1. Fault Characteristics and Repair of Damaged Capacitors on Engineering Circuit Boards

The faults caused by capacitor damage are the most common in electronic devices, especially the failure of electrolytic capacitors.

The manifestations of capacitor damage include: 1. Reduced capacitance; 2. Complete loss of capacitance; 3. Leakage; 4. Short circuit.

The role of capacitors in circuits varies, leading to different fault characteristics. In industrial control circuit boards, digital circuits dominate, and capacitors are mostly used for power filtering, with fewer used for signal coupling and oscillation circuits. If an electrolytic capacitor in a switching power supply is damaged, the switching power supply may fail to oscillate, resulting in no voltage output; or the output voltage may be poorly filtered, causing logic confusion due to unstable voltage, manifesting as intermittent machine operation or failure to start. If the capacitor is between the positive and negative terminals of the digital circuit power supply, the fault manifests similarly.

This is particularly evident on computer motherboards, where many computers exhibit intermittent startup issues after a few years of use. Upon opening the case, one can often see bulging electrolytic capacitors. Measuring the capacitance of a removed capacitor often reveals values significantly lower than expected.

The lifespan of capacitors is directly related to ambient temperature; the higher the temperature, the shorter the lifespan. This rule applies not only to electrolytic capacitors but also to other types. Therefore, when looking for faulty capacitors, one should focus on those close to heat sources, such as near heat sinks and high-power components. The closer they are, the higher the likelihood of damage.

I once repaired a power supply for an X-ray flaw detector where the user reported smoke coming from the power supply. Upon opening the case, I found a 1000uF/350V large capacitor leaking a viscous substance. After removing it, I measured its capacitance and found it only a few tens of uF. I also noted that this capacitor was the closest to the heat sink of the rectifier bridge, while others further away were intact and had normal capacitance. Additionally, I found a ceramic capacitor that had short-circuited, which was also close to a heat-generating component. Thus, when troubleshooting, one should prioritize these areas.

Some capacitors exhibit significant leakage, becoming hot to the touch; such capacitors must be replaced.

When troubleshooting intermittent faults, after ruling out poor connections, most issues are typically caused by capacitor damage. Therefore, when encountering such faults, it is advisable to closely inspect the capacitors; replacing them often yields surprising results (of course, one should pay attention to capacitor quality, selecting reputable brands like Rubycon or Nichicon).

2. Characteristics and Identification of Damaged Resistors

Many beginners often struggle with resistors during circuit repairs, disassembling and soldering them unnecessarily. However, with experience, understanding the characteristics of resistor damage can simplify the process.

Resistors are the most numerous components in electrical devices, but they are not the most failure-prone. The most common failure mode for resistors is open circuit, while increased resistance is less common, and decreased resistance is rare. Common types include carbon film resistors, metal film resistors, wire-wound resistors, and fusible resistors.

The first two types are widely used, with a higher failure rate for low resistance (below 100Ω) and high resistance (above 100kΩ) compared to mid-range resistances (hundreds of ohms to tens of kilohms). Low resistance failures often result in charred blackened appearance, making them easy to identify, while high resistance failures usually leave little to no visible trace.

Wire-wound resistors are typically used for high current limiting and have low resistance. Cylindrical wire-wound resistors may show blackening or surface cracking when burned, while others may leave no trace. Cement resistors, a type of wire-wound resistor, may break when burned, otherwise showing no visible signs. Fusible resistors may explode, leaving a portion of their surface damaged, but will never be charred black. Based on these characteristics, one can focus on specific resistors during inspection to quickly identify damaged ones.

Based on the characteristics listed above, we can first observe the circuit board for any charred marks on low resistance resistors. Then, based on the fact that most resistors fail by open circuit or increased resistance, and that high resistance resistors are prone to failure, we can use a multimeter to measure the resistance across the terminals of high resistance resistors on the circuit board. If the measured resistance is higher than the rated value, this resistor is surely damaged (note to wait for the resistance reading to stabilize before concluding, as there may be capacitive elements in parallel causing a charging/discharging process). If the measured resistance is lower than the rated value, it is typically not a concern. By measuring each resistor on the circuit board in this manner, even if a thousand are mistakenly identified as faulty, none will be overlooked.

3. Methods for Determining the Condition of Operational Amplifiers

Determining the condition of operational amplifiers can be challenging for many electronics repair technicians, not just due to educational background (I have many undergraduates who, without teaching, would not know, and even when taught, it takes a long time to grasp. I also have a graduate student specializing in variable frequency control who exhibits similar difficulties!). In this section, I would like to discuss this topic with everyone, hoping to provide some assistance.

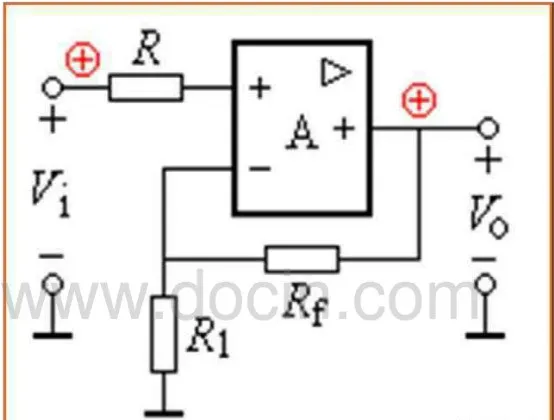

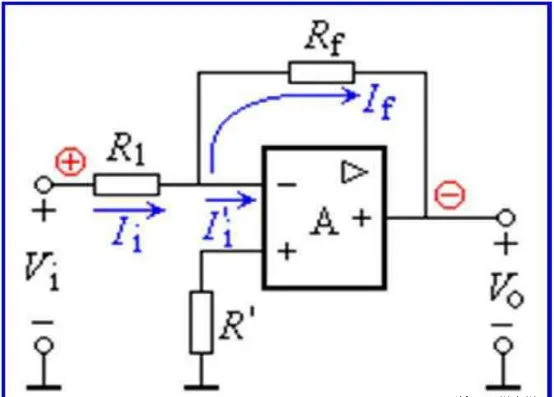

An ideal operational amplifier has the characteristics of “virtual short” and “virtual open,” which are very useful for analyzing linear applications of op-amp circuits. To ensure linear operation, the op-amp must operate in a closed-loop (negative feedback) configuration. Without negative feedback, the op-amp in open-loop amplification becomes a comparator. To determine the condition of the device, one should first clarify whether it is used as an amplifier or a comparator in the circuit.

From the diagrams, we can see that regardless of the type of amplifier, there is a feedback resistor Rf. When repairing, we can check this feedback resistor from the circuit by measuring the resistance between the output and the inverting input terminals with a multimeter. If the resistance is excessively high, such as several MΩ, we can be fairly certain that the device is used as a comparator. If this resistance is low (0Ω to several tens of kΩ), we should further check for any resistors connected between the output and the inverting input; if present, it is definitely used as an amplifier.

According to the principle of virtual short in amplifiers, if this operational amplifier is functioning normally, the voltages at the non-inverting and inverting inputs must be equal, with any difference being in the millivolt range. Of course, in some high-impedance input circuits, the internal resistance of the multimeter may slightly influence the voltage measurement, but generally, it should not exceed 0.2V. If there is a difference greater than 0.5V, the amplifier is undoubtedly faulty! (I use a FLUKE179 multimeter)

If the device is used as a comparator, the non-inverting and inverting inputs are allowed to be unequal. If the non-inverting voltage is greater than the inverting voltage, the output voltage approaches the positive maximum value; if the non-inverting voltage is less than the inverting voltage, the output voltage approaches 0V or the negative maximum value (depending on whether it is a dual power supply or single power supply). If the detected voltages do not conform to these rules, the device is undoubtedly faulty! This way, you do not need to use substitution methods or remove the chip from the circuit board to determine the condition of the operational amplifier.

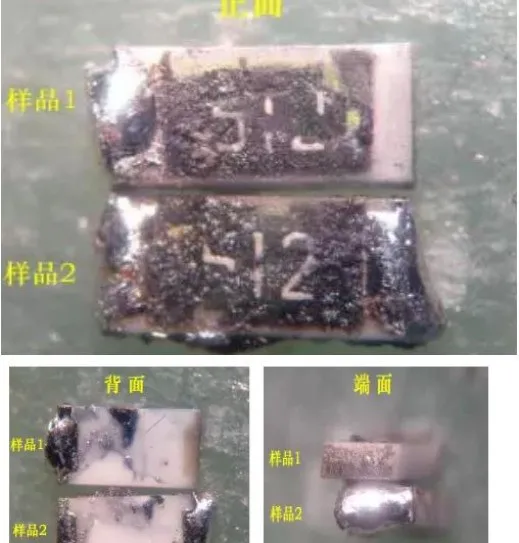

4. A Small Tip for Testing SMT Components with a Multimeter

Some surface-mounted components are very small, making it inconvenient to test them with standard multimeter probes. This can easily lead to short circuits and makes it difficult to access the metal parts of component pins on insulated circuit boards. Here’s a simple method that can greatly facilitate testing.

Take two of the smallest sewing needles, (Deep Industrial Control Repair Technology Column) align them with the multimeter probes, then take a thin copper wire from a multi-stranded cable and bind the probes and needles together with the copper wire, securing it with solder. This way, when using the fine-tipped probes to measure SMT components, the risk of short circuits is eliminated, and the needle tips can pierce the insulation to reach critical areas without the hassle of scraping off the coating.

5. Troubleshooting Short Circuit Faults in Common Power Supply on Circuit Boards

When repairing circuit boards, encountering short circuit faults in the common power supply can be quite daunting, as many components share the same power supply, and each component using this power supply may be suspected of having a short circuit. If there are few components on the board, using a “ground and pound” method may eventually locate the short circuit point. However, if there are too many components, relying on luck may not suffice. Here, I recommend a more effective method that can quickly pinpoint the fault.

You need a power supply that is adjustable in both voltage and current, with a voltage range of 0-30V and a current range of 0-3A. This power supply is not expensive, costing around 300 yuan. Set the open-circuit voltage to the level of the component power supply voltage, initially adjusting the current to the minimum. Apply this voltage to the circuit power supply points, such as the 5V and 0V terminals of 74 series chips. Depending on the severity of the short circuit, gradually increase the current. When you touch a component that feels noticeably hot, that is often the damaged component, which can be removed for further measurement and confirmation. Of course, during operation, the voltage must not exceed the component’s working voltage and must not be reversed; otherwise, other intact components may be damaged.

6. A Small Eraser Solves Big Problems

With the increasing use of industrial control boards, many boards utilize gold fingers inserted into slots. Due to the harsh environmental conditions in industrial settings—dusty, humid, and corrosive gas environments—these boards are prone to contact failure. Many friends may have resolved issues by replacing the boards, but the cost of purchasing boards can be quite significant, especially for certain imported devices. Instead, consider using an eraser to repeatedly clean the gold fingers, removing dirt and potentially resolving the issue! This method is simple and practical.

7. Analyzing Intermittent Electrical Faults

Various intermittent electrical faults can be categorized based on their probabilities:

1. Poor Connections Poor contact between the board and the slot, intermittent breaks in internal cables, poor contact at plugs and terminals, and cold solder joints are all examples;

2. Signal Interference For digital circuits, faults may only manifest under specific conditions, possibly due to excessive interference affecting the control system, or changes in parameters of individual components or overall performance causing the anti-interference capability to approach a critical point, resulting in faults;

3. Poor Thermal Stability of Components Based on extensive repair practices, electrolytic capacitors are the most common components with poor thermal stability, followed by other capacitors, transistors, diodes, ICs, resistors, etc.;

4. Moisture and Dust on the Circuit Board.

Moisture and dust can conduct electricity, exhibiting resistance effects, and during thermal expansion and contraction, the resistance may change. This resistance can have a parallel effect with other components, and when this effect is strong, it can alter circuit parameters and cause faults;

Some Electronic Book Screenshots