Is it possible not to place silkscreen position numbers on a PCB?

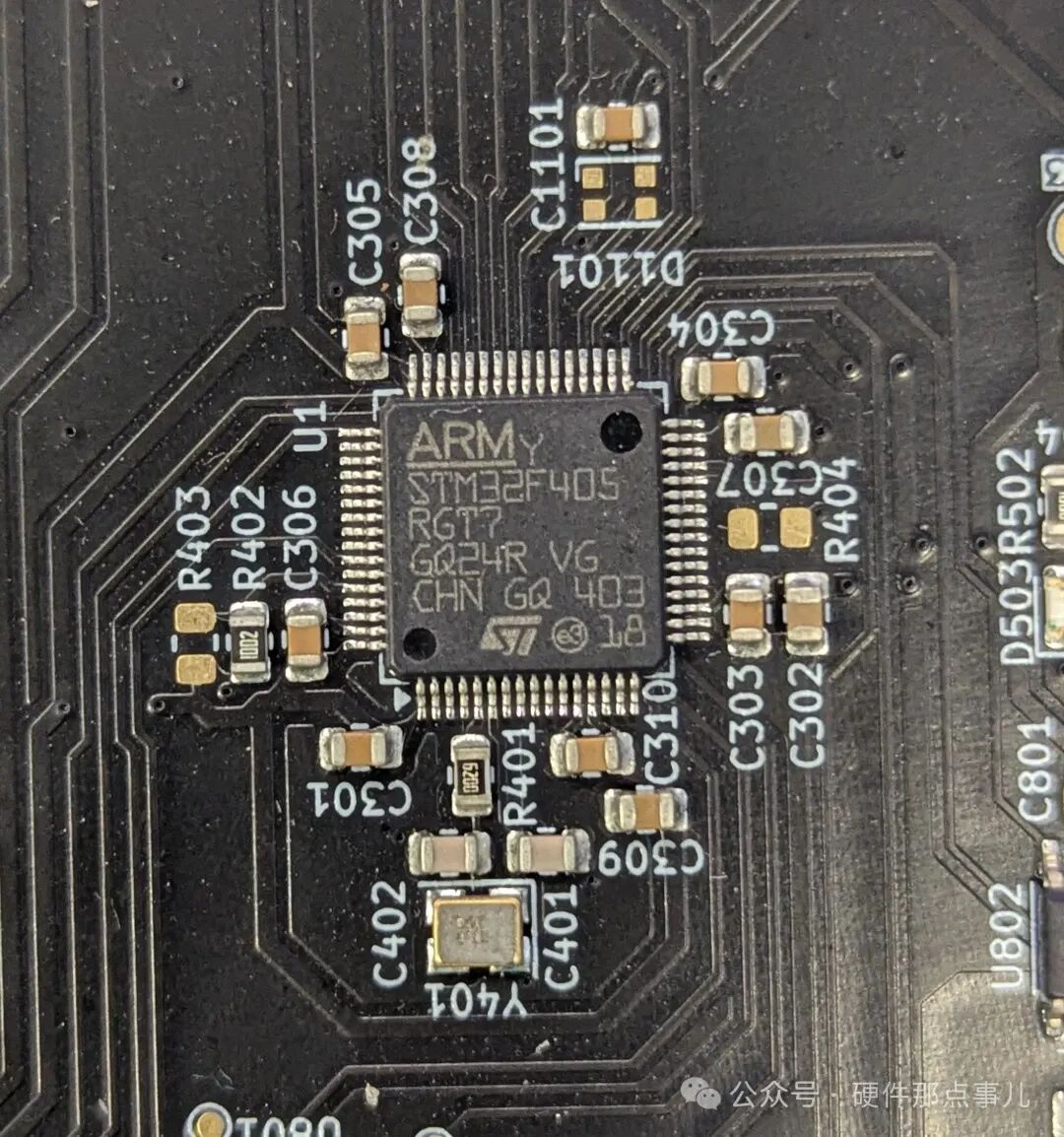

The silkscreen position number is mainly for convenience during manual soldering or prototype debugging stages, as it visually indicates the component positions, facilitating assembly, maintenance, and testing, primarily used in the prototype phase. It is indeed possible to manage without position numbers when opening the computer, but if after-sales maintenance or user debugging is considered, having position numbers would be more convenient.

In the mass production phase, SMT placement machines identify component positions through coordinate files, without relying on silkscreen, making position numbers less useful at that point.

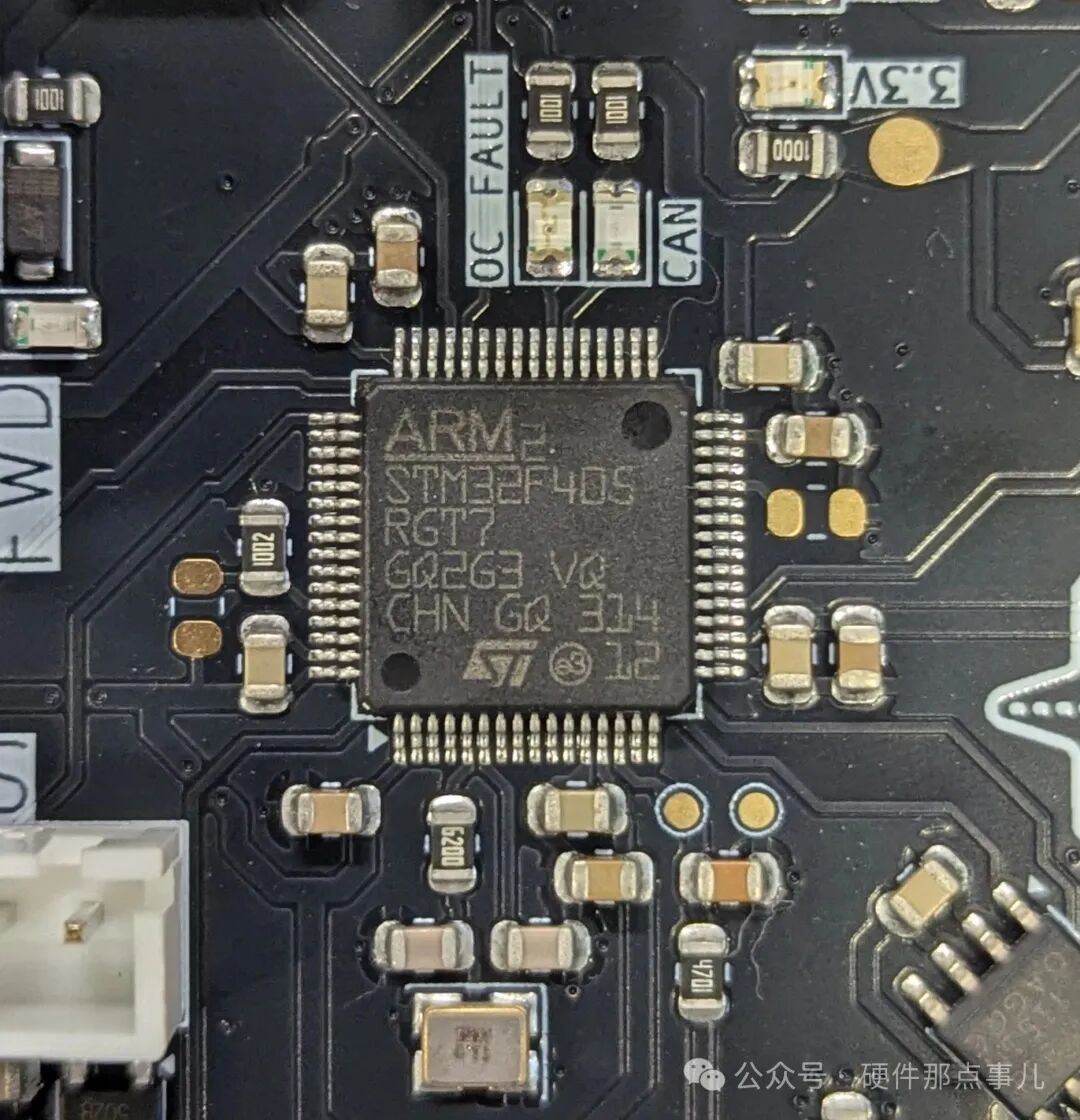

Moreover, in high-density PCB designs where space is limited, silkscreen position numbers can also be omitted to prioritize routing and component layout. On the other hand, it can also complicate reverse engineering; without position numbers, it increases the workload for others trying to replicate the board!