Introduction:

In recent years, the domain control of automotive electronic control has transformed from a few forward-looking projects into a direction that all manufacturers strive to implement. Why can we now propose the concept of domain control and even central computing platforms? What functions can be controlled by domains? What possible paths are there for the future? This article will attempt to deeply analyze the evolution of electronic and electrical domain control based on my years of development experience in the automotive industry.

01

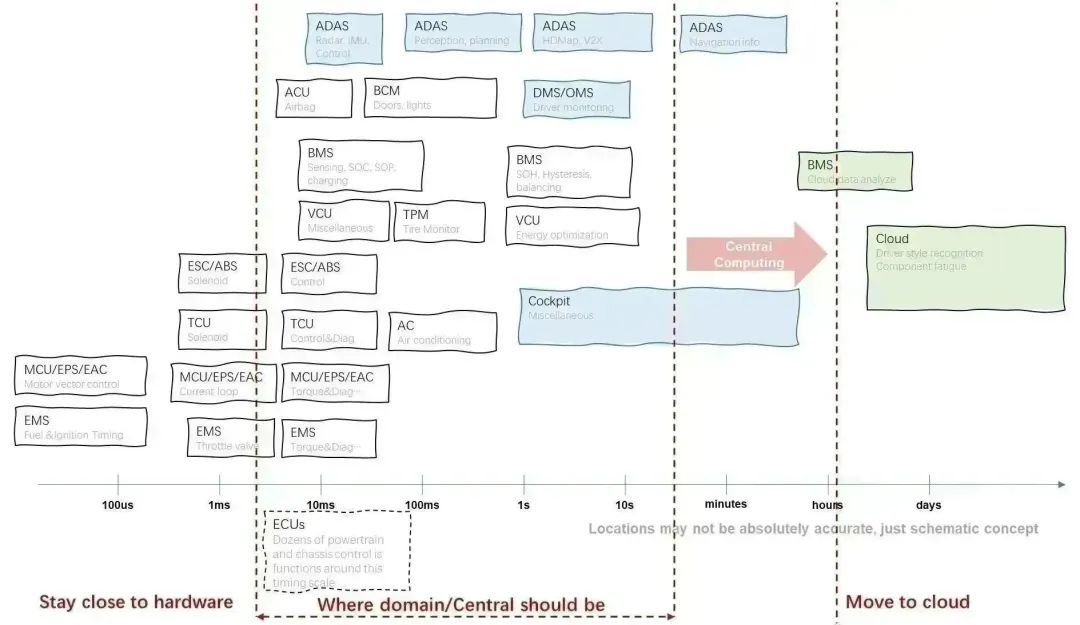

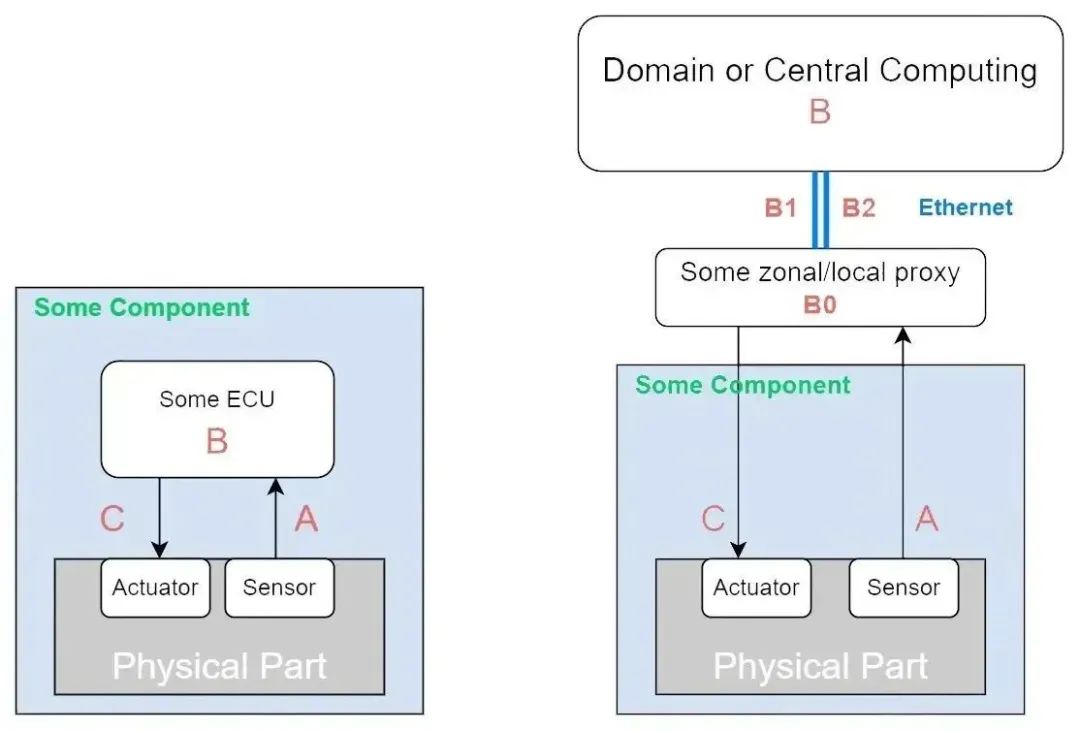

Why can we have domain control

02

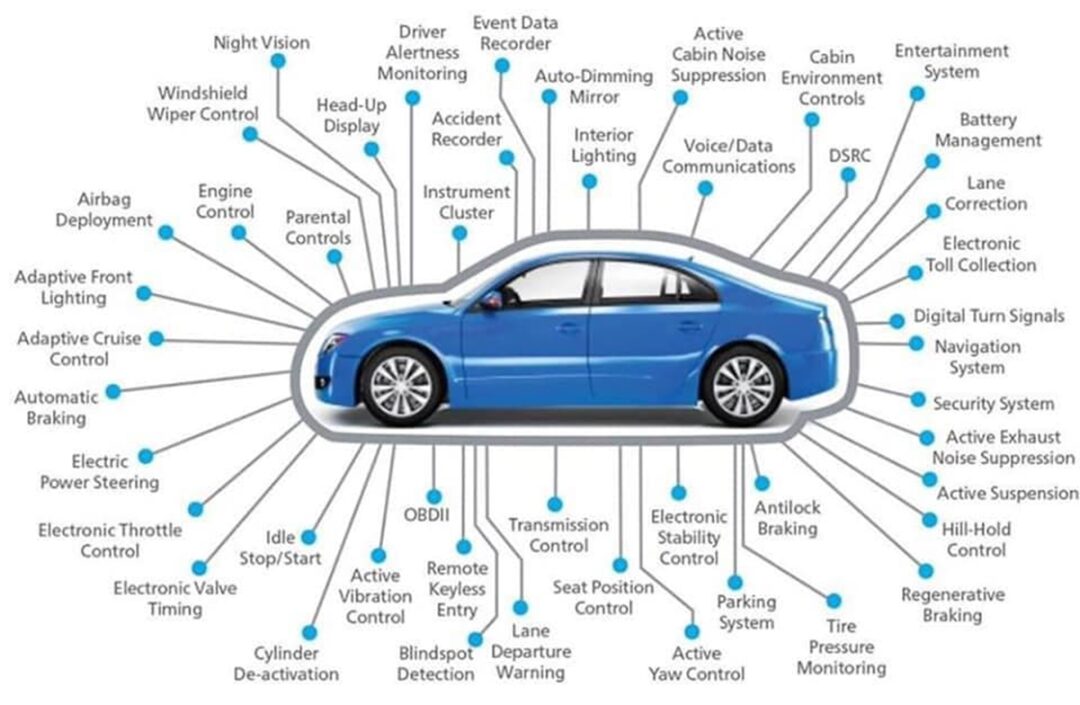

What functions can be domain-controlled

03

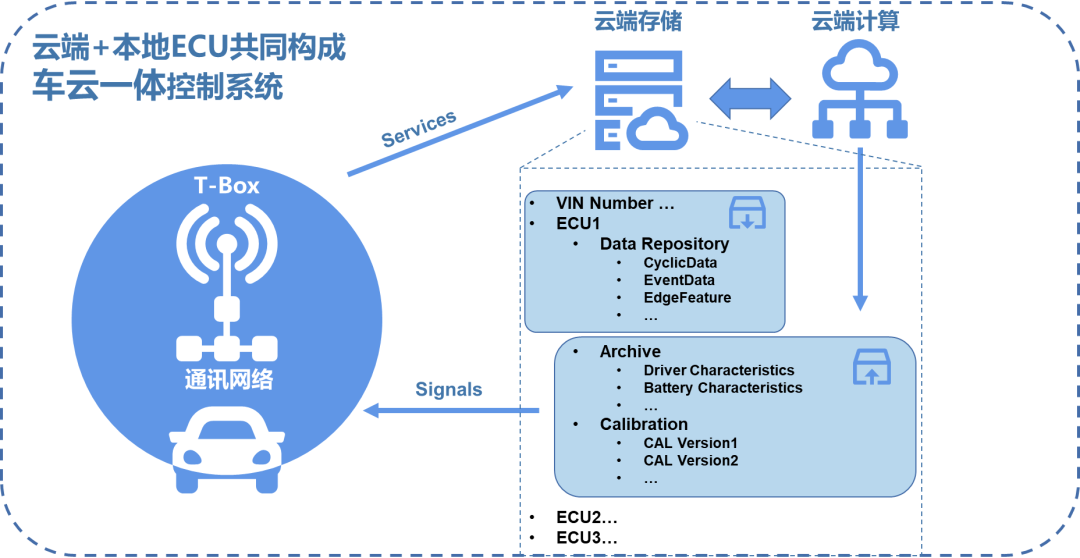

Possible Future Paths

END

Click the business card below

Follow us now