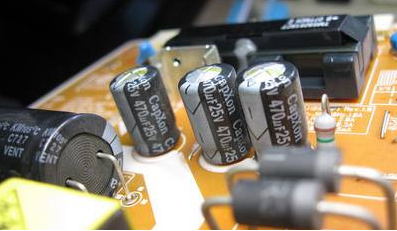

1. Fault Characteristics and Repair of Capacitor Damage in Industrial Control Circuit Boards Capacitor damage is the most common fault in electronic devices, particularly with electrolytic capacitors. The symptoms of capacitor damage include: 1. Decreased capacitance; 2. Complete loss of capacitance; 3. Leakage; 4. Short circuit.

The role of capacitors in circuits varies, leading to different characteristics of faults. In industrial control circuit boards, digital circuits account for the majority, with capacitors used mainly for power filtering, while capacitors for signal coupling and oscillation circuits are less common. If an electrolytic capacitor in a switching power supply is damaged, the power supply may fail to oscillate and produce no voltage output; or the output voltage may not be filtered properly, causing logic confusion due to unstable voltage, resulting in the machine working intermittently or failing to start. If the capacitor is positioned between the positive and negative terminals of the power supply in a digital circuit, the fault symptoms are the same.

This is particularly evident in computer motherboards, where many computers experience issues starting after several years of use. Upon opening the case, one often finds swollen electrolytic capacitors. If these capacitors are removed and measured, their capacitance is often found to be significantly lower than expected.

The lifespan of a capacitor is directly related to environmental temperature; the higher the temperature, the shorter the lifespan. This rule applies not only to electrolytic capacitors but also to other types of capacitors. Therefore, when searching for faulty capacitors, one should focus on those close to heat sources, such as near heat sinks and high-power components, as the closer they are, the more likely they are to be damaged.

I once repaired a power supply for an X-ray inspection machine where the user reported smoke coming from the power supply. Upon opening the case, I found a large 1000uF/350V capacitor leaking a viscous substance. After measuring, I discovered its capacitance was only a few tens of uF, and this capacitor was the only one located closest to the rectifier bridge’s heat sink, while others farther away were intact with normal capacitance. Additionally, I found a ceramic capacitor that had short-circuited, which was also close to a heat-generating component. Therefore, one should prioritize checking these components during repairs.

Some capacitors can leak significantly, and touching them can even cause burns; such capacitors must be replaced. When troubleshooting intermittent faults, if poor connections are ruled out, most cases are generally due to capacitor damage. Thus, when encountering such faults, one should focus on checking the capacitors, and replacing them often yields surprising results (of course, one should pay attention to capacitor quality, choosing reputable brands like Rubycon or Nichicon).

2. Characteristics and Identification of Resistor Damage

Many beginners often struggle with resistors during circuit repairs, repeatedly soldering and desoldering them. However, with experience, understanding the characteristics of resistor damage can significantly streamline the process.

Resistors are the most numerous components in electrical devices, but they are not the most failure-prone. The most common failure mode for resistors is an open circuit, while an increase in resistance is less common, and a decrease in resistance is very rare. Common types include carbon film resistors, metal film resistors, wire-wound resistors, and fusible resistors.

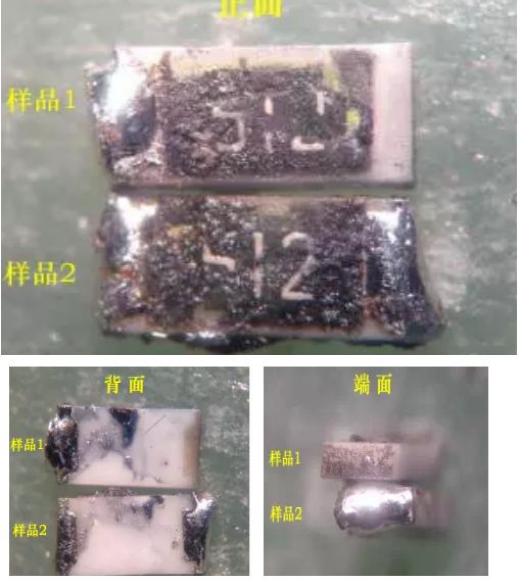

The first two types of resistors are widely used, and their failure characteristics include a higher failure rate for low resistance (below 100Ω) and high resistance (above 100kΩ), while mid-range resistances (like a few hundred ohms to tens of kilohms) rarely fail. Low resistance resistors often show signs of burning and blackening when damaged, making them easy to identify, while high resistance resistors usually show little to no visible signs of damage.

Wire-wound resistors are generally used for high current limiting and have low resistance values. When cylindrical wire-wound resistors fail, some may turn black or show surface peeling or cracks, while others may show no signs. Cement resistors, a type of wire-wound resistor, may break upon failure, otherwise showing no visible signs. Fusible resistors may have a piece of surface blown off when they fail, but often show no signs of burning or blackening. Based on these characteristics, one can focus on checking resistors to quickly identify the faulty ones.

According to the characteristics listed above, one can first observe if there are any blackened marks on low resistance resistors on the circuit board. Then, based on the fact that most resistors fail open or with increased resistance, and that high resistance resistors are prone to failure, we can use a multimeter to directly measure the resistance across high resistance resistors on the circuit board. If the measured value is greater than the nominal value, this resistor is certainly faulty (be sure to wait for the resistance to stabilize before concluding, as there may be parallel capacitive elements in the circuit causing a charging and discharging process). If the measured value is lower than the nominal value, it is generally not a concern. By measuring each resistor on the circuit board, even if we “wrongly” identify a thousand, we won’t miss one.

3. Methods for Judging the Quality of Operational Amplifiers

Determining the quality of operational amplifiers can be challenging for many electronic repair technicians, not only due to educational background (many technicians are undergraduates who won’t understand without instruction, and even after teaching, it takes a long time to grasp, while some graduate students specializing in frequency control also struggle!). Here, I hope to share insights that may help everyone.

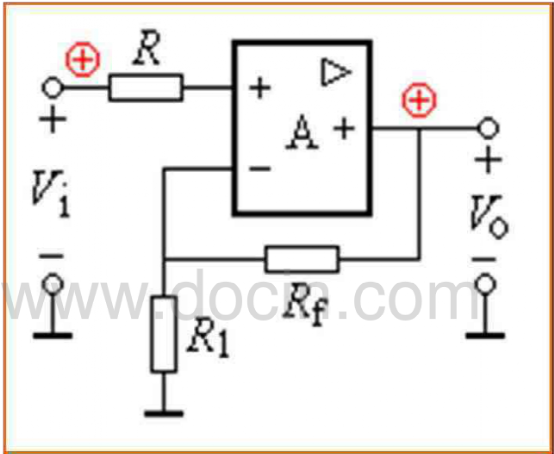

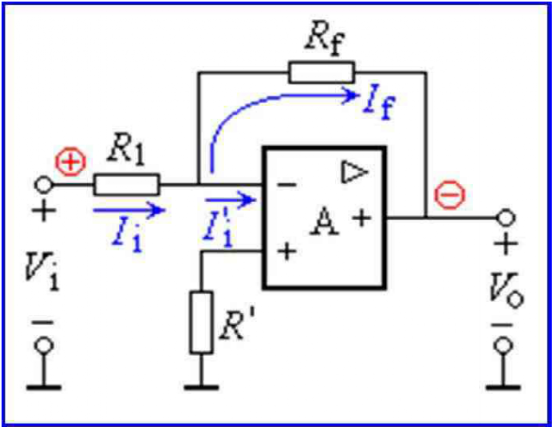

The ideal operational amplifier has the characteristics of “virtual short” and “virtual open,” which are very useful for analyzing linear applications of op-amp circuits. To ensure linear operation, the op-amp must operate under closed-loop (negative feedback) conditions. Without negative feedback, the open-loop op-amp behaves like a comparator. To assess the quality of the device, one must first determine whether it is used as an amplifier or as a comparator in the circuit.

From the diagrams, it can be seen that regardless of the type of amplifier, there is a feedback resistor Rf. Therefore, during repairs, we can check this feedback resistor on the circuit. Use a multimeter to measure the resistance between the output and the inverting input. If the resistance is excessively high, such as several MΩ, we can be fairly certain that the device is used as a comparator. If this resistance is small (0Ω to several tens of kΩ), check for any resistors connected between the output and the inverting input, as this would indicate it is being used as an amplifier.

According to the principle of virtual short in amplifiers, if this operational amplifier is functioning normally, the voltages at the non-inverting and inverting inputs must be equal, with any difference being in the millivolt range. Of course, in some high input impedance circuits, the internal resistance of the multimeter may slightly affect the voltage measurement, but generally, it should not exceed 0.2V. If there is a difference exceeding 0.5V, the amplifier is undoubtedly faulty! (I used a FLUKE 179 multimeter)

If the device is used as a comparator, the voltages at the non-inverting and inverting inputs are allowed to differ; if the non-inverting voltage > inverting voltage, the output voltage approaches the positive maximum; if the non-inverting voltage < inverting voltage, the output voltage approaches 0V or the negative maximum (depending on whether it is a dual or single power supply).

If the detected voltages do not conform to this rule, the device is undoubtedly faulty!

This way, you do not need to use substitution methods or remove the chip from the circuit board to determine the quality of the operational amplifier.

4. A Small Tip for Testing SMT Components with a Multimeter

Some surface-mount components are very small, making it inconvenient to test with ordinary multimeter probes, as it is easy to cause short circuits and difficult to contact the metal parts of the component leads on insulated circuit boards. Here, I will share a simple method that will greatly facilitate testing.

Take two of the smallest sewing needles, align them with the multimeter probes, and then take a fine copper wire from a multi-strand cable to bind the probes and needles together, securing them with solder. This way, when testing SMT components with the fine-tipped probes, there is no risk of short-circuiting, and the needle tips can pierce the insulation, directly accessing critical areas without needing to scrape off the coating.

5. Method for Repairing Short Circuit Faults in Common Power Supply on Circuit Boards

In circuit board repairs, encountering short circuit faults in common power supplies can be daunting, as many components share the same power supply, and each component using this power supply is suspected of having a short circuit. If the board has few components, a “ground search” method can ultimately find the short circuit point, but if there are too many components, success with this method may depend on luck. Here, I recommend a more effective method that can quickly identify the fault point.

One needs a power supply that can adjust both voltage and current, with voltage ranging from 0-30V and current from 0-3A. This type of power supply is inexpensive, around 300 yuan. Set the open-circuit voltage to the device’s power supply voltage level, first adjusting the current to the minimum. Apply this voltage to the circuit’s power supply points, such as the 5V and 0V terminals of 74 series chips, and gradually increase the current while feeling the components with your hand. When you touch a component that is noticeably hot, that component is often the damaged one, and you can remove it for further testing. Of course, during operation, the voltage must not exceed the device’s operating voltage, and it must not be reversed; otherwise, other good components may be damaged.

6. A Small Eraser Solves Big Problems

As industrial control boards become more prevalent, many boards use gold fingers inserted into slots. Due to harsh industrial environments—dusty, humid, and corrosive gases—these boards can suffer from contact failure. Many friends may have solved the problem by replacing the boards, but the cost of purchasing new boards can be significant, especially for imported equipment. Instead, consider using an eraser to repeatedly wipe the gold fingers clean; after removing the dirt, try the machine again—it might just solve the problem! This method is simple and practical.

7. Analysis of Intermittent Electrical Faults

Various intermittent electrical faults can roughly include the following situations: 1. Poor contact between the board and slot, internal wire breaks causing intermittent connectivity, poor contact at connectors and terminals, and cold solder joints; 2. Signal interference, where faults only appear under specific conditions, possibly due to excessive interference affecting the control system, or changes in parameters of individual components or overall performance pushing the anti-interference capability to a critical point, leading to faults; 3. Poor thermal stability of components.

Based on extensive repair experience, the primary culprit is often the poor thermal stability of electrolytic capacitors, followed by other capacitors, transistors, diodes, ICs, and resistors; 4. Moisture and dust on the circuit board. Moisture and dust can conduct electricity, creating resistance effects, and during thermal expansion and contraction, the resistance value may change, which can have a parallel effect with other components, significantly altering circuit parameters and causing faults; 5. Software is also a consideration, as many parameters in circuits are adjusted using software. If certain parameter margins are set too low and are within critical ranges, faults can occur when the machine operates under conditions that trigger these software-determined fault reasons.

8. How to Quickly Find Component Data

Modern electronic products are diverse, and the variety of components is ever-increasing. In circuit repairs, especially in the field of industrial circuit board repairs, many components may be unfamiliar or even unheard of. Additionally, even if one has all the data for the components on a particular board, the efficiency of repairs can be significantly reduced without a quick lookup method. In the field of industrial electronic repair, efficiency equates to money, and neglecting efficiency is akin to neglecting one’s finances.

We should be grateful to live in this great era where the internet is boundless, making every corner of the world seemingly accessible. Free information is ubiquitous, and everyone can reach out for it. Therefore, everyone should make good use of the powerful tool that the internet provides to make their work easier!

Source: Internet, copyright belongs to the original author.

Recommended articles: (Click the blue text below for article details)

(1) I was also stunned by this method!

(2) The king sent me to debug, and I was dumbfounded on-site!

(3) The reason for this elevator fault shocked the maintenance personnel!

(4) The escalator that was installed fell from the 5th floor!

(Click the image above to register)

Long press the QR code to follow this platform

For business cooperation, please call: 135-8595-9424

Long press the QR code to enter the front line

Following is true love