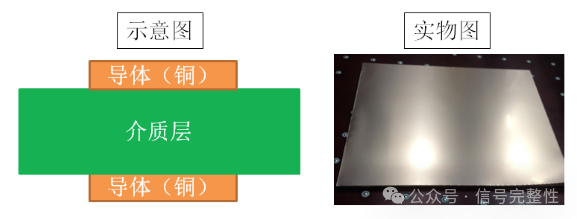

In the manufacturing of modern electronic devices, printed circuit boards (PCBs) are crucial components. The design of PCBs involves many factors, among which the characteristics of PCB materials are one of the key factors determining the performance and reliability of the circuit board. Different PCB materials exhibit different behaviors in thermal, mechanical, and electrical aspects, and the correct selection and application of these materials can optimize the performance of the circuit board to the greatest extent. The PCBs used in electronic products are mainly composed of copper foil and organic materials, as shown in the figure below:

Important PCB Material Characteristics

1. Electrical Performance

Electrical performance is one of the key factors determining signal transmission and performance of the circuit board. In PCB materials, the dielectric constant is an important electrical characteristic. The dielectric constant affects the speed and loss of signal propagation, especially in high-speed/high-frequency PCB designs. The dielectric constant varies with frequency, leading to signal dispersion and loss. Designers should pay special attention to the frequency dependence of the dielectric constant when selecting PCB materials to ensure accurate signal transmission in high-frequency applications.

2. Structural Characteristics

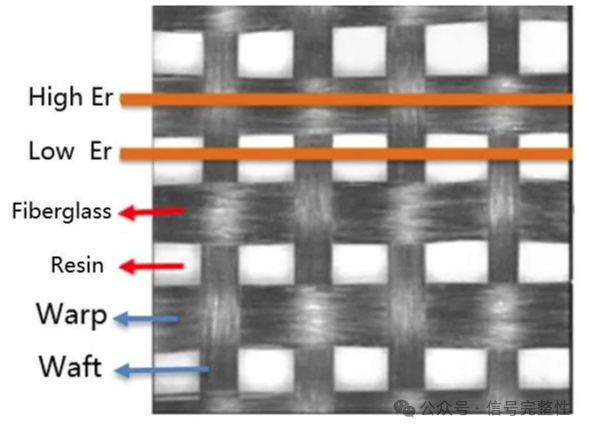

The structural characteristics of the PCB affect the mechanical, thermal, and electrical performance of the circuit board. Two key aspects are the glass weave style and the roughness of the copper conductors.

Glass Weave Style

The glass weave style leaves gaps on the PCB substrate, affecting the dielectric constant and mechanical performance of the substrate. The gaps in the glass weave style can cause what is known as the fiber weaving effect, leading to variations in the dielectric constant and signal loss. This is particularly evident in high-frequency applications and may affect the stability and quality of signal transmission.

Copper Conductor Roughness

The surface roughness of copper conductors affects the impedance and signal transmission of the circuit board. A rougher conductor surface increases losses during high-frequency signal transmission, reducing signal quality. Designers should choose appropriate conductor manufacturing methods and materials to ensure the smoothness and electrical performance of the conductor surface.

3. Thermal Performance

The thermal performance of the PCB is crucial for the heat dissipation and stability of electronic devices. When selecting PCB materials, thermal conductivity and specific heat are two important considerations.

Thermal Conductivity and Specific Heat

Thermal conductivity indicates the ability of a material to transfer heat, while specific heat indicates the amount of heat required for a temperature change in the material. These two parameters jointly affect the thermal conduction and temperature distribution of the circuit board. For applications requiring efficient heat dissipation, PCB materials with high thermal conductivity should be selected to ensure effective heat dissipation from the circuit board.

Glass Transition Temperature and Coefficient of Thermal Expansion (CTE)

The glass transition temperature and the coefficient of thermal expansion are important indicators determining the performance of PCB materials under thermal changes. The glass transition temperature is the temperature at which a material transitions from a glassy state to a rubbery state, affecting the mechanical performance and stability of the material. The coefficient of thermal expansion indicates the degree of volume change of the material under temperature variation, affecting the reliability and stability of the PCB during thermal cycling. Designers should select PCB materials with appropriate glass transition temperatures and coefficients of thermal expansion to suit the expected operating temperature range and thermal cycling environment.

Tg Indicators

(1) General Tg materials: 130℃~150℃, such as KB-6164F (140℃), S1141 (140℃); (2) Medium Tg materials: 150℃~170℃, such as KB-6165F (150℃), S1141 150 (150℃); (3) High Tg materials: 170℃ and above, such as KB-6167F (170℃), S1170 (170℃).

Conclusion

In circuit board design, the correct selection and application of PCB materials are key to ensuring the performance and reliability of the circuit board. Different PCB materials have different electrical, structural, mechanical, and thermal properties, and designers should carefully evaluate these characteristics based on application requirements. By considering key factors such as dielectric constant, structural characteristics, and thermal performance, designers can develop more stable and efficient electronic devices to meet the needs of various applications.

Frequently Asked Questions

Q1: Why is the dielectric constant important for PCB design?

A: The dielectric constant affects signal propagation speed and loss, which is critical for high-speed/high-frequency PCB designs.

Q2: What is the glass transition temperature?

A: The glass transition temperature is the temperature at which a material transitions from a glassy state to a rubbery state, affecting the mechanical performance and stability of the material.

Q3: How does copper conductor roughness affect signal transmission?

A: Copper conductor roughness increases losses during signal transmission, reducing signal quality.

Q4: Why is thermal conductivity important?

A: Thermal conductivity affects the heat dissipation performance of the circuit board, which is critical for high-power applications.

Q5: How to choose appropriate PCB materials?

A: Evaluate electrical, structural, mechanical, and thermal properties based on application requirements, and select the most suitable PCB materials to optimize performance and reliability.

1. The FR-4 we often choose is not a material name

What we often refer to as “FR-4” is a code for a flame-retardant material grade, which means that the resin material must be able to extinguish itself after burning; it is not a material name, but a material grade. Therefore, there are currently many types of FR-4 grade materials used in general circuit boards, but most are composite materials made of so-called tetra-functional (Tera-Function) epoxy resin combined with fillers and glass fiber.

For example, the FR-4 water green glass fiber board and black glass fiber board we currently use have properties such as high temperature resistance, insulation, and flame retardancy. So when selecting materials, it is essential to clarify what characteristics the required materials need to achieve. This way, it will be easier to purchase the desired products.

The substrates for printed circuit boards mainly fall into two categories: organic substrates and inorganic substrates, with organic substrates being the most commonly used. Different numbers of layers require different PCB substrates; for example, 3-4 layer boards use prefabricated composite materials, while double-sided boards mostly use glass-epoxy resin materials.

|

Classification |

Material |

Name |

Code |

Features |

|

Rigid Copper Clad Laminate |

Paper Substrate |

Phenolic Resin Copper Foil Laminate |

FR-1 |

Economical, Flame Retardant |

|

FR-2 |

High Electrical Properties, Flame Retardant (Cold Press) |

|||

|

XXXPC |

High Electrical Properties (Cold Press) |

|||

|

XPC Economical |

Economical (Cold Press) |

|||

|

Epoxy Resin Copper Foil Laminate |

FR-3 |

High Electrical Properties, Flame Retardant |

||

|

Polyester Resin Copper Foil Laminate |

||||

|

Glass Fabric Substrate |

Glass Fabric-Epoxy Resin Copper Foil Laminate |

FR-4 |

||

|

Heat Resistant Glass Fabric-Epoxy Resin Copper Foil Laminate |

FR-5 |

G11 |

||

|

Glass Fabric-Polyimide Resin Copper Foil Laminate |

GPY |

|||

|

Glass Fabric-PTFE Resin Copper Foil Laminate |

||||

|

Composite Material Substrate |

Epoxy Resin Type |

Paper (Core)-Glass Fabric (Face)-Epoxy Resin Copper Foil Laminate |

CEM-1, CEM-2 |

(CEM-1 Flame Retardant); (CEM-2 Non-Flame Retardant) |

|

Glass Mat (Core)-Glass Fabric (Face)-Epoxy Resin Copper Foil Laminate |

CEM3 |

Flame Retardant |

||

|

Polyester Resin Type |

Glass Mat (Core)-Glass Fabric (Face)-Polyester Resin Copper Foil Laminate |

|||

|

Glass Fiber (Core)-Glass Fabric (Face)-Polyester Resin Copper Foil Laminate |

||||

|

Special Substrate |

Metal Substrate |

Metal Core Type |

||

|

Metal Core Type |

||||

|

Coated Metal Type |

||||

|

Ceramic Substrate |

Alumina Substrate |

|||

|

Aluminum Nitride Substrate |

AIN |

|||

|

Silicon Carbide Substrate |

SIC |

|||

|

Low-Temperature Sintered Substrate |

||||

|

Heat Resistant Thermoplastic Substrate |

Polyphenylsulfone Resin |

|||

|

Polyetherketone Resin |

||||

|

Flexible Copper Foil Laminate |

Polyester Resin Copper Foil Laminate |

|||

|

Polyimide Copper Foil Laminate |

[Latest PCB and Related Material IEC Standard Information]

The International Electrotechnical Commission (IEC) is a global standardization organization composed of technical committees from various countries. China’s national standards are mainly based on IEC standards, and IEC standards are among the fastest-developing and advanced international standards in the field of PCBs and related substrates. To facilitate peers’ understanding of the IEC technical standards information for PCBs and related materials, and to promote the rapid integration of PCB technology with international standards, the current effective PCB substrate (copper foil laminate) standards, PCB standards, technical standards for PCB-related materials, and the corresponding testing method standards and revision status are organized as follows:

PCB and Substrate Testing Method Standards:

1. IEC61189-1 (1997-03): Test methods for electronic materials, interconnection structures, and components—Part 1: General test methods and methodology. 2. IEC61189 (1997-04): Test methods for electronic materials, interconnection structures, and components—Part 2: Test methods for interconnection structure materials, first revision in January 2000. 3. IEC61189-3 (1997-04): Test methods for electronic materials, interconnection structures, and components—Part 3: Test methods for interconnection structures (printed boards), first revision in July 1999. 4. IEC60326-2 (1994-04): Printed boards—Part 2: Test methods, first revision in June 1992.

PCB Related Materials Standards

1. IEC61249-5-1 (1995-11): Interconnection structure materials—Part 5: Specification for uncoated conductive foils and conductive films—Part 1: Copper foil (for manufacturing copper-clad substrates). 2. IEC61249-5-4 (1996-06): Printed boards and other interconnection structure materials—Part 5: Specification for uncoated conductive foils and conductive films—Part 4: Conductive inks. 3. IEC61249-7- (1995-04): Interconnection structure materials—Part 7: Specification for core materials—Part 1: Copper/Invar/Copper. 4. IEC61249-8-7 (1996-04): Interconnection structure materials—Part 8: Specification for non-conductive films and coatings—Part 7: Marking inks. 5. IEC61249 8 8 (1997-06): Interconnection structure materials—Part 8: Specification for non-conductive films and coatings—Part 8: Permanent polymer coatings.

Printed Board Standards

1. IEC60326-4 (1996-12): Printed boards—Part 4: Rigid multilayer printed boards—Specification. 2. IEC60326-4-1 (1996-12): Printed boards—Part 4: Rigid multilayer printed boards—Specification—Part 1: Capability detailed specification—Performance levels A, B, C. 3. IEC60326-3 (1991-05): Printed boards—Part 3: Printed board design and use. 4. IEC60326-4 (1980-01): Printed boards—Part 4: Specification for single- and double-sided ordinary printed boards (this standard was first revised in November 1989). 5. IEC60326-5 (1980-01): Printed boards—Part 5: Specification for single- and double-sided ordinary printed boards with metallized holes (this standard was first revised in November 1989). 6. EC60326-7 (1981-01): Printed boards—Part 7: Specification for single-sided flexible printed boards (this standard was first revised in November 1989). 7. EC60326-8 (1981-01): Printed boards—Part 8: Specification for flexible printed boards with metallized holes (this standard was first revised in November 1989). 8. EC60326-9 (1981-03): Printed boards—Part 9: Specification for flexible printed boards with metallized holes (this standard was first revised in November 1989). 9. EC60326-9 (1981-03): Printed boards—Part 10: Specification for rigid-flexible double-sided printed boards (this standard was first revised in November 1989). 10. EC60326-11 (1991-03): Printed boards—Part 11: Specification for rigid-flexible multilayer printed boards. 11. EC60326-12 (1992-08): Printed boards—Part 12: Specification for laminated composite boards (multilayer printed board semi-finished products).

(1) Paper-based printed boards use a substrate made of fiber paper as a reinforcing material, which is soaked in a resin solution (phenolic resin, epoxy resin, etc.), dried, and processed, then coated with a glued electrolytic copper foil, and pressed under high temperature and pressure. According to the model specified by ASTM/NEMA (American National Standards Institute/National Electrical Manufacturers Association), the main varieties are FR-1, FR-2, FR-3 (the above are flame-retardant types, XPC, XXXPC (the above are non-flame-retardant types). More than 85% of the global market for paper-based printed boards is in Asia. The most commonly used and produced are FR-1 and XPC printed boards.

(2) Epoxy glass fiber printed boards use epoxy or modified epoxy resin as an adhesive and glass fiber fabric as a reinforcing material. This type of printed board is currently the most produced and used globally. In the ASTM/NEMA standards, epoxy glass fiber boards have four models: G10 (non-flame-retardant), FR-4 (flame-retardant); G11 (retains thermal strength, non-flame-retardant), FR-5 (retains thermal strength, flame-retardant). In fact, non-flame-retardant products are decreasing year by year, with FR-4 accounting for the vast majority.

(3) Composite substrate printed boards use substrates made of different reinforcing materials for the face and core. The copper-clad laminate substrates used are mainly from the CEM (composite epoxy material) series, with CEM-1 and CEM-3 being the most representative. The CEM-1 substrate has glass fabric for the face, paper for the core, and epoxy resin that is flame-retardant; the CEM-3 substrate has glass fabric for the face, glass fiber paper for the core, and epoxy resin that is flame-retardant. The basic properties of composite printed boards are comparable to those of FR-4, while the cost is lower, and the machinability is better than that of FR-4.

(4) Special substrate printed boards include metal substrates (aluminum, copper, iron, or Invar steel) and ceramic substrates, which can be made into single, double, or multilayer printed boards or metal core printed boards based on their characteristics and uses.

2. When selecting board materials, we need to consider the impact of SMT

During the lead-free electronic assembly process, due to the increase in temperature, the degree of bending of the printed circuit board increases when heated, so it is required to use materials with minimal bending, such as FR-4 types of substrates, in SMT. Because the expansion stress on the components caused by the substrate’s thermal expansion and contraction may lead to electrode delamination, reducing reliability, attention should also be paid to the expansion coefficient of the materials, especially when the components are larger than 3.2×1.6mm. Surface mount technology requires PCBs to have high thermal conductivity, excellent heat resistance (150℃, 60min), solderability (260℃, 10s), high copper foil adhesion strength (above 1.5×104Pa), and bending strength (25×104Pa), high electrical conductivity, low dielectric constant, good punching precision (±0.02mm), and compatibility with cleaning agents. Additionally, a smooth and flat appearance is required, with no warping, cracks, scratches, or rust spots.

3. PCB Thickness Selection

The thicknesses of printed circuit boards are 0.5mm, 0.7mm, 0.8mm, 1mm, 1.5mm, 1.6mm, (1.8mm), 2.7mm, (3.0mm), 3.2mm, 4.0mm, 6.4mm, where 0.7mm and 1.5mm thick PCBs are used for designs with gold fingers on double-sided boards, and 1.8mm and 3.0mm are non-standard sizes. From a production perspective, the minimum single board should not be less than 250×200mm, with the ideal size generally being (250~350mm)×(200×250mm). For PCBs with a long edge less than 125mm or a wide edge less than 100mm, it is easy to use a panel method. The surface mount technology specifies that the allowable bending of a 1.6mm thick substrate is ≤0.5mm for upward bending and ≤1.2mm for downward bending. The usual allowable bending rate is below 0.065%. According to metal materials, there are three types, as shown for typical PCBs; according to structure, there are three types, and electronic plugs are also developing towards high pin counts, miniaturization, SMD, and complexity. Electronic plugs are installed on the circuit board through pins and soldered on the other side; this technology is called THT (Through Hole Technology) insertion technology. This requires drilling holes for each pin on the PCB, illustrating a typical application method for PCBs.

4. Drilling

With the rapid development of SMT technology, multilayer circuit boards require conduction between them, which is ensured through drilling and subsequent plating. This necessitates various drilling equipment. To meet these requirements, different performance PCB CNC drilling equipment has been launched both domestically and internationally. The production process of printed circuit boards is complex, involving a wide range of processes, mainly involving photochemistry, electrochemistry, and thermochemistry; the processes involved in manufacturing are also numerous, taking hard multilayer circuit boards as an example to illustrate its processing procedures. Drilling is a very important process in the entire procedure, and the time taken for hole processing is also the longest. The positioning accuracy of the holes and the quality of the hole walls directly affect the subsequent metalization and packaging processes, as well as the processing quality and cost of the printed circuit boards. The principles, structures, and functions of CNC drilling machines, as well as common methods for drilling holes on circuit boards, include CNC mechanical drilling methods and laser drilling methods, with mechanical drilling methods currently being the most widely used.

【1】Driven by Interest and Passion

【2】Should Hardware Engineers Draw PCBs Themselves?

【3】How Long Should PCB Traces Be?

【4】How Wide Should PCB Traces Be?

【5】PCB Internal Power Layers

【6】Via Holes

【7】Can PCB Traces Have Sharp Corners and Right Angles?

【8】Should Dead Copper Be Retained? (PCB Islands)

【9】Can Vias Be Placed on Pads?

【10】What Exactly Does FR4 Refer To?

【11】Why Is the Solder Mask Layer Often Green?

【12】Stencil

【13】Pre-layout

【14】Key Points for PCB Layout and Routing

【15】Cross-Splitting Traces

【16】Signal Reflection

【17】Dirty Signals

【18】span>Surface Treatments such as Gold Plating, Tin Spraying, etc.

【19】Trace Spacing

【20】Capacitor Placement

【21】Crosstalk

【22】Flying Probe Testing for PCBs

【23】Overview and Simulation of FPC

【24】Why Do PCBs Warp and Bend? How to Solve It?

【25】Understanding “Characteristic Impedance” in One Article

【26】PCB Layer Design

High-Speed Circuit PCB Reflow Path

Power Management and Plane Segmentation in PCB Design

Jagged PCB Traces—Tabbed Routing

What Is the Dielectric Loss Angle in PCB?

How Does Copper Foil Roughness Affect High-Speed Signals?

Why Should Crystals Not Be Placed at the Edge of the PCB?

What Are High-Speed Signals?

What Is a Transmission Line?

Pre-emphasis, De-emphasis, and Equalization

How to Utilize PCB for Heat Dissipation

PCB Design Considerations for Stubs

To Ground or Not to Ground: GND Protection Traces Between Traces?

PCB Copper Cladding

Rules to Follow When Designing PCBs

“Pseudo Eight-Layer” in PCB Layer Design

In addition to Strip Lines and Microstrip Lines, there are also “Co-planar Waveguides”

PCB Pad Design Process Parameters

Why Should Ground Holes Be Drilled on PCB Edges?

PCBs That Are Easier to Dissipate Heat: Aluminum Substrates

Why Should Reference Planes Be Hollowed Out?

Crystal Oscillator PCB Design

PCB Design of DC/DC Power Supplies with EMC Considerations

PCB Bends: Round Corners Are Not Always the Best Routing

Why Should Vias Be Blocked? “Conductive Via Plugging Process”

Key Points for Power PCB Layout and Routing

Rigid-Flex Boards (Rigid-Flex Hybrid Boards)

Mixed Signal PCB Design

Capacitor Placement in PCB Design

Impact of Via Stubs in PCB Design

Decoupling Capacitor Placement and Routing in PCB Design

PCB Design Checklist: Structure

PCB Design Checklist: Power

PCB Design Checklist: Routing

PCB Design Checklist: High-Speed Digital Signals

Process Edge

PCB Design: Gold Fingers

PCB Design: Differential Pairs

PCB Design and Simulation for DDR4

——Recommended Hardware Books——