-

F-15 Fighter Jet and Weapons Open Source!! A total of 250G……

-

Animation Demonstrating I2C, SPI, UART Communication Processes, Very Intuitive!

-

US Military Sonar Buoy Captured in the South China Sea, Let’s Take a Look Inside!

-

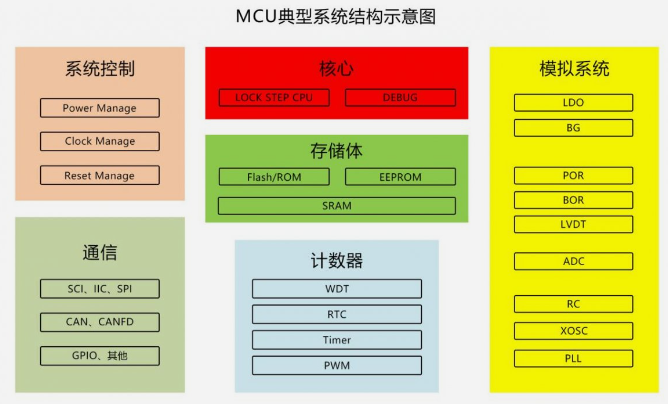

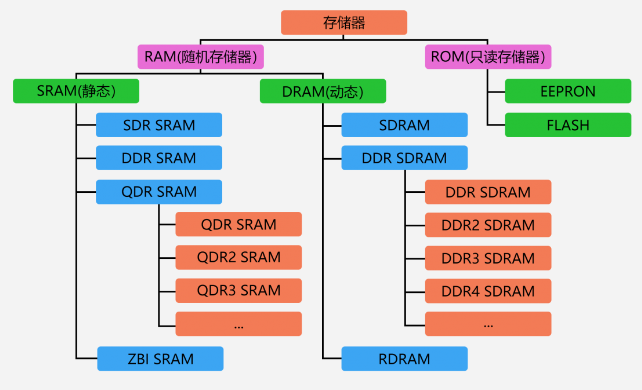

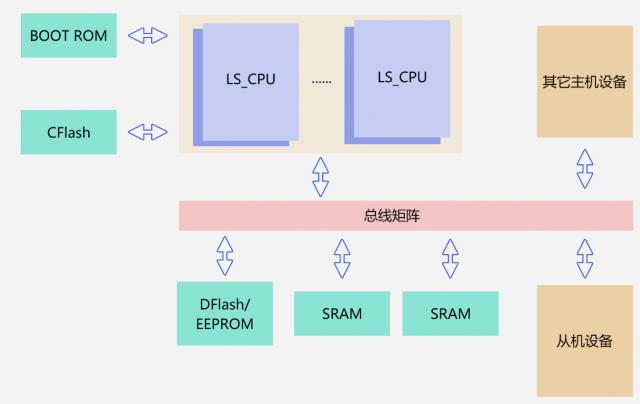

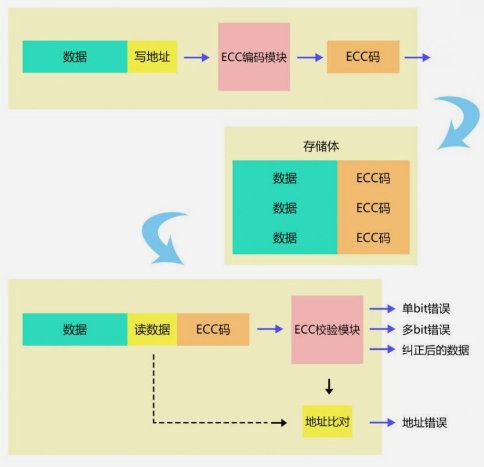

32-bit MCU Tape-Out Successful! Vocational Schools Can Also Develop Their Own Chips Now

-

SK Group Restructuring, HBM Welcomes Major Investment