Click the blue text to follow us

When manufacturers face the production of blade servers, the numerous unconventional components on the PCB often prevent full automation, with some components still requiring manual operation, resulting in a yield rate below 98%. To find a comprehensive automation solution, while improving product yield, the following requirements must be met.

Four Major Requirements:

-

Extra-large PCB size: at least 500mm x 550mm

-

Assembly of 65 unconventional components: 24 DIMM sockets + 41 through-hole components

-

Throughput yield must exceed 98%

-

Fully automated mass production speed requirement: <72 seconds (50 UPH)

The solution from Global Instruments is a production line consisting of two FuzionOF machines and one Fuzion2-14 for unconventional through-hole assembly.

Assembly Capabilities of the Production Line:

Assembly Capabilities of the Production Line:

-

PCB size: 508mm x 813mm, exceeding 500 x 550

-

Custom multiple grippers and vacuum nozzles for the unconventional components to be assembled

-

Utilizes an upgraded unconventional vision system for 100% pin detection, improving product yield to 99.8%

-

Maximum assembly speed: <55 seconds, outperforming 72 seconds

-

Component size range: from 0201 to 150 square millimeters, height up to 25 millimeters

-

Upgraded high-placement force head configured for DIMM sockets

-

Specialized two DIMM socket feeders, along with three bowl feeders

-

Supports disc, tube, horizontal, and belt feeders

Additional Benefits:

Additional Benefits:

-

Utilizes fully automated feeding, achieving the highest OEE

-

Replaces manual insertion workstations requiring 8 workers across two shifts

-

Increases throughput yield (99.8%) and reduces rework costs by 20%

-

Capable of mixed assembly at the highest speed across the widest range of component sizes

-

Highest speed DIMM socket placement head

-

Flexibly accommodates the widest range of component sizes

-

Complete feeder solutions (disc, tube, bulk/bowl, belt, horizontal)

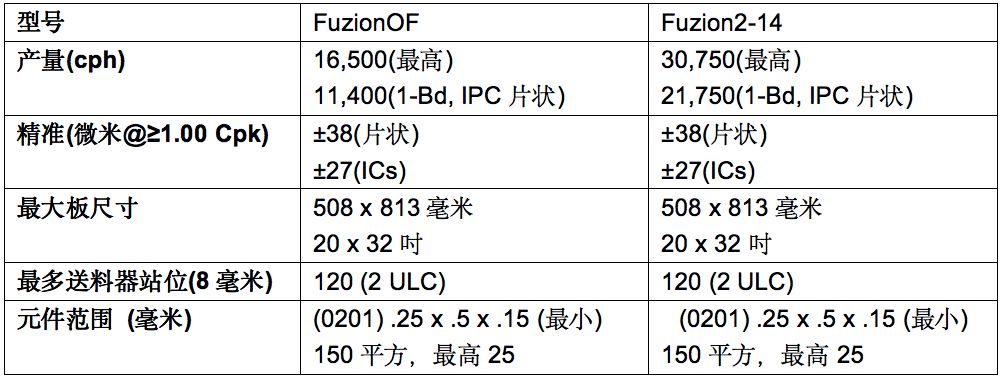

FuzionOF and Fuzion2-14 Technical Specifications

ENDS

If

you have any questions or comments regarding automation equipment, feel free to leave a message or contact:

Mobile:13828788390

Email: [email protected]

LongPressAttentionDiscover more exciting content

Global Precision Equipment Manufacturing Shanghai

WeChat ID: UIC_Asia

Website: http://cn.uic.com

Like

Share

Collect