In the manufacturing of printed circuit boards (PCBs), the PCB assembly technology has emerged to improve production efficiency, reduce costs, and optimize material utilization. Below, we will briefly introduce three common methods of PCB assembly, hoping to be helpful to everyone.

Generally speaking, PCB assembly refers to the practice of circuit board manufacturers connecting smaller PCBs together for easier production and cost savings.

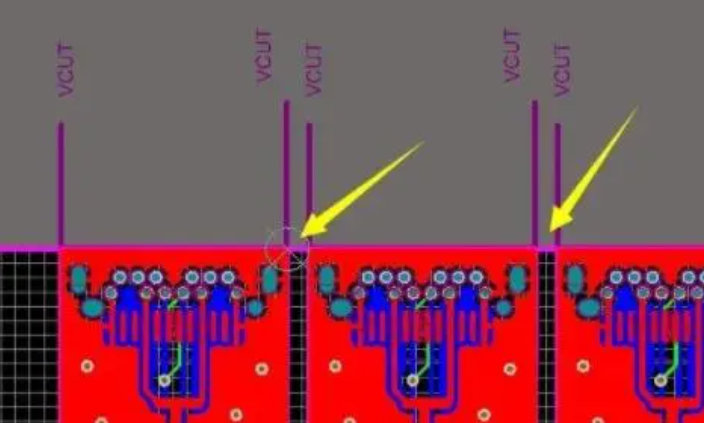

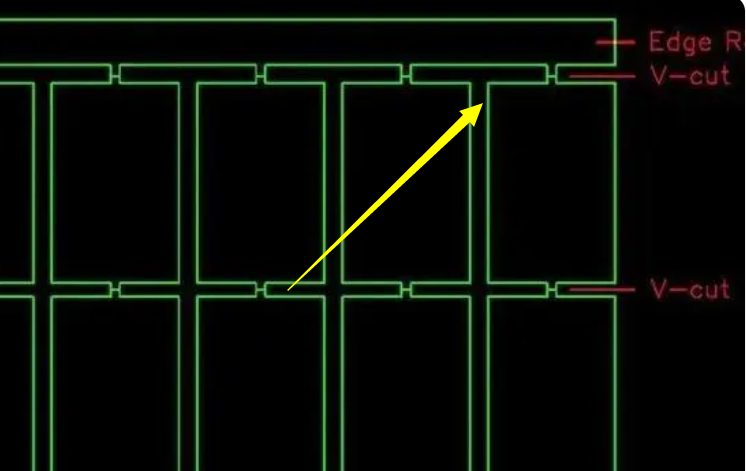

1. V-Cut

Definition: V-Cut is a method of assembling PCBs by cutting a V-shaped groove between two PCB boards, allowing the finished product to be easily broken apart in subsequent processes.

Characteristics: Suitable for PCBs with straight connections, simple design, and easy to operate. The depth and width of the groove must be precisely controlled to ensure that it is easy to separate without affecting the strength of the board.

Application: Widely used in the mass production of PCBs with regular shapes, effectively improving production efficiency.

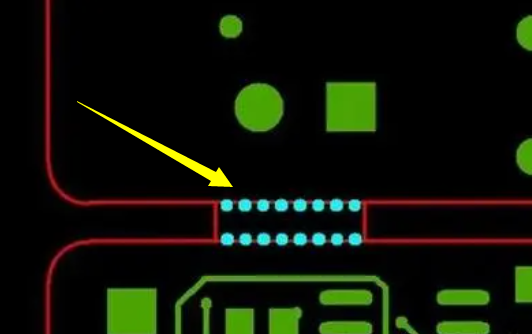

2. Stamping Hole Assembly

Definition: Stamping hole assembly uses small pieces of material as connecting bridges, with multiple holes designed on the bridge to facilitate easy manual or mechanical separation.

Characteristics: Highly adaptable, suitable for irregular PCBs or applications requiring high precision, with neat edges after separation, similar to stamp edges.

Application: Widely used in the assembly of prototypes, oval, or other non-standard shaped PCBs, ensuring production flexibility and product quality.

3. Hollow Connecting Strip Assembly

Definition: A hollow connecting strip is a narrow and thin connecting structure used to connect two PCB boards, with no through holes in the connecting part, providing sufficient strength support only at the separation points.

Characteristics: Suitable for PCBs that require half-hole processing, the design of the connecting strip is flexible and can be adjusted in width and position according to actual needs. However, it may leave slight bumps at the connection points after separation.

Application: In complex modules with half-hole designs all around, the hollow connecting strip becomes the only feasible assembly method, ensuring smooth production.

This article is an original piece by Fanyi Education. Please indicate the source if reproduced!