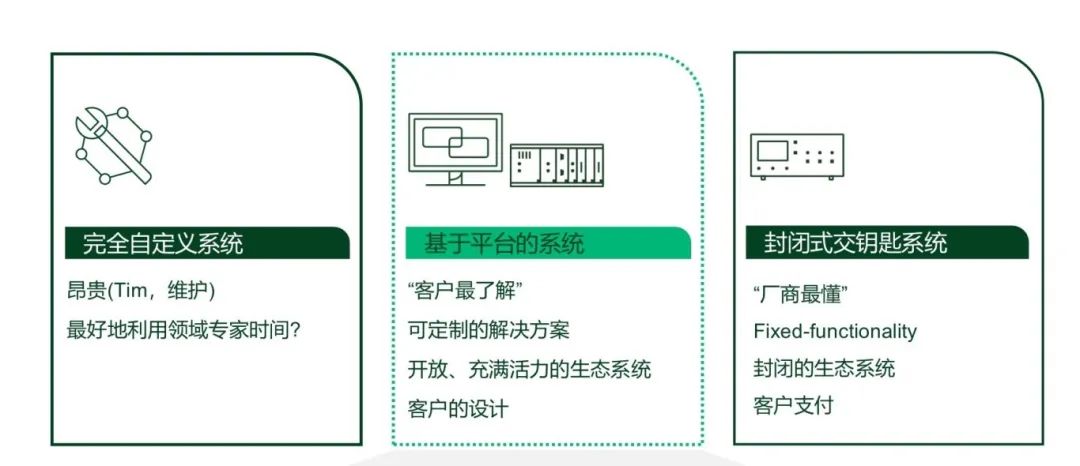

Currently, there are three common methods for constructing HIL systems in the industry: fully customized systems, closed turnkey systems, and platform-based systems.

👉 Fully Customized Systems

Customers need to define all the details of hardware and software from scratch. The advantage of this approach is that it can be fully customized according to their needs, but the drawbacks are also obvious: it requires a significant amount of time to develop hardware and software, and software development is particularly complex as it involves building and maintaining models, which typically requires a long accumulation of time and a certain technical threshold.

👉 Closed Turnkey Systems

Another common method is to have a professional system supplier provide a complete HIL solution, known as a “turnkey solution.” These suppliers usually have a mature toolchain that covers automated testing software, real-time simulation machines, and model libraries. Although they provide comprehensive solutions, the iteration and upgrade of these systems are often limited by the original supplier. This means that each upgrade iteration incurs additional costs, and users have lower autonomy in system management, leading to higher costs.

👉 Platform-Based Systems

Platform-based solutions can overcome the limitations of the previous two approaches and are advocated by NI. Open platforms have two main characteristics:

-

Openness at the Software Level: The platform allows users to customize various plugins through programming interfaces. For example, if the testing system needs to support new types of sensors, users can integrate new devices by writing specific drivers or plugins. This approach enhances the flexibility and adaptability of the system, allowing users to quickly iterate existing systems without having to repurchase the entire set of equipment.

-

Expandable Hardware: At the hardware level, the open platform provides development kits (such as MDK) that allow users or third-party vendors to develop custom I/O modules as needed. For instance, if high-speed signal transmission is required, users can choose high-performance ADC/DAC modules available on the market to replace existing components. This approach not only enhances the system’s scalability but also allows users to make more precise adjustments in signal conditioning.

For users, whether it is cabinets, power supplies, system architectures, or commonly used analog and digital interfaces, these can all be standardized. In fact, unique signal conditioning, specific communication protocols, and new sensor simulations or model iterations only arise when facing different devices under test (DUTs) or different electronic control units (ECUs). For these unique needs, we have provided corresponding interfaces and support. Additionally, NI’s hardware design also follows the open standardization concept, such as PXI standard hardware products. Many manufacturers in the market also produce PXI hardware, which means users can find a wide range of compatible components on our platform.

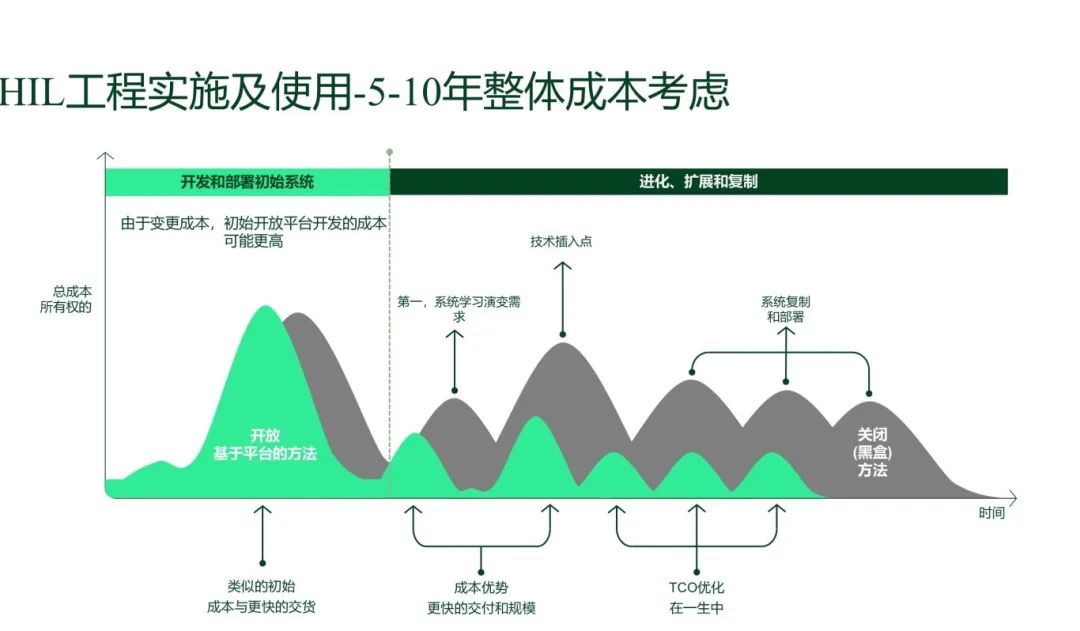

A HIL system is typically used in vehicle manufacturers or T2 suppliers for 5 to 10 years. Therefore, the initial cost of purchasing equipment accounts for a small proportion of the entire lifecycle, while the real cost lies in the expenses incurred during long-term use.

Using an open platform architecture, while the initial learning cost is high, the long-term benefits, especially during rapid technological iterations, are significant. With the rapid development of ECU electronic and electrical architectures, whether in software or hardware structural changes, open platforms can provide greater flexibility and a rich array of interface options, helping users quickly adapt to these changes.

For example, from the initial CAN, CAN FD to the current Ethernet, or from supporting simple permanent magnet synchronous motors to asynchronous motors, and from 400V to 800V voltage increases, these iterations can be quickly realized on an open platform. Once users become familiar with the system, they can independently import new models for iteration without incurring additional high upgrade costs. This is known as “reducing costs and improving efficiency”—in terms of time dimension, open platforms offer higher overall cost-effectiveness.

The Advantages of NI HIL Mainly Manifest in the Following Aspects:

-

Model Integration: Execute power electronics, motor, and vehicle dynamics models across desktop, real-time, and FPGA computing instances within a single platform.

-

Advanced Computing Power: Achieve higher fidelity by determining parameters of configurable models at high speed within the FPGA connected to I/O.

-

I/O Range: A wide range of I/O ensures meeting the testing requirements of advanced technologies.

-

Customizability: Customizable open platforms allow you to adapt to changing needs and reduce the risks of purchasing systems.

-

Integration: Integration with legacy systems and third-party systems can help you adapt to changing needs and reduce investment risks.

The NI platform-based HIL system can directly feedback to customers on cost reduction and efficiency improvement. For instance, by using NI hardware and software platforms with FPGA-based simulations, Subaru achieved the simulation speed and model fidelity required for motor ECU verification,reducing testing time to 1/20 of that required for equivalent testing on a dynamometer. Cummins utilized the NI platform toreduce design time by 50%.