When I first saw the AMBelievable tennis racket shock absorber, I must admit I was skeptical. I doubted its promotional claims, questioned the product’s capabilities, and pondered what impact this technology could have.

However, two years later, I have completely changed my perspective and fully believe that this technology can revolutionize the world of tennis.

The AMBelievable Universal tennis racket shock absorber installed on a tennis racket

AMBelievable is a startup from Turin, Italy, founded in 2022. Its mission is simple: to enhance the enjoyment of tennis using metamaterial technology. After testing their product for three months, I can attest that I now enjoy tennis more than ever before.

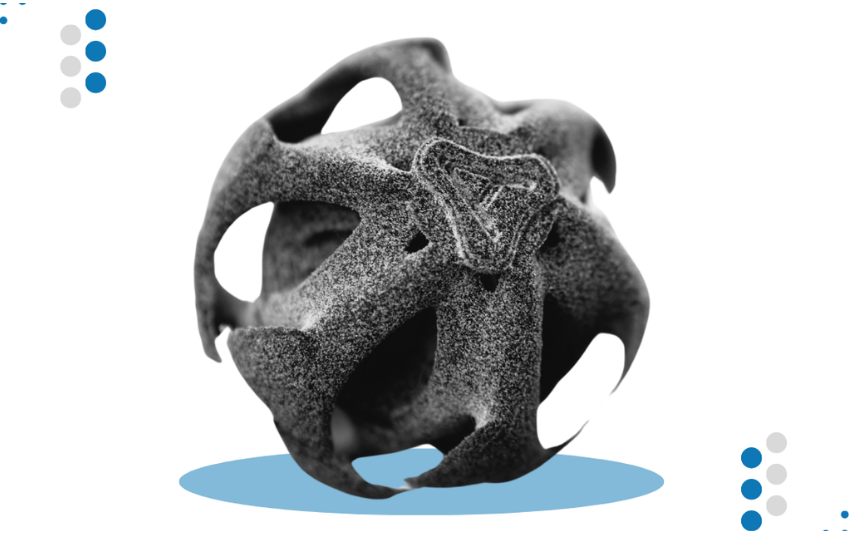

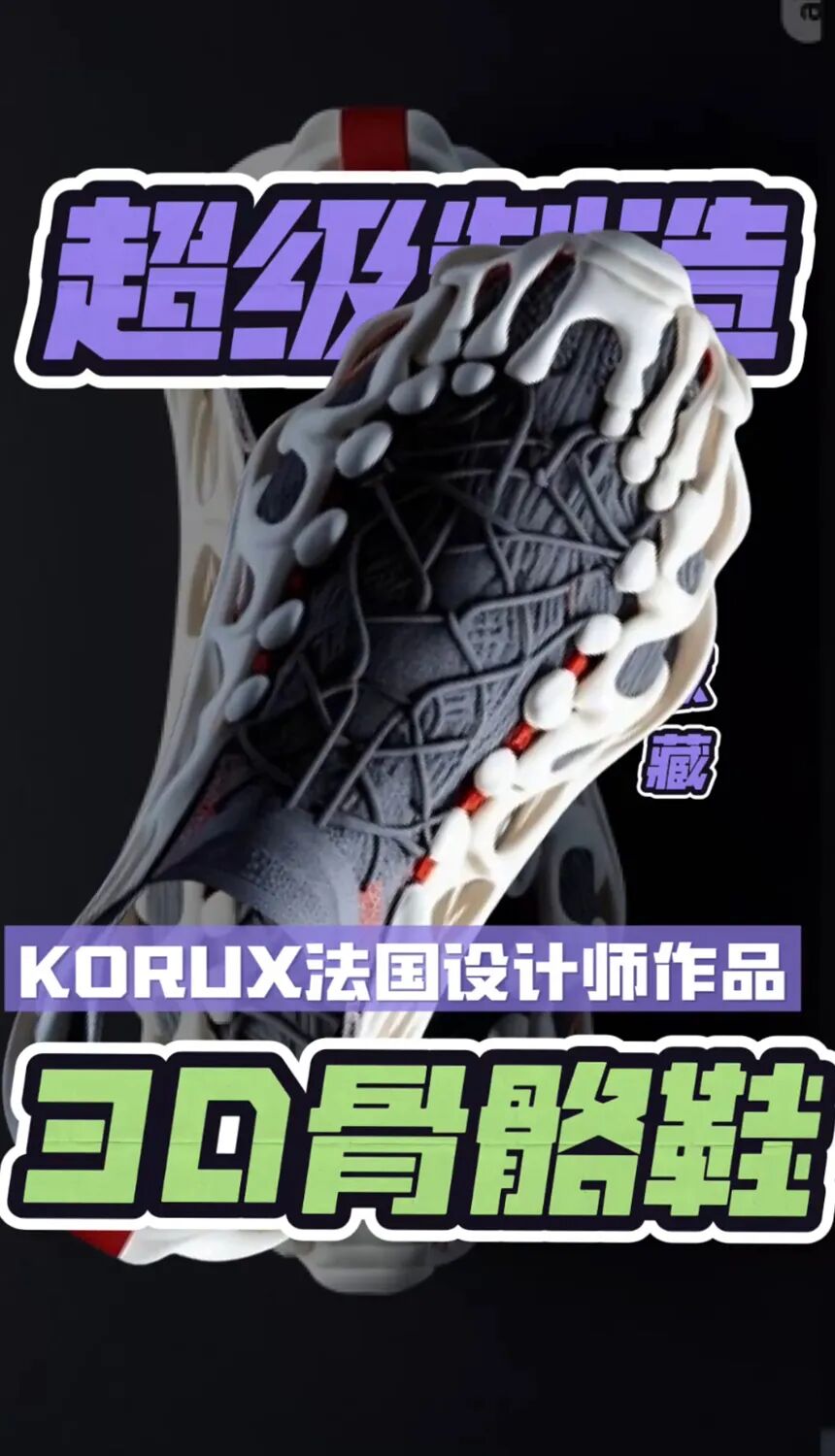

The shock absorber from AMBelievable is manufactured using Selective Laser Sintering (SLS) technology, a 3D printing process that fuses powdered TPU into precise shapes. What is fascinating is how they utilize lattice structures inspired by metamaterials to control the shock absorber’s response to different vibrations. These internal geometries allow it to absorb vibrations at specific frequencies while maintaining incredible lightweight—something traditional injection molding simply cannot achieve.

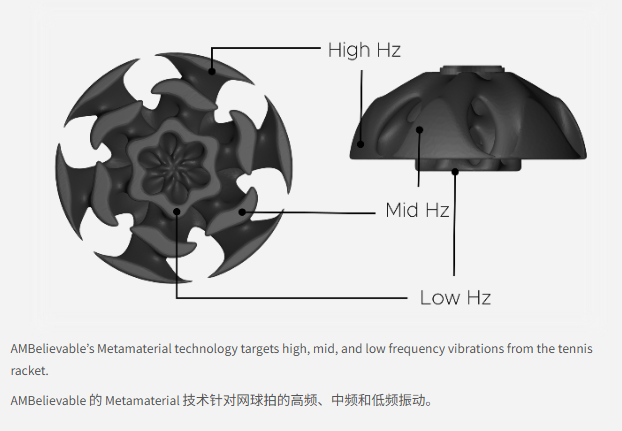

This technology is based on the metamaterial architecture shown in the image below. They are designed to dissipate specific frequencies according to player preferences, providing a truly customized feel. Moreover, they are tuned not only for the player’s “feel” but also to eliminate vibrations associated with tennis elbow.

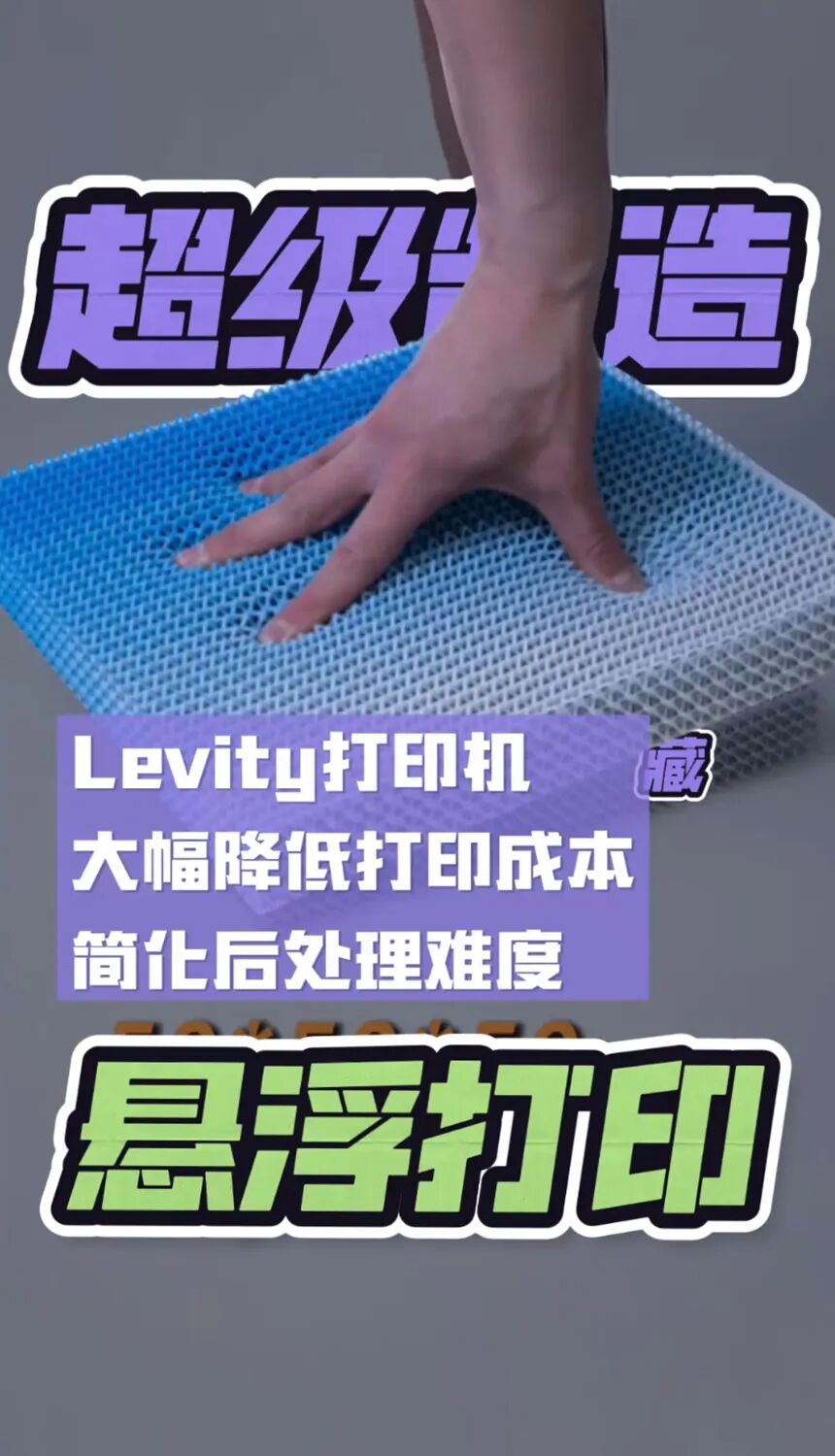

AMBelievable’s metamaterial technology targets high, medium, and low-frequency vibrations generated by tennis rackets

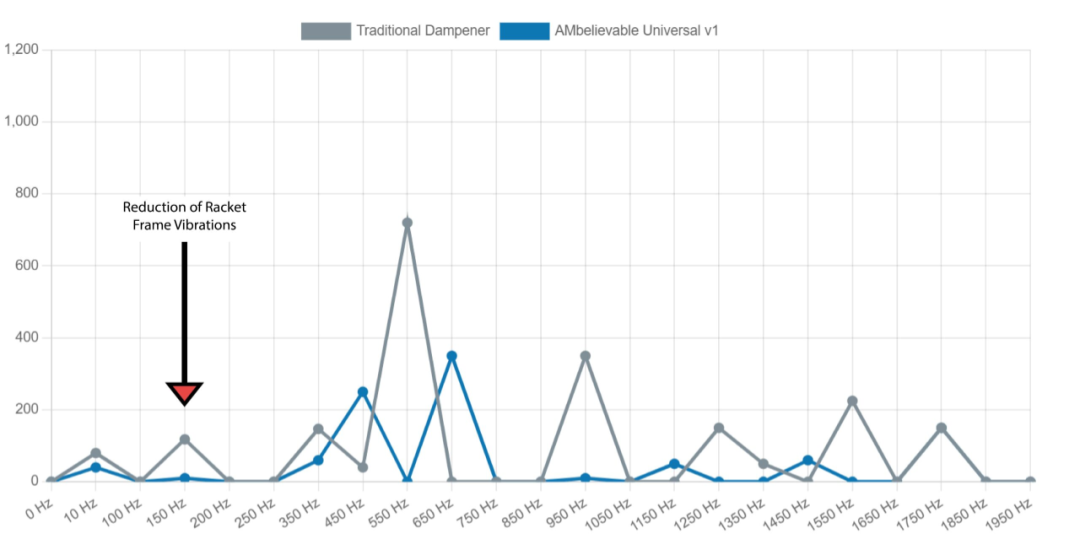

Independent laboratory HEAD acoustics even validated AMBelievable’s claims with their own lab data, and you can find an interactive chart on AMBelievable’s website to view this data for yourself.

HEAD acoustics data from the AMBelievable website shows the reduction of frame vibrations

This is a significant departure from traditional tennis racket shock absorbers. Traditional absorbers only target the mid-frequency (250-350 Hz) to high-frequency (650-750 Hz) range generated by the strings, neglecting the low-frequency (80-200 Hz) vibrations from the frame, which are associated with tennis elbow.

I am excited about the future of AMBelievable. While their CTO Tomasso Becutti believes their work will remain in the sports field and may branch into other sports, I see numerous applications for such metamaterials beyond sports. Tomasso did mention Phononic-Vibes, another spin-off from the same parent company, exploring the application of this technology in acoustics. I believe there are many use cases there, such as noise-canceling headphones, soundproof walls, and quieter car interiors.

Imagine driving on the highway without hearing the sound of tires rolling on the pavement?! How blissful.

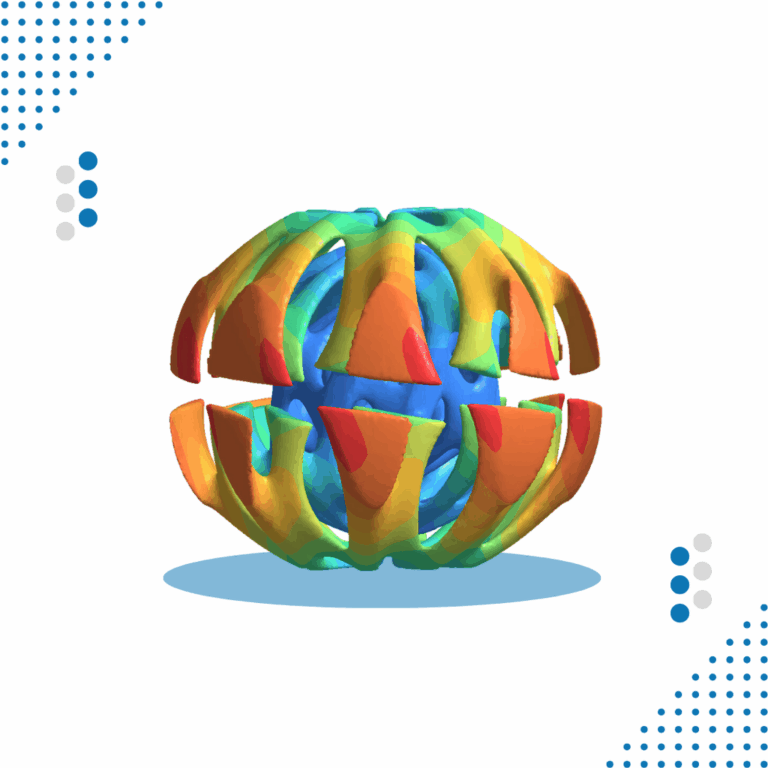

Simulation of the AMBelievable Universal tennis racket shock absorber

Overall, I am extremely impressed with AMBelievable, and the findings from HEAD have dispelled my biggest criticism from the first article.

If you are interested in trying this shock absorber for yourself, you can purchase it on the AMBelievable website. I have been using the “Universal” model, but they also offer a “Tuned” model and can customize the shock absorber into the shape of a logo. However, be warned: once you try their shock absorber, you may forever abandon all your Agassi rubber band shock absorbers and become a believer in AMBelievable like I did.

@ 3D Printing Insights

@ 3D Printing Insights

I am Xu Fanglei, a design professional, PhD, Fellow of the Royal Society of Arts, focusing on industrial design, additive manufacturing, and business models. Here, I will use my expertise and experience to take you deep into the world of 3D printing, sharing the latest industry trends, interpreting cutting-edge technologies, and discussing business applications.

END

END

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

About 3D Printing Technology

About 3D Printing Technology

We integrate timely insights, technological trends, application scenarios, competitive strategies, and in-depth dynamics from the US and globally for professionals in 3D printing and artificial intelligence, providing high-value information. We are passionate about 3D printing and welcome contributors from around the world.

Disclaimer:3D Printing Technology has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in this article.3D Printing TechnologyImages and videos are sourced from the internet and are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original authors; if there are any infringement issues, please contact the rights holders, and we will delete them promptly. The copyright of the images in this article belongs to the copyright holders,3D Printing Technologywatermarks are automatically added for auxiliary reading and do not represent ownership of the images; for image usage, please consult the relevant copyright holders.3D Printing TechnologyThe article does not constitute any investment advice,3D Printing Technologyis not responsible for any direct or indirect losses caused by the use of the information in this article.