There are two types of engineers in the PCB industry.

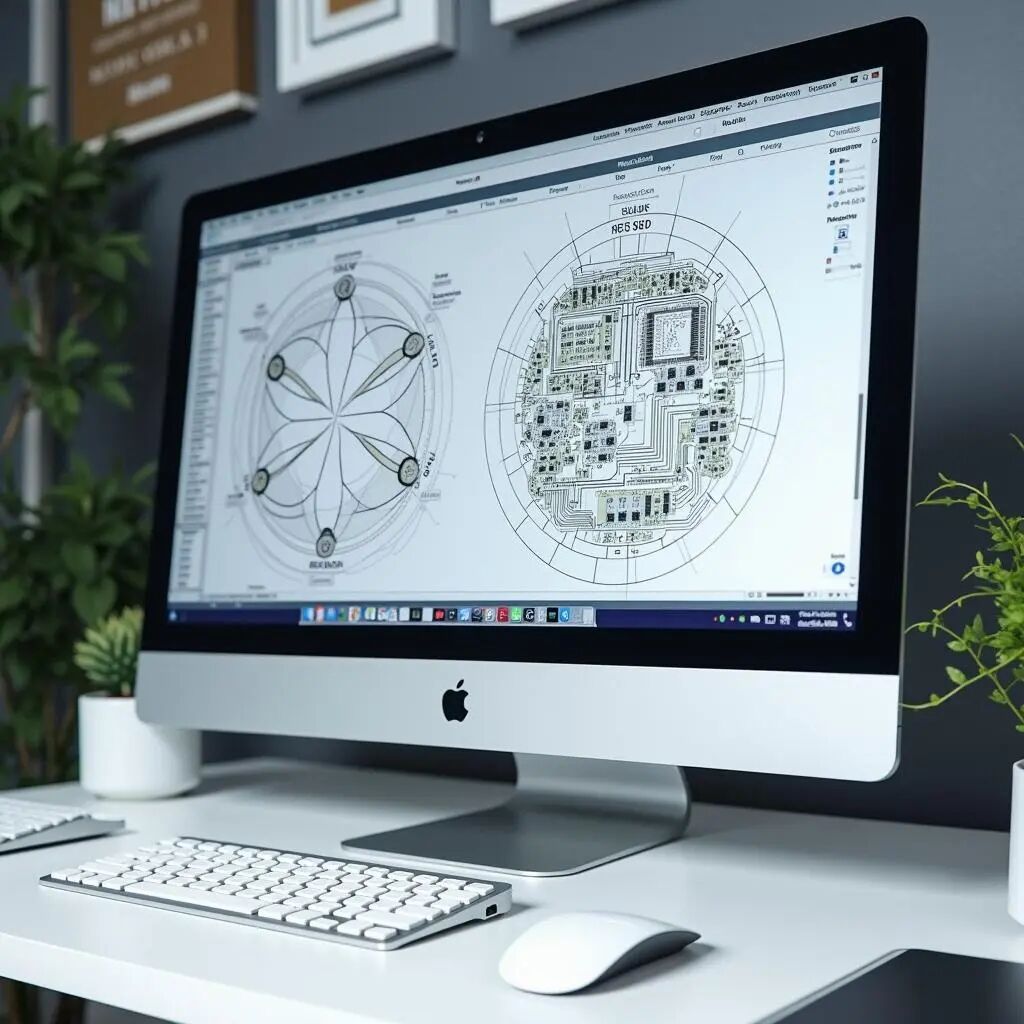

One type of designer possesses specialized knowledge and adheres to strict design standards. Their network wiring, surface mount components, and text are well-organized, with reasonable layout in functional areas that facilitate production optimization. They communicate smoothly, are open to suggestions, work efficiently, and handle their projects with ease, creating a pleasant experience.

The other type of designer tends to start strong but finish weakly, with numerous design flaws and violations of conventional design practices, leading to many quality risks. Their layouts are chaotic, with layer data not properly displayed, cramped or overly spacious areas, numerous broken connections, excessive irrelevant overlapping elements, broken holes, exposed traces, pad overlaps, sharp right-angle traces, surface mount components covered in solder mask, characters exceeding standard recognition sizes, and critical networks of components too close to the outer frame… Such designs complicate the analysis and processing of all production stages.

When issues arise, they often shift the blame for their mistakes and omissions onto others, complaining that others did not discover, inquire, or provide feedback. Their responses during communication are often off-topic and unprofessional. In summary, one person does the work, and everyone else has to clean up the mess.

These two types of engineers represent two different working styles, reflecting distinct corporate cultures and images. They are also an open secret within the industry.

So, which type of electronic products designed by them do you prefer to consume and purchase?

[Further Reading]

PCB Board Delivery Times

PCB Industry Job Guide: Newcomers’ “Pitfall Avoidance” Manual

Domestic Jialichuang CAM Auxiliary Manufacturing Software

Abbreviations for Electronic Components on Circuit Boards