For more in-depth information, reports, and knowledge about sensor technology, sensor testing technology, IoT sensor technology, etc., please follow the Sensor Expert WeChat public account and set it as a star to view past content.

1. Introduction

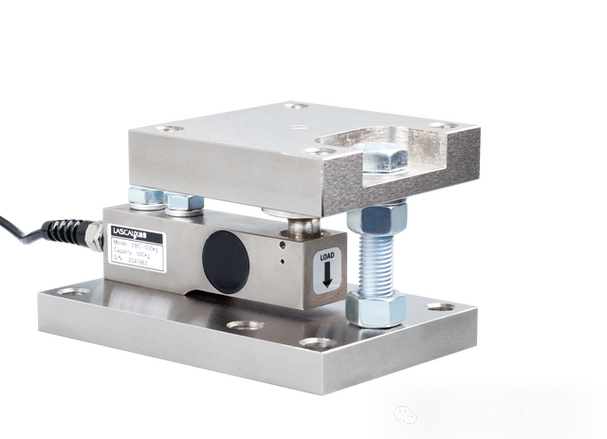

A load cell is a device that converts mass or gravitational signals into measurable electrical signals. In modern industries, logistics, and healthcare, load cells play a crucial role due to their high precision, stability, and reliable performance. This article will detail the basic principles, classifications, applications, and selection principles of load cells, helping readers better understand and apply this technology.

2. Basic Principles of Load Cells

The working principle of load cells is primarily based on the strain gauge principle. When an object is placed on the sensor, its weight causes deformation in the elastic element inside the sensor. This deformation is sensed by strain gauges fixed to the elastic element, resulting in a change in the resistance value of the strain gauge. Through specific circuits, this change in resistance can be converted into an electrical signal output, which is proportional to the weight of the object being measured.

Specifically, load cells typically consist of elastic elements, sensors, signal processing circuits, and output devices. The elastic element is the core component of the sensor, responsible for deforming according to the weight or mass of the object; the sensor converts this deformation into an electrical signal; the signal processing circuit amplifies and filters the electrical signal to obtain a stable and accurate usable signal; the output device can be a display, alarm, etc., used to show or process the measurement results.

3. Classification of Load Cells

Load cells can be classified based on different criteria. For example, based on the physical quantity measured, they can be divided into pressure load cells, strain load cells, capacitive load cells, and electromagnetic load cells. Based on the working principle, they can be categorized into resistive strain, capacitive, magnetic, vibrational, and gyroscopic types, among others. The resistive strain load cell is the most widely used type.

Additionally, based on shape and structure, load cells can be classified into S-type, cantilever, wheel hub, plate ring, diaphragm, bridge, and cylindrical types. Each type of load cell has its characteristics and is suitable for different application scenarios.

4. Applications of Load Cells

The application fields of load cells are very broad, covering industries such as manufacturing, logistics, healthcare, agriculture, and environmental monitoring. Here are some typical application scenarios:

-

Industrial Production: Load cells are essential components of electronic scales, widely used in electronic balances, truck scales, and hanging scales. They can accurately measure the weight of raw materials, semi-finished products, and finished products, ensuring quality control and material management during the production process.

-

Logistics Transportation: Load cells are installed on trucks, containers, and other transport vehicles to monitor the weight of goods in real-time, ensuring transport safety and compliance with road weight limits. At traffic weighing stations, load cells have become effective tools for law enforcement, accurately measuring the weight of passing vehicles to effectively curb overloading.

-

Healthcare: Load cell technology is used in hospital scales, bed pressure sensors, and other devices to accurately measure patients’ weight changes, providing important data for doctors to assess health conditions and develop treatment plans. Additionally, with the development of telemedicine and smart wearable devices, load cells are also used in consumer electronics such as smart bands and scales.

-

Agriculture and Animal Husbandry: Load cells play an important role in feed weighing, animal weight monitoring, and grain storage. By accurately measuring the amount of feed and the growth of animals, farmers can scientifically adjust feeding plans; load cells in grain storage can monitor inventory levels in real-time, preventing waste and loss of grain.

-

Environmental Monitoring: Load cells are used to monitor the weight and level changes in containers such as trash bins, storage tanks, and water tanks, providing data support for environmental management and resource scheduling.

5. Selection Principles for Load Cells

When selecting load cells, several factors need to be considered:

-

Measurement Accuracy: Choose the appropriate load cell based on the accuracy requirements of the actual application scenario. High-precision sensors are usually more expensive but can provide more accurate measurement results.

-

Measurement Range: Select the appropriate measurement range based on actual measurement needs. Ensure that the sensor will not be damaged due to overload during measurement, while avoiding a range that is too large, which could lead to decreased measurement accuracy.

-

Operating Environment: Consider the operating environment of the sensor, including temperature, humidity, vibration, and other factors. Choose sensors that are highly adaptable and can operate stably in harsh environments.

-

Installation Method: Choose the appropriate installation method based on the site conditions. For precise measurement scenarios, fixed installation may be preferred; for frequently moved scenarios, portable installation may be more suitable.

-

Cost Budget: Consider the cost budget while meeting performance requirements. Select load cells with a good cost-performance ratio to reduce overall costs.

6. Conclusion

As a device that converts mass signals into measurable electrical signals, load cells play an irreplaceable role in modern industries, logistics, and healthcare. By understanding their basic principles, classifications, applications, and selection principles, we can better apply this technology to improve production efficiency, ensure safety, and promote the development of various industries. With the continuous advancement of technology, it is believed that load cell technology will become more advanced and its application fields will become even broader.

Starred content = content you care about, according to the WeChat public account recommendation principle, if you do not set the Sensor Expert public account homepage as a star, you will not be able to receive the latest information in the sensor industry in a timely manner!

Disclaimer:Reprinting this article is for the purpose of conveying more information. If there are any errors in source attribution or infringement of your legal rights, please contact us, and we will correct or delete it promptly. Thank you.

If you have submission or interview needs, please email:[email protected].Recommended Reading:

- China’s Sensors Depend on You! Summary of Sensor Research Information from 30 Top Universities

- Finally Understood, Modern Warfare is All About Sensors

- China’s Chip Tycoon Actually Comes from Sensors

- Woke Up to Find Chinese Companies Can’t Design Sensors?!