All modernKulite pressure sensors utilize sensing elements that are silicon-on-insulator (SOI) devices with medium isolation. This is a fundamental difference between Kulite sensors and the technologies adopted by most other silicon pressure sensor manufacturers.Kulite sensors consist of a complex structure made up of three layers of atomically bonded materials:

The first layer is single-crystal N-type silicon, which is micromachined to form a mechanical pressure-sensitive diaphragm. The thickness of the diaphragm varies according to its designed full-scale pressure range, with the selection principle ensuring that this layer experiences a strain of approximately 350 to 400 microinches per inch under full-scale pressure. This level of strain is extremely conservative for single-crystal silicon, ensuring the long-term stability and robust mechanical performance of the sensor.

The second layer is a layer of silicon dioxide, which is directly grown on top of the N-type silicon diaphragm. This layer provides medium isolation between the N-type silicon and the third layer (the P-type silicon layer containing the Wheatstone bridge circuit), thereby eliminating the P-N junction in the device design and enabling operation at higher temperatures.

The third layer is molecularly bonded to the silicon dioxide layer through a proprietary high-temperature process. This layer contains four strain gauges made of P-type silicon arranged in a Wheatstone bridge configuration. The patterning of the P-type silicon is achieved through photolithography and reactive ion etching (RIE) to ensure precise control of the strain gauge dimensions. The strain gauge network (including interconnections) forms a continuous P-type silicon integrated circuit, with components isolated by the silicon dioxide layer—an extension of the second layer that completely separates the N-type silicon layer from the P-type silicon layer.

The positioning of the strain gauges in the third layer is designed in relation to the physical relationship with the first layer’s mechanical diaphragm: when pressure is applied, the strain on the diaphragm causes two strain gauges to be in tension (increased resistance) and the other two strain gauges to be in compression (decreased resistance). In the Wheatstone bridge, the two tensioned strain gauges are arranged diagonally, while the two compressed strain gauges are also arranged diagonally, maximizing the output of the bridge through the resistance imbalance caused by the stress. The degree of imbalance is proportional to the magnitude of the applied stress, which is the fundamental working principle of all “strain gauge” pressure sensors.

The advantages ofKulite’s technology route are as follows:

Silicon-on-Insulator (SOI) Sensors—No P-N Junction

-

High Temperature Capability: Can operate continuously at temperatures up to 932°F (500°C).

-

Electromagnetic Interference (EMI) Resistance: Sensors without other active electronic components can operate normally in an electric field of 200 volts/meter.

-

Electrostatic Discharge (ESD) Resistance

-

Single Crystal Silicon Integrated Sensing Structure

-

High Reliability: The average mean time between failures (MTBF) of the sensor body is calculated to be 3 million hours.

-

No Hysteresis Effect

-

High Accuracy: The typical static error band of Kulite pressure sensors (including non-linearity, hysteresis, and repeatability) is less than 0.1% of full scale (0.1% FS).

Leadless Sensors—Eliminating Gold Wires and Related Mechanical Contacts

-

High Shock and Vibration Resistance

-

High-Temperature Resistance

-

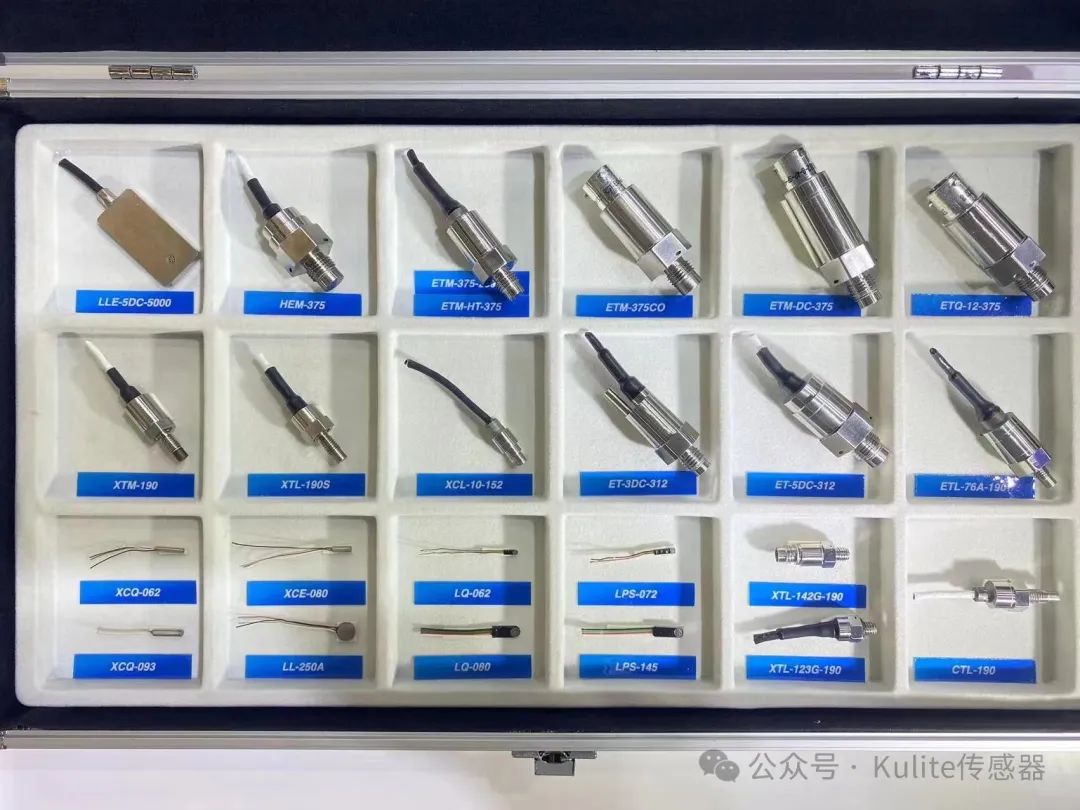

Miniaturized Design

-

Small Size and Lightweight: Sensor sizes range from 0.03×0.03 inches to 0.1×0.1 inches, supporting ultra-miniature packaging.

-

Low Vibration and Acceleration Sensitivity: The extremely low mass of the ultra-miniature sensing elements gives them a very high natural frequency while exhibiting mechanical insensitivity to shock and vibration until reaching extremely high levels.

Additionally,Kulite has developed and patented a new type of sensor technology that completely eliminates the impact of extreme vibrations on the sensor output signal.

Kulite’s Leadless Technology Traditionally, silicon sensors are interconnected with sensor circuits using fine gold wires. These gold wires are soldered to the metal contact pads of the sensor and then connected to pins or printed circuit boards inside the sensor. Under extreme vibration or rapid pressure cycling conditions, these gold wires and their solder joints are prone to fatigue failure.

In the “leadless” pressure sensor, these problematic gold wires and their associated risks are completely eliminated. The sensor forms a hermetically sealed solid-state mechanical structure through glass layer bonding. Gold pins embedded directly in the package utilize conductive paste to bond with the glass layer, achieving electrical connection between the pins and the sensor chip. Through special materials and processes, the sensor structure and package form a hermetically sealed mechanically stable whole. Conventional electrical connections are achieved directly through the back of the sensor-package structure, which can be installed in various sensor housings, adapting to a wide range of application scenarios.

Based on this technology, ultra-miniature pressure sensors can be compatible with most fluids (including conductive fluids, as long as the fluid does not corrode silicon or glass), with operating temperatures up to 500°C (932°F).

For the latest tariff issues, please contact Engineer Zhang: 13283820042 WeChat: z13283820042