After the delivery of a previous design project, due to an operational error by the on-site debugging personnel, the exposed wire ends touched the circuit board (which was coated with a conformal coating) when the rear panel of the device was opened, ultimately causing a short circuit. The feedback from the site indicated that the microcontroller was not functioning, and a ‘ticking’ sound was heard from the circuit board when it was powered on.

Troubleshooting began in earnest…

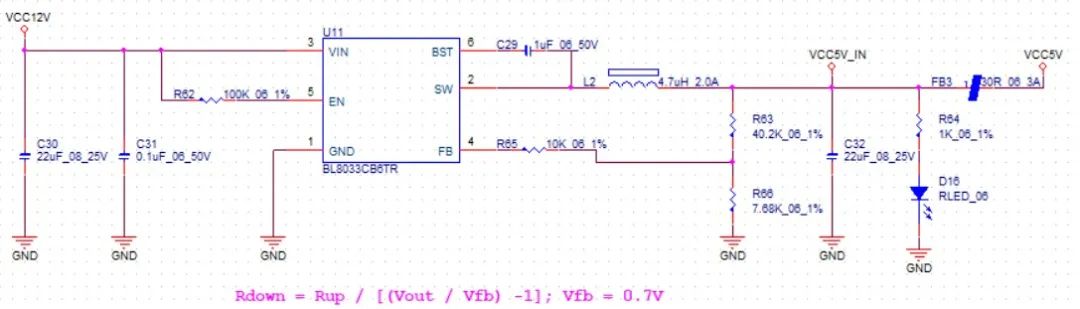

Power Supply Schematic

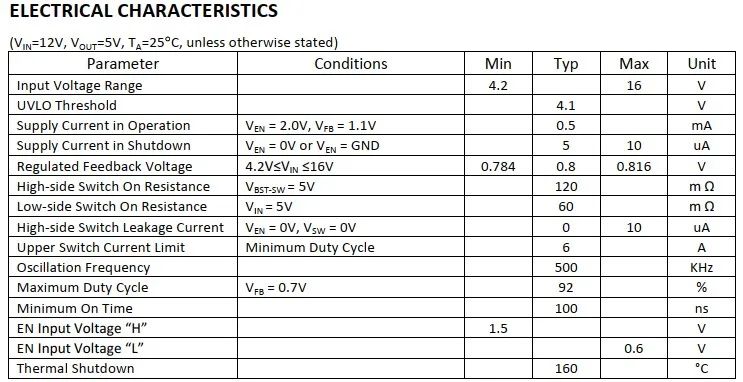

The power supply uses the BL8033 synchronous buck switching power supply. The maximum input is 16V, maximum output is 3A, and efficiency can reach up to 96%.

Electrical Characteristics of the BL8033

According to the feedback, the ‘ticking’ sound on the circuit board was caused by a short circuit. Knowing this issue, we can basically locate the sound as coming from near the power supply, and further analysis can confirm it originates from the inductor. So why does the power supply cause the inductor to emit a ‘ticking’ sound when a load short circuit occurs? Let’s analyze it below.

Why does the inductor squeal?

1. High-power switching power supply short circuit squeal.When the switching power supply is operating at full load, if the power supply is suddenly shorted, a squeal may sometimes be heard; or when setting current protection, a squeal may occur when the current is adjusted to a certain level. The reason is that when the load approaches the output power limit of the power supply, the switching transformer operates in a non-steady state.

In the first cycle, due to the excessive duty cycle of the switch tube, the conduction time is too long, thus transmitting too much energy through the transformer to the subsequent stage; the energy storage inductor of the DC rectification circuit cannot completely release the energy stored in the first cycle during the second cycle; when the third cycle arrives, the power supply chip will not allow the switch tube to conduct, or will allow the switch tube to conduct with a very small duty cycle.

As a result, the energy stored in the energy storage inductor is released during the second and third cycles, leading to a decrease in output voltage. Thus, when the fourth cycle arrives, the power supply chip will drive the switch tube to conduct with a large duty cycle, and this cycle will cause the transformer to produce low-frequency vibrations, resulting in sounds audible to the human ear.

When the power supply operates in a non-steady state, the output ripple voltage is also much larger than when operating in normal conditions. When the number of cycles in which the switch tube is fully off reaches a certain proportion of the total cycles, the switching frequency of the power supply shifts from the high-frequency range to the audio range, thus producing a sharp squeal. At this point, the transformer is already in a severely overloaded state and may burn out at any time.

2. When unloaded or under very light load, the switch tube may also experience intermittent full-off cycles. When the proportion of full-off cycles reaches a certain level, the switching frequency of the power supply shifts from the high-frequency range to the audio range, thus producing a sharp squeal.

Additionally, in unloaded or light load scenarios, the back electromotive force generated by the transformer cannot be well absorbed, leading to many noise signals coupling into the primary and secondary windings of the transformer. When the low-frequency components of these noise signals resonate with the inherent oscillation frequency of the transformer, resonance occurs. To avoid the resonant frequency falling into the audio range and producing squeal, a selective frequency circuit can be added to the circuit to filter out low-frequency components.

3. Poor transformer potting, including no potting treatment. When the transformer is poorly potted, although the load capacity is generally not affected, it will produce squeal, and the output waveform will have spikes. It is important to note that poor transformer design may also cause squeal due to vibrations during operation.

4. Poor grounding of the primary voltage regulator chip.When the grounding is poorly routed, common manifestations include probabilistic failures (some products work normally while others fail). The failure phenomenon is an inability to carry load, or even unable to oscillate. At this time, squeal is often accompanied.

5. Grounding errors of the secondary voltage regulator chip.The grounding of the reference voltage regulator chip on the secondary side of the transformer has similar requirements to that of the primary voltage regulator chip: it must not be directly connected to the cold ground or hot ground of the transformer. If connected together, it will lead to a decrease in load capacity and produce squeal. The larger the load, the more pronounced the squeal.

How to resolve the short circuit after locating the squeal cause?

1. If hardware conditions permit, the channel between the power supply output and the load can be disconnected. In the power supply designed above, a “FB3” ferrite bead is used, so excluding the power supply short circuit is very convenient;

2. Check the configuration parameters of the power supply, then reapply power to the power supply to ensure the output meets design requirements;

3. If the power supply issue is ruled out but the short circuit phenomenon still exists, then the subsequent load needs to be analyzed to determine which component caused the short circuit (ultimately locating the microcontroller short circuit);

4. To eliminate the load short circuit, I generally start from small components to large components that are easy to solder, removing one point and measuring one point, and the removed chips themselves also need to be measured.

5. Pay attention to the solder balls on the board (soldering residues);

Why does short circuit still occur even after applying conformal coating?

Conformal coating mainly protects against: mold, moisture, and salt spray.Therefore, it cannot effectively prevent short circuits. Many components on the PCB generate heat during operation, and if conformal coating is applied at this time, it will significantly hinder the component’s heat dissipation. Additionally, the reason that connectors on the board cannot be coated increases the risk of short circuits.

Of course, this PCB short circuit incident should not have occurred. Due to the complexity of the on-site debugging environment and the carelessness of the debugging personnel, this low-level issue ultimately arose.

Note:This article is reproduced from the Electronic Circuit WeChat public accountIf there are any issues regarding copyright or other matters, please contact the author at 13237418207, and we will handle it promptly!