Today, I am sharing a small experiment I conducted many years ago, paying tribute to Mr. Jin and all the comrades from the PCBA soldering improvement team!Background IntroductionDuring the transition from leaded to lead-free soldering, various failures such as remote control malfunction and failure to power on occurred in TV products during the damp heat aging chamber tests. Upon disassembly, black residues were found around the solder joints of the main board, power board, or remote control board, and under a microscope, a phenomenon of whisker growth was observed.The investigation and analysis process will not be detailed here; I will directly state the conclusion: Residual flux on the surface of the PCBA solder joints absorbs moisture in a high-temperature, high-humidity environment, leading to condensation. Under aging and powered conditions, a micro-battery effect forms, causing metal ions to migrate, precipitating metals or compounds, resulting in short circuits. The immersion silver surface treatment process used for PCBs was limited in conditions and did not undergo compositional analysis; it is now believed to be due to Ag ion migration.We conducted verification using the TV remote control board; this experiment is relatively simple and can be reproduced by following these steps.

Drip Test

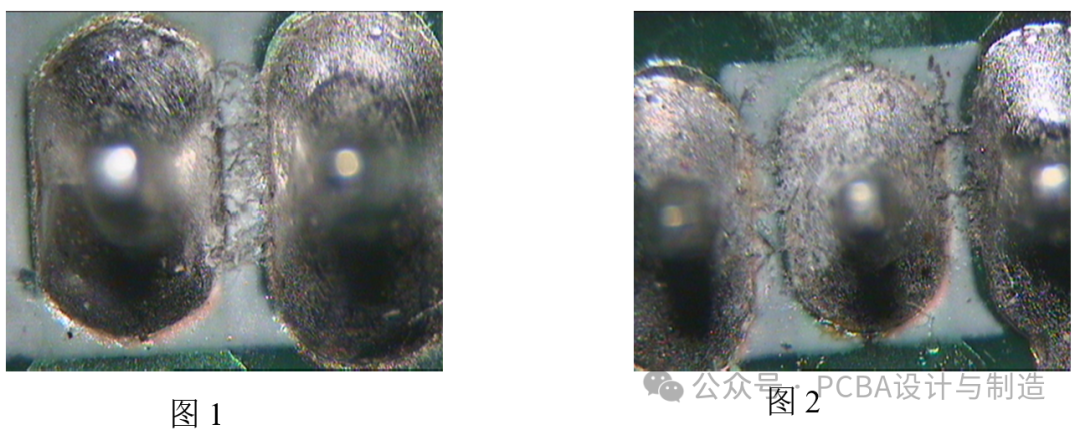

1. Use the condensation method to extract water vapor from the damp heat aging chamber, cool it down to obtain condensate. The pH of the condensate is 6.4 (laboratory standard 6-7), and the conductivity is 128μs/m (far exceeding the laboratory standard ≤5μs/m). The drip test is conducted using both condensate and distilled water.2. Take a PCBA and apply a 5V DC power supply to the power and ground pins of the socket, then drip the condensate between the two solder joints (one end is 5V, the other end is GND).3. The black material on the pads or PCB surface moves directionally in a short time (generally around 10-15 minutes). After stopping the power supply, a fluffy gray-black substance remains on the PCBA. Using a multimeter to measure the resistance between the two points shows a rapid decrease in resistance, approaching conduction, as shown in Figure 1.4. Take another PCBA, apply a 5V DC power supply to the power and ground pins of the socket, and drip distilled water between the two solder joints (one end is 5V, the other end is GND).5. The black material on the pads or PCB surface moves directionally in about 30 minutes. After stopping the power supply, a fluffy gray-black substance remains on the PCB, and using a multimeter to measure the resistance between the two points shows a rapid decrease in resistance, approaching conduction, as shown in Figure 2. The video of the drip test is as follows:

The video of the drip test is as follows:

Test Analysis

The fundamental cause of whisker growth is the formation of a micro-battery structure between the two solder pads, causing the directional movement of scattered metallic compounds such as tin on the PCB and pads. Once the directional movement reaches equilibrium, a conductive “bridge” forms between the pads, observed under a microscope as whisker growth.

1. Elements for micro-battery formation:

-

Potential: The voltage difference between the two solder pads (the potential induces the directional movement of metal ions).

-

Electrolyte: After entering the high-temperature, high-humidity aging chamber, condensation forms on the PCB surface, constituting the electrolyte (Note: Solid metal ions do not move; once metal ions dissolve in the electrolyte, they will move directionally under the influence of potential).

-

Electrolytes: Metallic compounds such as tin and silver (these substances are conductive).

2. Micro-battery structure induces whisker growth, leading to short circuit failures.

-

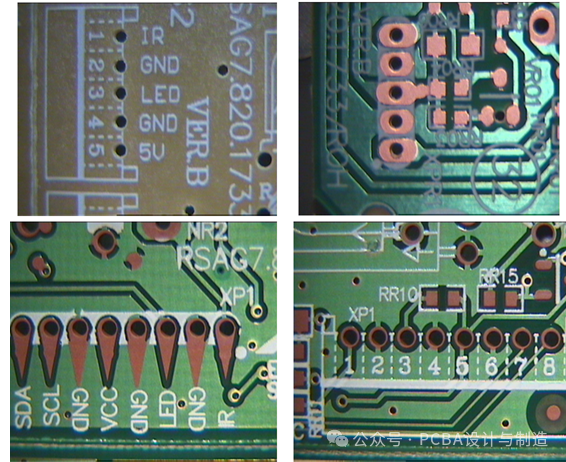

In the socket layout design, the power (high voltage) and ground (0 voltage) are arranged in a cross pattern, and the distance between the pads is shortened, providing potential for micro-battery formation and illustrating the directional movement distance of black impurity ions.

-

The condensation on the PCBA surface promotes the directional movement of black impurities.

-

The black impurities are conductive impurities.

The PCB diagram is as follows:

Test Summary

(1) The higher the conductivity of the water condensation on the PCBA surface, the faster the directional movement speed of the black material, meaning the whisker formation speed is faster;

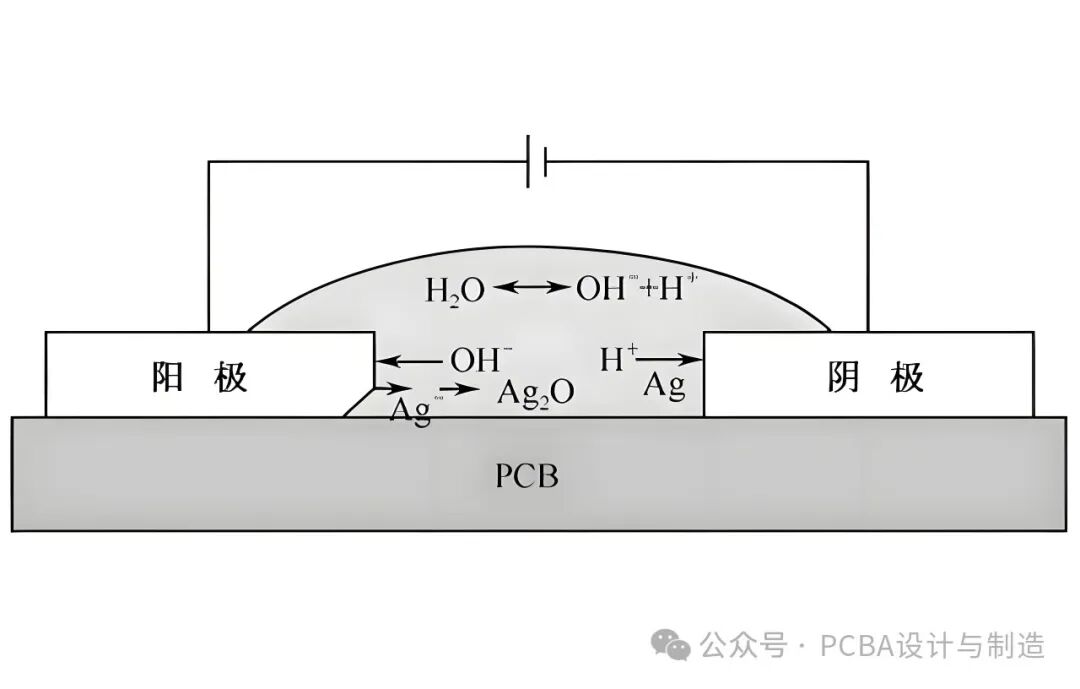

(2) Conditions for ion migration formation: DC potential difference, black material (ion residue), humidity.Ag Ion Migration Mechanism (Note: The following content is excerpted from Professor Fan Rongrong’s book “1100 Questions in Modern Electronic Assembly Engineering”)When a DC voltage is applied between Ag electrodes (Ag-plated pins or PCB pads) on an insulating substrate, and the insulating board adsorbs moisture or contains halogen elements, the anode is ionized, as shown in the figure below. Water (H2O) is ionized under the action of the electric field:H2O⇄OH–+H+

Water (H2O) is ionized under the action of the electric field:H2O⇄OH–+H+

H+moves towards the cathode, gaining electrons from the cathode to become hydrogen gas (H2) released into the space, whileOH–moves back towards the anode, dissolving the silver at the anode to form silver hydroxide, with the chemical reaction as follows:

Ag⇄Ag++e(oxidation reaction) Ag++OH–⇄AgOH(reduction reaction)

The AgOH generated from the electrochemical reaction is unstable and easily reacts with oxygen in the air or groups in synthetic resins, forming silver oxide on the anode side.

2AgOH⇄Ag2O+H2O

If the anode side is continuously eroded, silver oxide continues to grow until it reaches the cathode, where it is reduced and precipitated as Ag, with the reaction as follows:

Ag2O+H2O⇄2AgOH⇄2Ag++2OH–

Since the above reaction is a continuous cycle,Ag2O continues to grow in a branched manner from the anode to the cathode,Ag2O is continuously reduced and precipitated as Ag at the cathode.

References[1] Fan Rongrong, Modern Electronic Assembly Engineering Applications 1100 Questions, Beijing: Electronics Industry Press, 2013Please “like”, “share”, and “recommend”, thank you!