Introduction(Written by Wang Liwei, e-works Industry Research)

In industrial production, the role of sensors is becoming increasingly important, especially under the trend of the Internet of Things, where smart sensors have received unprecedented attention. As the foundation of smart manufacturing, smart sensors have quietly found applications across various industries.

1. Concept and Development of Sensors

According to the national standard GB/T 7665-2005, a sensor is a device or apparatus that can sense a measured quantity and convert it into a usable output signal according to certain rules.

The development of sensors is divided into three stages:

● First Stage began in the 1950s with the emergence of structural sensors, which utilize changes in structural parameters to sense and convert signals.

● Second Stage started in the 1970s with the gradual development of solid-state sensors, which are composed of solid components such as semiconductors, dielectrics, and magnetic materials. These sensors utilize the thermoelectric effect and Hall effect to create thermocouple sensors, Hall sensors, etc.

● Third Stage began at the end of the 20th century with the emergence and rapid development of smart sensors. These sensors are products of the combination of computer technology and detection technology, capable of certain detection, self-diagnosis, data processing, and adaptive capabilities, making them the mainstream of current sensors.

Smart sensors refer to multi-component integrated circuits that have functions such as information collection, information processing, information exchange, and information storage. They are system-level products that integrate sensing units, communication chips, microprocessors, driver programs, and software algorithms.

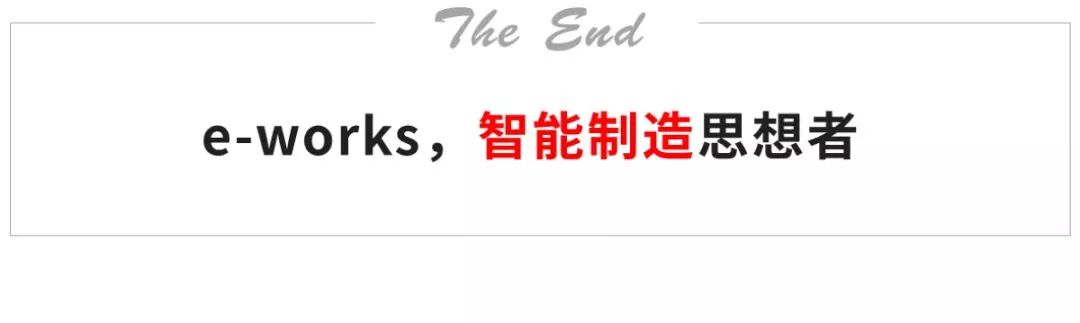

The basic structure of smart sensors is shown in the figure below, generally consisting of a sensing unit, a computing unit, and an interface unit. The sensing unit is responsible for signal collection, the computing unit processes the input signal according to the settings, and then communicates with other devices through the network interface. The implementation of smart sensors can adopt modular (combining sensors, signal conditioning circuits, and microprocessors with bus interfaces into a whole), integrated (using micro-mechanical processing technology and large-scale integrated circuit technology to integrate sensitive elements, signal conditioning circuits, interface circuits, and microprocessors on the same chip), or hybrid structures (integrating various sensor components in different combinations on multiple chips and packaging them in one shell).

Figure 1 Basic Structure of Smart Sensors

Figure 1 Basic Structure of Smart Sensors

2. Key Technological Advances in Smart Sensors

Sensor technology is the cornerstone of achieving smart manufacturing. In the current era of intelligence, the rise and development of high-performance, highly reliable multifunctional complex automatic measurement and control systems, as well as the Internet of Things based on radio frequency identification technology, further highlight the importance and urgency of rapidly developing smart sensors with perception and cognitive capabilities.

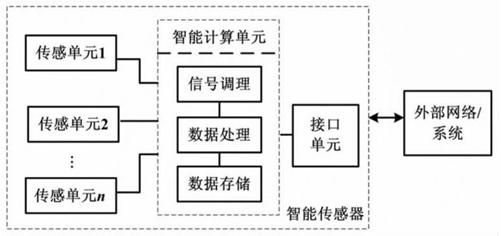

Smart sensors are generally classified based on the different measured quantities into physical quantity smart sensors, chemical quantity smart sensors, and biological quantity smart sensors.

Figure 2 Classification of Smart Sensors

Figure 2 Classification of Smart Sensors

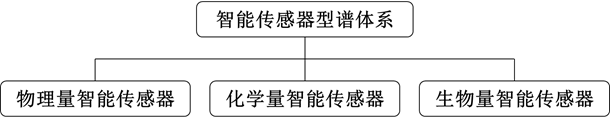

Among them, physical quantity smart sensors can be simply categorized based on the measured physical quantities into six major categories: force, heat, sound, light, electricity, and magnetism. Each major category of sensors contains multiple branches. For example, the branches of mechanical quantity sensors are listed below:

Figure 3 Detailed Classification of Mechanical Quantity Sensors

Figure 3 Detailed Classification of Mechanical Quantity Sensors

A truly smart sensor should have the following functions:

1) Self-calibration, self-standardization, and automatic compensation functions;2) Automatic data collection, logical judgment, and data processing functions;3) Self-adjusting and adaptive functions;4) A certain degree of storage, recognition, and information processing functions;5) Bidirectional communication, standard digital output, or symbolic output functions;6) Algorithm judgment and decision-making processing functions.

Sensing materials, MEMS chips, driver programs, and application software are the core technologies for smart sensors to achieve these functions, especially MEMS chips, which have become important carriers for smart sensors due to their small size, light weight, low power consumption, high reliability, and ability to integrate with microprocessors. Below, we will introduce the technological advances of MEMS-based smart sensors using commonly used temperature, pressure, optical, and RFID sensors as examples.

① Smart Temperature Sensors

Smart temperature sensors are suitable for industries such as metallurgy, petrochemicals, oil, chemicals, pharmaceuticals, papermaking, dyeing, brewing, environmental protection, and electricity. Current smart temperature sensors are rapidly developing towards high precision, multifunctionality, bus standardization, high reliability and safety, developing virtual sensors and network sensors, and creating single-chip temperature measurement systems. Currently, various high-precision, high-resolution smart temperature sensors have been launched abroad, using 9-12 bit A/D converters, with resolutions reaching 0.5-0.625°C. The DS1624 high-resolution smart temperature sensor developed by Dallas Semiconductor in the USA can output 13-bit binary data, with a resolution of up to 0.03°C and a measurement accuracy of ±0.2°C.

② Smart Pressure Sensors

Smart pressure sensors based on MEMS technology have advantages such as miniaturization, low cost, and easy integration. The sensing range of pressure is also wide, from 1 kPa to 100 MPa. They can be widely used in micro-electromechanical systems, automotive, aerospace dynamics, process control, and biomedicine. Current research hotspots in smart pressure sensor technology focus on alleviating the contradiction between sensitivity and linearity to improve sensor accuracy. The new BPS140 pressure sensor developed by Bourns in the USA has stable performance, with a total error of 2.5% FS when used in a temperature range of -40°C to 150°C, and a product life variation of 0.5% FS.

③ Optical Sensors

Non-contact and non-destructive measurement is a significant advantage of optical sensors, which are widely used in electronic product testing. Currently, CCD and CMOS image sensors are the two mainstream imaging technologies. With continuous improvements in image sensor technology, pixel accuracy has been continuously enhanced (reaching the 5μm level), while the requirements for environmental illumination have been continuously reduced. Onsemi’s KAI-50140 is currently the highest resolution ITCCD image sensor on the market, reaching 50 million pixels, with key detail imaging capabilities and high image uniformity, suitable for applications in smartphone display testing, circuit board testing, and mechanical assembly testing.

④ RFID

RFID, or radio frequency identification technology, commonly known as electronic tags, is a communication technology that uses radio signals to automatically identify specific targets and read and write related data without establishing mechanical or optical contact between the identification system and the specific target.

RFID is a method of automatic identification and data capture (AIDC) and is an important component of the Internet of Things (IoT), applicable in logistics management on production lines, such as material sorting. In recent years, research hotspots in RFID have mainly focused on data integrity and security, such as improving the accuracy of data recognition while ensuring that user privacy is not leaked, and utilizing RFID technology to achieve applications in other fields, such as indoor positioning based on RFID technology.

3. Typical Application Scenarios of Smart Sensor Technology

For the manufacturing industry, smart sensors are the foundation for achieving smart manufacturing. Many traditional manufacturing industries widely adopt sensors in production, testing, and logistics during their transformation to smart manufacturing.This article selects typical industries such as machinery manufacturing, automotive, high-end equipment, electronics, petrochemicals, and metallurgy to introduce the applications of smart sensors involved.

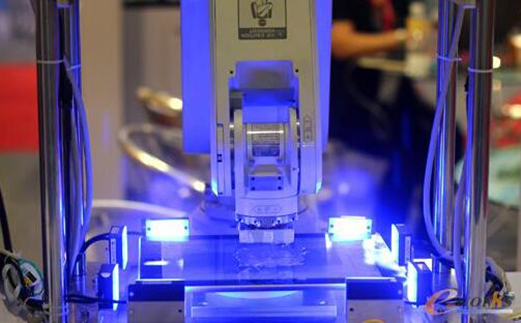

Figure 4 Machine Vision System on Automated Production Line

Figure 4 Machine Vision System on Automated Production Line

One typical application of smart sensing in the manufacturing process is reflected in the widely adopted CNC machine tools in the machinery manufacturing industry. Modern CNC machine tools deploy high-performance sensors to detect displacement, position, speed, pressure, etc., enabling real-time monitoring of processing status, tool status, wear conditions, and energy consumption, achieving flexible error compensation and self-correction, thus realizing the intelligent development trend of CNC machine tools.Additionally, the adoption of visual monitoring technology based on visual sensors makes intelligent monitoring of CNC machine tools more convenient.

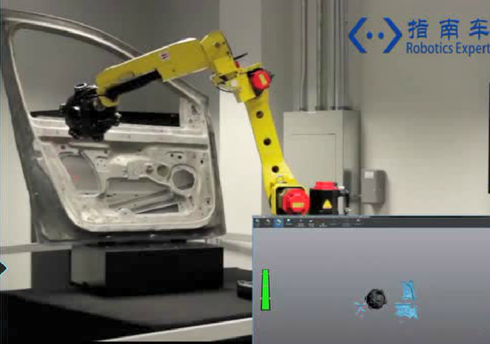

Figure 5 Automotive Door Detection (Image Source: e-works Training Materials)

Figure 5 Automotive Door Detection (Image Source: e-works Training Materials)

The automotive manufacturing industry also extensively applies smart sensors.Taking optical sensing-based machine vision as an example, there are three main applications in the industrial field: visual measurement, visual guidance, and visual inspection. In the automotive manufacturing industry, visual measurement technology ensures that factory products meet quality standards by measuring key dimensions, surface quality, and assembly effects; visual guidance technology significantly improves manufacturing efficiency and body assembly quality by guiding machines to complete automated handling, optimal matching assembly, and precise hole drilling; visual inspection technology can monitor the stability of the body manufacturing process,and can also be used to ensure product integrity and traceability, helping to reduce manufacturing costs.

In the high-end equipment industry, sensors are often used in equipment operation and health management. For example, smart sensors equipped in aircraft engines enable control systems to have fault self-diagnosis and fault handling capabilities, enhancing the system’s ability to respond to complex environments and precise control. Based on smart sensing technology, integrating multi-domain modeling techniques and new information technologies, a digital twin that can accurately simulate physical entities is constructed. This model reflects the physical characteristics of the system and its response to changing environmental characteristics, enabling performance evaluation, fault diagnosis, and life prediction of the engine. Additionally, based on multi-dimensional feedback data sources throughout the lifecycle, it rapidly learns and autonomously simulates in the behavioral state space, predicting responses to safety events, and through the comparative analysis of interaction data between physical and digital entities, timely identifying issues, activating self-repair mechanisms, mitigating damage and degradation, and effectively avoiding fatal system behaviors.

In the field of industrial electronics, smart sensors are involved in production, handling, testing, and maintenance, such as robotic arms, AGV navigation vehicles, and AOI detection equipment. In the consumer electronics and medical electronics product fields, the application of smart sensors is even more diverse. Common smart sensors in smartphones include distance sensors, light sensors, gravity sensors, image sensors, three-axis gyroscopes, and electronic compasses. The most basic function of wearable devices is to achieve motion sensing through sensors, typically incorporating various sensors such as MEMS accelerometers, heart rate sensors, pulse sensors, gyroscopes, and MEMS microphones. Smart home technologies (such as robotic vacuum cleaners, washing machines, etc.) involve position sensors, proximity sensors, liquid level sensors, flow and speed control, environmental monitoring, security sensing, and other sensor technologies.

Figure 6 Application of Gas Sensors in the Petrochemical Industry (Image Source: WEG Official Website)

Figure 6 Application of Gas Sensors in the Petrochemical Industry (Image Source: WEG Official Website)

Compared to discrete industries, the application of sensors in process industries is more extensive in terms of both the number and the stages involved, especially in petrochemical and metallurgy industries, where the entire production, processing, transportation, and usage stages emit a significant amount of hazardous and polluting gases. It is necessary to detect toxic gases such as carbon monoxide, sulfur dioxide, hydrogen sulfide, ammonia, ethylene oxide, propylene, vinyl chloride, acetylene, and organic vapors such as benzene, aldehydes, and ketones, necessitating a large number of gas sensors for safety protection to prevent poisoning and explosion accidents. Additionally, a large number of sensors are required for raw material ratio management, process parameter control, and equipment operation and health management.

4. Outlook on Sensor Technology

With the widespread application of new materials and technologies, new types of sensors based on various functional materials are developing rapidly, and their impact on manufacturing is becoming increasingly significant.In the future, the development trends of new sensor devices will be towards intelligence, miniaturization, multifunctionality, low power consumption, low cost, high sensitivity, and high reliability. New sensor materials and devices will be an important direction for the future development of smart sensing technology.