Heat exchangers are indispensable in various applications. Generally, heat exchangers are used to transfer heat between fluids (usually moving fluids) to eliminate excess heat generated by components during operation. Particularly in aerospace applications, most of the cooling for engines is provided by air-oil heat exchangers located between the engine and the cabin, which can cool the engine oil while it is running, thereby optimizing the engine’s capacity as much as possible. Therefore, this device must be able to operate under high temperatures, severe corrosion, and wear conditions, suitable for aircraft that experience long downtimes in marine atmospheres, dynamic vibrations, and extended operations.

Heat exchangers are indispensable in various applications. Generally, heat exchangers are used to transfer heat between fluids (usually moving fluids) to eliminate excess heat generated by components during operation. Particularly in aerospace applications, most of the cooling for engines is provided by air-oil heat exchangers located between the engine and the cabin, which can cool the engine oil while it is running, thereby optimizing the engine’s capacity as much as possible. Therefore, this device must be able to operate under high temperatures, severe corrosion, and wear conditions, suitable for aircraft that experience long downtimes in marine atmospheres, dynamic vibrations, and extended operations. Challenges in Traditional Development and Manufacturing of Heat ExchangersDue to their complex structure, aerospace heat exchangers are traditionally produced through a lengthy process of brazing or diffusion bonding thin plates.Brazing uses filler metals with melting points lower than the base materials being joined, creating strong bonds and enhancing properties such as corrosion resistance, but it is not entirely suitable for large components with multiple joints and requires highly skilled and experienced operators to achieve optimal results.Innovative diffusion bonding allows for better and easier joining between metal components, resulting in high-performance compact heat exchangers.Specifically, this process involves applying high temperatures and pressures to bond the plates without melting or deforming their shapes.However, this process requires specialized equipment and longer processing times.Additionally, the success of the bonding depends on surface treatment and tight contact between surfaces, limiting the application range of complex geometries.Over the years, the aerospace industry has made significant technological advancements, and today, the manufacturing efficiency of heat exchanger components has improved to minimize waste.However, the development of new, more efficient heat exchangers continues.Most importantly, the final weight of components must be reduced by influencing dimensions, while performance in terms of thermal efficiency must reach high levels.Therefore, there are several main objectives in the design and manufacturing process of heat exchangers, which are challenging from both engineering and production cost perspectives.

Challenges in Traditional Development and Manufacturing of Heat ExchangersDue to their complex structure, aerospace heat exchangers are traditionally produced through a lengthy process of brazing or diffusion bonding thin plates.Brazing uses filler metals with melting points lower than the base materials being joined, creating strong bonds and enhancing properties such as corrosion resistance, but it is not entirely suitable for large components with multiple joints and requires highly skilled and experienced operators to achieve optimal results.Innovative diffusion bonding allows for better and easier joining between metal components, resulting in high-performance compact heat exchangers.Specifically, this process involves applying high temperatures and pressures to bond the plates without melting or deforming their shapes.However, this process requires specialized equipment and longer processing times.Additionally, the success of the bonding depends on surface treatment and tight contact between surfaces, limiting the application range of complex geometries.Over the years, the aerospace industry has made significant technological advancements, and today, the manufacturing efficiency of heat exchanger components has improved to minimize waste.However, the development of new, more efficient heat exchangers continues.Most importantly, the final weight of components must be reduced by influencing dimensions, while performance in terms of thermal efficiency must reach high levels.Therefore, there are several main objectives in the design and manufacturing process of heat exchangers, which are challenging from both engineering and production cost perspectives.

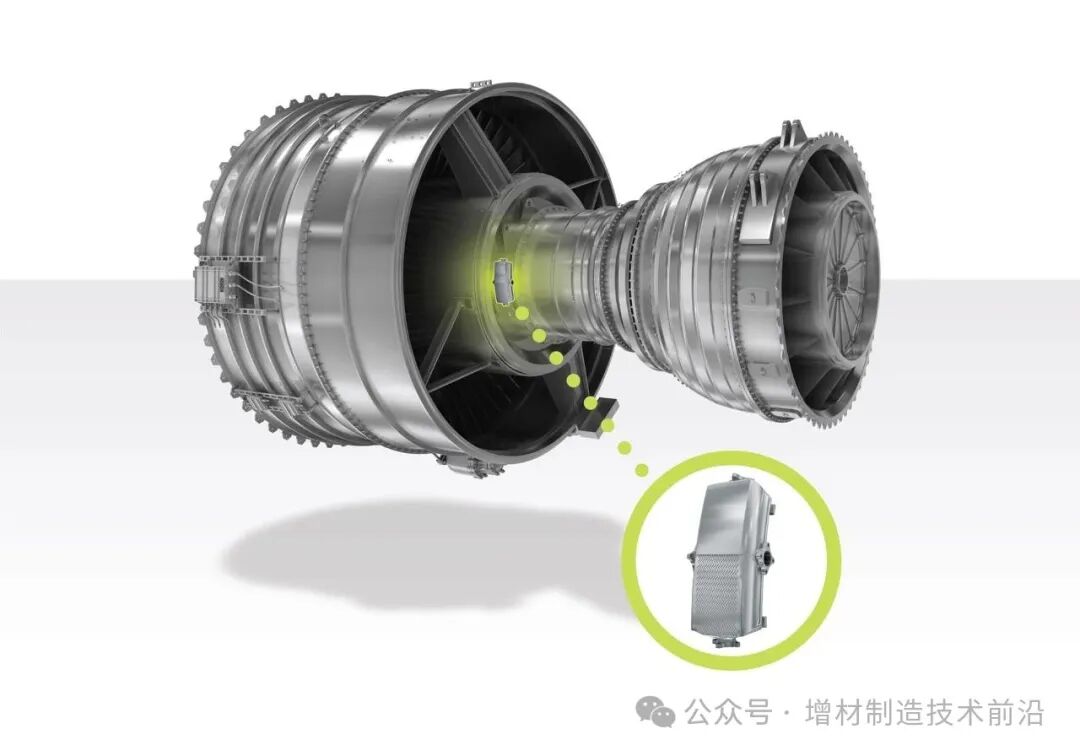

Oil heat exchangers in aircraft engines

Today, all components used in the aerospace field demand manufacturing and service life requirements to meet the strictest environmental regulations, forcing these industries to have a new vision for heat exchangers, hoping to enhance heat exchange efficiency through complex designs, but achieving the manufacturing of complex systems through traditional manufacturing techniques. Furthermore, this new regulation has triggered considerations for new manufacturing technologies, thus also considering materials with high density/strength ratios.

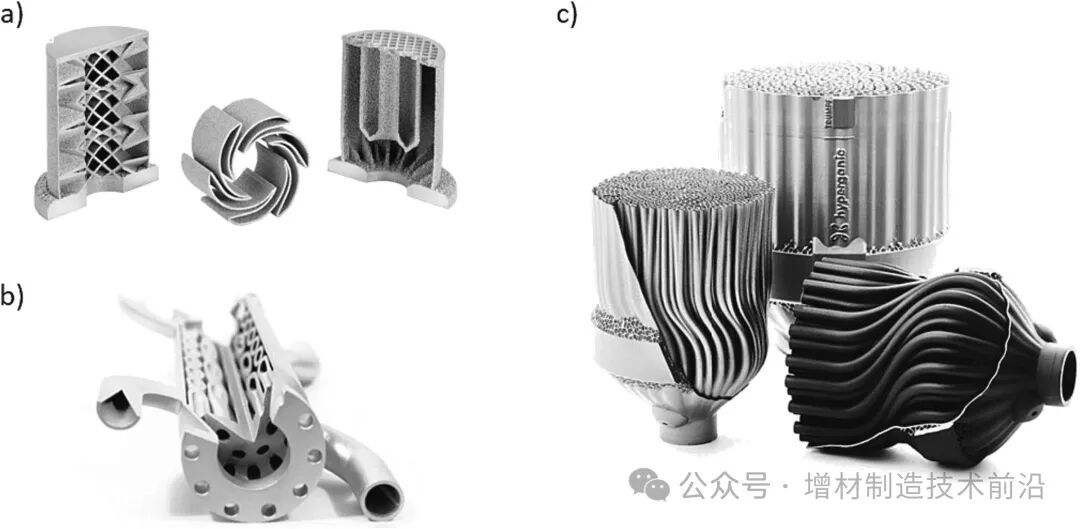

Heat exchangers manufactured by 3D printing

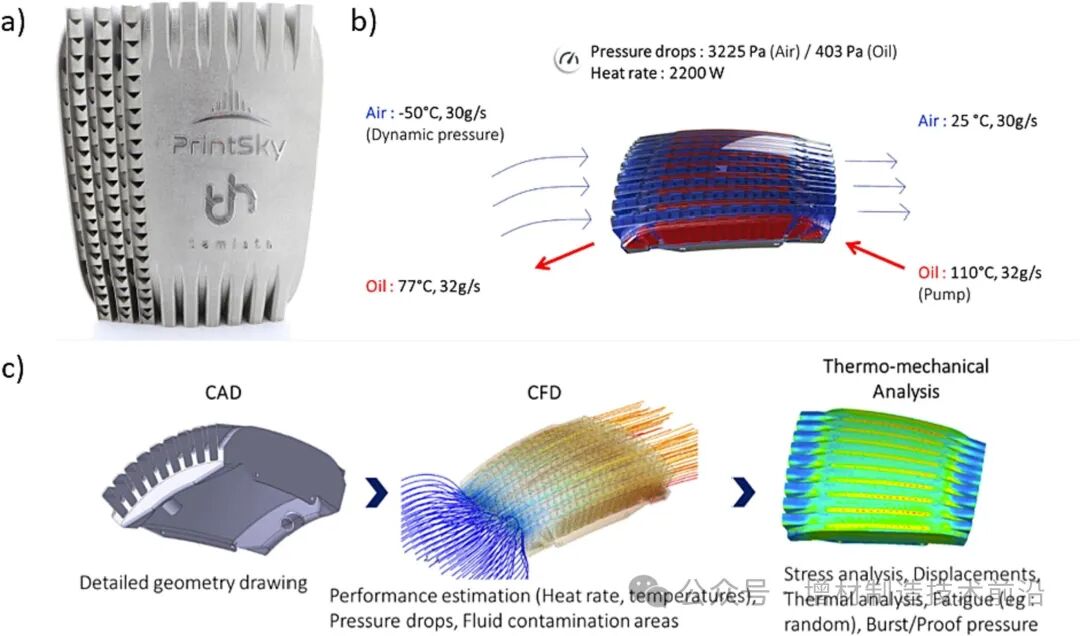

The design of heat exchangers typically involves a complex balance between maximizing the surface area of parts and minimizing the pressure drop within the parts. Generally, heat exchangers can be classified in various ways, such as by transfer mechanism, process nature, fluid flow, and compactness. Compact heat exchangers are characterized by a large amount of heat exchange surface per unit volume, and maximizing heat transfer by minimizing the overall volume of components is the basis of compact heat exchanger design. Due to their relatively small volume, lightweight, and high thermal efficiency, these compact heat exchangers have been widely used in the aerospace field.Focus on Topology Optimization and Lattice StructuresThe scientific community is still exploring new design tools and manufacturing methods to address the existing limitations of heat exchangers and maximize thermal efficiency,while achieving extreme compactness and lightweight components.Many details of heat exchangers are ultimately driven not by performance requirements but by manufacturing capabilities.Therefore, understanding the impact of variables such as pitch, fin height, and fin thickness is crucial for the repeatable production of lightweight, high-performance heat exchangers. In the past, extensive research on the correlation between fin shapes and thermal efficiency has driven the design of new heat exchangers. Traditionally, the types of fins used are the result of metal sheet forming or bending processes, and their geometries must allow for easy connection on the final component. This reduces the possible combinations of geometries available for generating new, more powerful heat exchangers.

Sintavia 3D printing manufacturing of large heat exchangers

Modern industry has reached a certain level of technological advancement that can ensure overcoming the aforementioned limitations. In particular, the combination of topology optimization in the design phase and additive manufacturing in the production phase has expanded the production space for heat exchangers, increased the possible categories, and may help improve performance under certain limitations for aerospace and other applications.Topology optimization is a mathematical technique that uses variable design parameters and constraints to generate shapes that ensure the maximization or minimization of one or more objective functions.Specifically, the optimization is achieved by adjusting the values of engineering parameters to reach the maximum or minimum of the objective function while satisfying the constraints. This useful tool, combined with advanced computational modeling software and additive manufacturing technology, can create heat exchanger designs with optimized surfaces and low weight.

New heat exchangers produced using optimized models and additive manufacturing

The growing demand for maximizing heat dissipation and performance represents a new vision for heat exchanger design. For example,the use of lattice structures has proven to be a potential method for enhancing heat transfer and thus improving heat exchanger efficiency. Lattice structures are composed of pillars arranged in a periodically ordered topology, repeating once or multiple times. The grid structure ensures significant mechanical resistance, forming an efficient load-bearing system, and also provides the possibility for cross-flow heat exchange. Due to the cross-flow of cold fluid through the channels, heat from the hot fluid dissipates locally through conduction and convection through the mesh structure. The combination of high thermal conduction and convection in the voids of the lattice structure, along with low flow resistance, leads to efficient heat exchange. Traditionally, lattice structures were produced using conventional manufacturing techniques, which imposed many limitations on the number of architectures. On the other hand, the introduction of modern additive manufacturing technology has expanded the possible geometries that can be created.

3D printed heat exchangers with lattice structures

Currently, research is ongoing regarding the use of hollow structures,which, when combined with lattice structures, can significantly improve thermal efficiency. These new hollow wall heat exchangers manufactured through additive manufacturing have enormous industrial development potential, but the relationship between heat transfer, losses, and types of structures still needs to be properly evaluated. Nevertheless, some limitations of additive manufacturing of lattice structures and thin-walled features remain challenges that scientific research is still striving to address. The limitations of minimum and maximum angles, thickness, and precision do not always guarantee the manufacturing of complex structures.Additive Manufacturing of Heat Exchangers

Additive manufacturing is a modern manufacturing process that provides great flexibility and opportunities for creating new products with complex geometries.In recent decades, additive manufacturing has begun to have a significant impact on industrial sectors where traditional manufacturing techniques struggle to produce products and where raw material waste is severe.Moreover,the introduction of additive manufacturing has made the implementation of technologies such as topology optimization possible, thereby improving performance by reducing the weight of components.Therefore, using these processes to manufacture components in the aerospace field has increased opportunities for innovation and provided new methods for manufacturing heat exchangers.

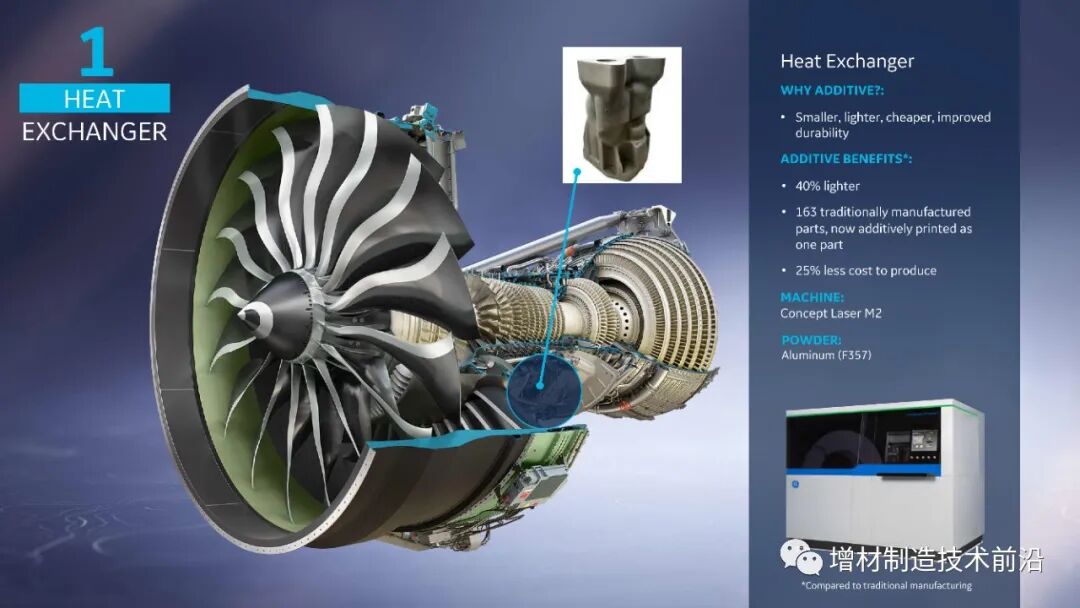

3D printed heat exchangers on GE9X

3D printed heat exchangers on GE9X

New high-performance heat exchangers from Safran Metal 3D Printing

Today, there are dozens of additive manufacturing processes, but the 3D printing processes capable of manufacturing heat exchangers need to be carefully selected. Direct Energy Deposition (DED) technology can produce large components, but the final surface and dimensional accuracy of the products are poor, making this process unsuitable for producing thin-featured heat exchangers. Ultrasonic Additive Manufacturing (UAM) uses ultrasonic friction to bond thin metal sheets, which are then machined through subtractive processes to create the desired geometries; many studies are currently demonstrating the capability of this technology to manufacture heat exchangers. Powder Bed Fusion technology is the most widely used additive manufacturing method for large-scale production of metal parts, and this process has produced the most common 3D printed heat exchangers to date.Designing more efficient heat exchangers for industries such as aircraft engines has become possible due to the maturity of 3D printing technology..

Statement: The content of this article is sourced from the forefront of additive manufacturing technology. It is for sharing purposes only and does not represent the position of this account; images are for non-commercial use. If there is any infringement, please contact the editor for deletion, thank you!

Follow our official WeChat

Join the group chat