Click the blue text to follow us

Overview of Ion Contamination in PCB Circuit Boards

In the field of electronic manufacturing, with the advancement of technology, the integration of PCB circuit boards continues to rise, leading to denser component layouts and increasingly smaller line spacings.In this technological context, the cleanliness requirements for PCB circuit boards have also increased.Ion contamination, as one of the important factors affecting the cleanliness of PCB boards, has become particularly critical to control. Jin Jian Laboratory possesses advanced testing equipment and a professional technical team to provide ion contamination testing for clients.

When PCB circuit boards operate in humid environments, they may encounter various issues related to ion contamination residues. These residues may originate from flux residues, chemical cleaning agent residues, air humidity, electroplating, wave soldering, reflow soldering, and other processes. The main sources of contamination include flux, ionizing surfactants, and human sweat. These residues can lead to ion contamination on the circuit board, encompassing both anionic and cationic pollutants. Due to the charged nature of these ions, they may trigger electrochemical effects on the circuit board, thereby affecting its performance and reliability.

The minute residues of ion contaminants are often difficult to detect visually, yet they may pose risks to the quality of PCB circuit boards. Therefore, strengthening the control of ion contaminant levels and employing appropriate quantitative analysis methods to analyze the anionic content on the surface of PCB circuit boards is crucial for mitigating the risks of ion contamination.

Methods for Testing Ion Contamination

The professional testing services provided by Jin Jian Laboratory can help clients identify and control potential risks that may affect the performance and lifespan of electronic products, ensuring that products meet market demands.

The IC ion chromatography method is currently a widely recognized testing method for measuring ion contamination levels in the industry.The operational process of this method includes:First, measuring the surface area of the PCB board, then preparing the extraction tape, placing the PCB board into the extraction tape, and adding a solvent for extraction at a constant temperature of 80 degrees for 1 hour.After pre-treatment, the clear liquid of the extraction solution is taken for quantitative analysis, and finally, data analysis is performed using an IC ion chromatograph.

Standards for Ion Contamination Testing

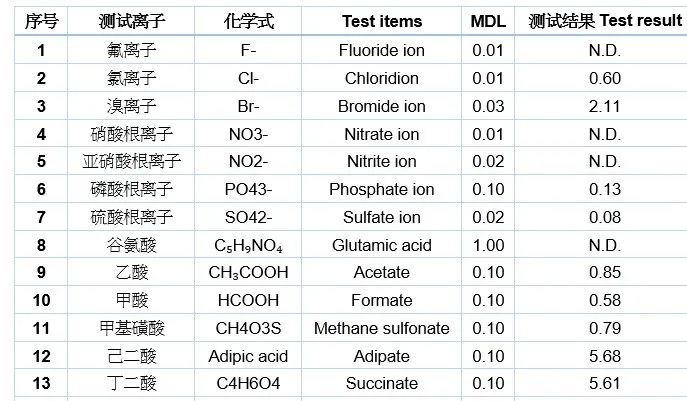

Referring to the IPC-TM-650 2.3.28B standard, accurately analyzing the types and contents of contaminants on the surface of the circuit board is key to quickly resolving ion contamination issues.High levels of chlorine and bromine in the test results may indicate issues with flux residues in wave soldering and reflow soldering processes;while high levels of organic acids may suggest contamination introduced during the product cleaning process. Jin Jian Laboratory strictly adheres to regulations and standards to ensure the accuracy and reliability of test results.

Ion Contamination Testing Reports

The contamination levels of different PCB circuit boards vary, and the testing report will detail the levels of ion contamination.The testing report typically includes quantitative analysis results of ion contamination levels, as well as potential sources of contamination analysis.These reports provide manufacturers with important information regarding the cleanliness of their products, helping them identify and address potential contamination issues.

Jin Jian Laboratoryhas various functional laboratories and advanced large-scale instruments and equipment.Jin Jian Laboratorycan provide laboratory services such as PCBA cleanliness testing, ion concentration testing, semiconductor chip testing, and issue detailed analysis testing reports.Choosing an experienced third-party testing organization can ensure the accuracy and reliability of tests, helping manufacturers ensure the quality and performance of their products.

In today’s competitive market, ensuring that the ion contamination levels of PCB circuit boards are kept within acceptable ranges is crucial. This not only helps improve product reliability and lifespan but also avoids costly recalls and damage to brand reputation due to contamination issues. Therefore, investing in advanced testing equipment and professional testing services is a wise and necessary decision for electronic manufacturers.

Jin Jian Laboratory provides PCB ion contamination testing services, including PCBA cleanliness testing, concentration testing of specific ions such as chlorine, fluorine, bromine, and iodine, SMT quality analysis, and semiconductor chip testing. Jin Jian Laboratory can provide customized analysis testing reports based on different PCB circuit boards, reflecting the specific ion contamination levels in detail.

Learn about technical knowledge or testing requirements

Please scan the QR code below to contact your dedicated testing consultant

Disclaimer:Some content of this article is sourced from the internet; This account maintains neutrality regarding all statements and views of original and reprinted articles, and the articles pushed are for readers’ learning and communication purposes only. The copyrights of articles, images, etc. belong to the original authors, and any infringement will be deleted!!

Recommended Reading